Hot melting bushing welder

A welding machine and casing technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as manpower is difficult to last for too long, welding work is difficult, PE pipe or joint interface is skewed, and the production cost is reduced. and maintenance costs, the welding process is stable and reliable, and the effect of reducing the possibility of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with each accompanying drawing, the present invention is described in detail.

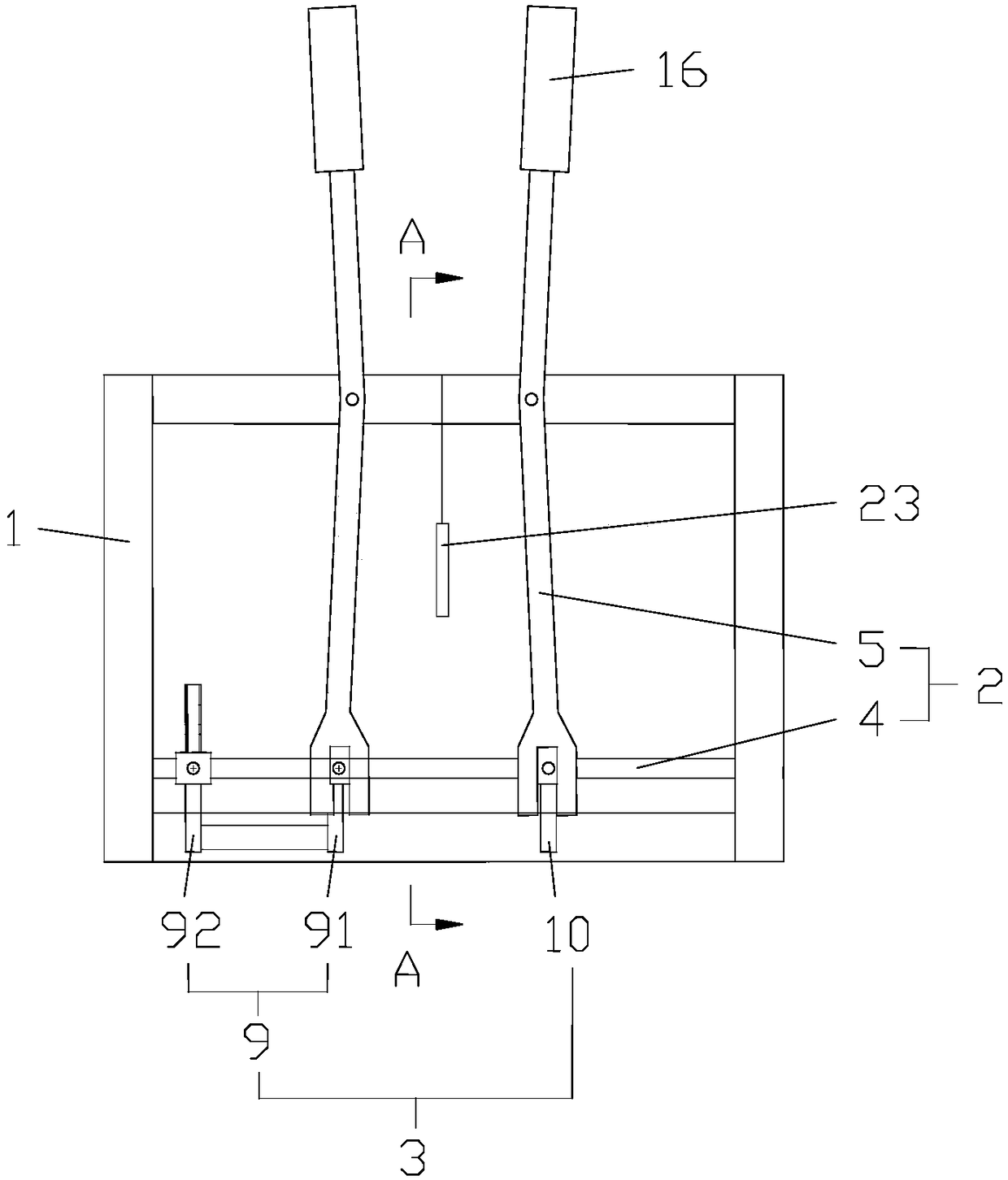

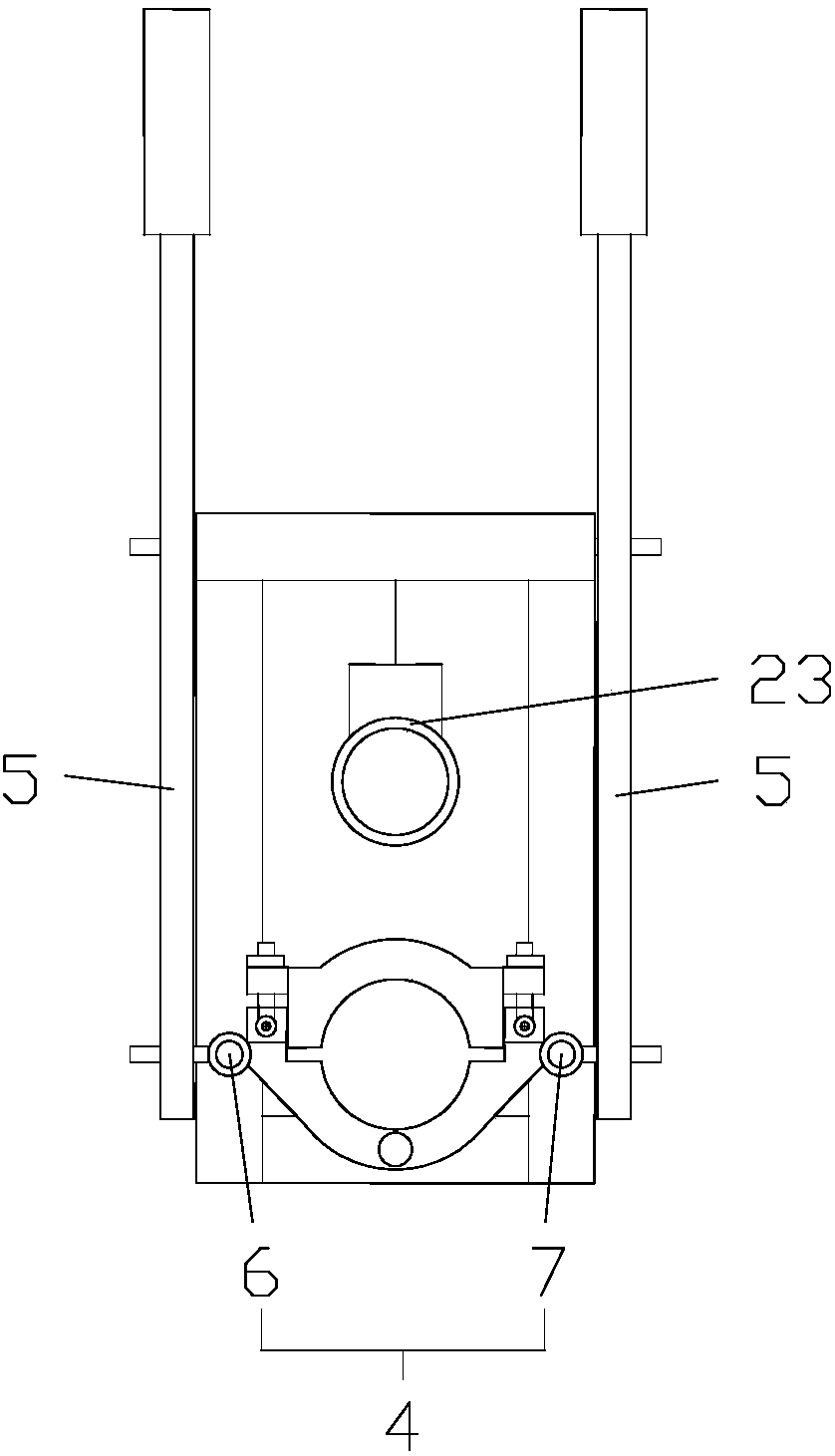

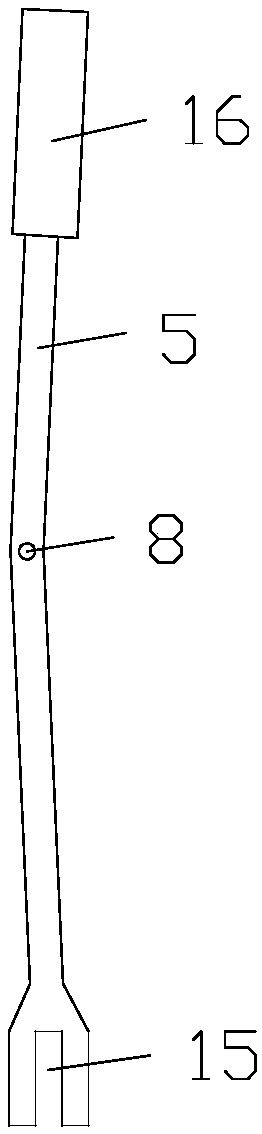

[0031] see Figure 1-Figure 7 , the present embodiment is a hot-melt casing welding machine, including a frame 1, a guide mechanism 2, a fixing mechanism 3 and a fuser 23.

[0032] see Figure 1-2 , the guiding mechanism 2 and the fixing mechanism 3 are installed on the frame.

[0033]The fixing mechanism 3 includes a pipe fitting fixing device 9 and a sleeve fixing device 10, which are respectively used for fixing the pipe fitting and the sleeve. The pipe fixing device 9 is connected with the guide mechanism 2, and the position of the pipe fixing device 9 can be changed through the guide mechanism 2. The sleeve fixing device 10 is also connected with the guide mechanism 2, and the position of the sleeve fixing device 10 can be changed through the guide mechanism 2. The fuser 23 is used to heat the pipe fittings and sleeves.

[0034] The frame 1 is used as the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com