Device for welding plastic

a technology of plastic welding and nozzles, which is applied in the direction of welding/soldering/cutting articles, other domestic objects, manufacturing tools, etc., can solve the problems of affecting the quality and ultimately strength of welds, nozzles that deliver the focused stream of heated air are often overheated, and handheld applicators are susceptible to damage, etc., to achieve strong and reliable welds, durable and safe to use, and low cost of manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Welding Device 11

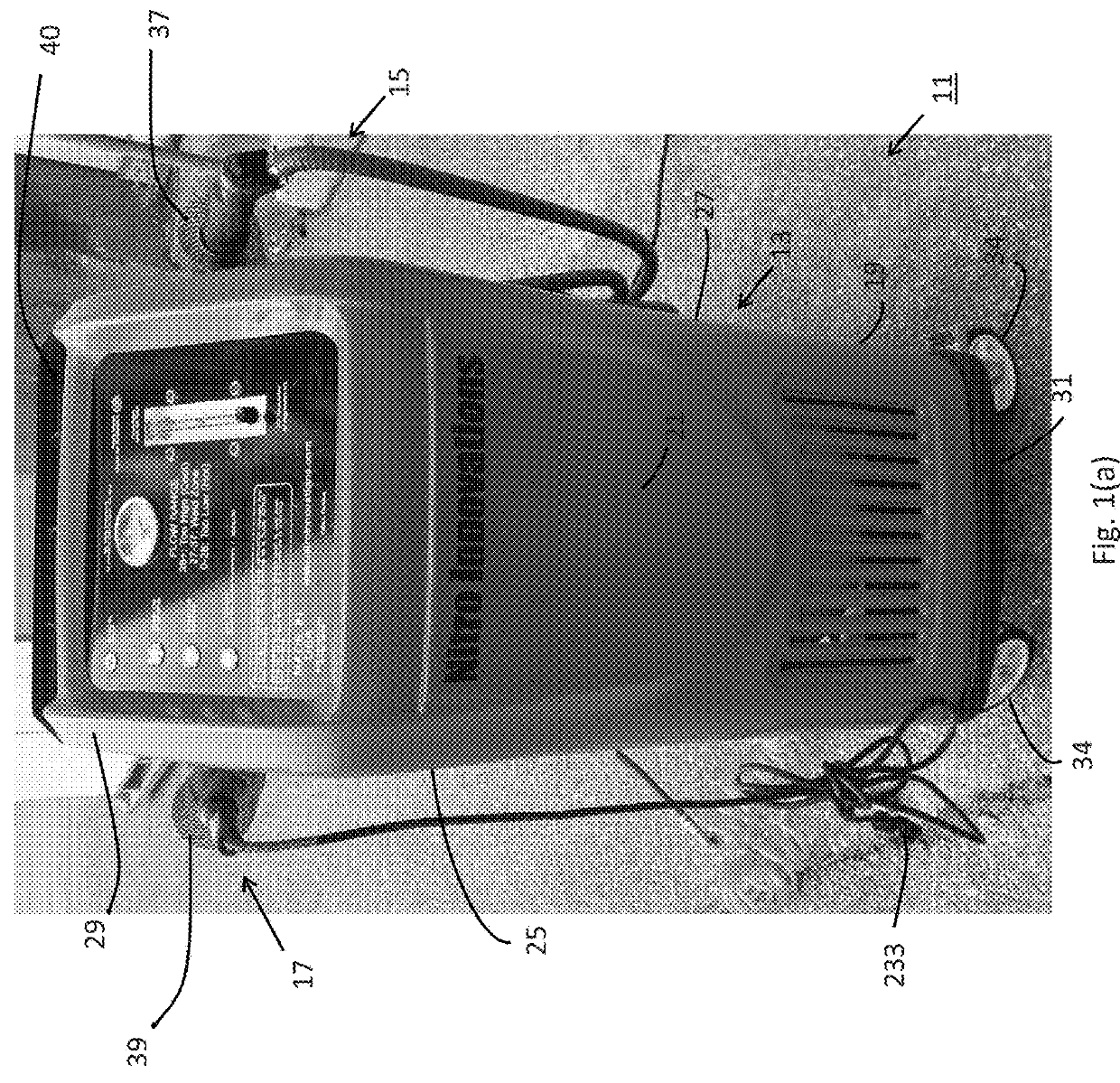

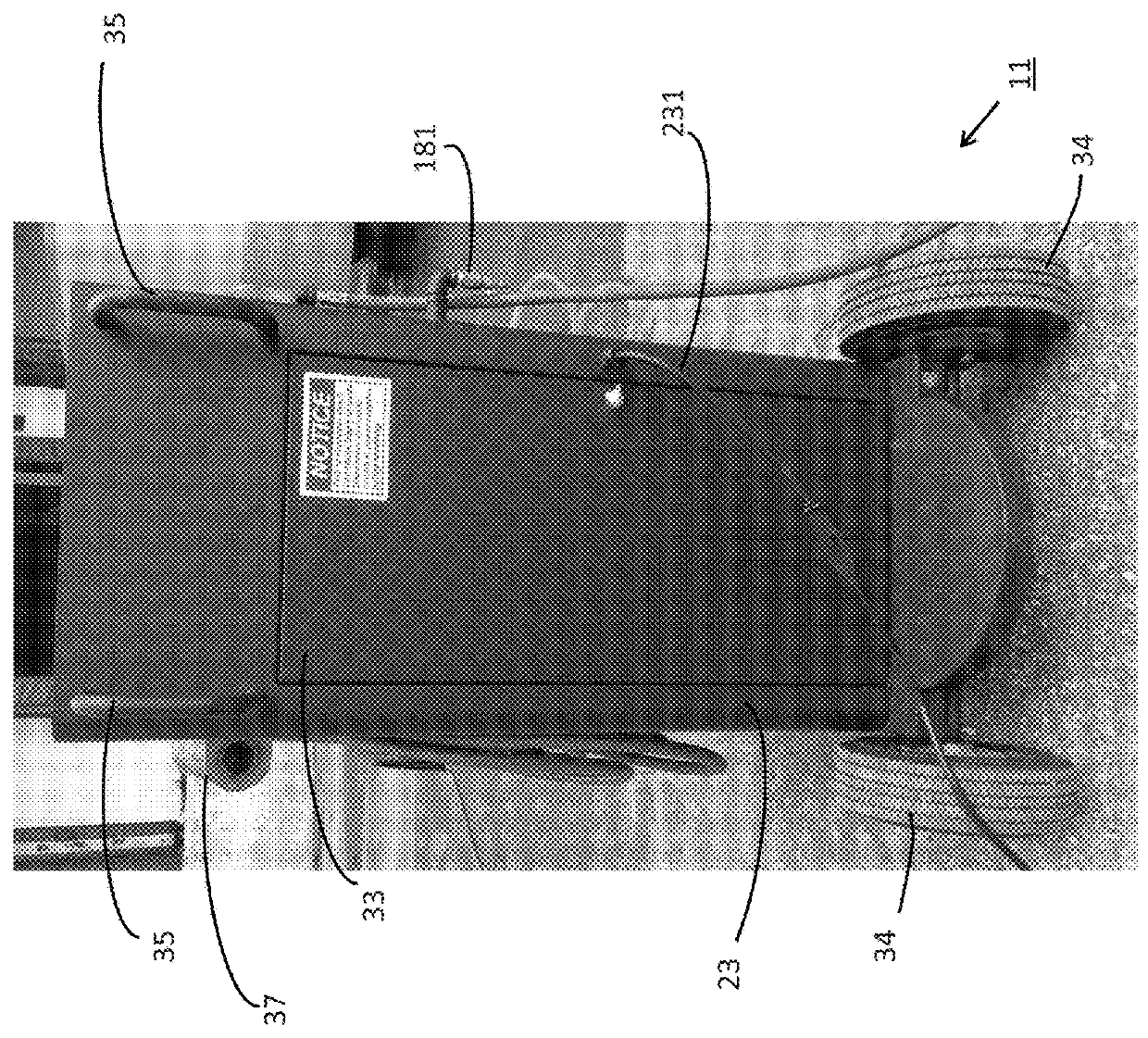

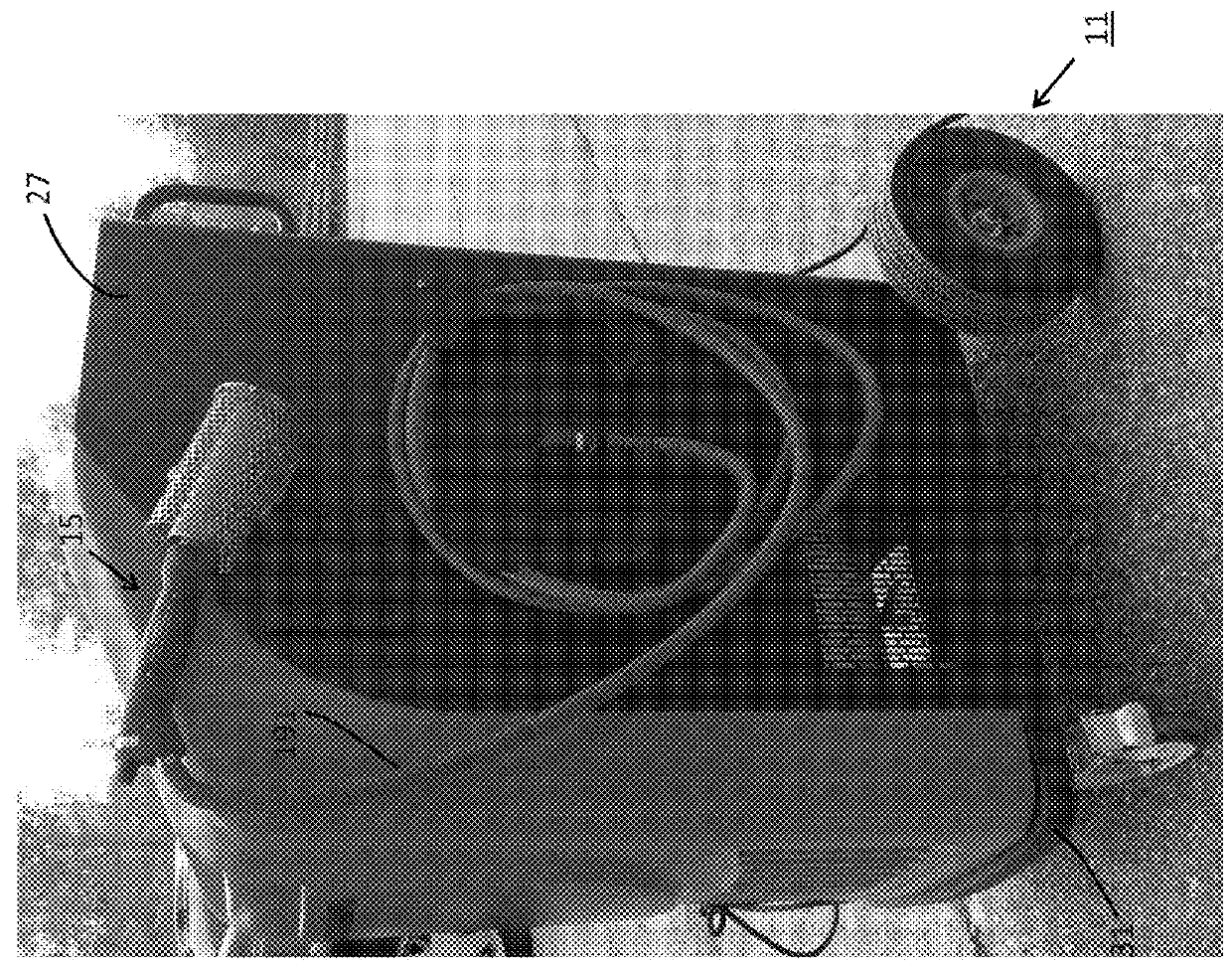

[0021]Referring now to FIGS. 1(a)-(c), there are shown front perspective, rear perspective, and right side perspective views, respectively, of a welding device constructed according to the teachings of the present invention, the welding device being identified generally by reference numeral 11. As will be described in detail below, welding device 11 is specifically designed to yield a high-quality and durable weld in a safe and reliable fashion.

[0022]Welding device 11 is designed primarily for use in the welding together of plastic materials of similar compositions. Most notably, device 11 is particularly well-suited for use in repairing cracked, torn or otherwise damaged automotive bumpers, which are traditionally constructed of polypropylene or other similar thermoplastic material. However, it should be noted that device 11 is not limited for use in the welding of specific materials in any particular application. Rather, it is to be understood that device 11 could...

PUM

| Property | Measurement | Unit |

|---|---|---|

| air pressure | aaaaa | aaaaa |

| air pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com