Automatic loading or unloading device for profile steel hanging system

A suspension system and automatic feeding technology, which is applied to the surface coating liquid device, transportation and packaging, conveyor objects, etc., can solve the problems of low loading and unloading efficiency, high labor intensity, and high safety hazards, and achieve the goal of loading and unloading The effect of high efficiency, good safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

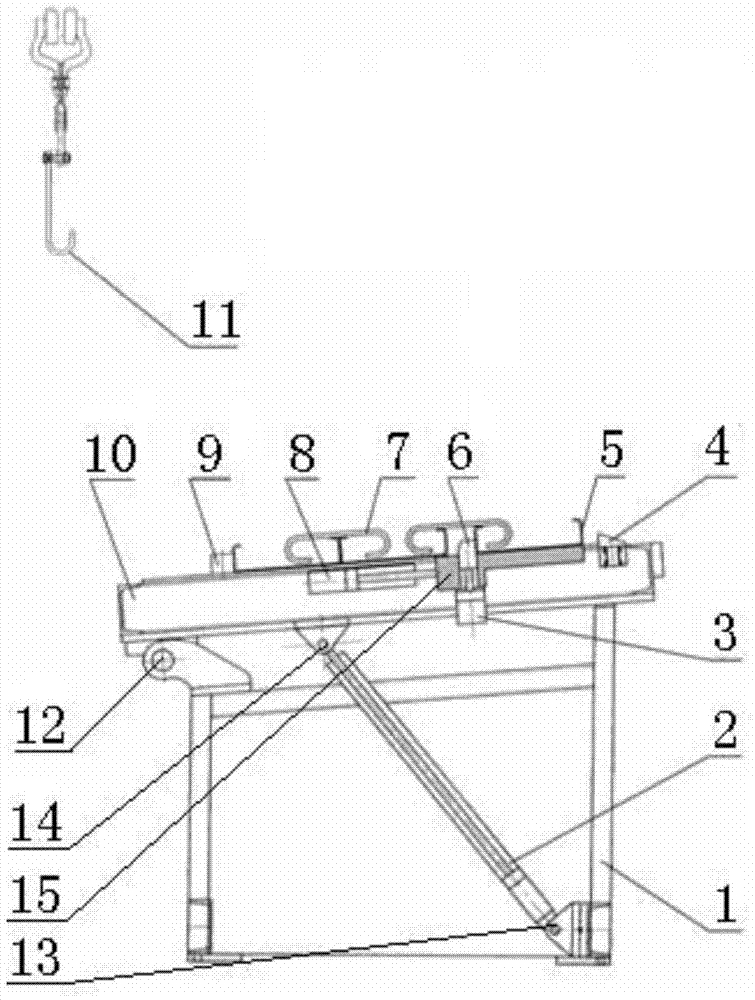

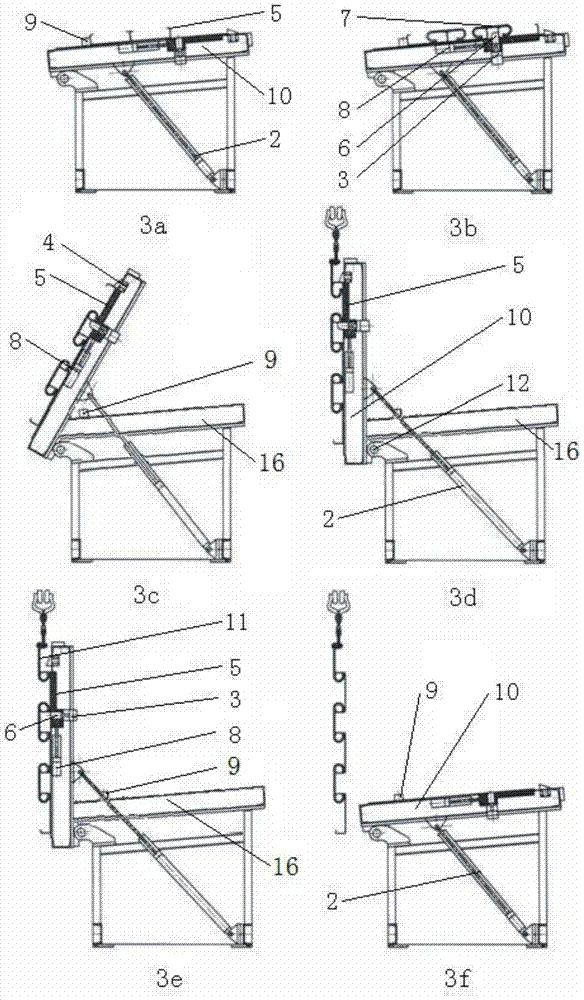

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and taking C-shaped steel as a specific implementation case.

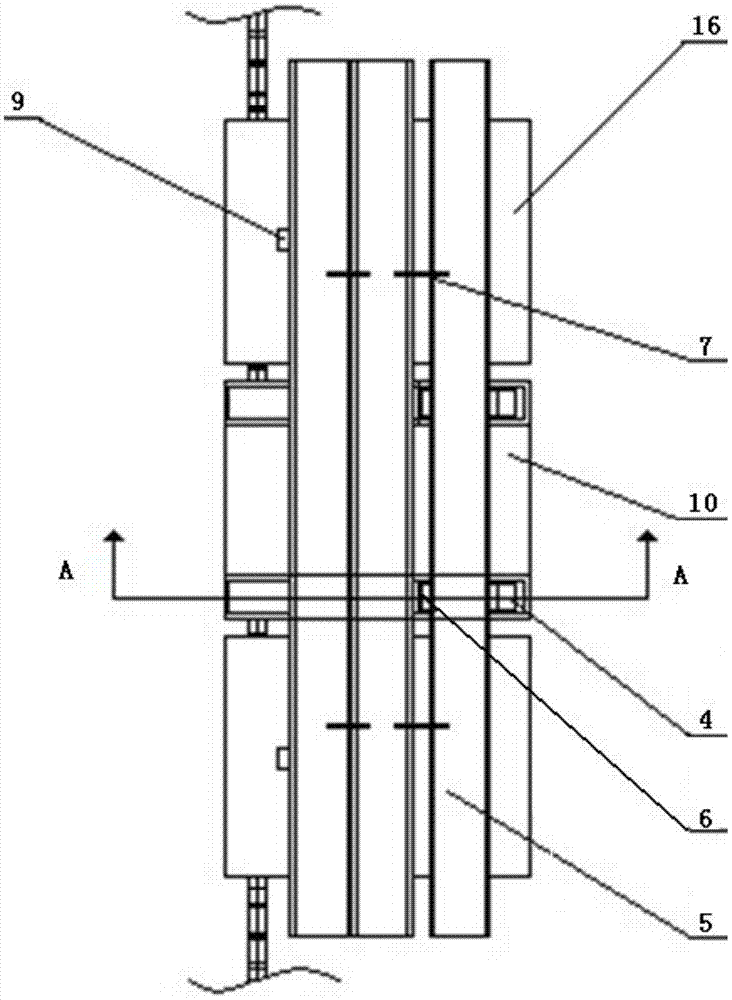

[0025] see figure 1 ( figure 1 for figure 2 A cross-sectional view in the middle direction), an automatic loading and unloading device mainly suitable for C-shaped steel, channel steel and bar-shaped steel suspension systems with similar cross-sections, including a flipping loading and unloading mechanism and a hook 11 or The hanging feeding mechanism of the fixture, the flipping loading and unloading mechanism is also provided with a positioning mechanism.

[0026] The overturning loading and unloading mechanism is composed of an overturning workbench 10 hinged on the platform 1 and an overturning oil cylinder 2, and the overturning workbench 10 is arranged horizontally or obliquely at a small angle (0°-20°); when the overturning workbench 10 When placed horizontally, the upper edge (the edge away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com