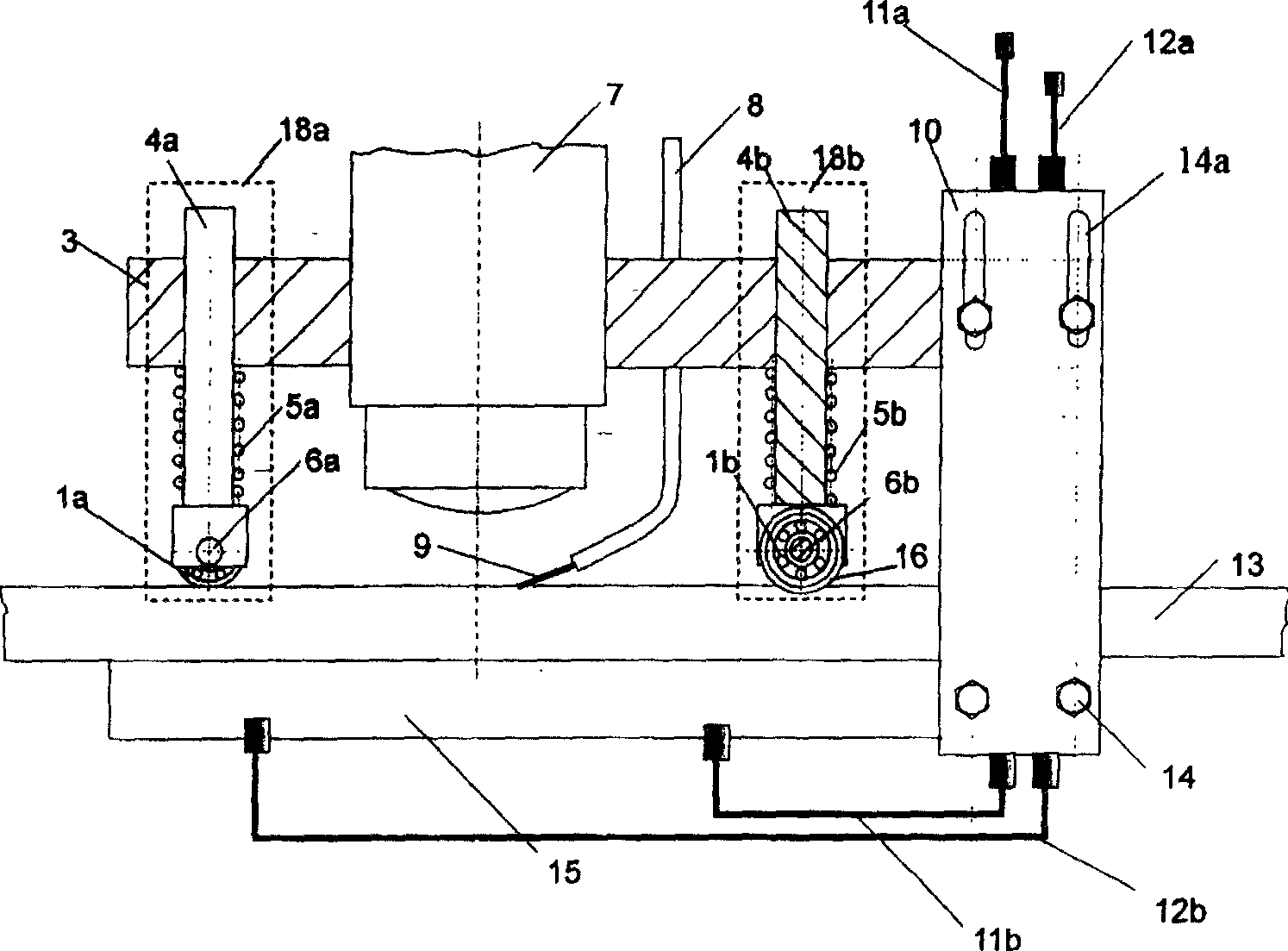

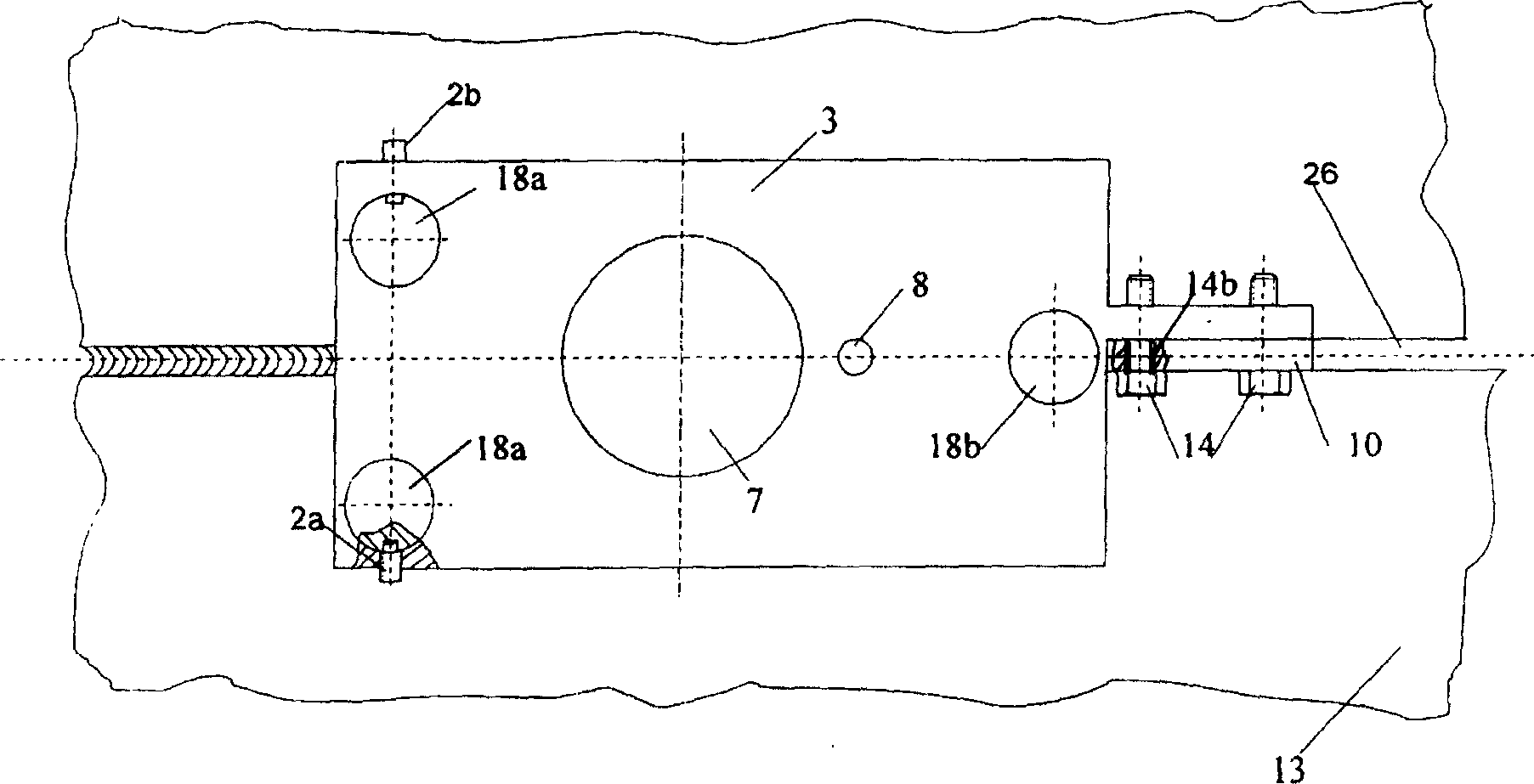

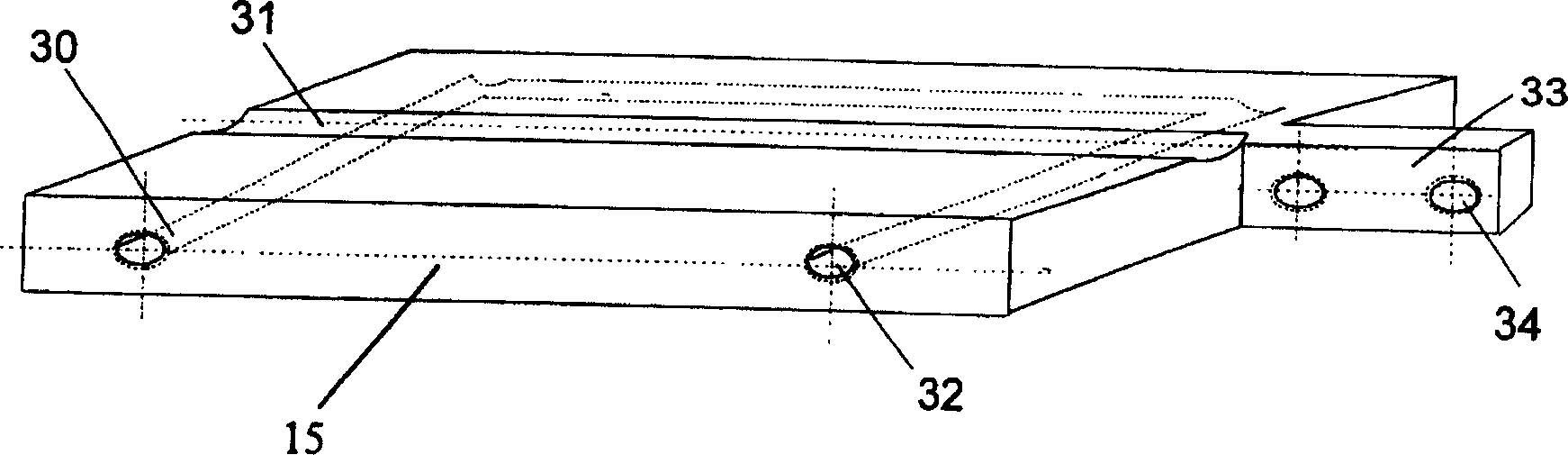

Railless walking single-pass full-penetration arc welding equipment and method

A full penetration and arc welding technology, applied in the field of welding devices, can solve the problems of difficult assembly and disassembly of backing pads, complex equipment, poor sensing reliability, etc., to avoid welding seam tracking technology, reduce production costs, and weld process reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Example 2 of the welding method using the welding device of the present invention: using the device of the present invention, the submerged arc welding process is used to perform full penetration butt welding without processing the groove or processing the groove to reserve a weld gap.

Embodiment 3

[0040] Example 3 of the welding method using the welding device of the present invention: using the welding device of the present invention, using the flux-cored wire gas shielding or self-shielding welding process method, the butt weld seam back sealing is performed under the condition that the weld seam gap is reserved for processing the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com