New material stirring mixing device capable of changing stirring scope

A technology for mixing and mixing new materials, which is applied to mixers, mixers, mixer accessories and other directions with rotating mixing devices, which can solve the problems of large material volume, easy sedimentation and adsorption, and insufficient raw materials, so as to optimize the mixing effect, Avoid deposition adsorption, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

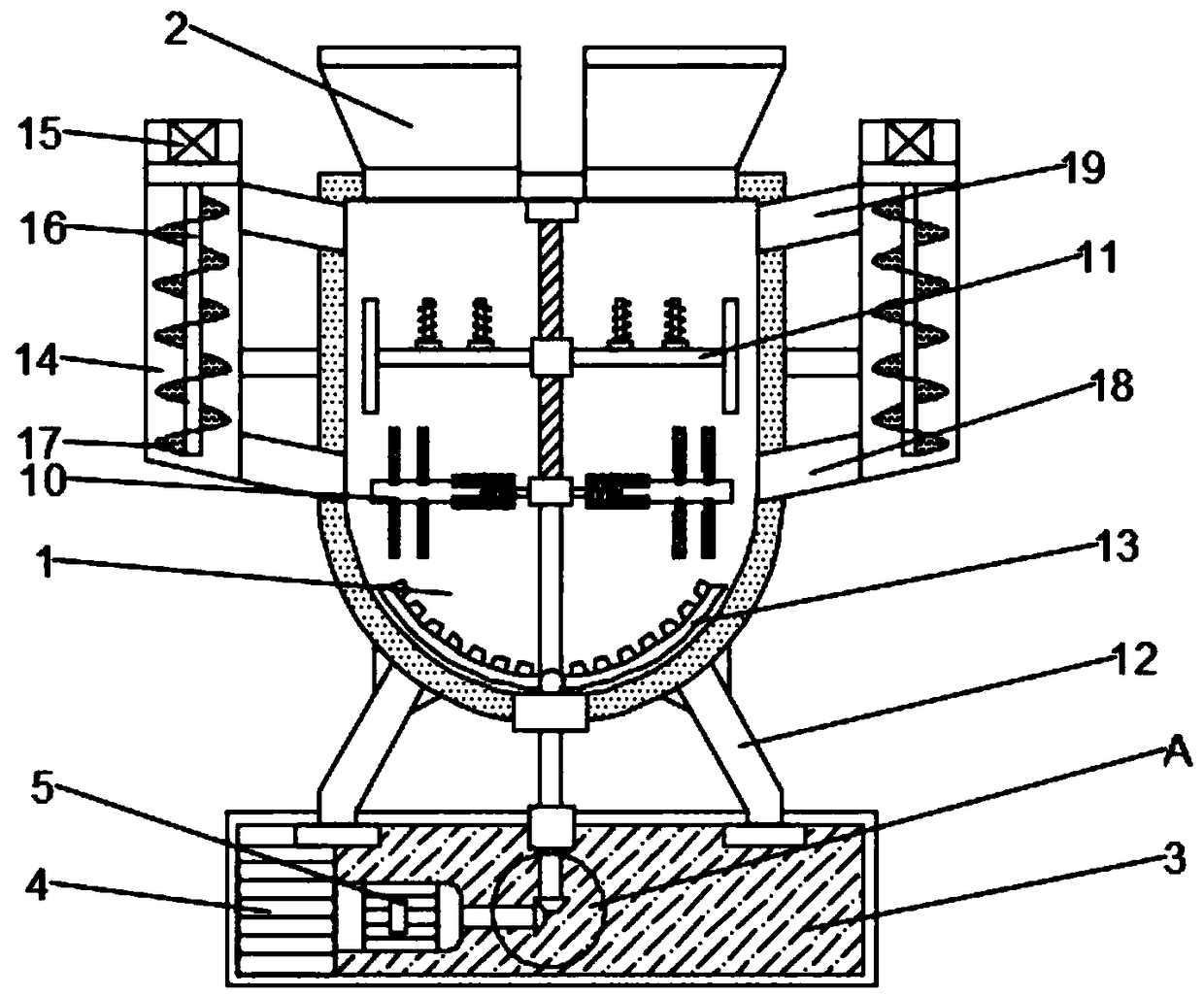

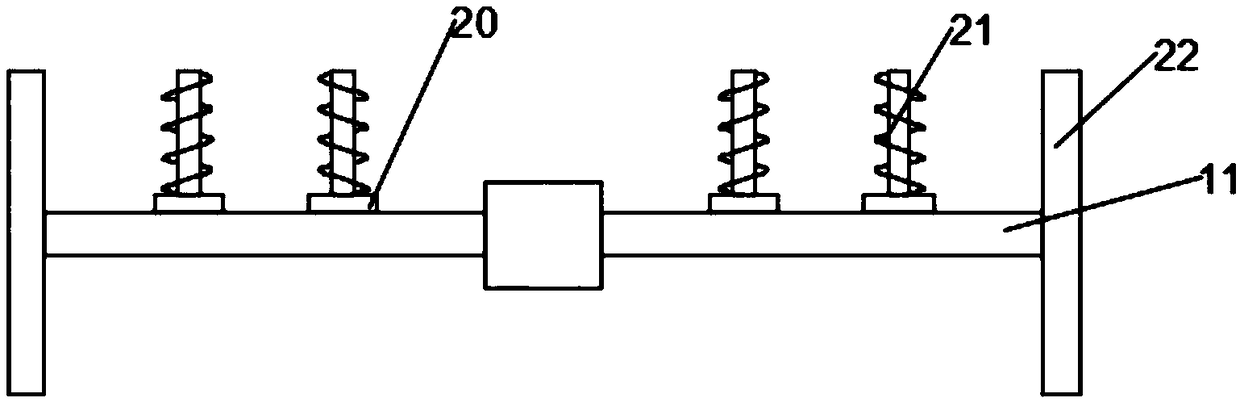

[0024] Such as Figure 1~5As shown, in the embodiment of the present invention, a new material raw material stirring and mixing device that can change the stirring range includes a housing 1, a material inlet 2, a supporting base 3, a first stirring shaft 10, a second stirring shaft 11, a support Legs 12 and a material circulation chamber 14, the bottom of the housing 1 is provided with a support base 3, the support legs 12 are welded symmetrically on both sides of the lower surface of the housing 1, the support legs 12 are arranged obliquely, and the lower ends of the support legs 12 are fixed On the upper surface of the support base 3, the inner cavity of the housing 1 is provided with a bottom stirring paddle 13, a first stirring shaft 10 and a second stirring shaft 11 in sequence from bottom to top, and two symmetrically arranged on the upper surface of the housing 1. Material inlet 2, two material circulation chambers 14 are vertically arranged symmetrically on both sides...

Embodiment 2

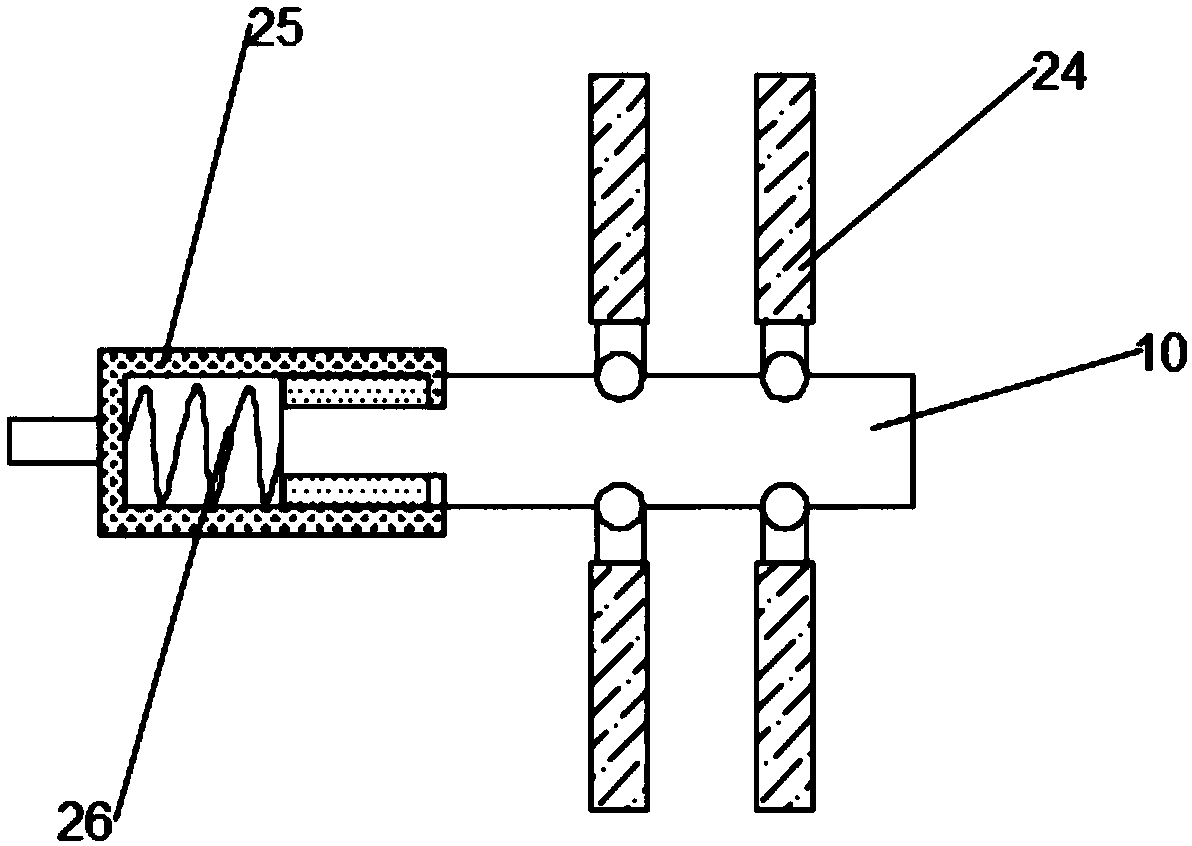

[0026] Such as figure 1 As shown, in this embodiment, the connection mode between the mixing plate 24 and the first stirring shaft 10 is hinged, so that the first stirring shaft 10 can slide horizontally along the cavity of the limiting chute 25 while achieving The limiting chute 25 swings around the first stirring shaft 10, thereby strengthening the stirring and mixing effect, avoiding the occurrence of dynamic balance during the mixing and stirring process, thereby affecting the normal mixing of raw materials; Parts match.

[0027] The working principle of the present invention is: the raw material flows into the inner cavity of the housing 1 through the material inlet 2, the servo motor 5 is started, and the servo motor 5 starts to drive the first rotating shaft 6 and the second rotating shaft 9 Rotate with the limiting chute 25, and then drive the first stirring shaft 10 to rotate, and at the same time drive the first stirring shaft 10 to slide along the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com