A welding system for large wall thickness steel plates

A welding system, thick steel plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of thick steel plate turnover, improve production efficiency, facilitate worker operation, stable and reliable welding and turnover process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

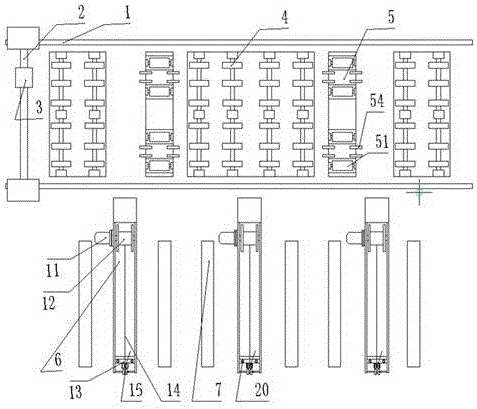

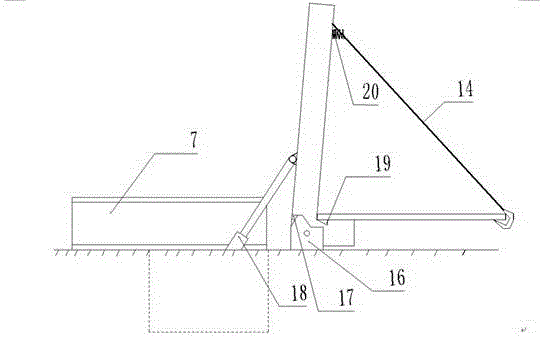

[0024] As shown in the figure, the gantry-type welding mechanism is composed of rail 1, row frame 2 and movable welding torch 3, and the welding torch can move up, down, left, and right in the plane. A steel plate support structure is arranged between the two rails 1, and the steel plate support structure is composed of three sets of idler rollers 4, each of which has two rows of idler rollers 4 in the left and right groups, and the central set has four rows of idler rollers 4. The steel plate support structure is used to place the steel plate to be welded, and the steel plate can be moved left and right by the supporting roller 4.

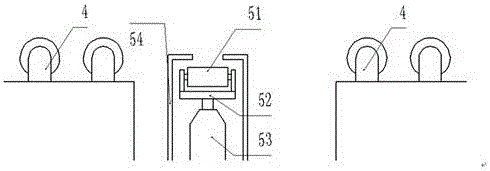

[0025] A lifting mechanism 5 is set between two adjacent groups of idlers 4, and the lifting mechanism 5 is composed of a roller 51 and a mounting frame 52, and the axis of the roller 51 is perpendicular to the axis of the idler 4. Four rollers 51 are installed on each mounting frame 52, and the mounting frame 52 is installed on the lifting hydrau...

Embodiment 2

[0029] The gantry-type welding mechanism is composed of a rail 1, a row frame 2 and a movable welding torch 3, and the welding torch can move up, down, left, and right in a plane. A steel plate support structure is arranged between the two rails 1, and the steel plate support structure is composed of four sets of rollers 4, the left and right groups each have two rows of rollers 4, and the central two groups have four rows of rollers 4. The steel plate support structure is used to place the steel plate to be welded, and the steel plate can be moved left and right by the supporting roller 4.

[0030] A lifting mechanism 5 is set between two adjacent groups of idlers 4, and the lifting mechanism 5 is composed of a roller 51 and a mounting frame 52, and the axis of the roller 51 is perpendicular to the axis of the idler 4. Four rollers 51 are installed on each mounting frame 52, and the mounting frame 52 is installed on the lifting hydraulic cylinder 53, and the limit frame 54 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com