Independent wheel suspension for motor vehicles

An independent suspension and wheel technology, applied in suspension, elastic suspension, vehicle springs, etc., can solve problems such as expensive structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

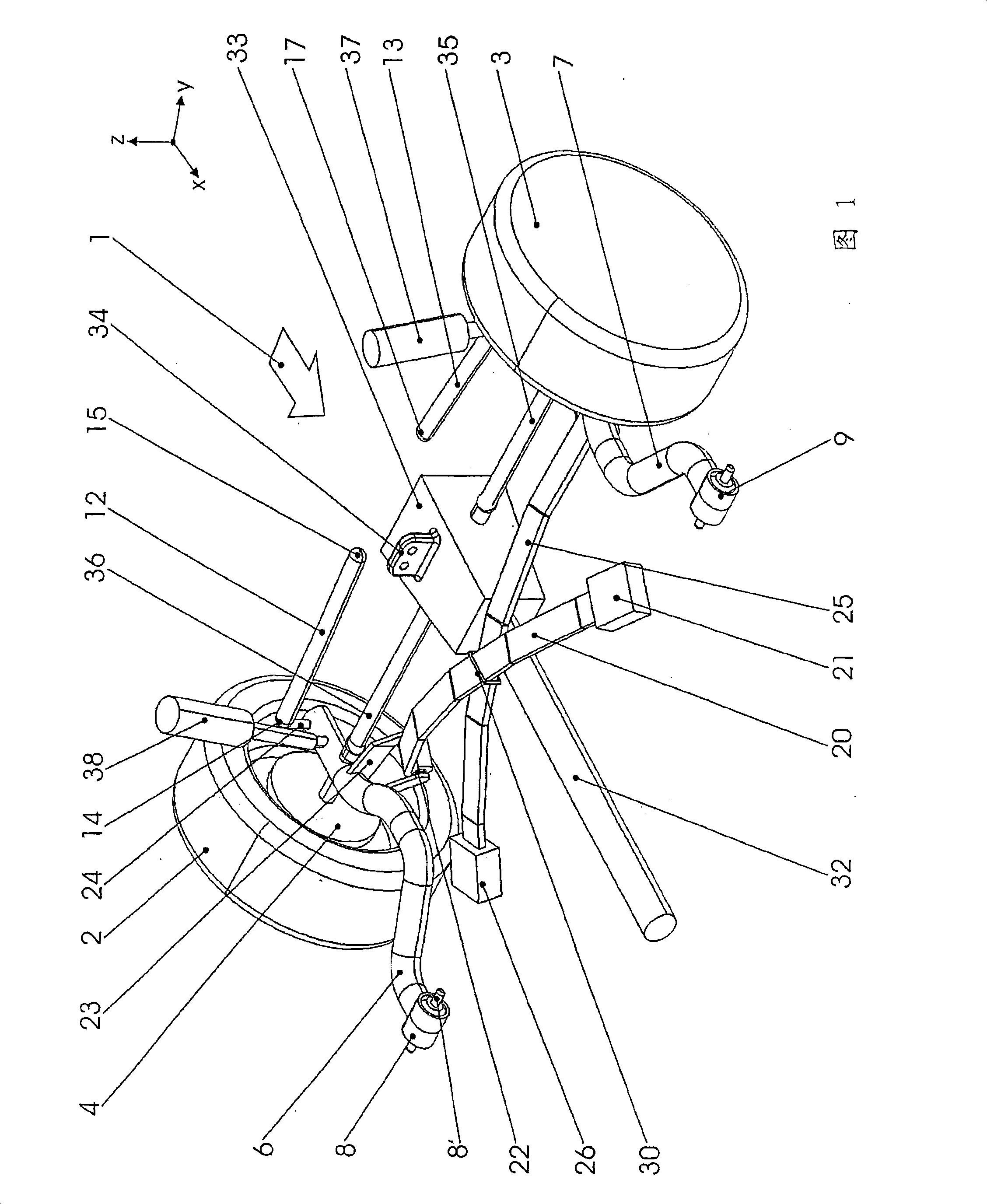

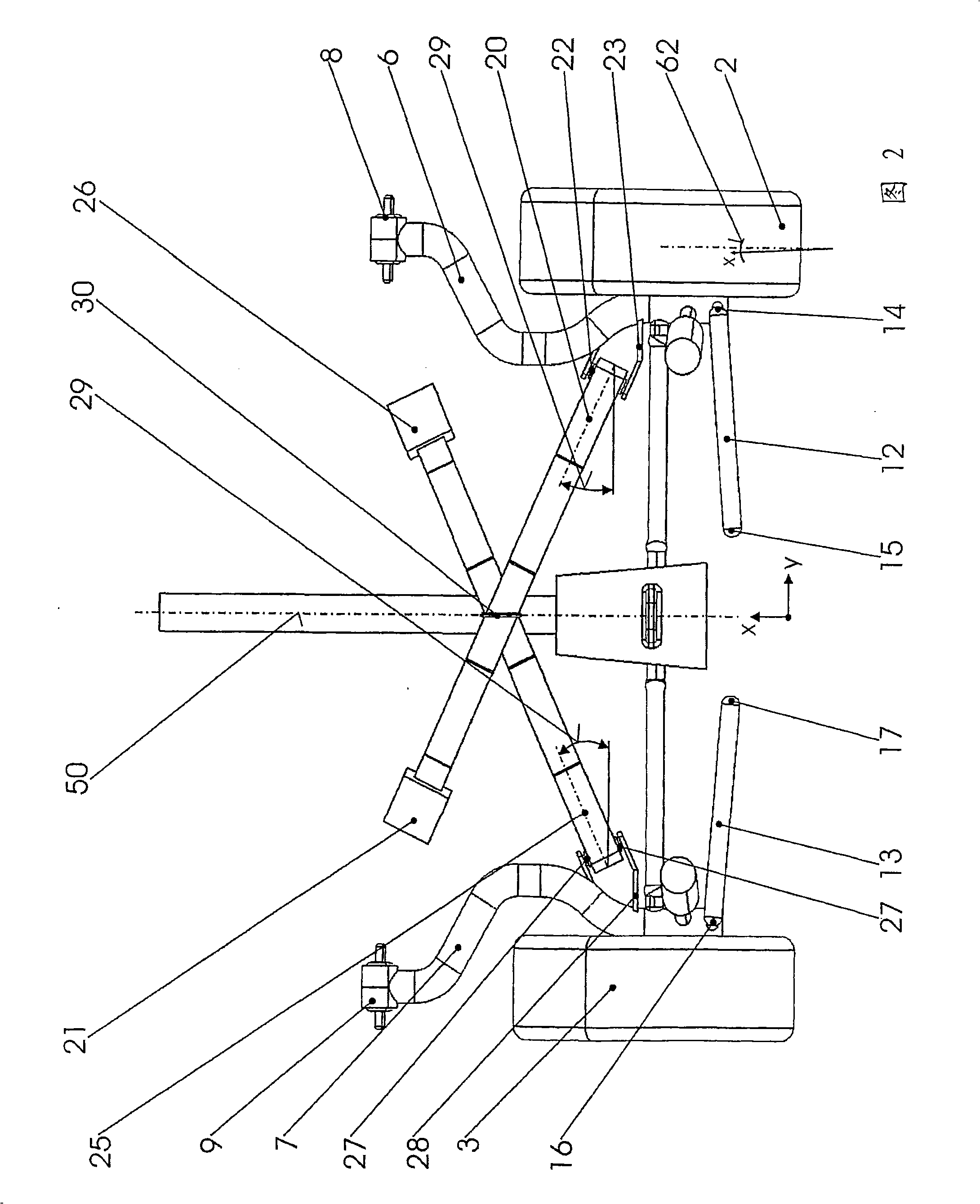

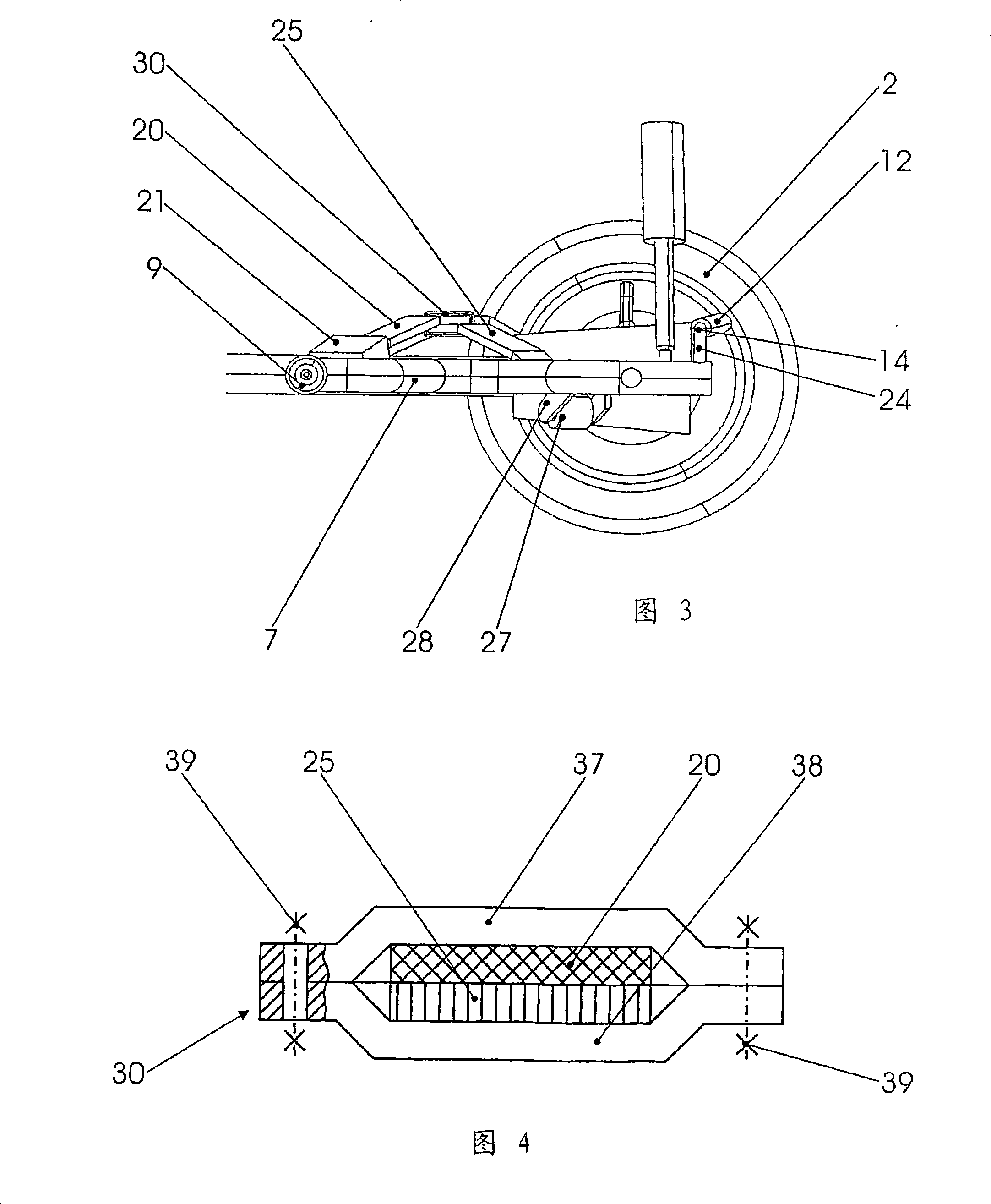

[0023] 1 , 2 , 3 relate to a rear axle, the direction of travel of which is indicated by the reference number 1 . There is no representation of the car itself. The suspensions of the right wheel 2 and the left wheel 3 and their wheel supports 4, 5 are of course symmetrical. Wheel frames 4, 5 are fixedly connected or integrated with wheel longitudinal swing arms 6 (right), 7 (left). The longitudinal wheel arms 6 , 7 are here hollow bodies in the form of bent tubes, which are articulated pivotally on the vehicle in joint points formed by the first elastic bushings 8 , 9 . The first elastic bushing allows rotation about the pin 8' in the x-z plane and a slight pivoting of the wheel longitudinal arms 6, 7 in the x-y plane, and rotation in the y-z plane when the wheel camber changes. It is also possible to use a ball and socket joint instead of a bush. Furthermore, transverse control arms 12 , 13 are provided. The right transverse control arm 12 is articulated at an articulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com