Weld joint positioning device and welding equipment for aluminum alloy automatic butt joint trolley

A positioning device and automatic docking technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of low efficiency of flat butt welding of aluminum alloy materials, reduce the influence of human factors and labor intensity, and save labor costs , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

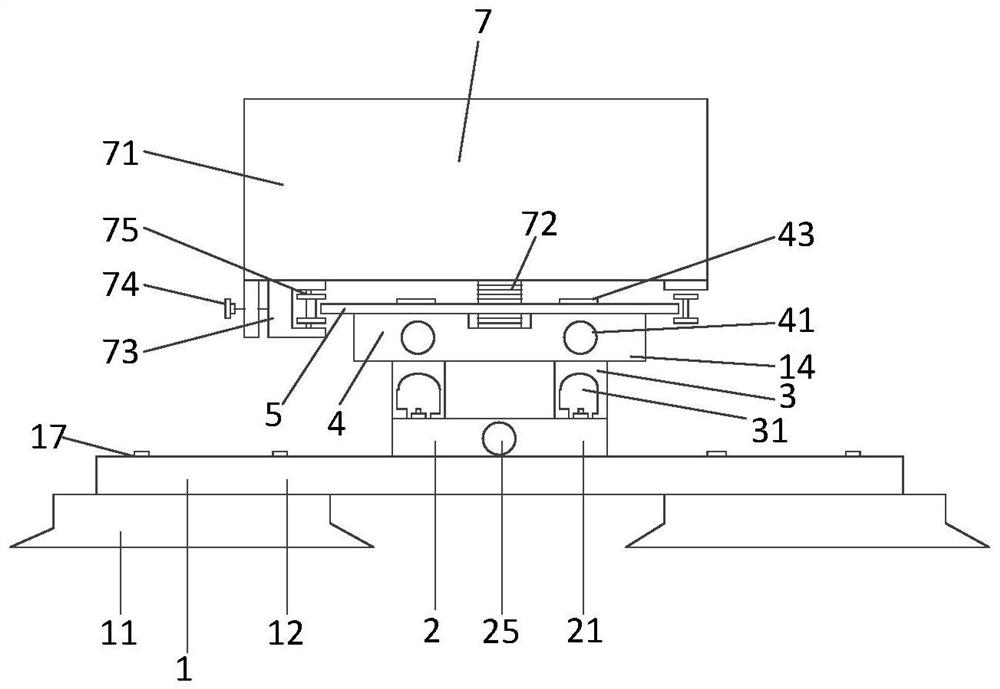

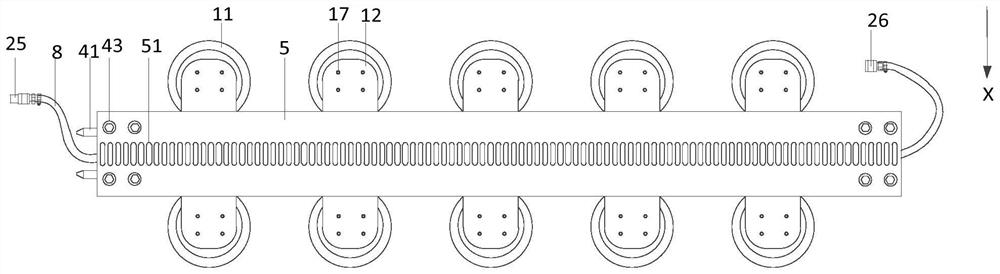

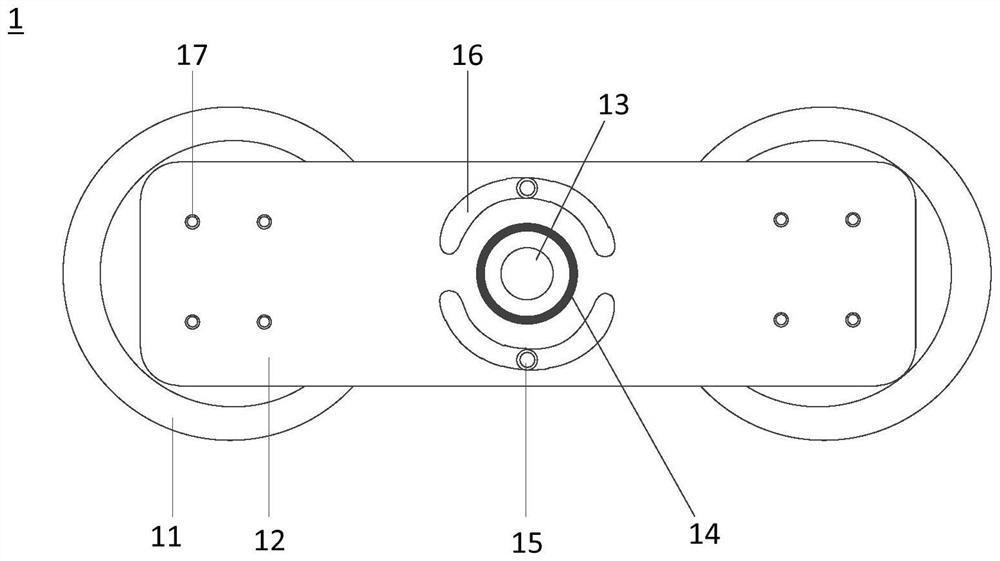

[0087] This embodiment provides a welding seam positioning device for an aluminum alloy automatic docking trolley. The welding seam positioning device includes a walking track and at least one suction cup assembly for fixing the walking track, wherein: the walking track has a first surface and a second surface arranged oppositely. Two surfaces, the first surface of the walking track is used for welding the trolley to form a connection. The suction cup assembly is fixedly arranged on the second surface of the traveling track, so as to adsorb the traveling track to the predetermined welding seam position.

[0088] Therefore, the welding seam positioning device described in this embodiment can fix the walking track at the predetermined welding seam position of the non-magnetic material to be welded through the suction cup assembly, which facilitates the precise positioning of the welding seam positioning device and realizes stable quality and high efficiency. Automate the welding...

Embodiment 2

[0099] This embodiment also provides a welding device, which includes the welding seam positioning device described in the above embodiment, and a welding trolley 7 disposed above the welding seam positioning device. The welding trolley 7 cooperates with the traveling track to move along the first surface of the traveling track 5 .

[0100] Specifically, refer to figure 1 , the welding trolley 7 includes a trolley body 71 and a gear 72 , the gear 72 is fixedly arranged under the trolley body 71 , and the gear 72 meshes with the tooth slot of the walking track 5 . In addition, a welding arm (not shown in the figure) is provided on the carriage body 71 .

[0101] In an alternative embodiment, refer to figure 1 and figure 2 , the welding trolley 7 also includes a movable slider 73, an adjusting screw 74 and a clamping wheel. The movable slider 73 is fixed under the trolley body 71 and can reciprocate along the extending direction X perpendicular to the running track; the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com