Novel laser welding jig for trial-manufacture vehicle and use method thereof

A technology of laser welding and tire film, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of roof deformation wedge-shaped block pressure relaxation, welding solder leakage, single-side soldering of solder, etc., to achieve Reduce the amount of artificial adjustment, improve work efficiency, and reduce the effect of surface depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

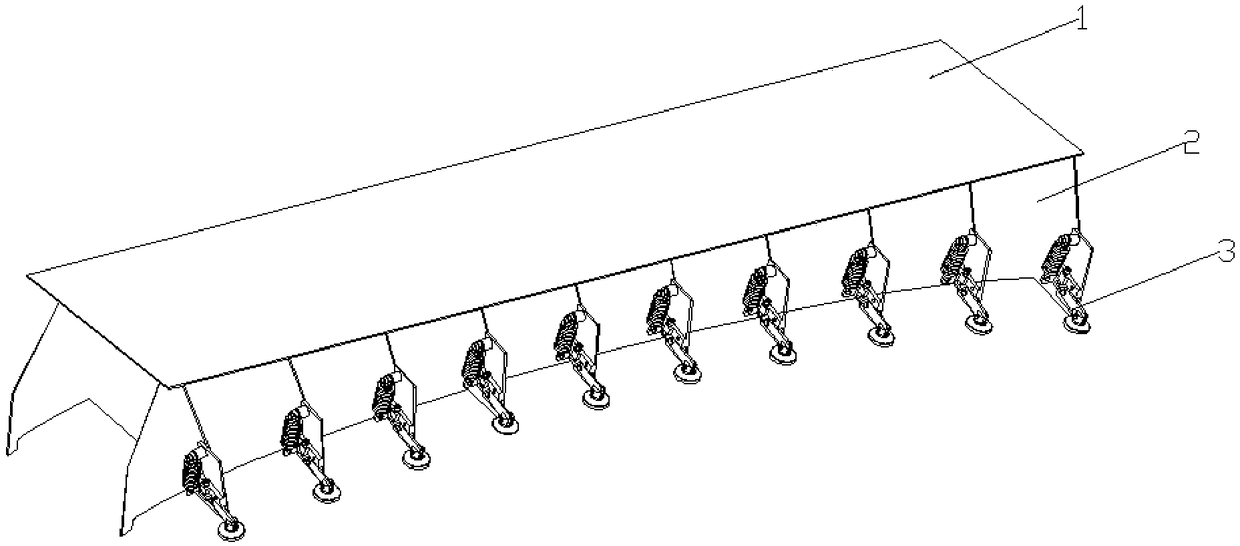

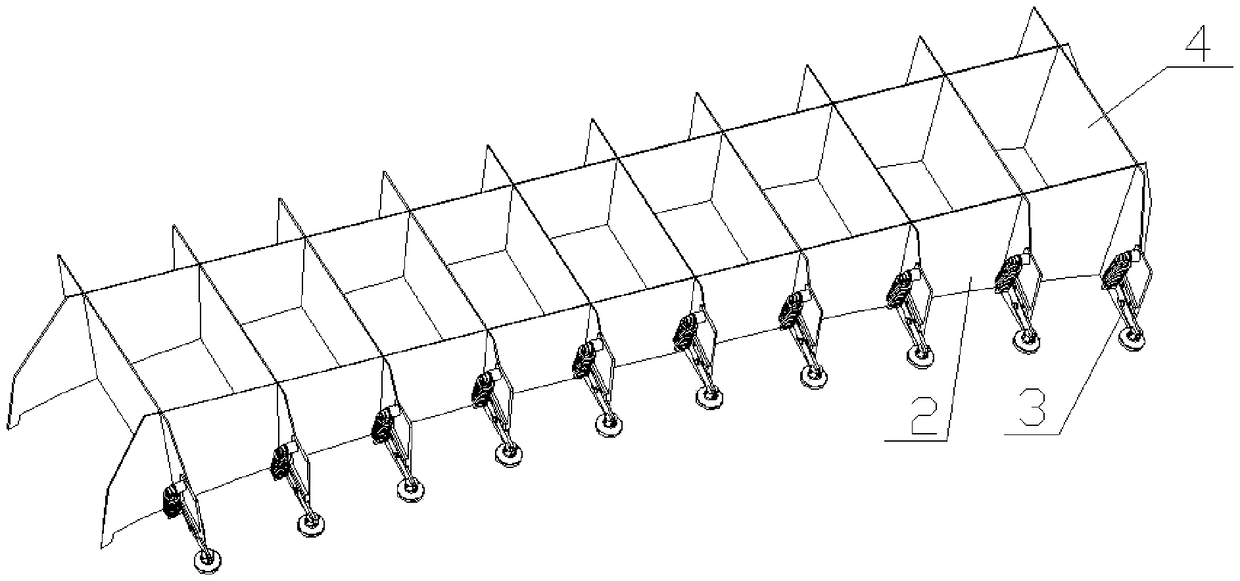

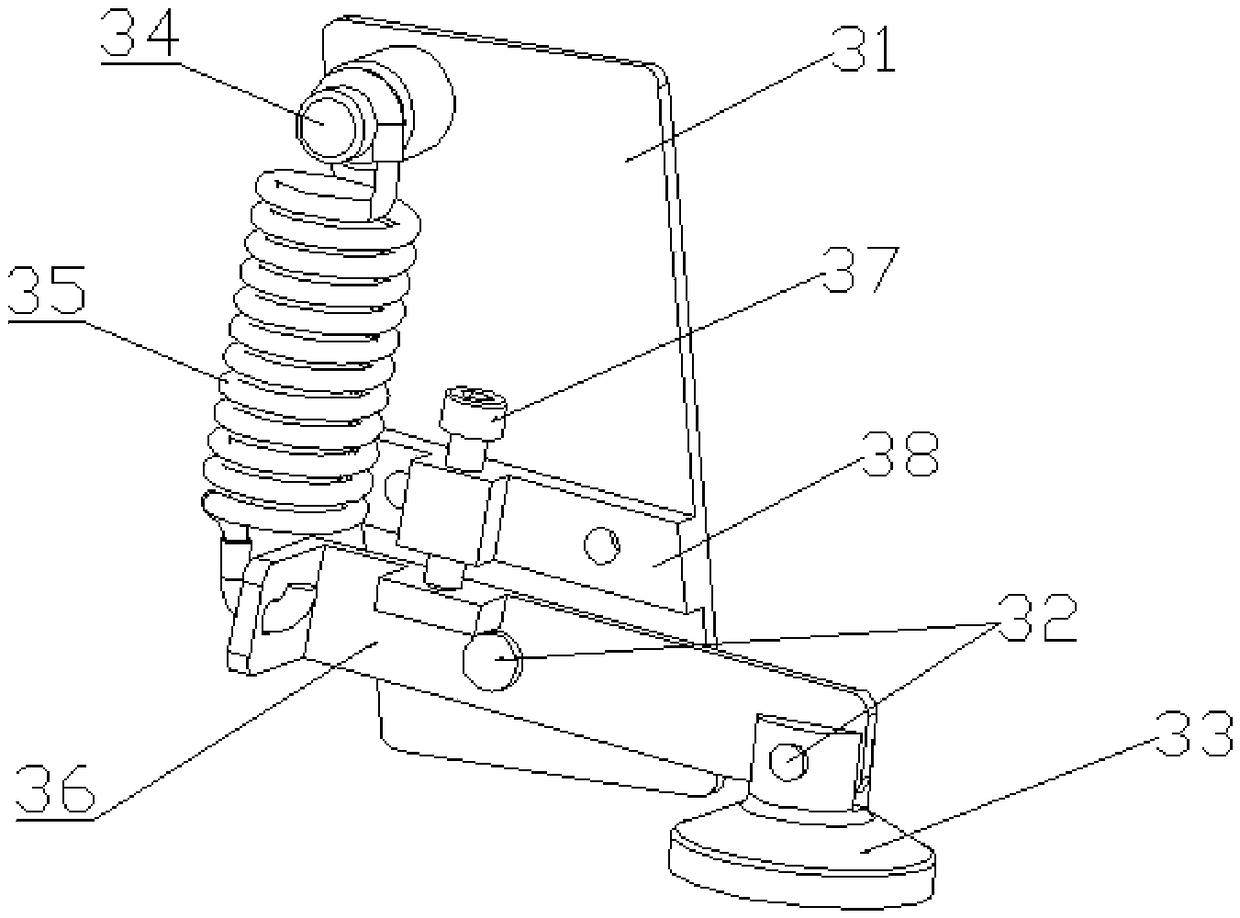

[0035] This embodiment relates to a new type of laser welding film clamp for trial production vehicles, and its structural schematic diagram is as attached figure 1 , 2 As shown in and 3, it includes: an upper cover plate 1, a tire mold frame X-direction positioning plate 2, a spring pressing mechanism 3 and a partition 4; the tire mold skeleton X-direction positioning plate 2 is provided with two pieces, each of which is composed of a rectangular plate One end of which is a polygonal structure, and the top corner of the lower end has an extension block, and the upper side wall is provided with a plurality of equally spaced notches. The tire mold skeleton is formed in the notches of the X-direction positioning plate 2 of the two tire mold skeletons, which are in a plurality of connected well-shaped structures, that is, the partition plate 4 and the X-direction positioning plate 2 of the tire mold skeleton are non-aligned buckles, and the tire mold skeleton The upper cover pla...

Embodiment 2

[0041] This embodiment relates to a new type of laser welding film clamp for trial production vehicles, the structure of which is the same as that of Embodiment 1.

[0042] This embodiment provides a new method of using a laser welding tire film clamp for trial production vehicles, and the schematic diagram of the installation of the vehicle body and the roof is as follows Figure 4 shown, including the following steps:

[0043] Step 1, place the roof 5 on the body 6 and fix it;

[0044] Step 2, adjust the laser welding tire film, adjust the limit bolt 37 downward, and adjust the swing arm 36 upward to the limit stop 38, so that the circular roof pressing block 33 goes up accordingly; prevent the circular roof pressing block from 33 Scratching the roof surface;

[0045] Step 3, place a laser welded tire membrane in parallel on the left and right sides of the roof 5, determine the X-direction position of the tire mold skeleton by the X-direction positioning plate 2 of the tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com