High-speed and high-accuracy magneto-rheological grease flexible manipulator connection rod and multi-connection-rod manipulator system

A flexible manipulator and magnetorheological grease technology, applied in the field of manipulators, can solve the problems of dynamic characteristics, large end load, large structure size, etc., and achieve fast and flexible operation, simple control mechanism, and good vibration reduction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

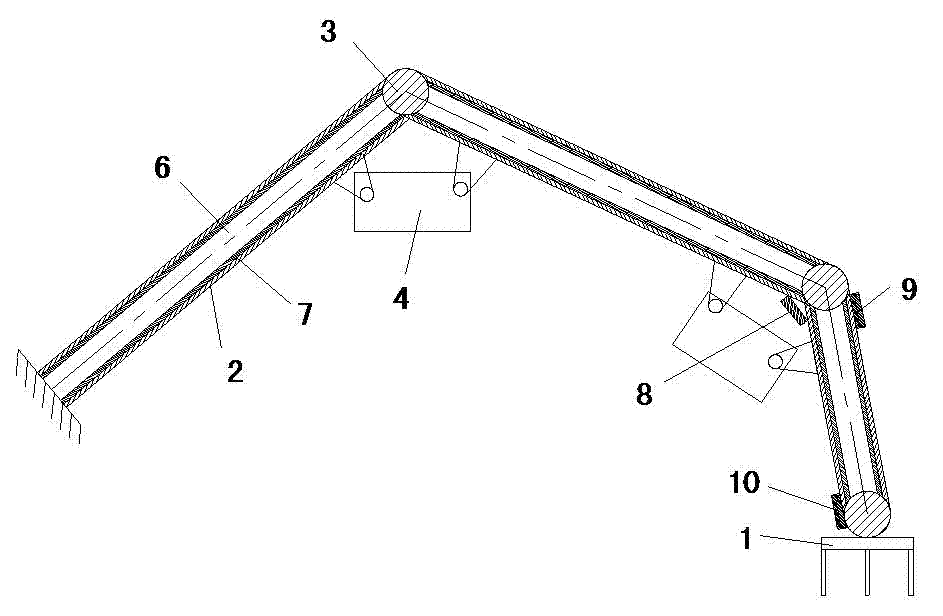

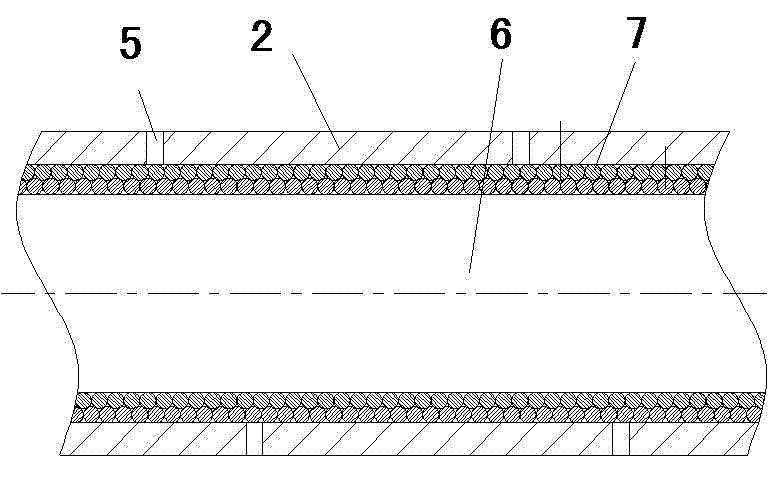

[0023] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the high-speed and high-precision magnetorheological grease flexible multi-link manipulator system of the present invention. The high-speed and high-precision magneto-rheological grease flexible multi-link manipulator system of this embodiment includes an end gripper 1, at least two manipulator links 2 and an excitation coil 7 arranged in the manipulator link 2 The power supply device for power supply is connected to the connecting rods 2 of the two mechanical arms through the hinged connection of the hinge shaft 3, and the connecting rods 2 and the hinged shafts 3 are coupled by magneto-rheological grease, and the two adjacent connecting rods 2 of the mechanical arms A driving vibration controllable device 4 for driving the action of the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com