Patents

Literature

48results about "Cooled electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

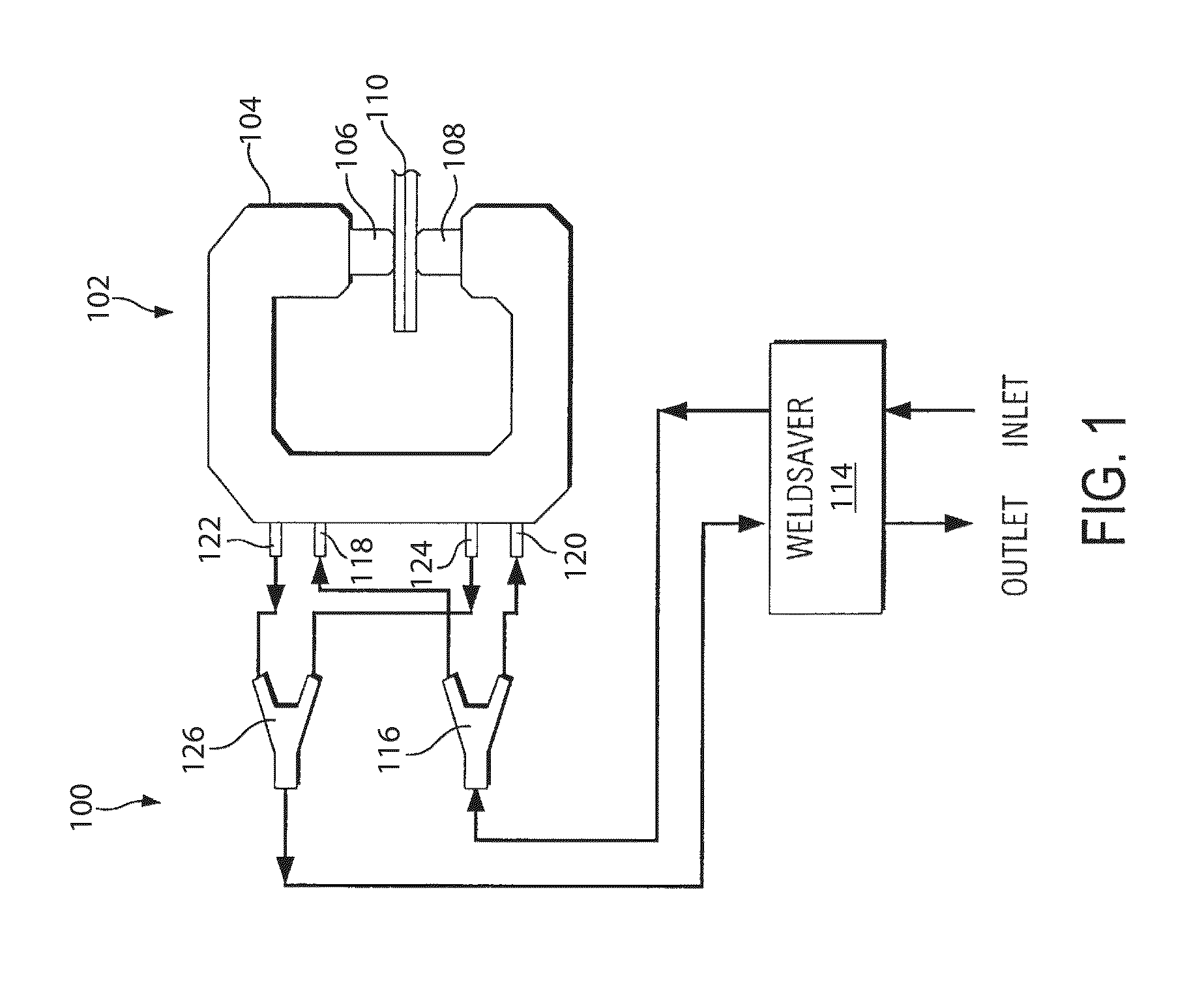

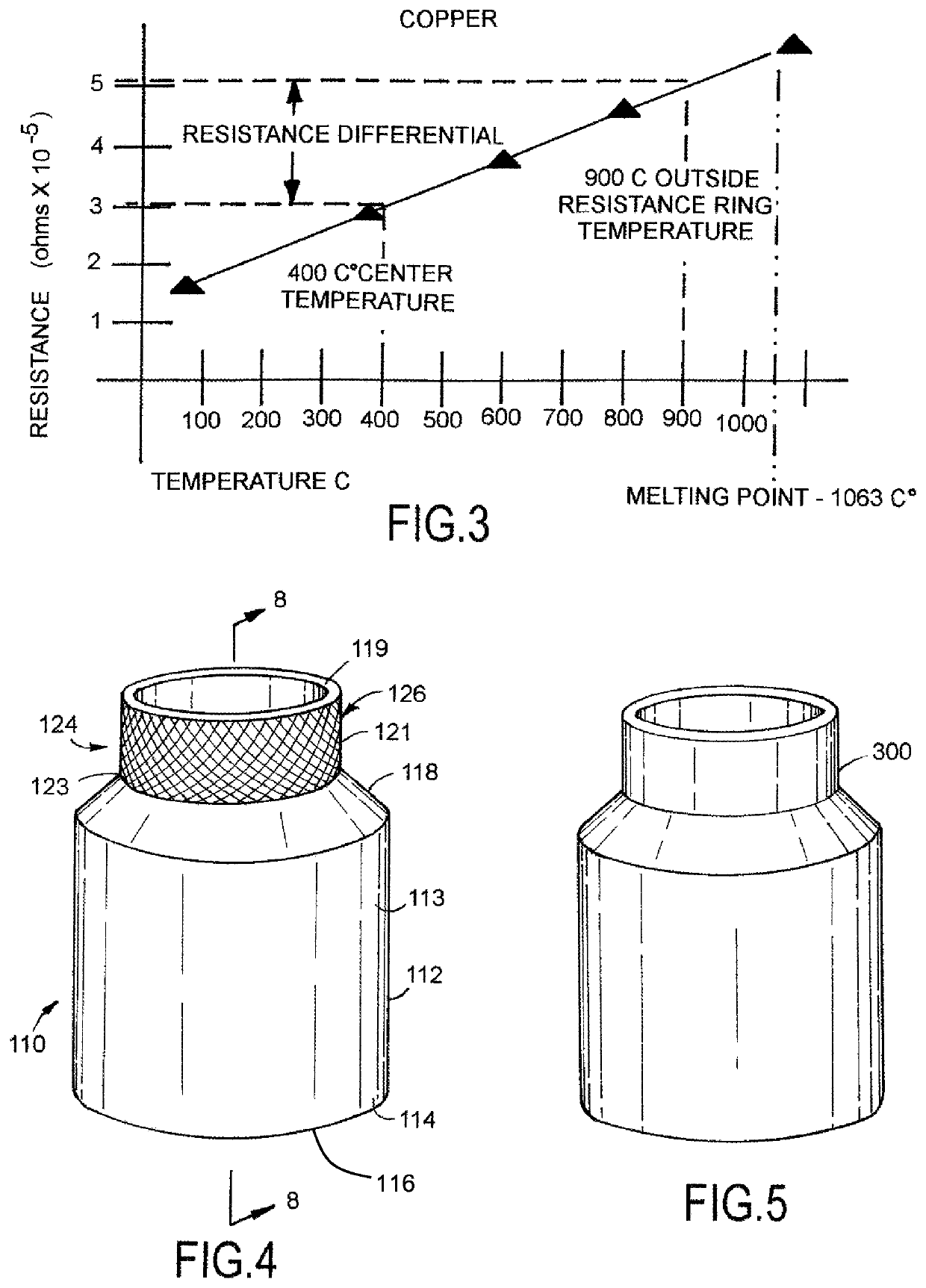

Resistance spot welding steel and aluminum workpieces with hot welding electrode at aluminum workpiece

ActiveUS20150083693A1Facilitate subsequent spot welding processHigh thermalWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingAluminium alloy

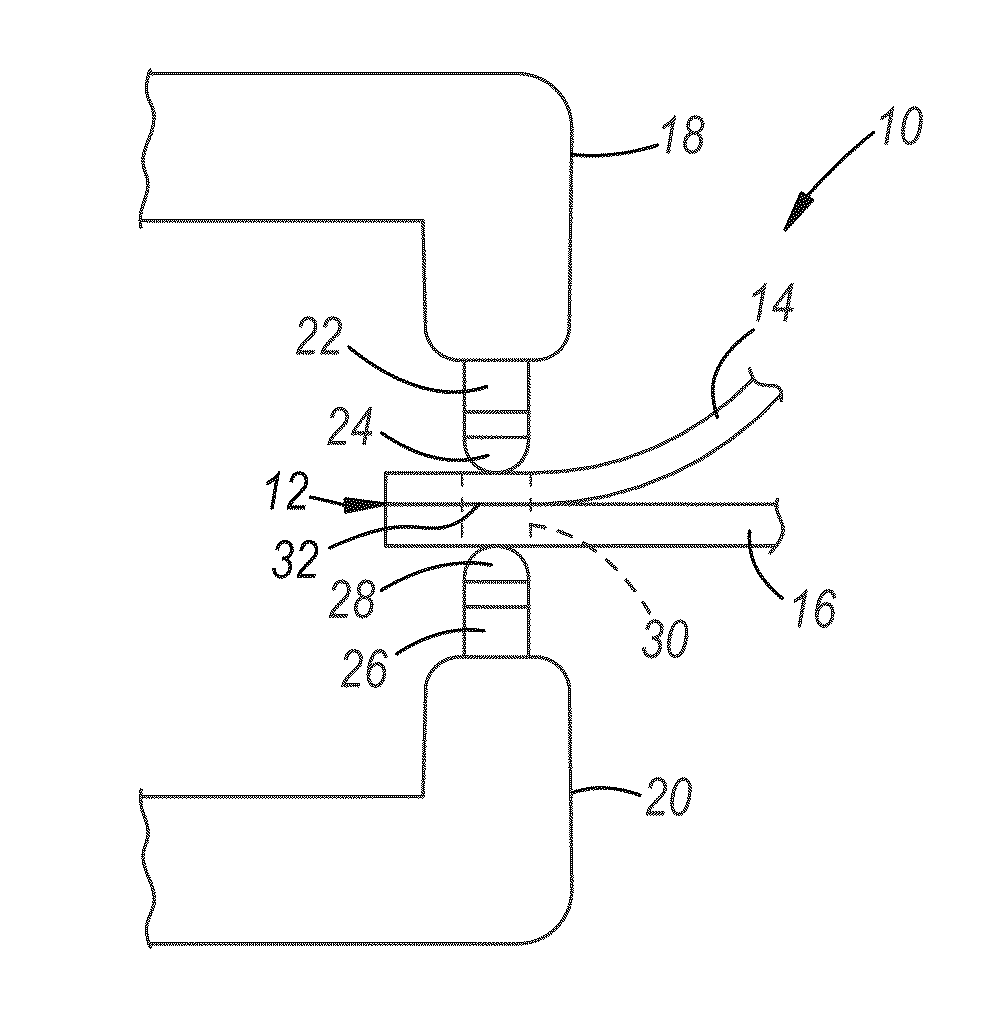

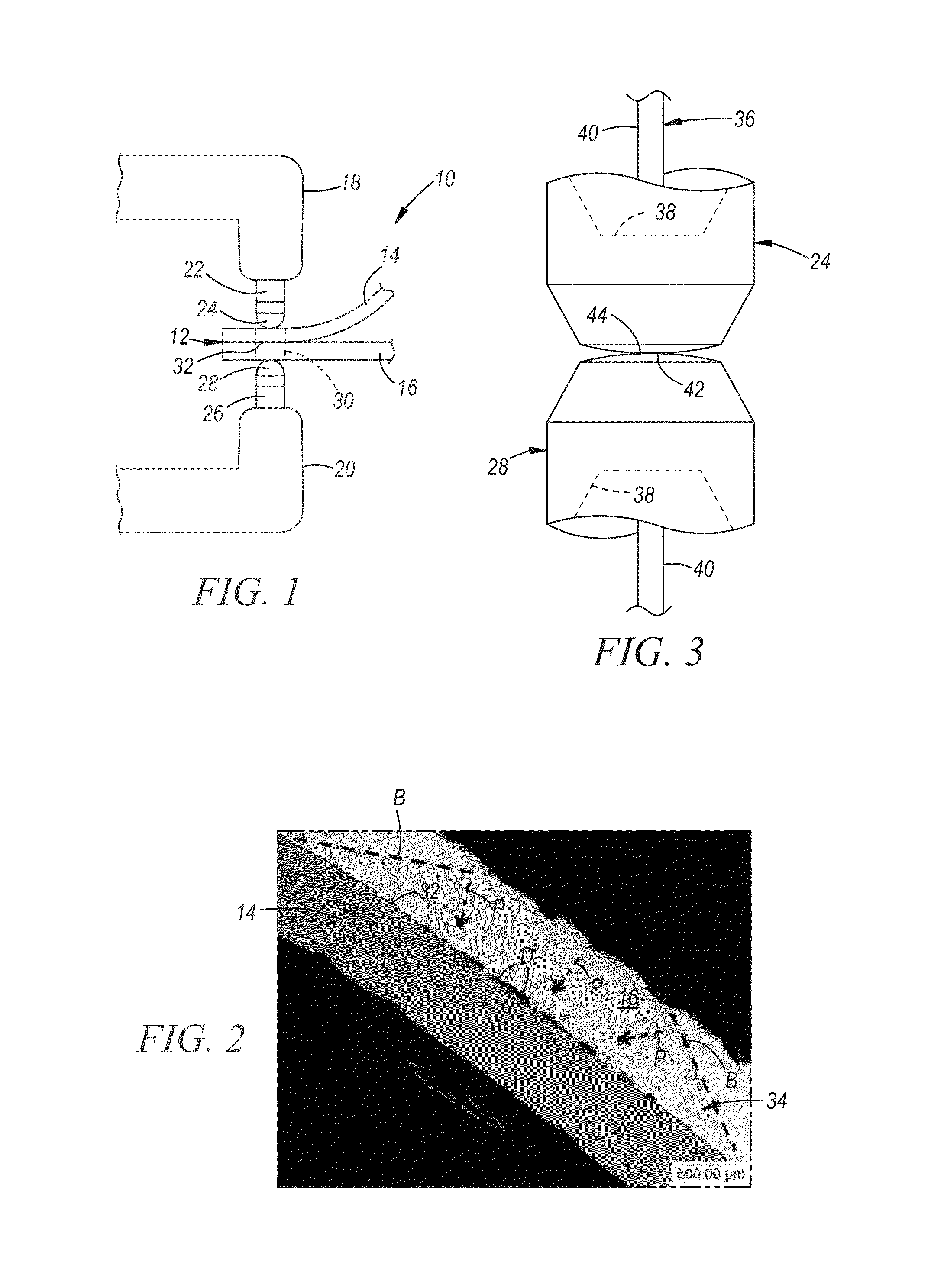

A method of resistance spot welding a steel workpiece to an aluminum or aluminum alloy workpiece is disclosed. One step of the disclosed method involves providing a workpiece stack-up that includes a steel workpiece and an aluminum workpiece. Another step involves preheating the welding electrode that is meant to contact the aluminum or aluminum alloy workpiece. Yet another step of the disclosed method involves pressing the preheated welding electrode and another welding electrode against opposite sides of the workpiece stack-up, with the preheated welding electrode abutting the aluminum or aluminum alloy workpiece, and passing an electrical current between the two welding electrodes at a weld site to initiate and grow a molten weld pool within the aluminum or aluminum alloy workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

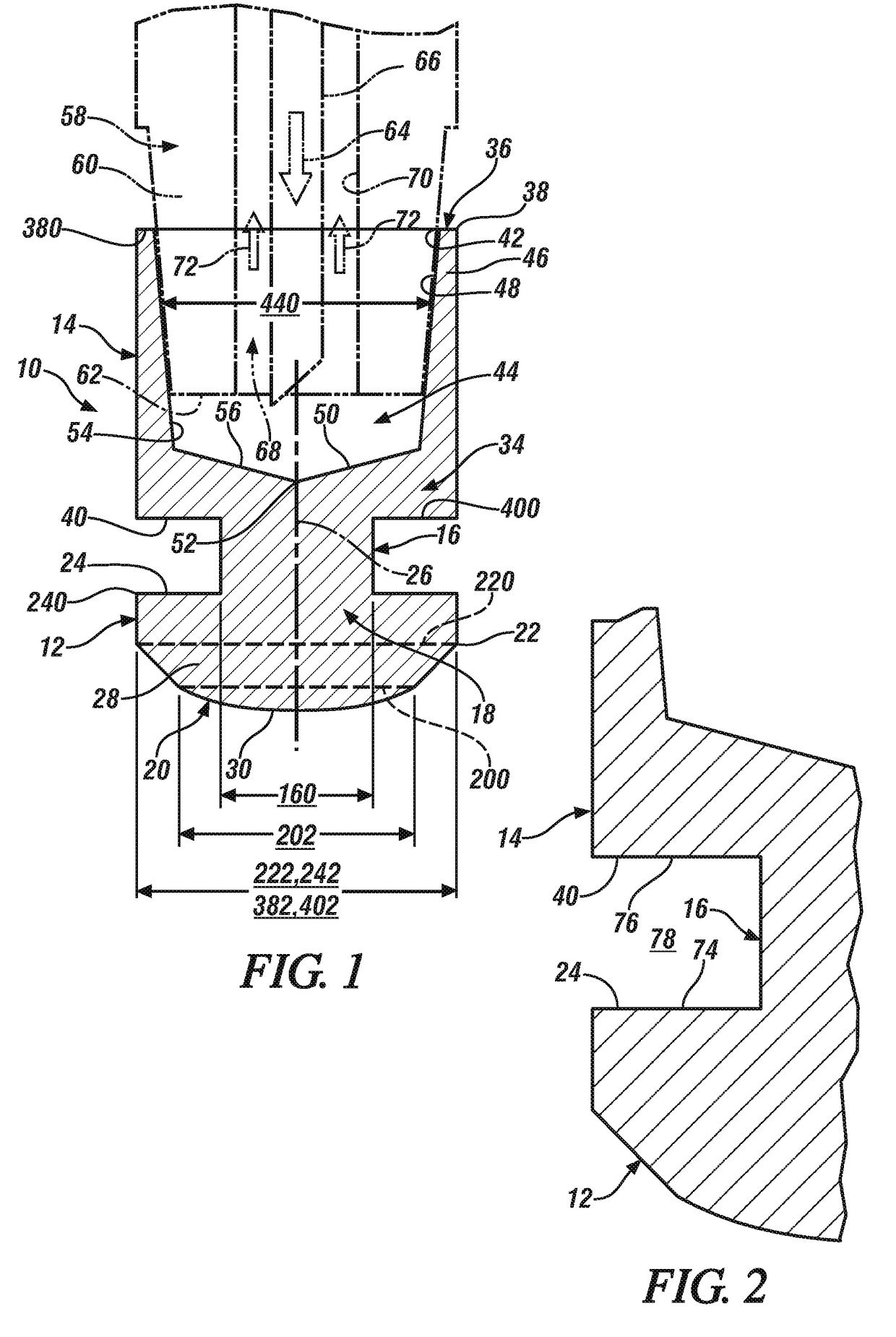

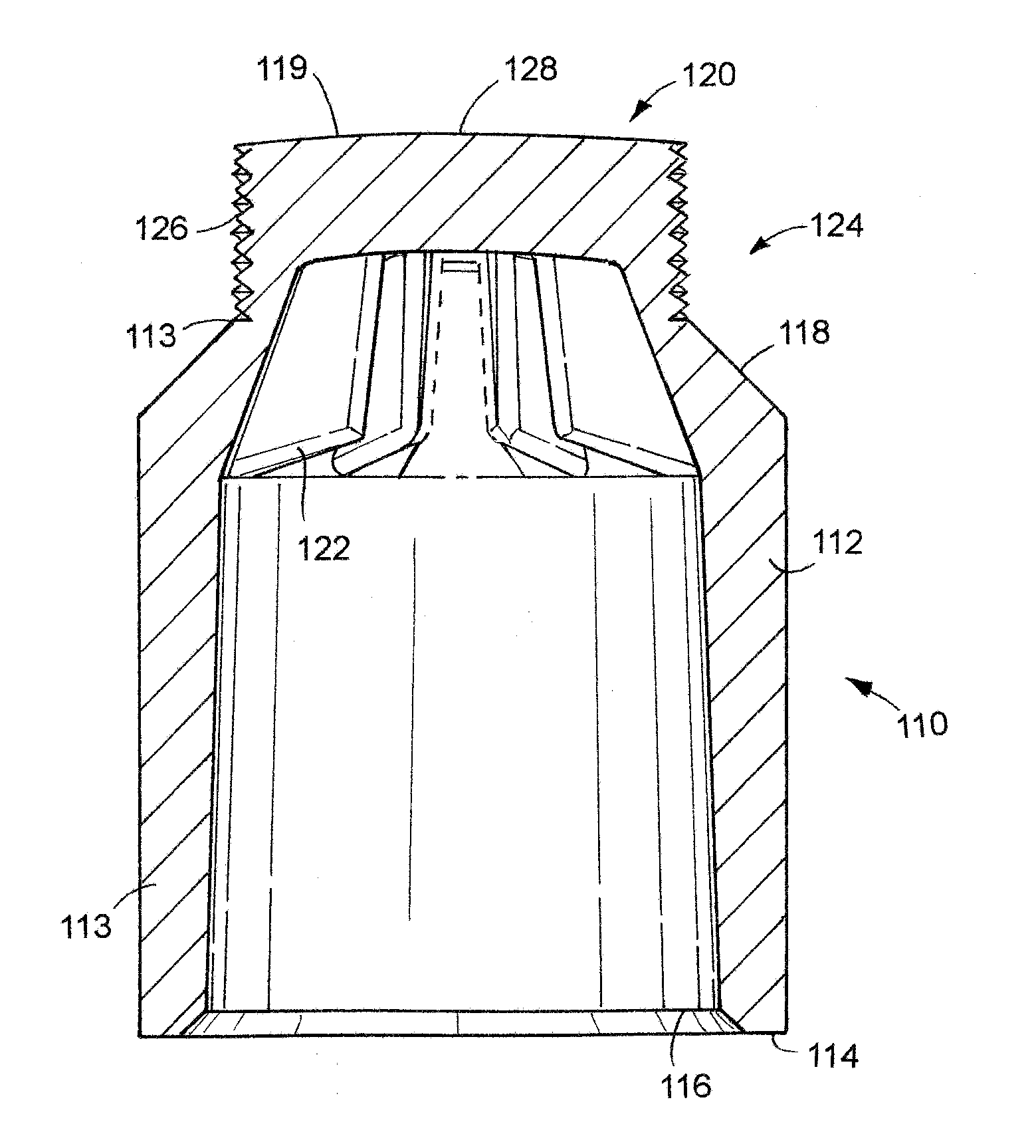

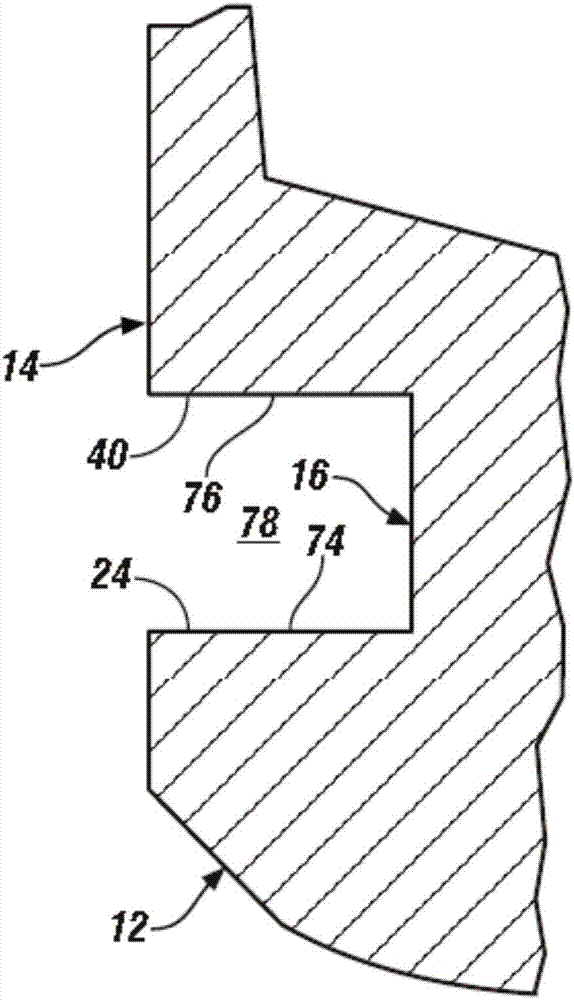

Welding electrode for use in resistance spot welding workpiece stack-ups that include an aluminum workpiece and a steel workpiece

InactiveUS20170157697A1Improve thermal conductivityPeel strength-ofPressure electrodesWelding/cutting media/materialsElectrical resistance and conductanceCombined use

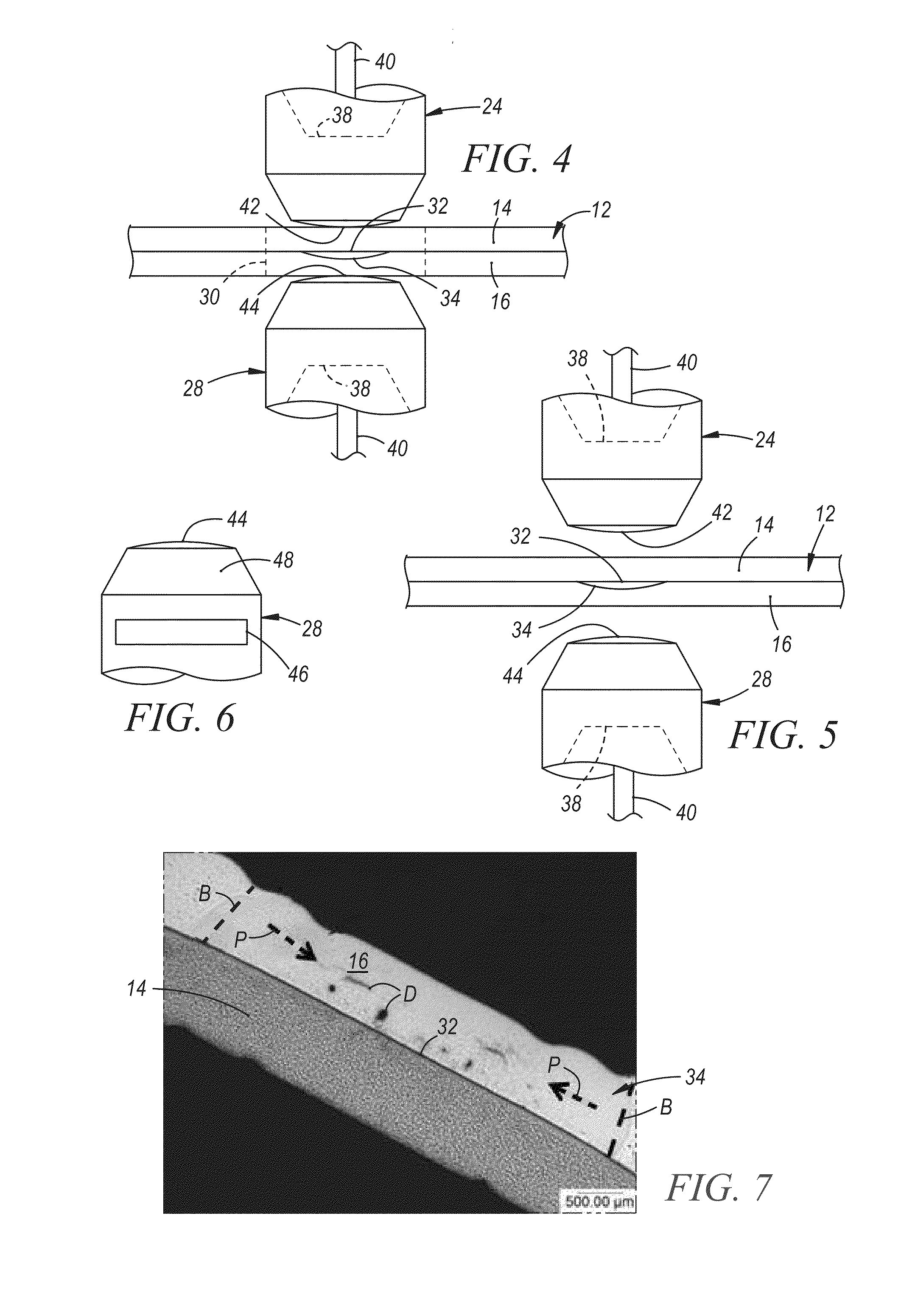

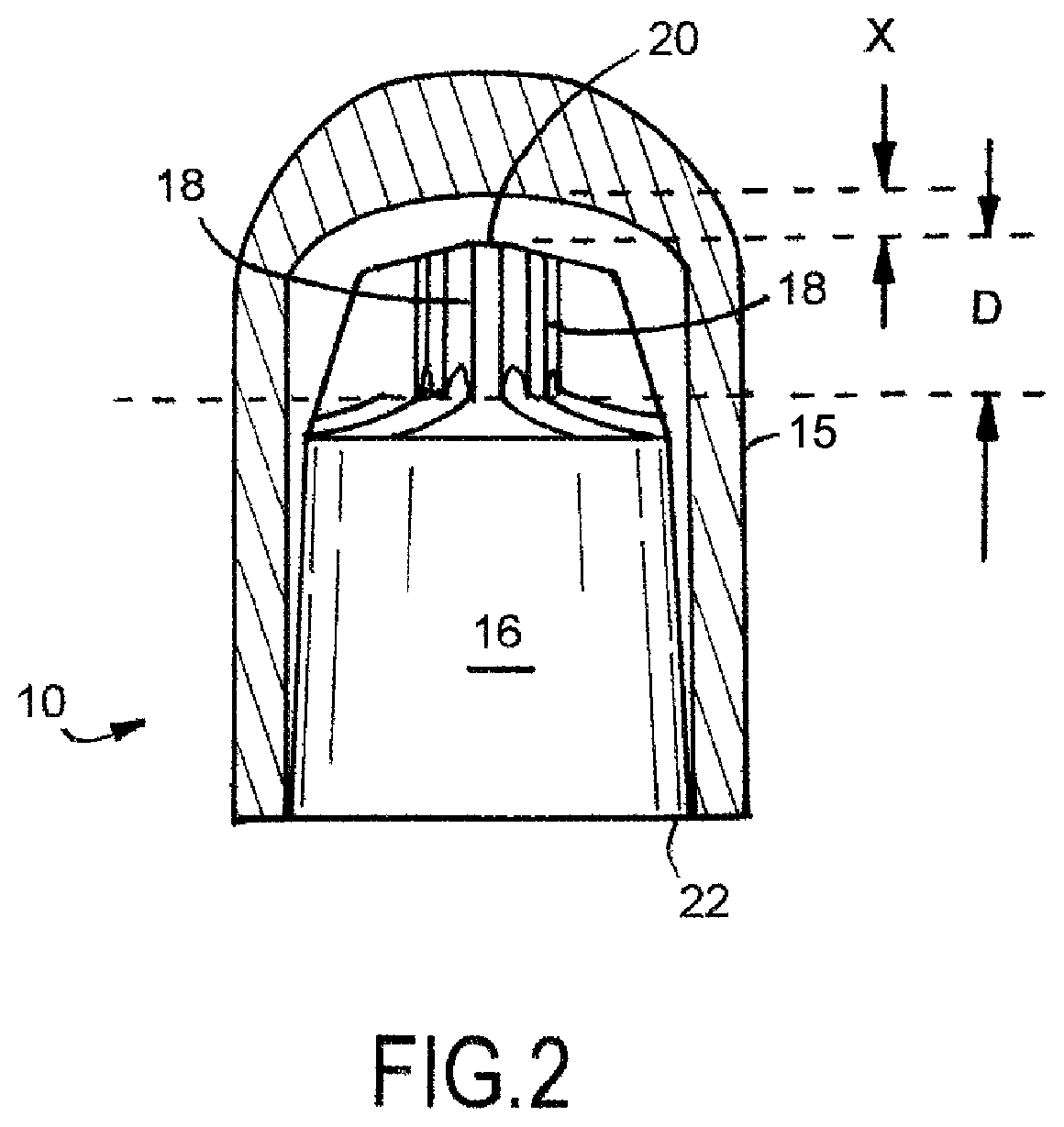

A welding electrode suitable for resistance spot welding applications includes a first portion, a second portion, and a reduced diameter portion that extends between and connects the first and second portions. The first portion includes a weld face and the second portion includes a mounting base that opens to an internal recess having a cooling pocket. The reduced diameter portion extends between a back surface of the first portion and a front surface of the second portion such that a gap separates the back and front surfaces from each other. The gap may be vacant or filled with a low conductivity material. The disclosed welding electrode may be used in conjunction with another welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum workpiece and an adjacent overlapping steel workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

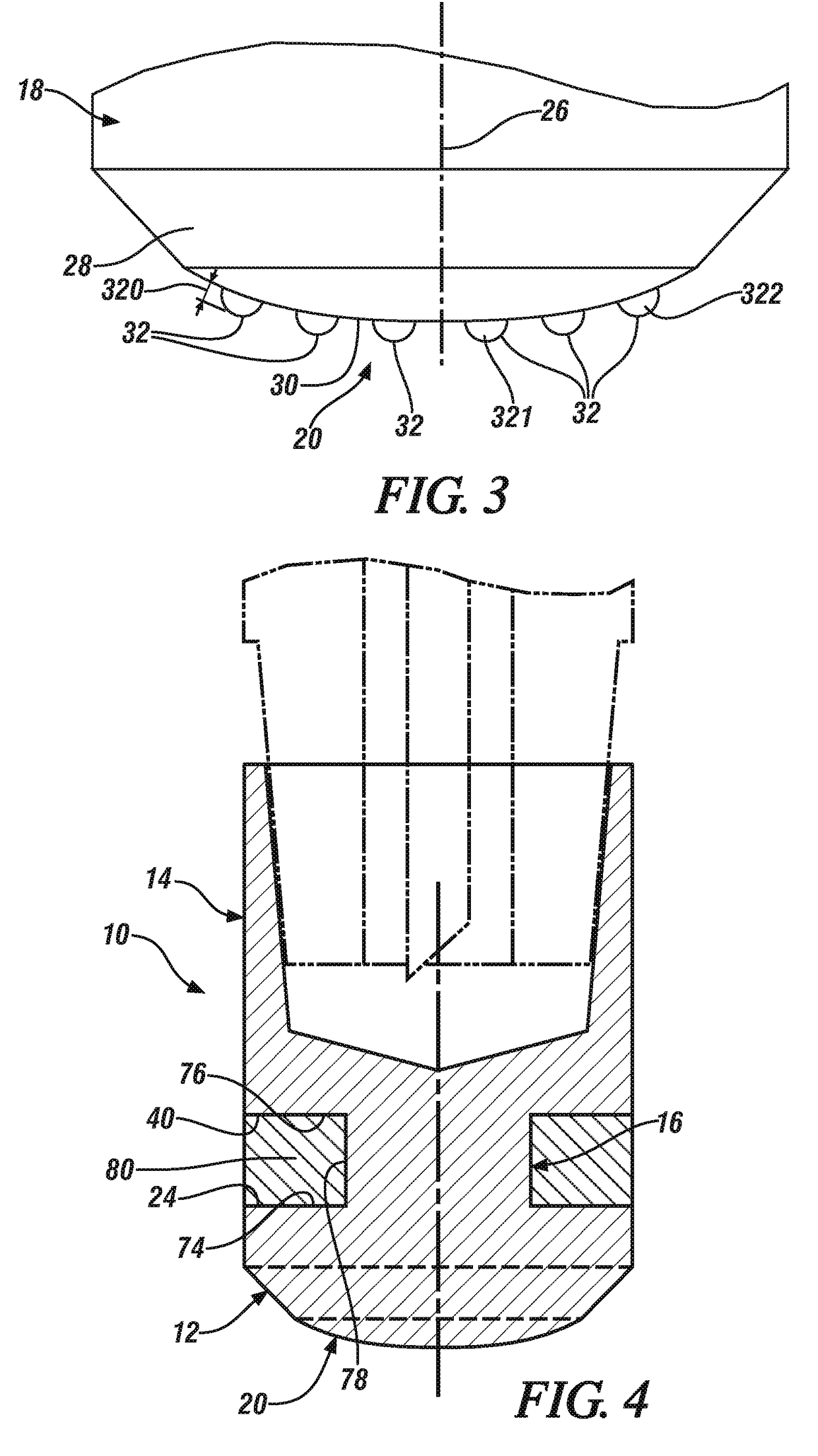

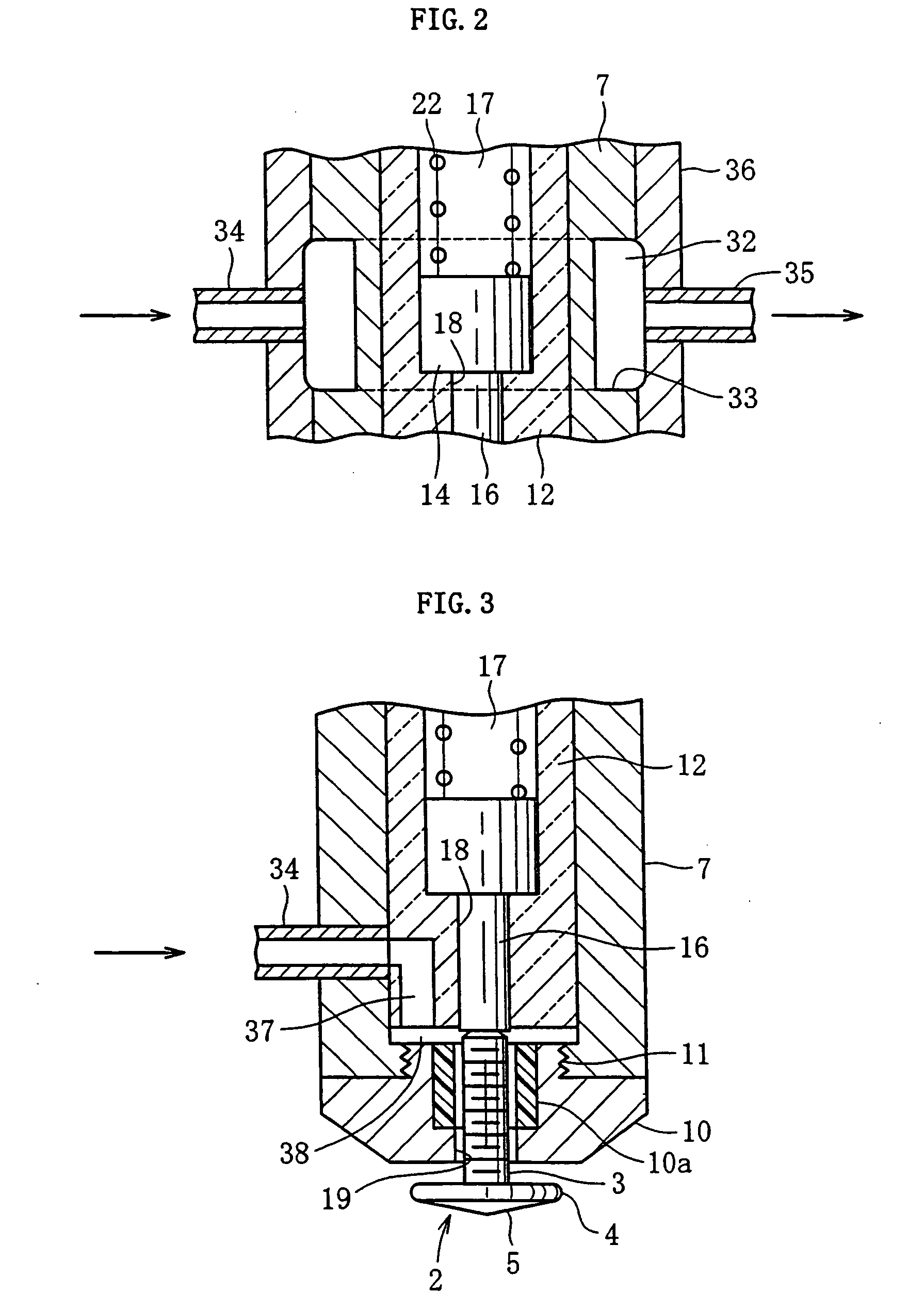

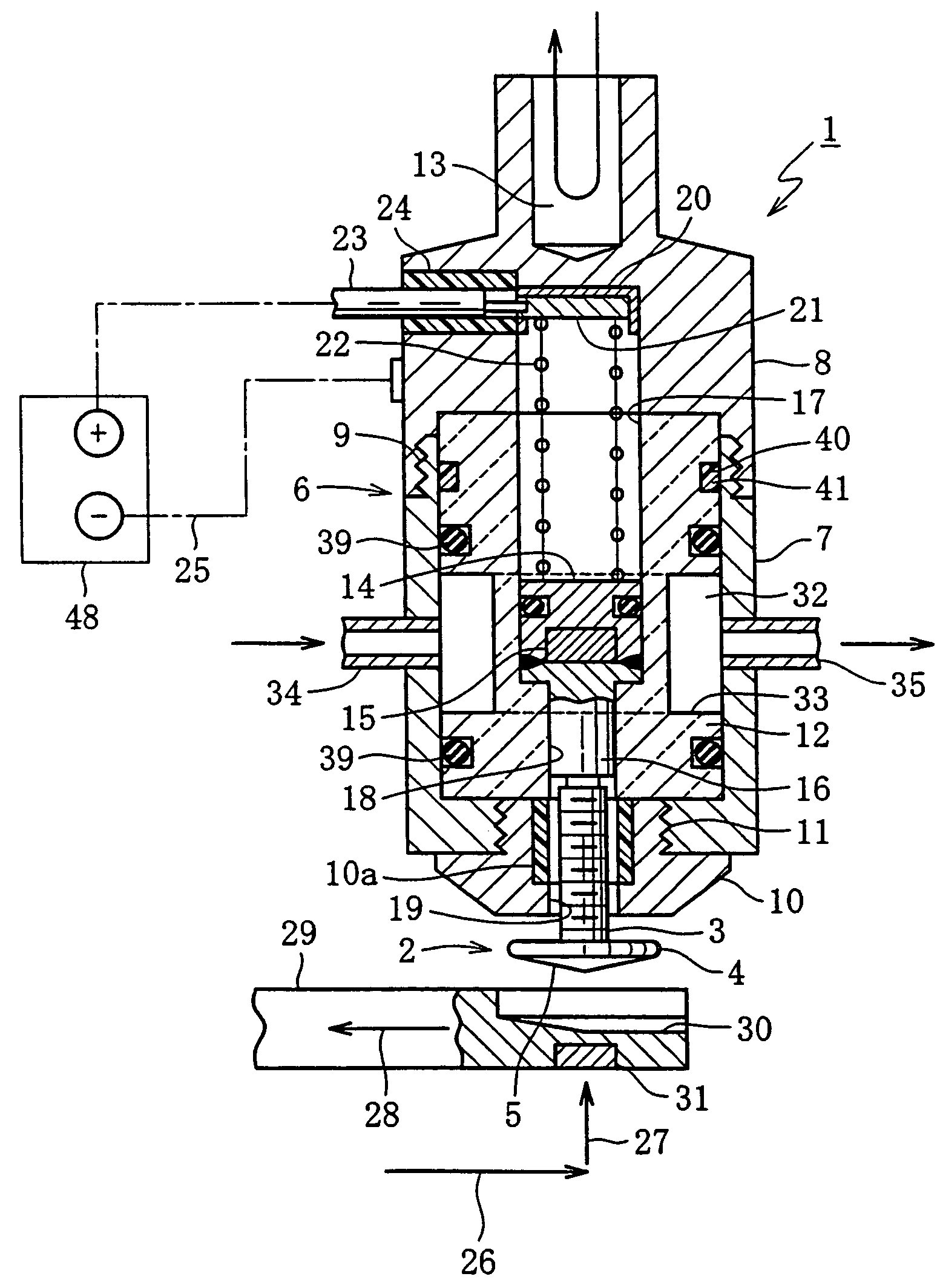

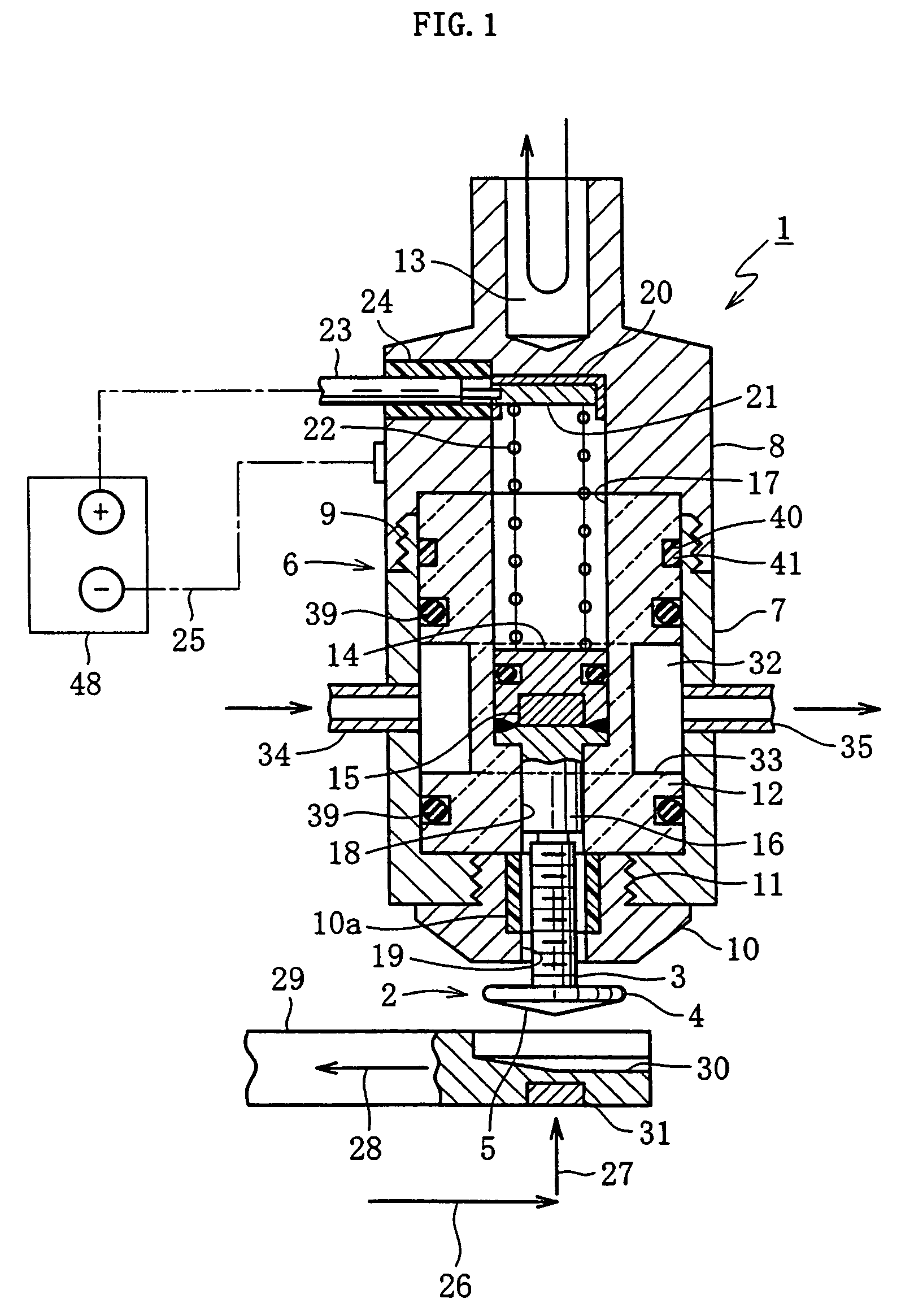

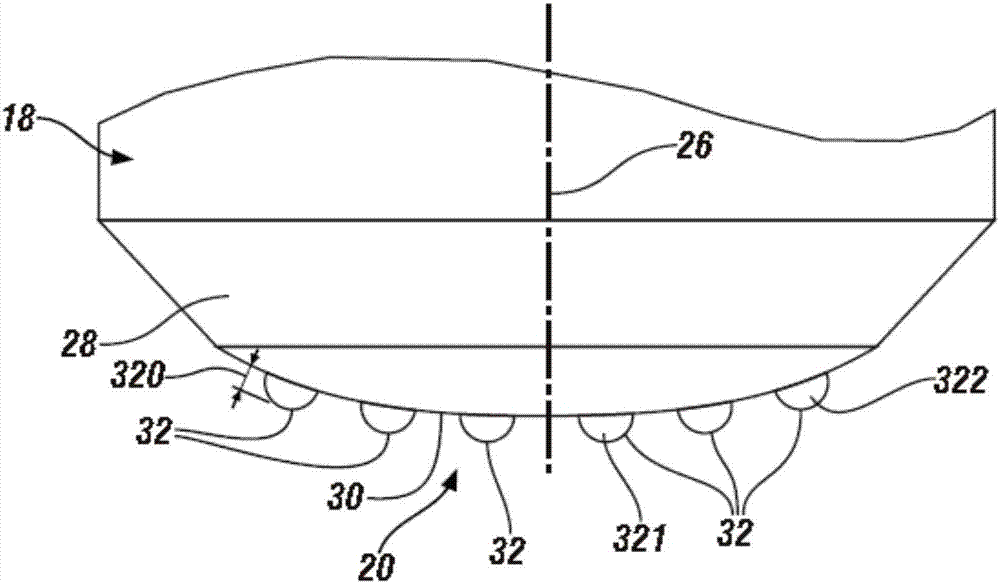

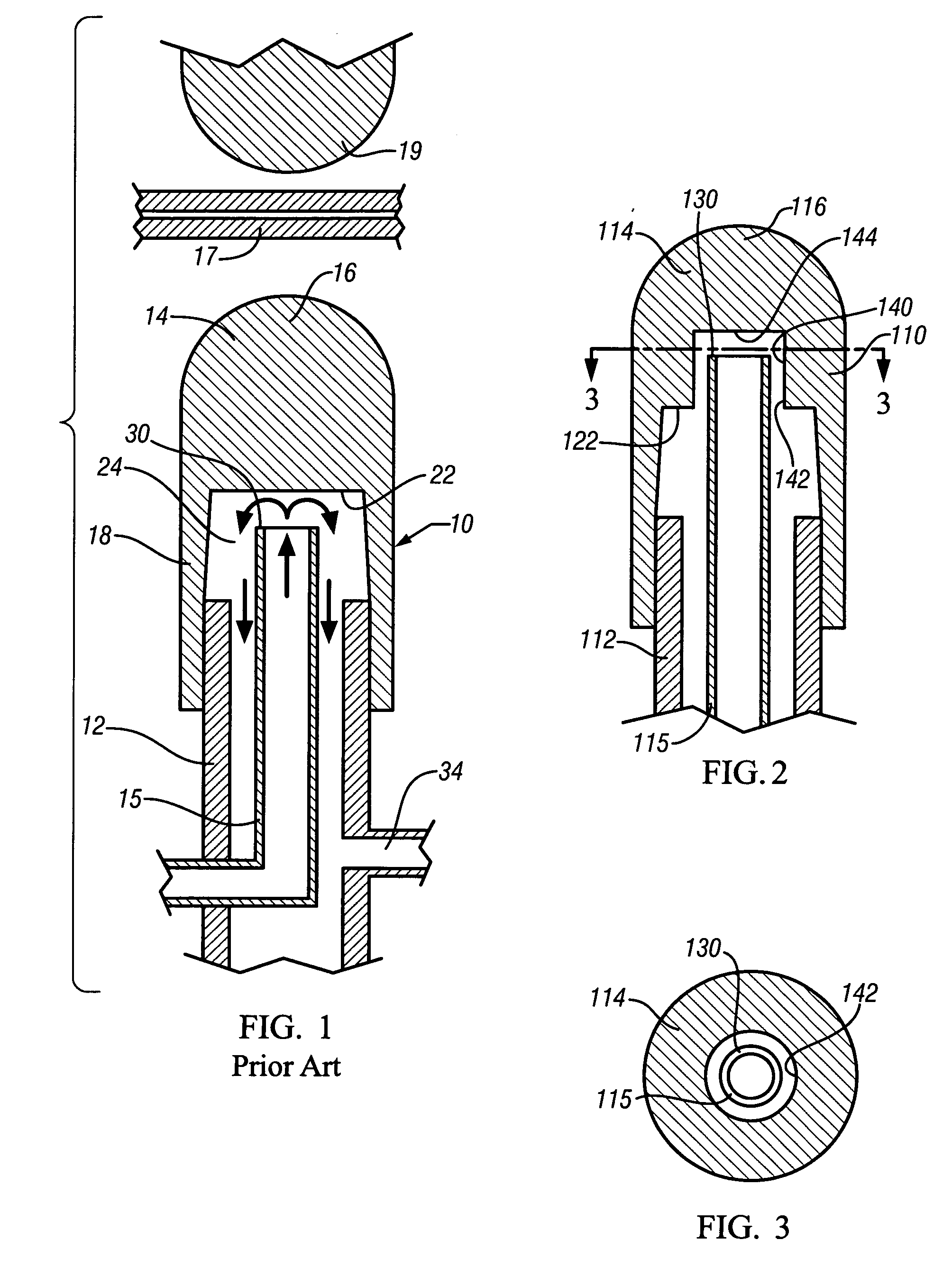

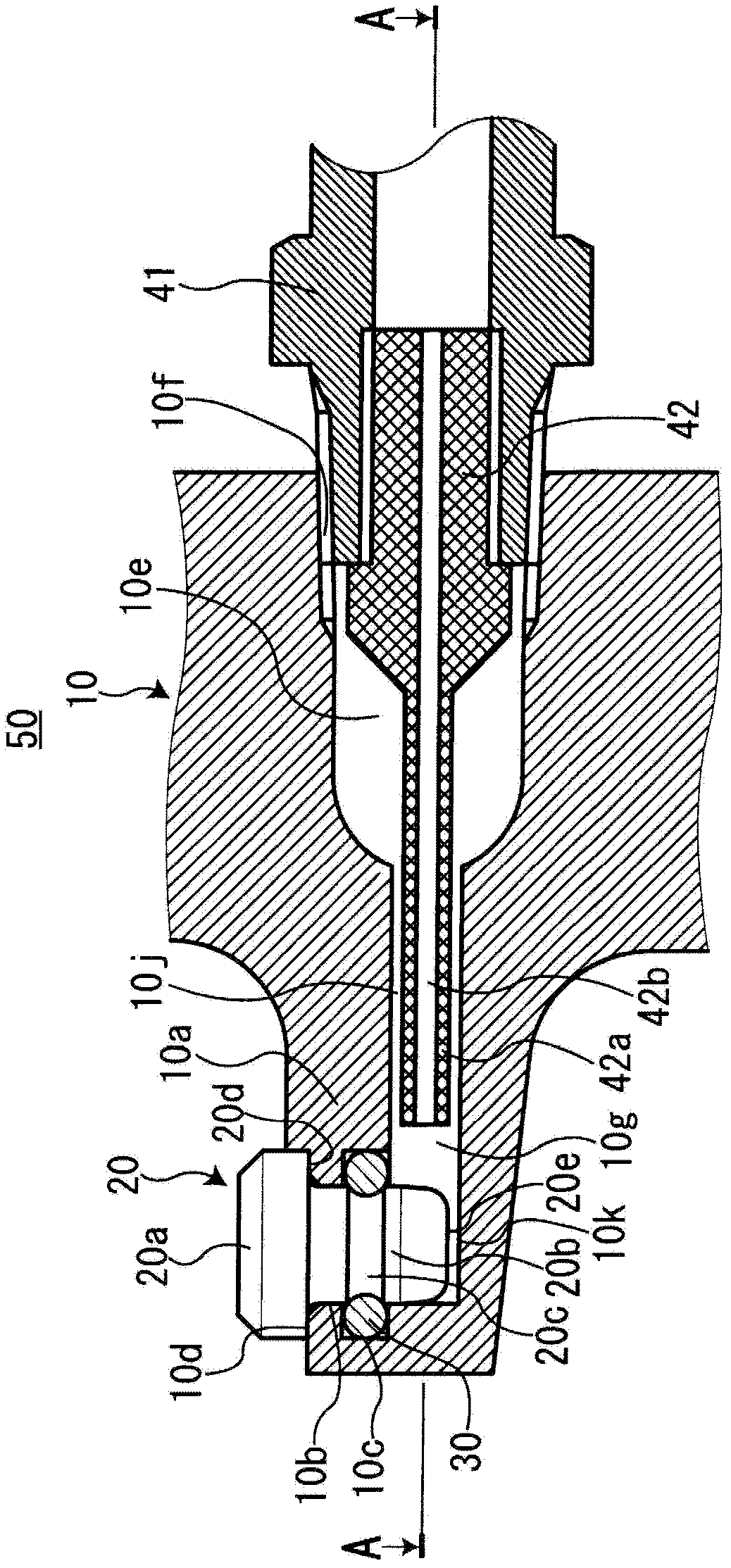

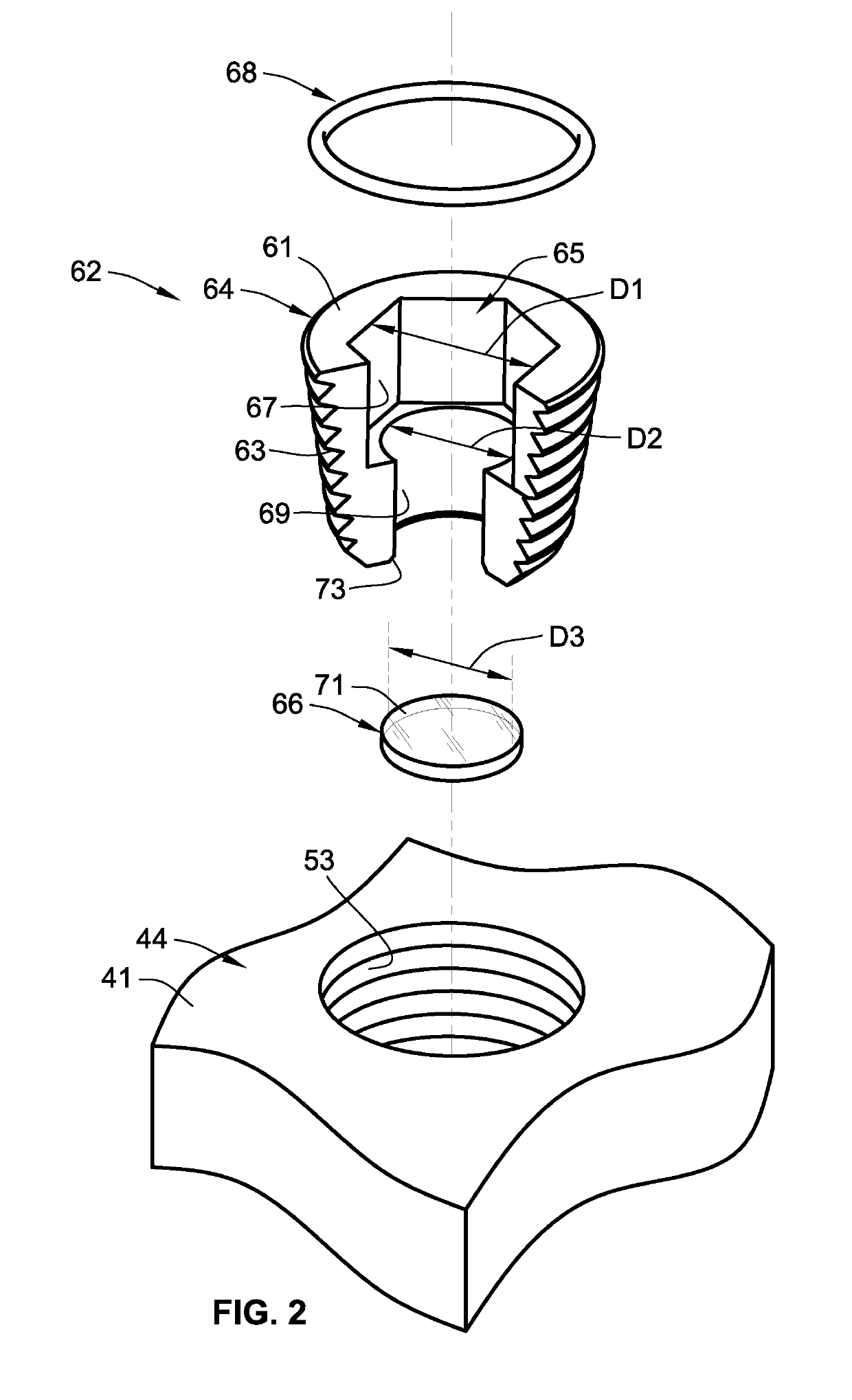

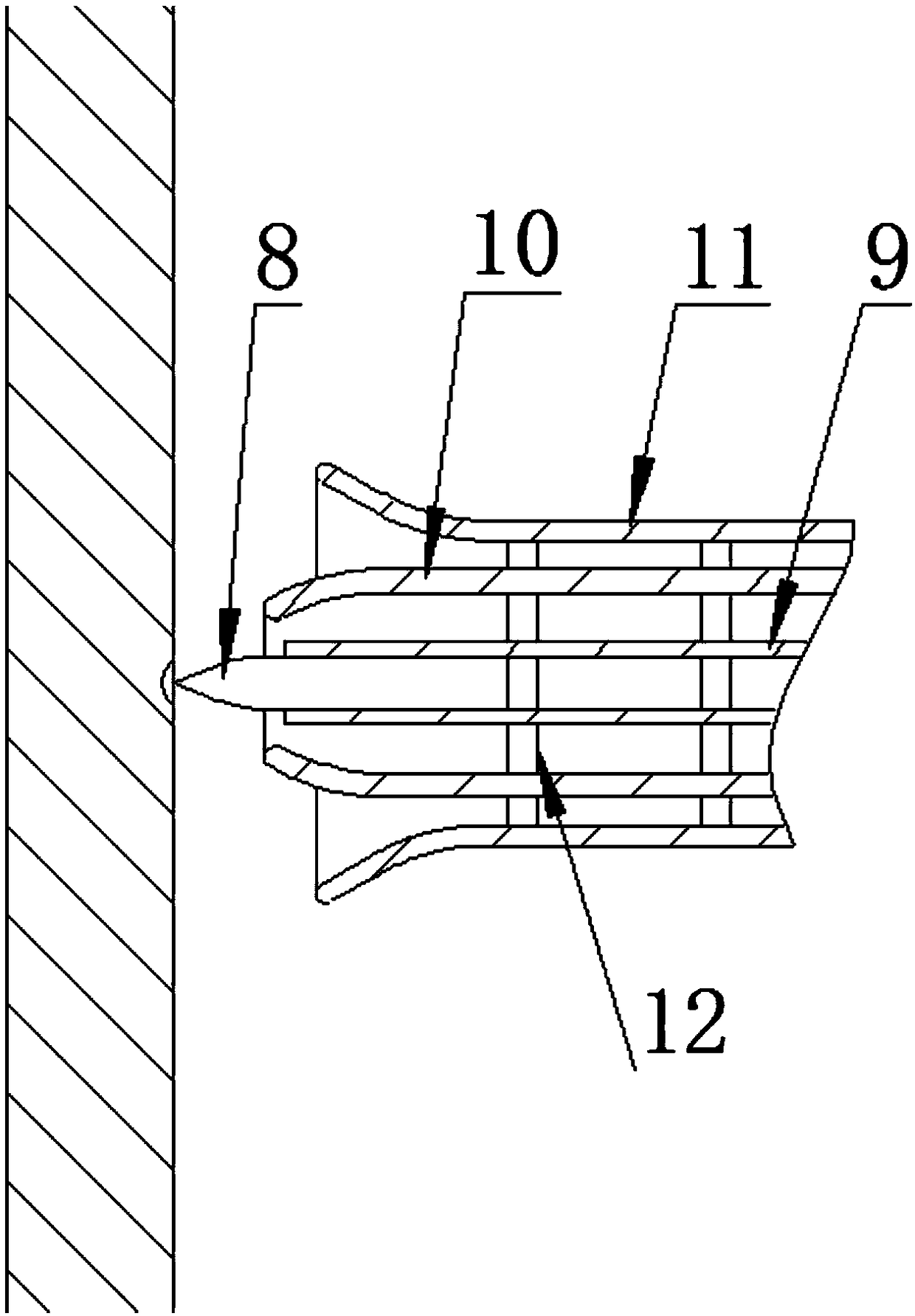

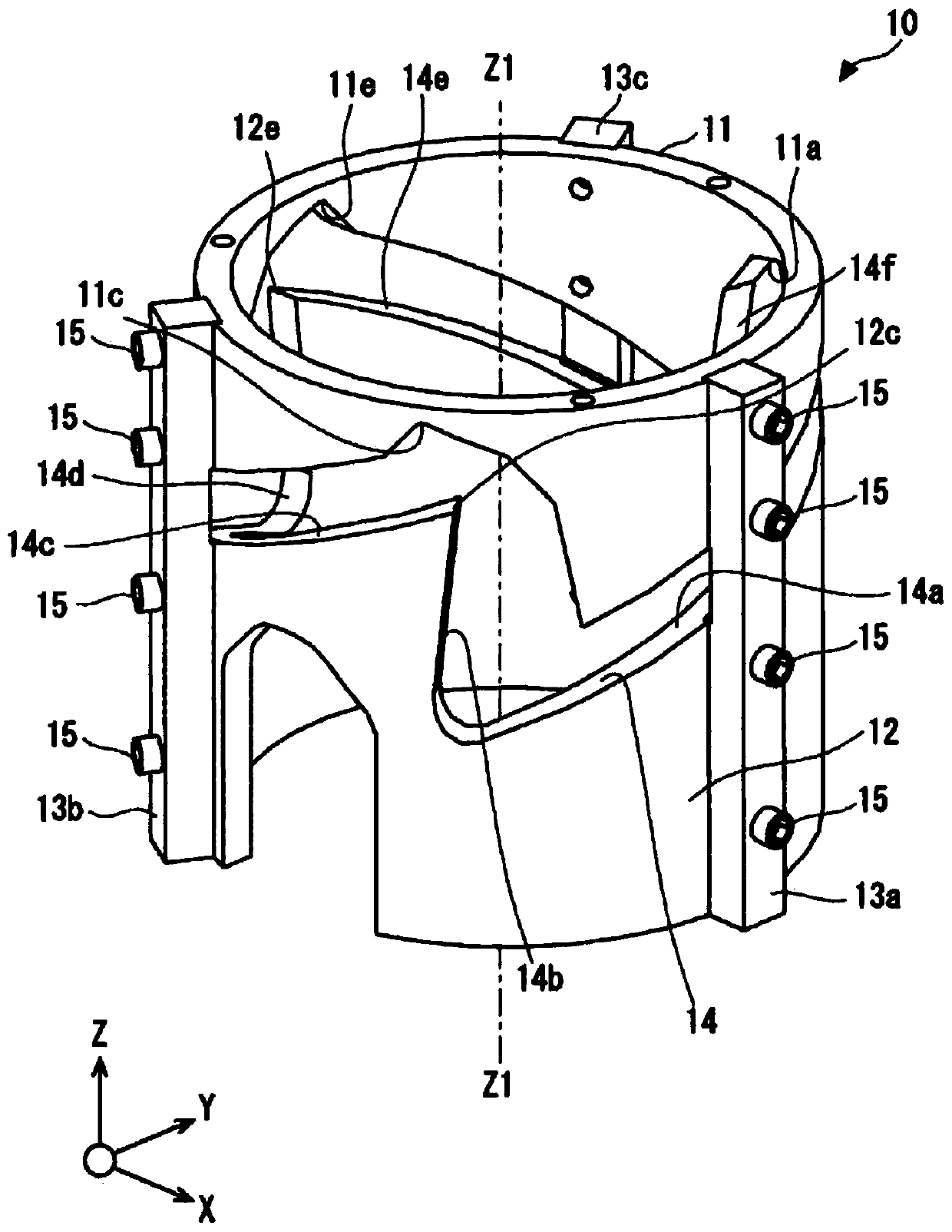

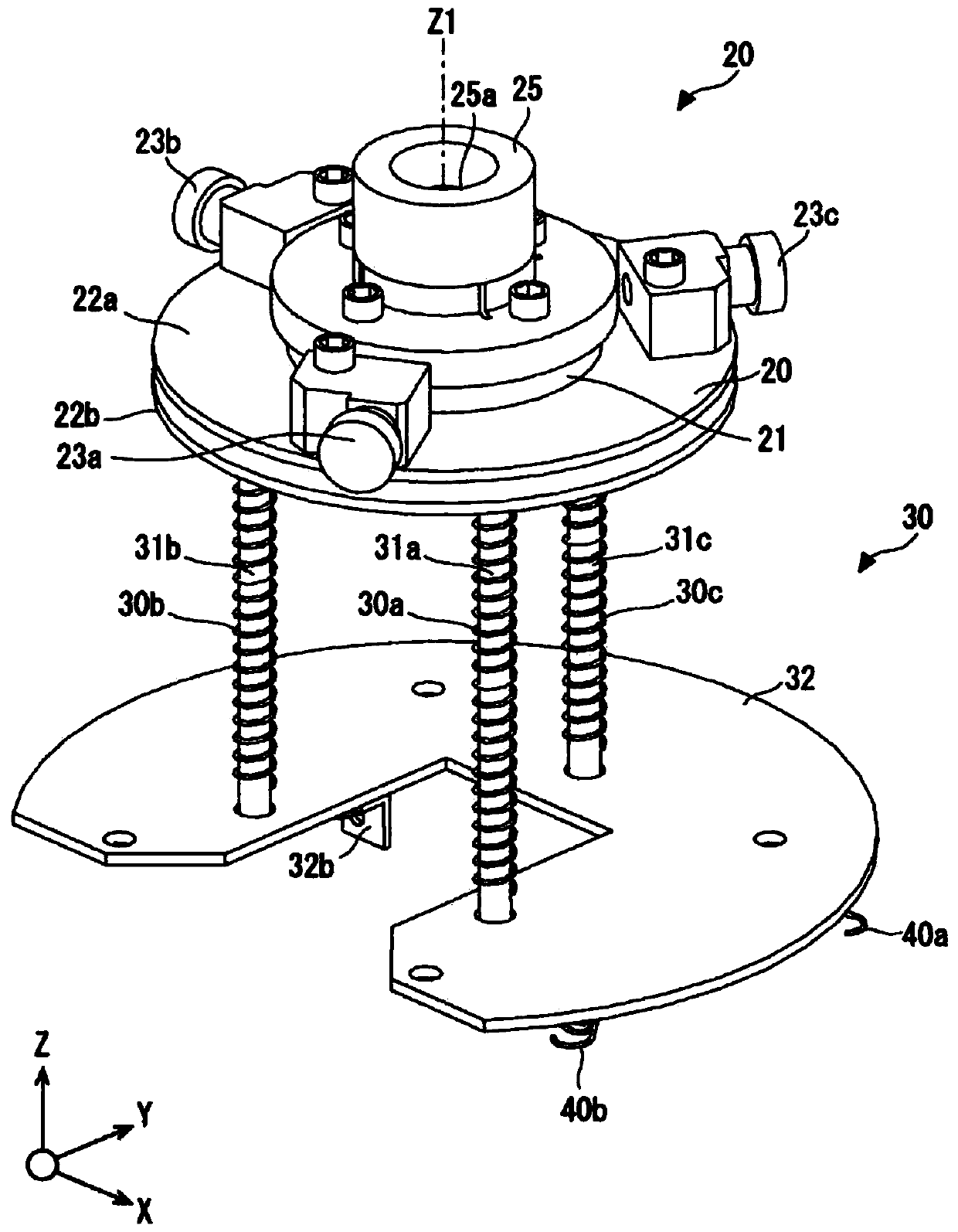

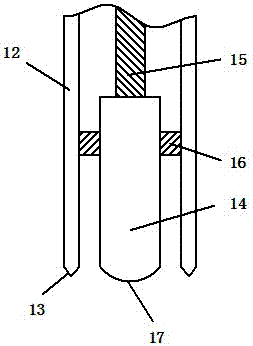

Electrode for projection welding

InactiveUS20050284847A1Cut surfacePrevent thermal degradationWelding/cutting auxillary devicesElectrode supporting devicesBiomedical engineeringWelding

In an electrode for projection welding, an end cover (10) of metal having a through hole (19) is attached to the end of a main body (6) of metal having a cylindrical shape, a guide sleeve (12) of insulation material is disposed in the main body (6), the end of the guide sleeve (12) being formed with a receiving hole (18) for a part (2) in a state in which the receiving hole (18) communicates with the through hole (19) in the end cover (10), and a cooling passage (32) for fluid which cools the guide sleeve (12) is formed.

Owner:KUBUSHIKI KAISHA AOYAMA

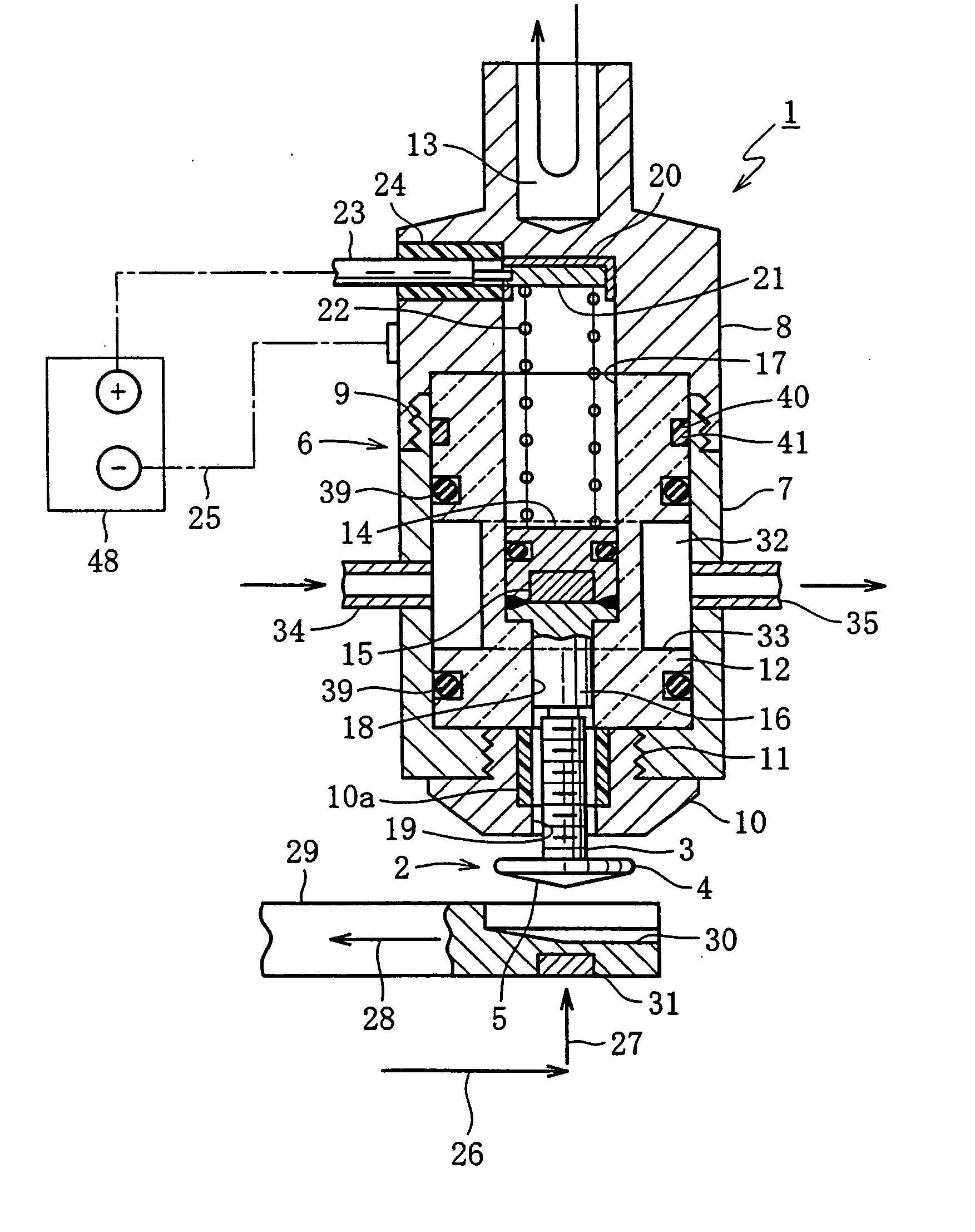

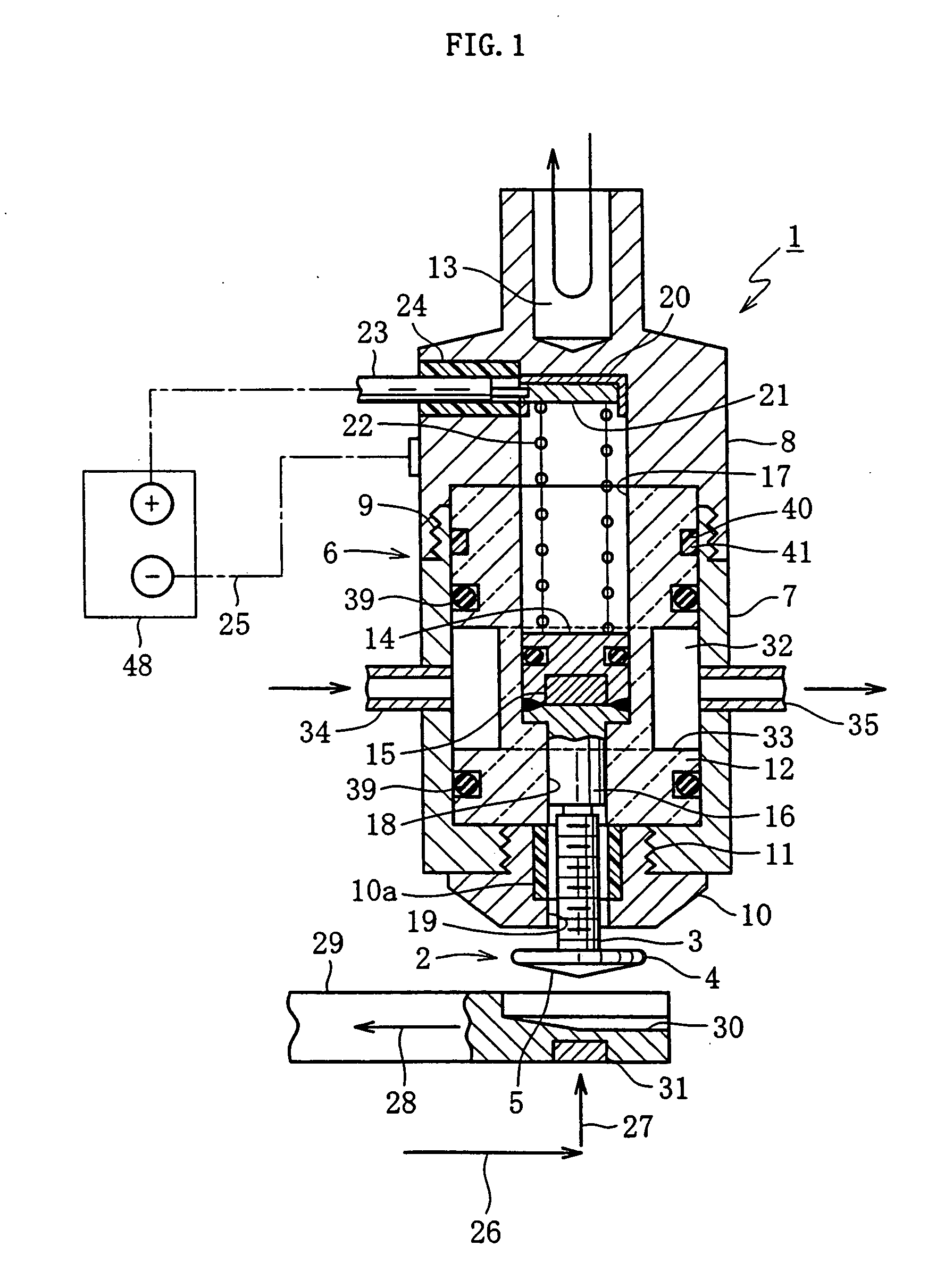

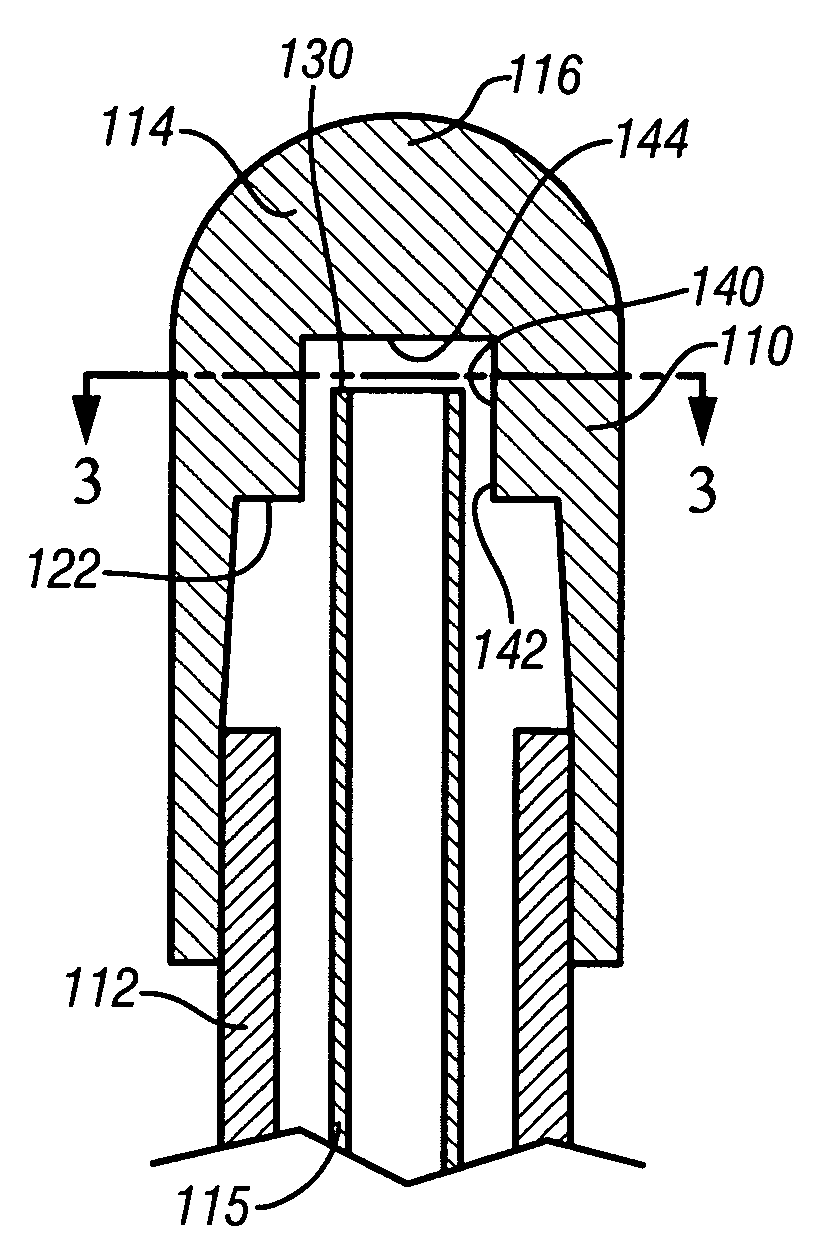

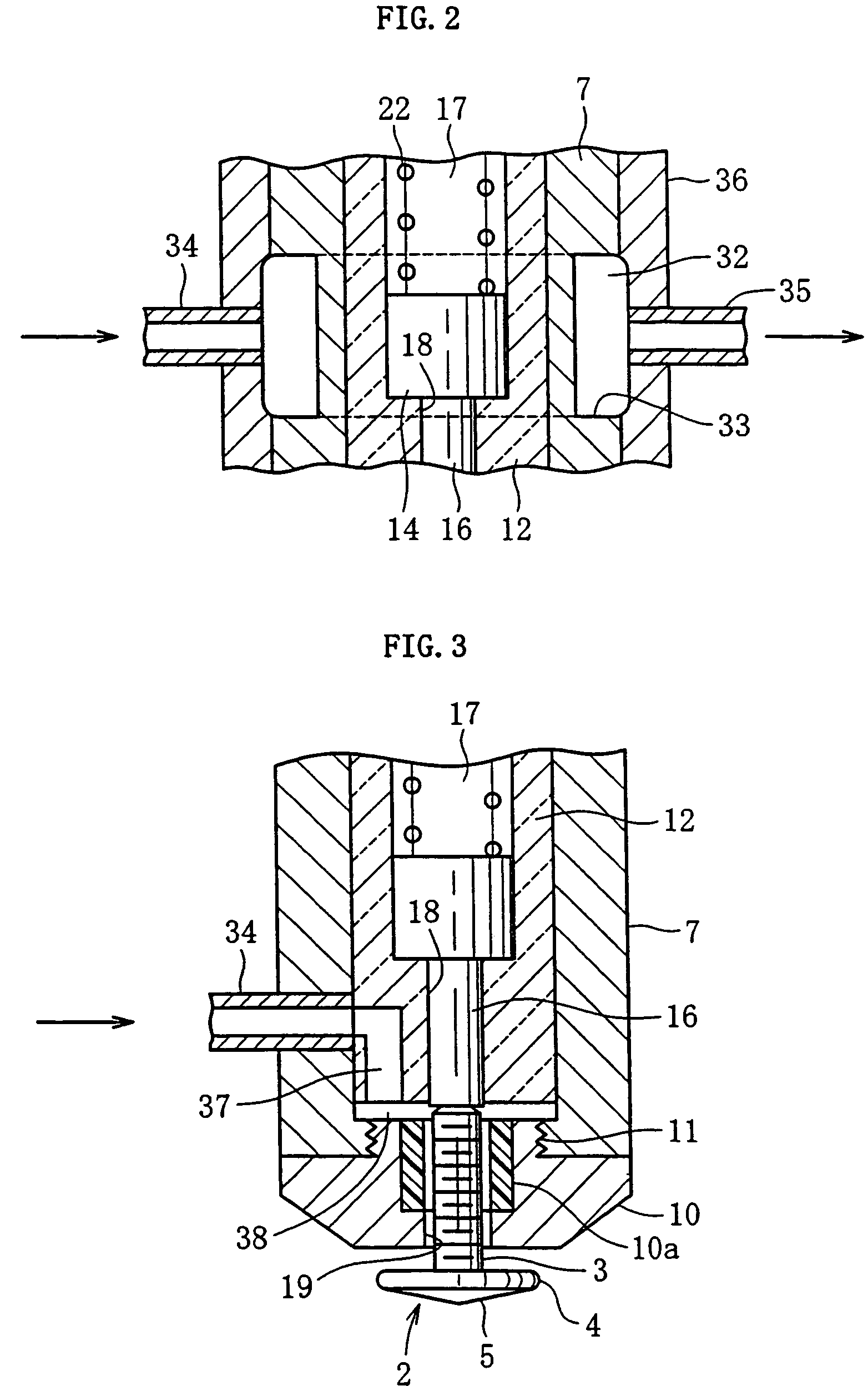

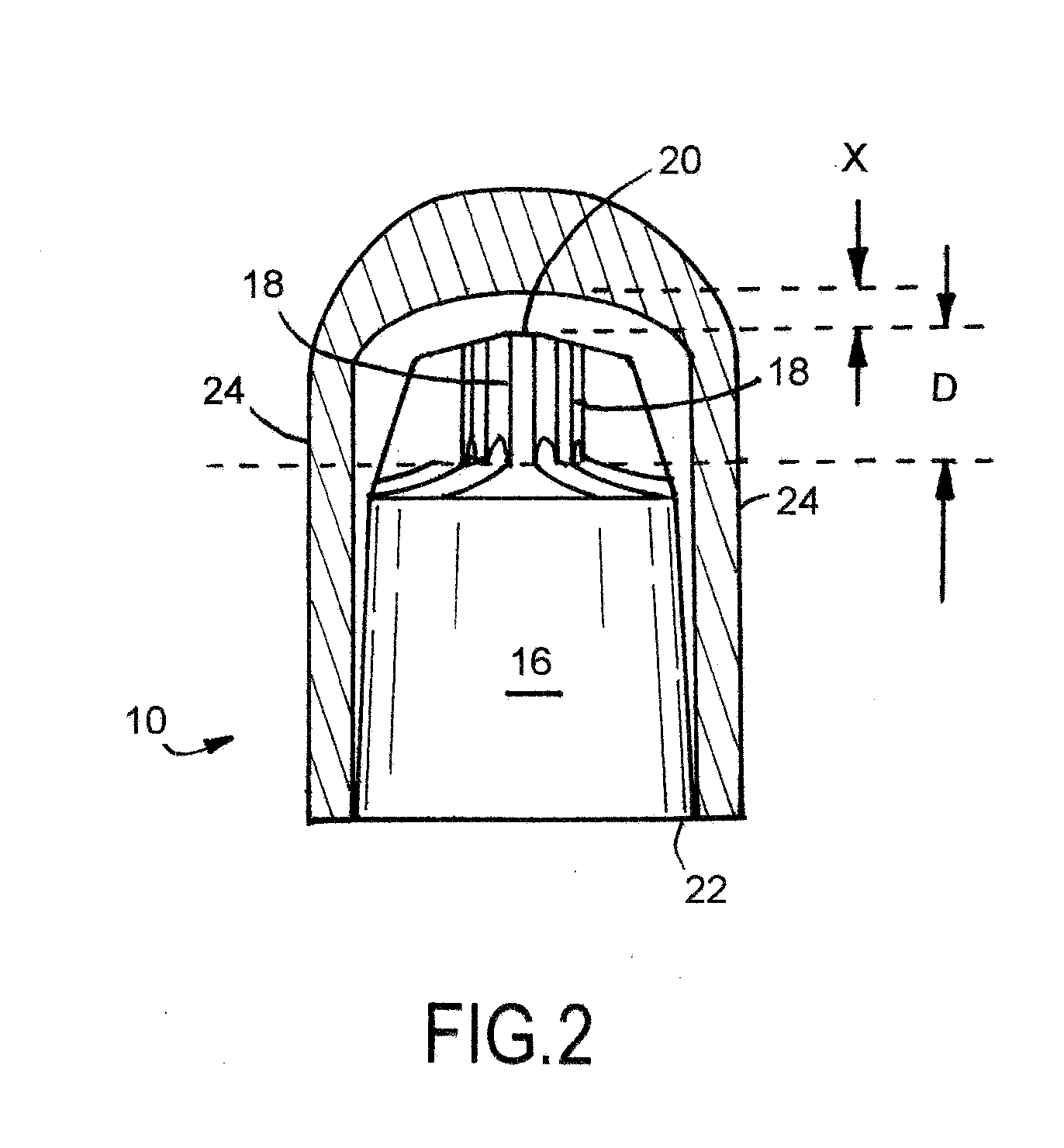

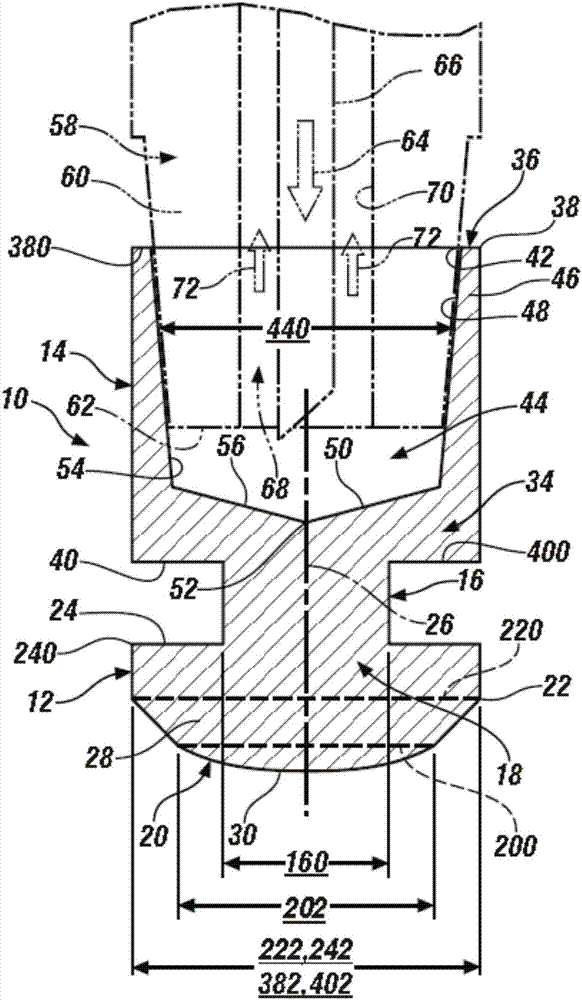

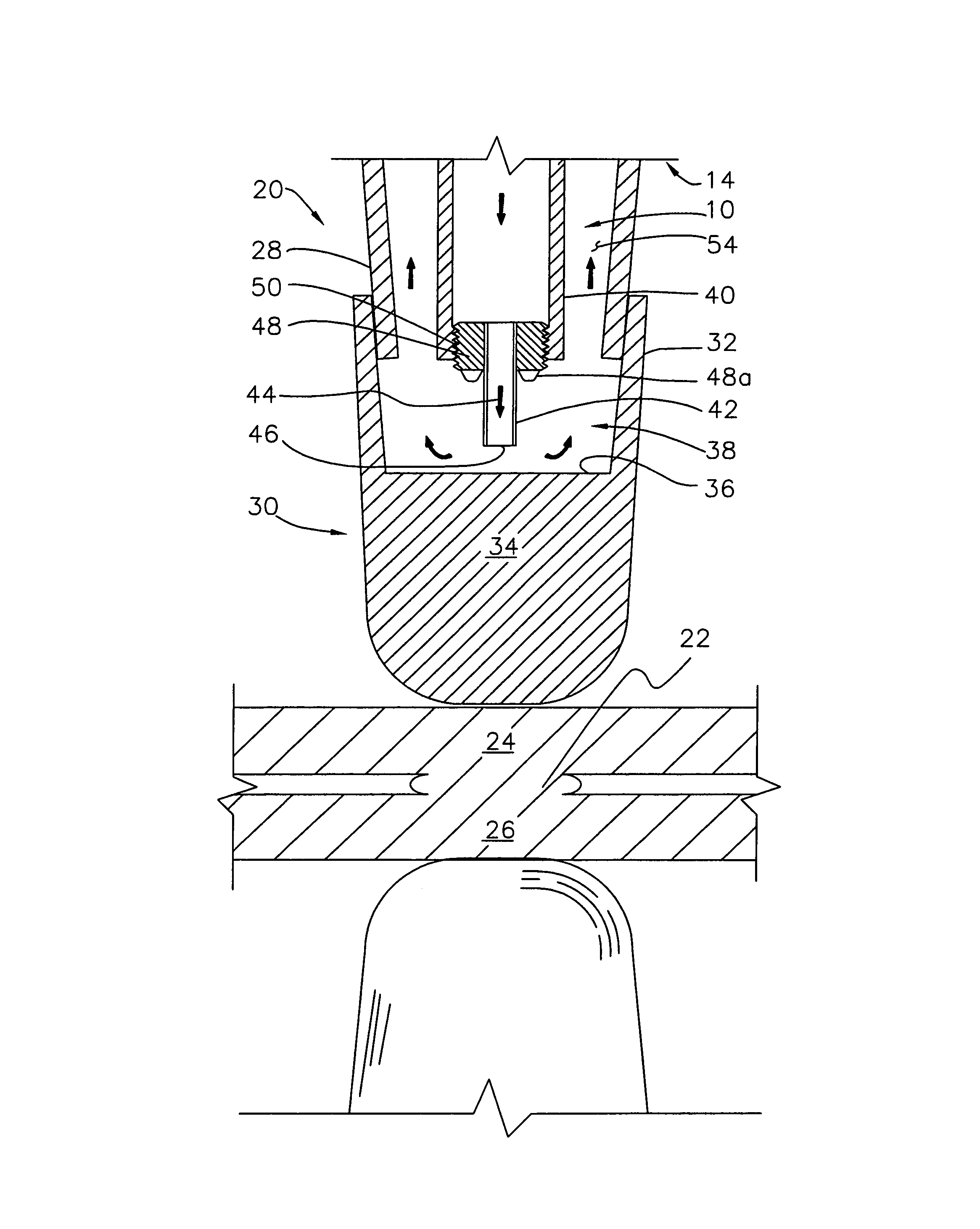

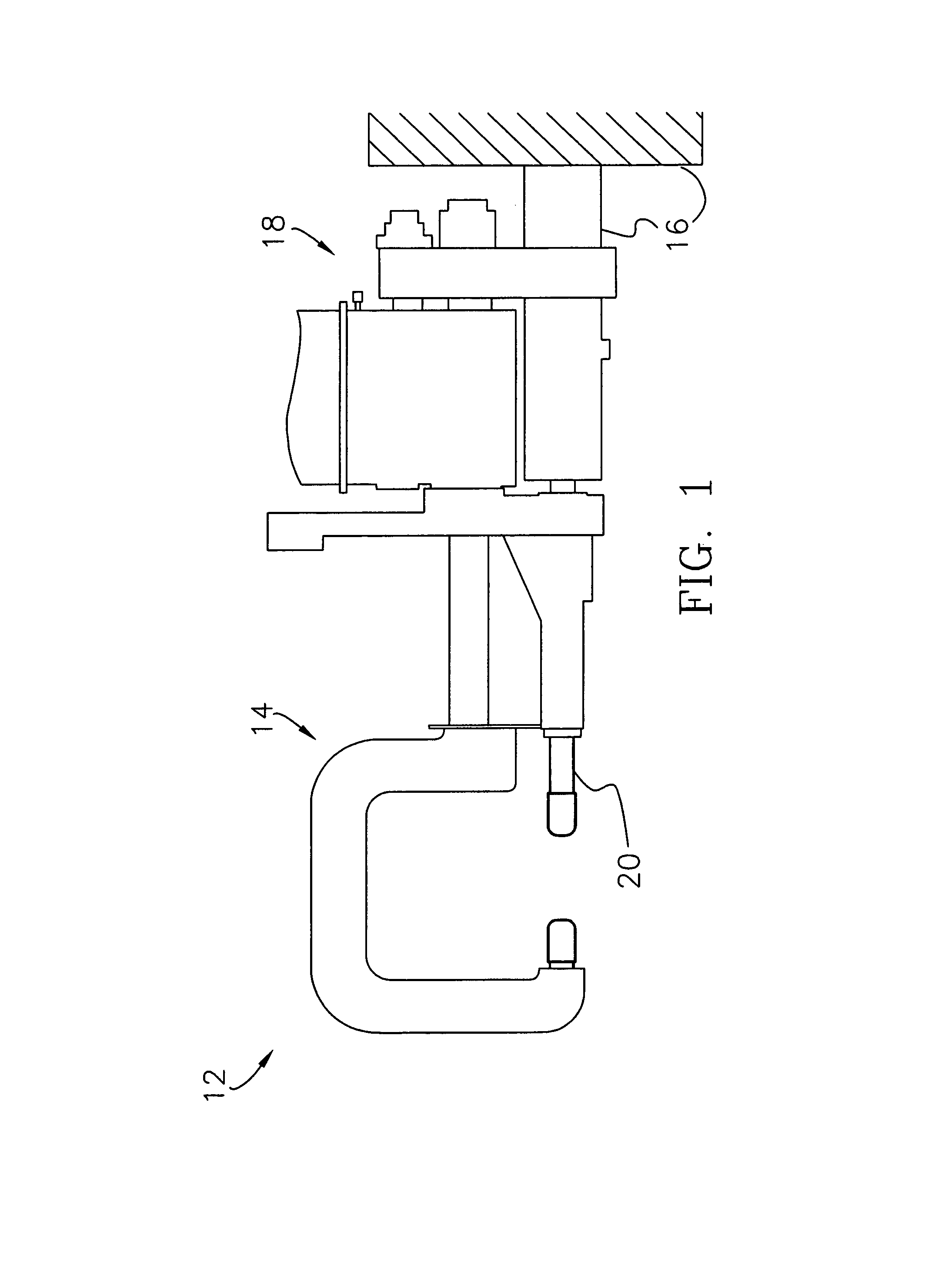

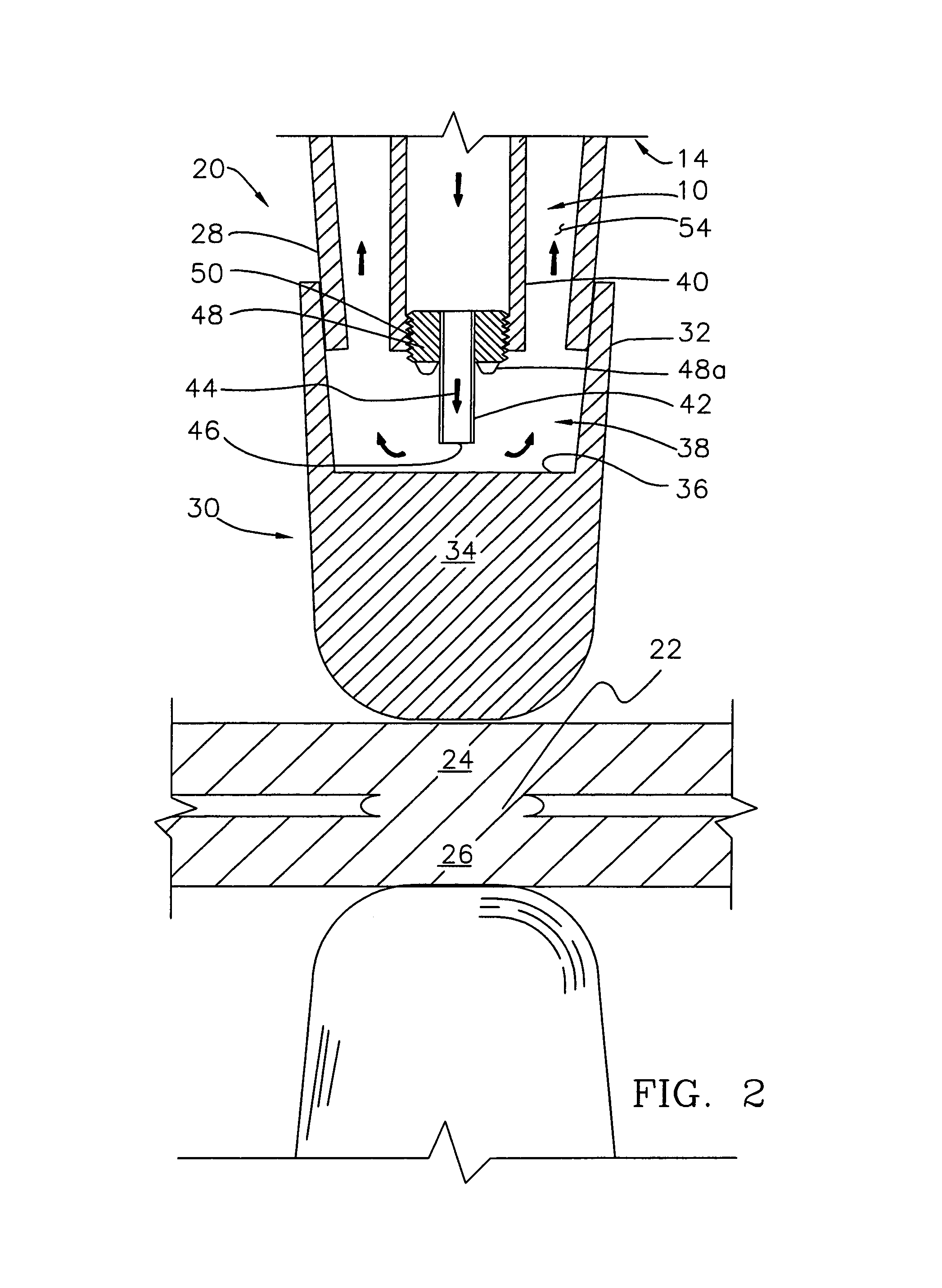

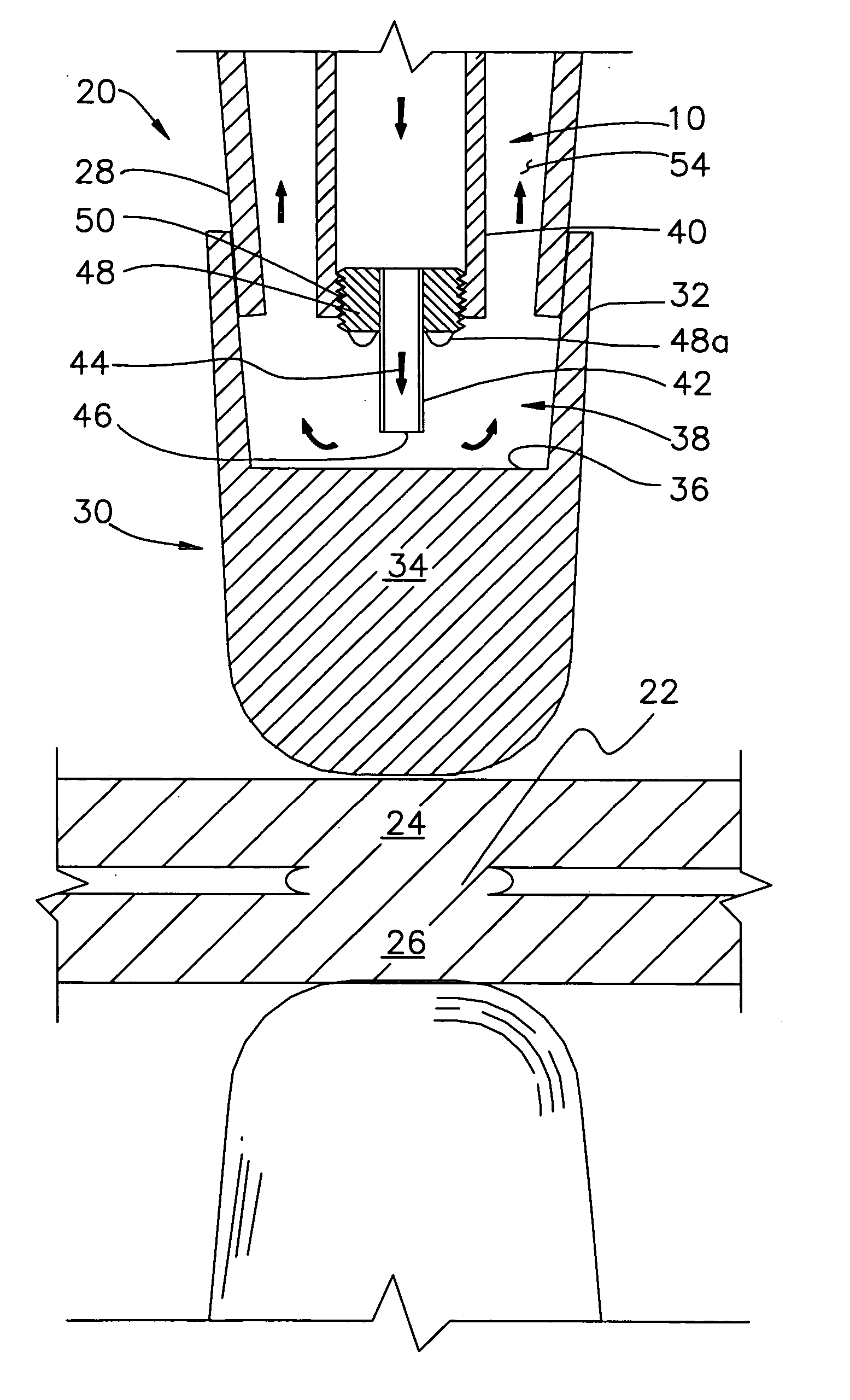

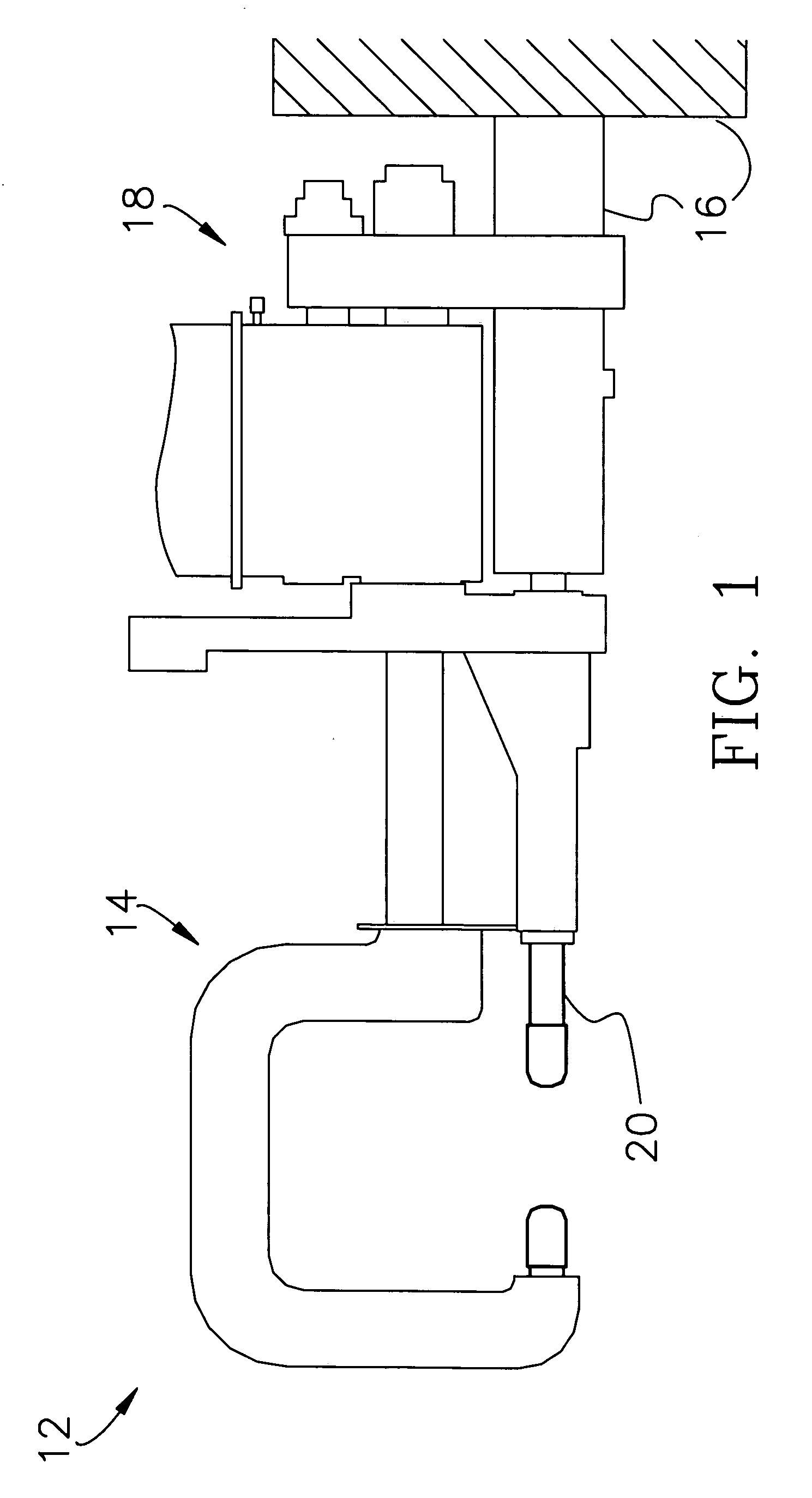

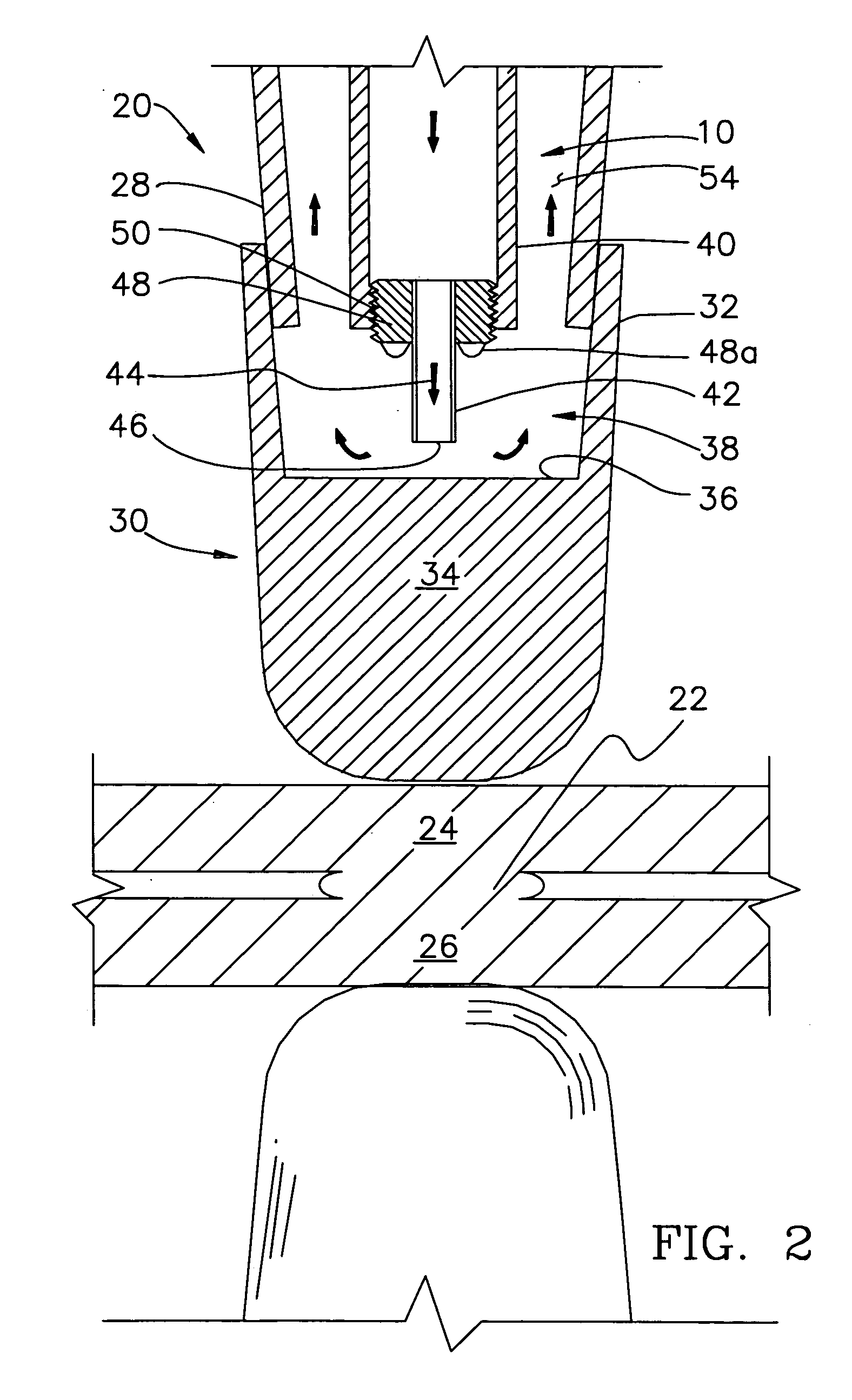

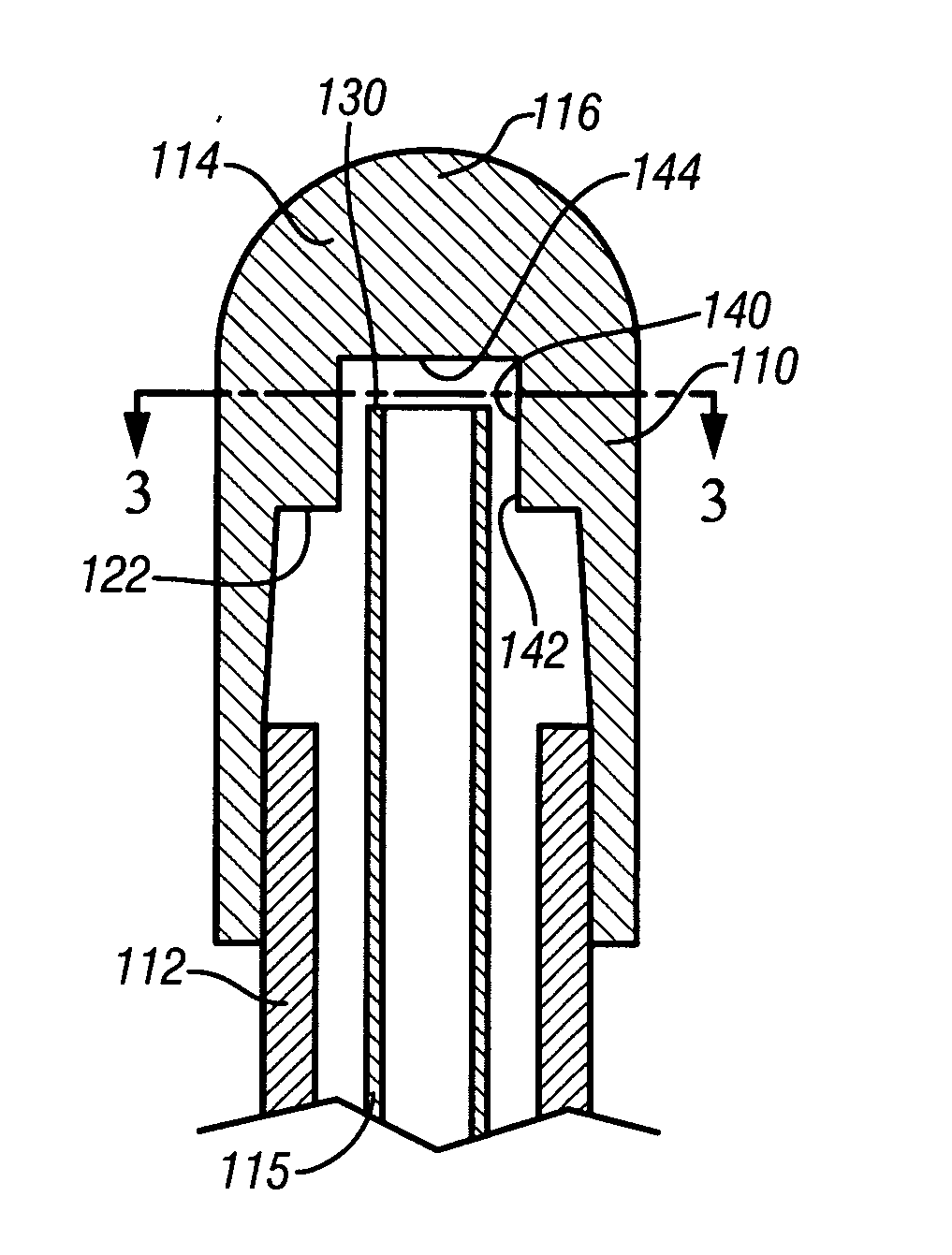

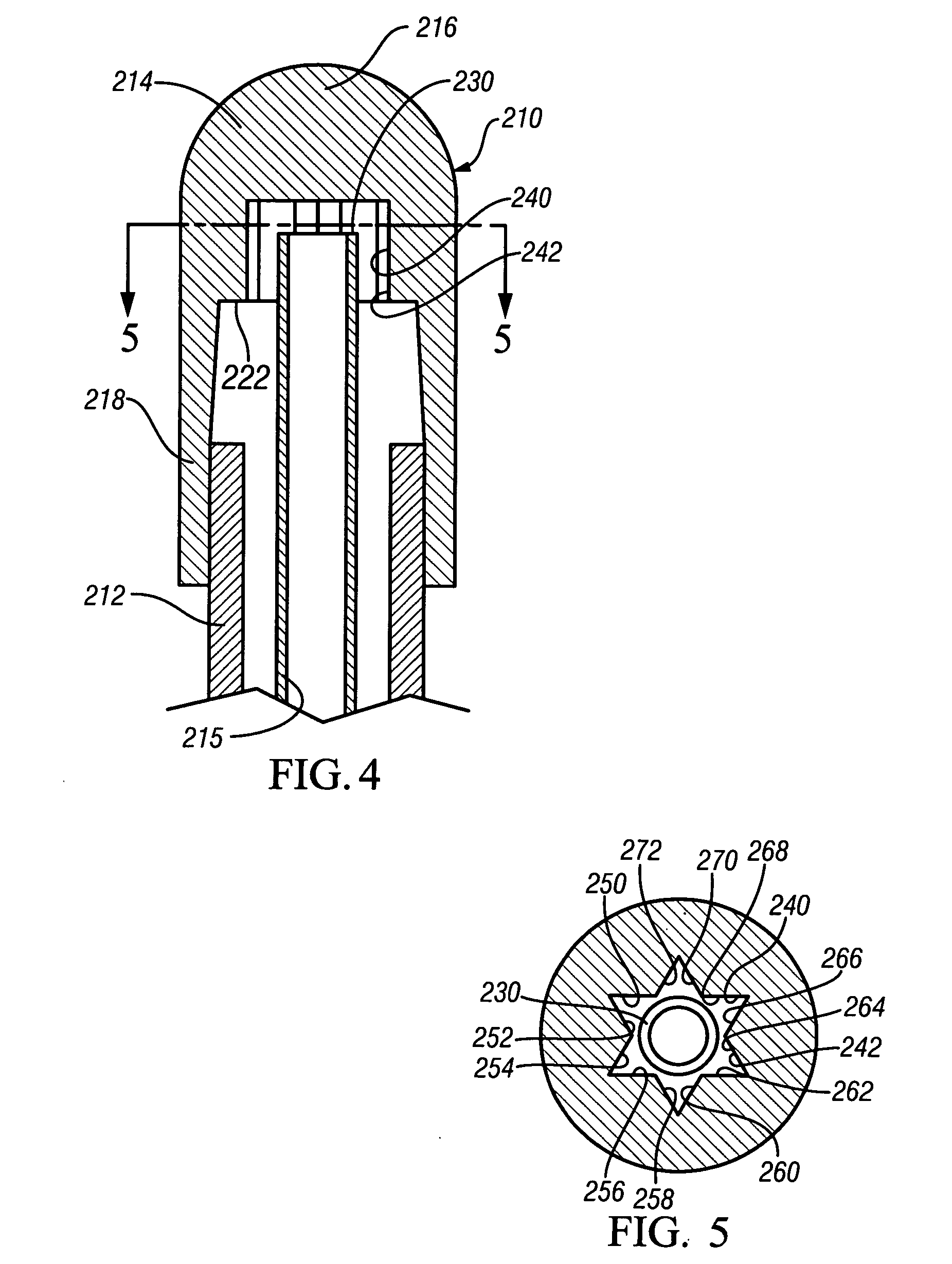

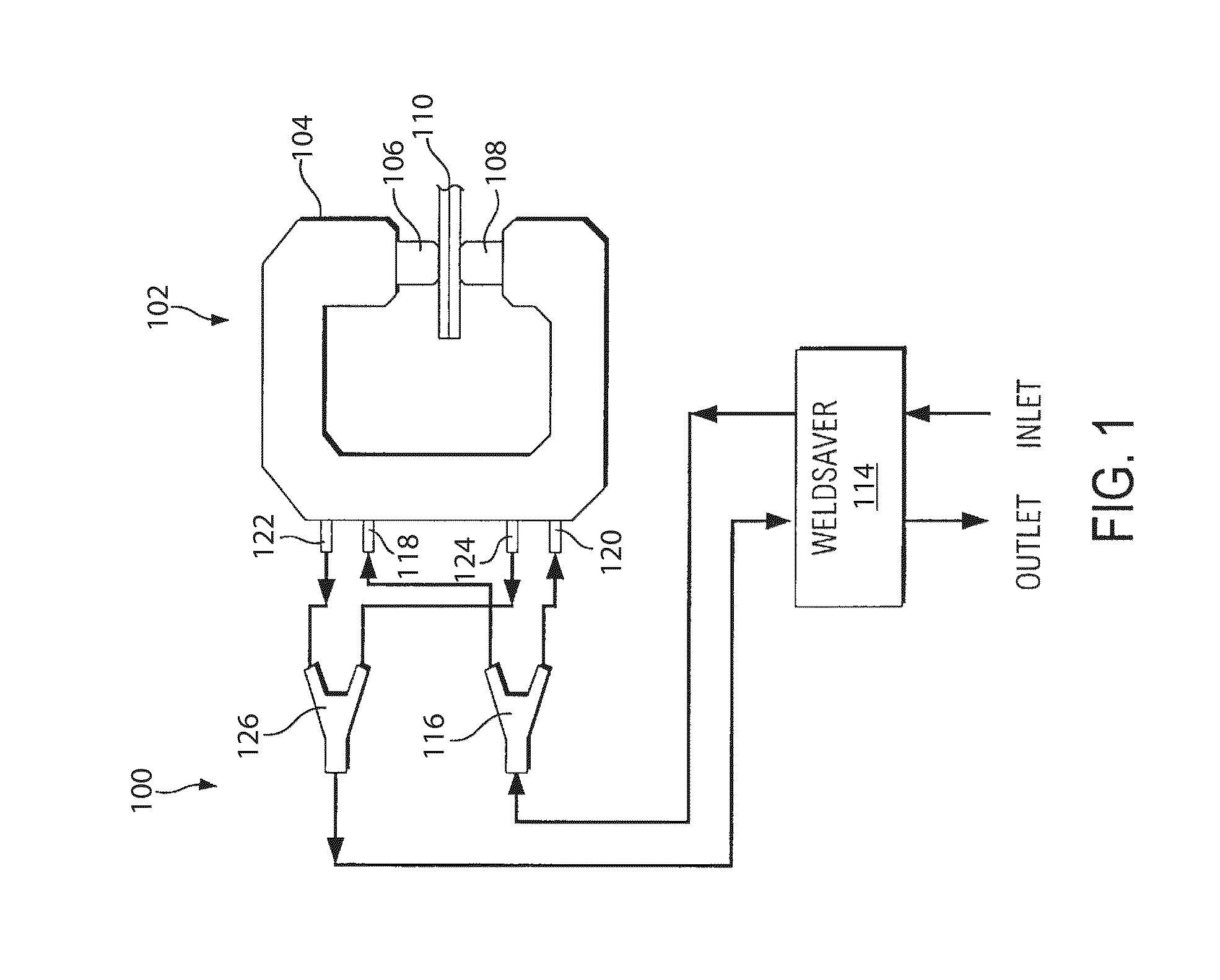

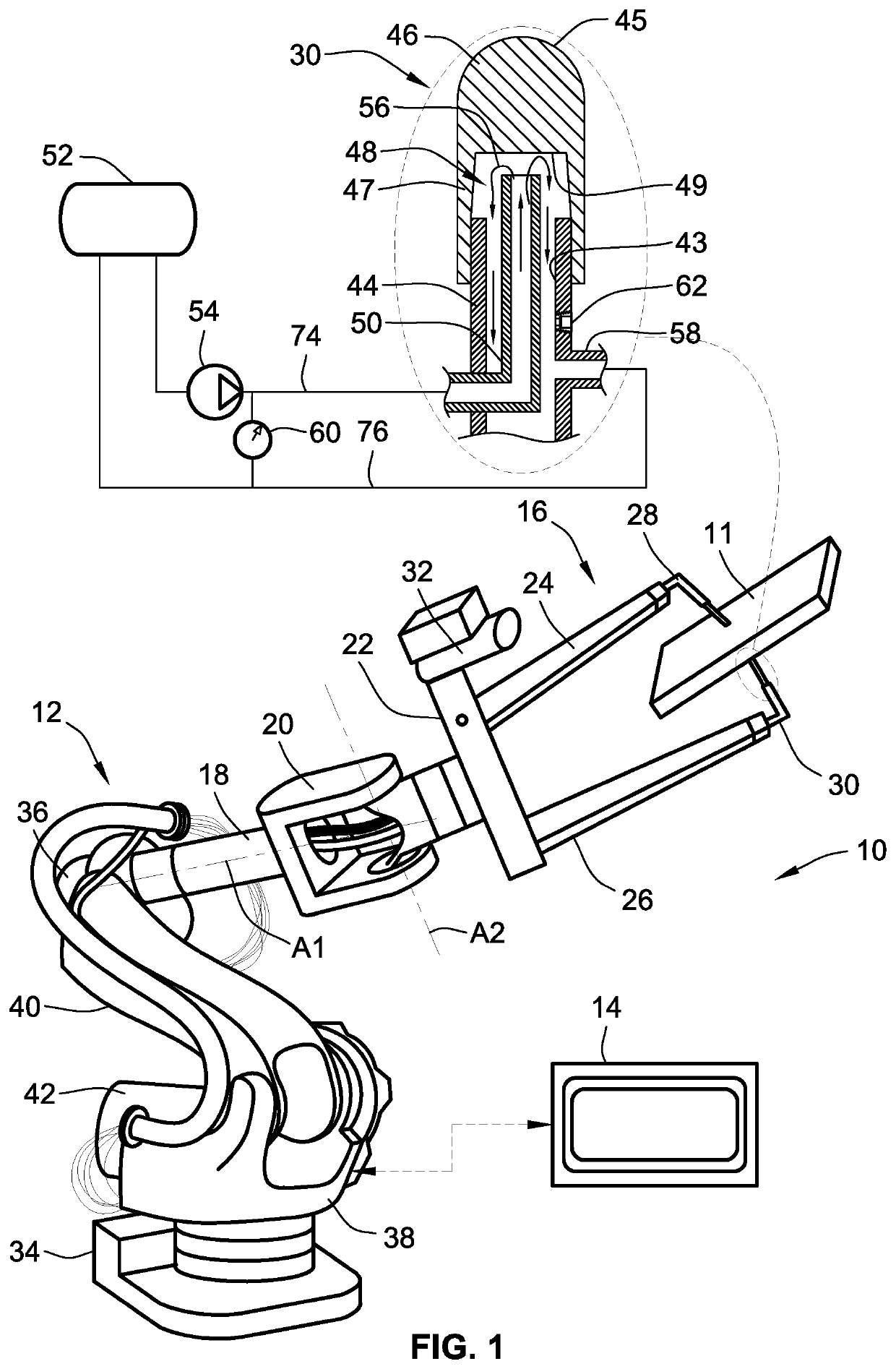

Method and apparatus for improved cooling of resistance welding cap

According to the invention a hollow cylindrical shank of electrically conducting metal is connected to a resistance welder. A coolant supply tube passes through the shank and has an interior coolant supply passage. The coolant supply tube has an outer diameter less than the inner diameter of the hollow cylindrical shank. A weld cap seats on the shank and has a cap tip and a cap skirt that depends from the cap tip and is attached to the shank. An underside of the cap tip faces the shank and the supply tube. A coolant receiving bore formed into the underside of the weld cap extends into the cap tip to receive the coolant supply tube part way into the bore. The bore formed into the underside of the cap tip defines a bore sidewall that provides added area of heat transfer contact between the coolant and the cap tip.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

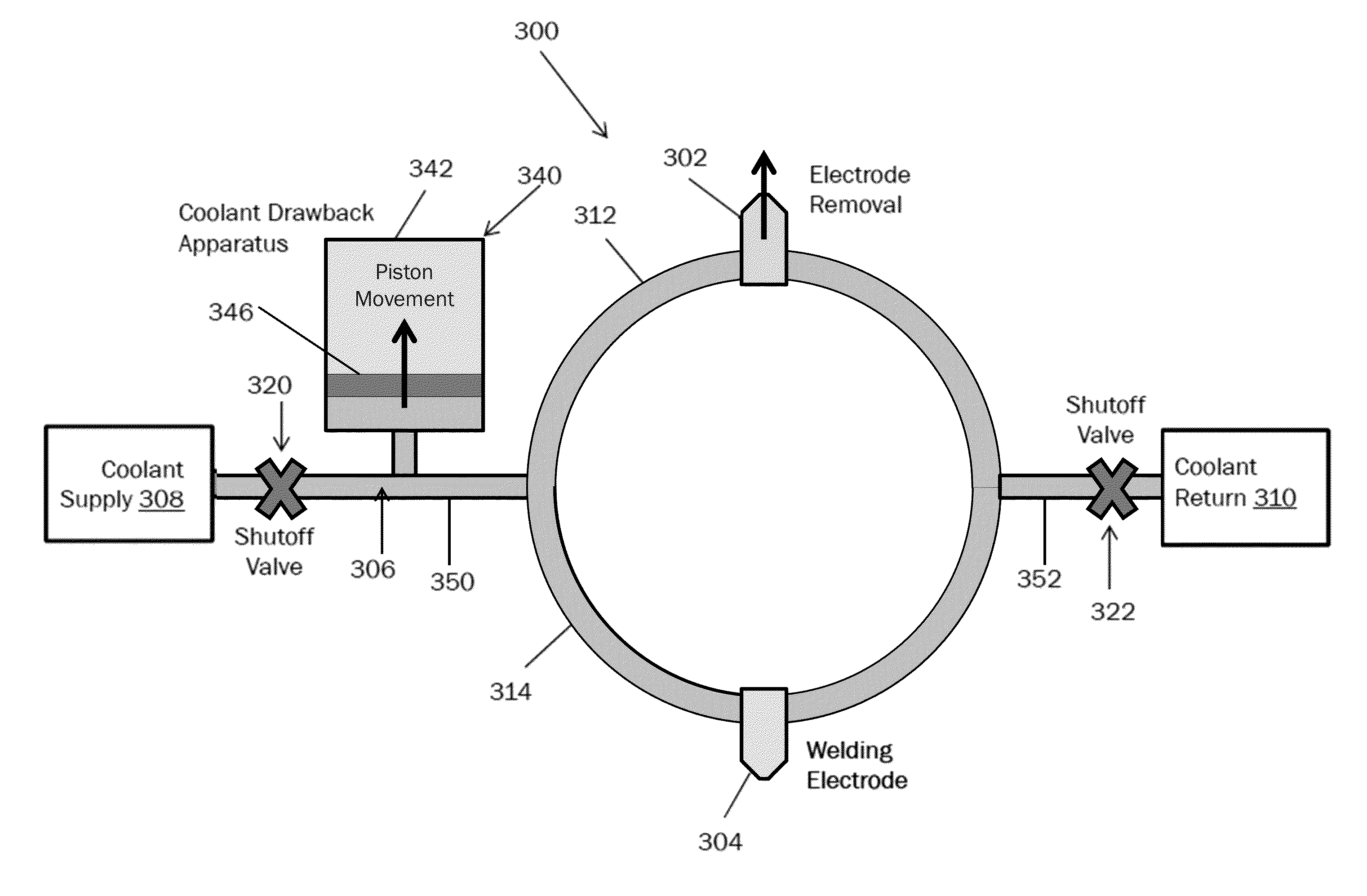

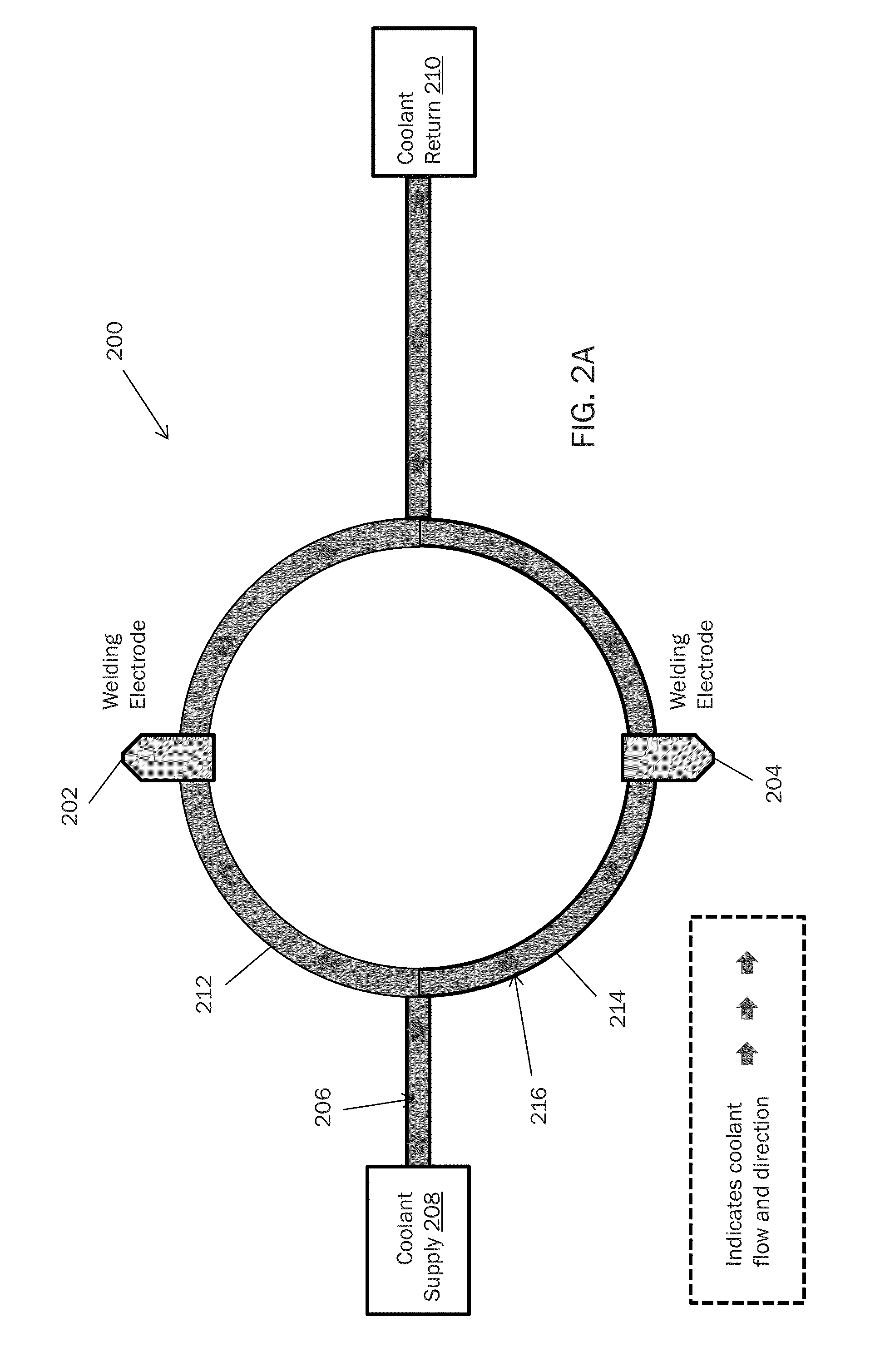

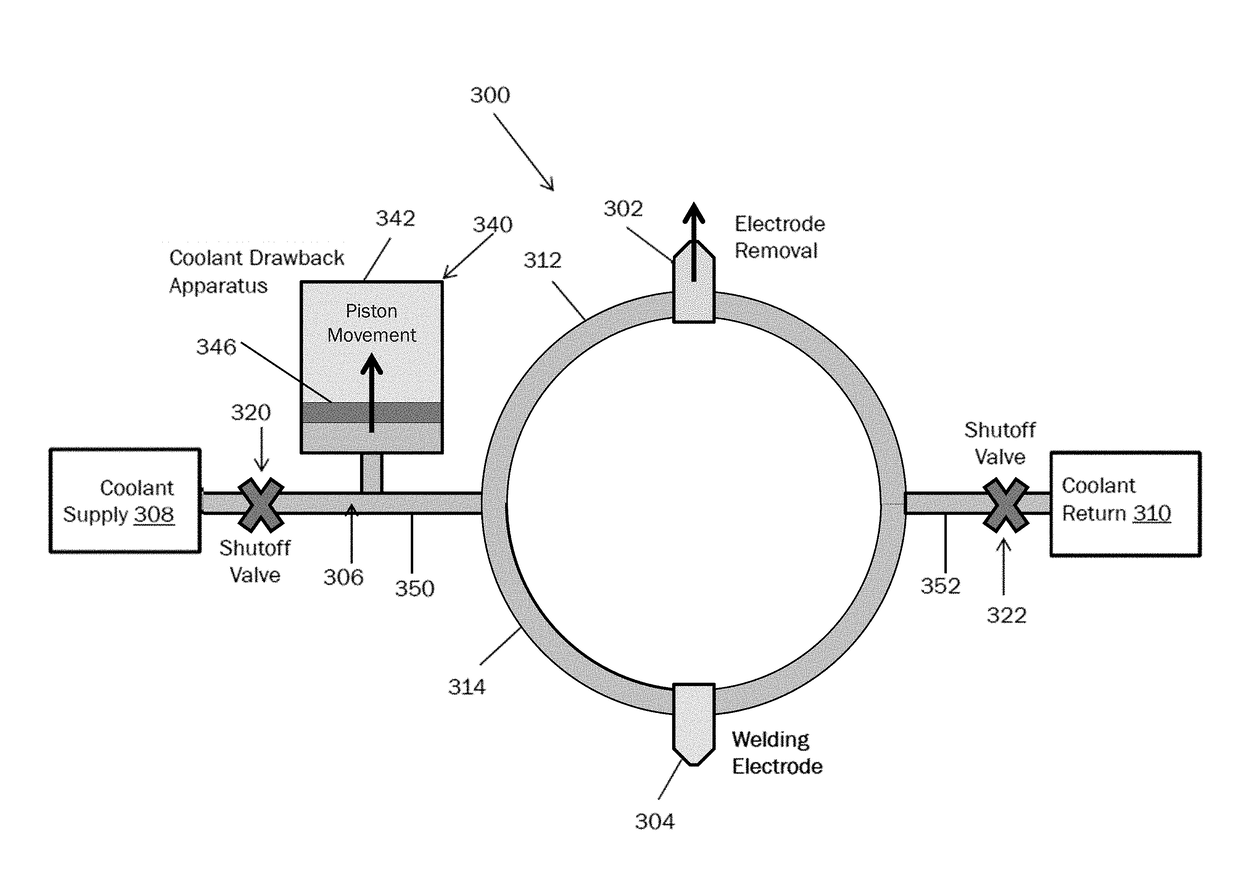

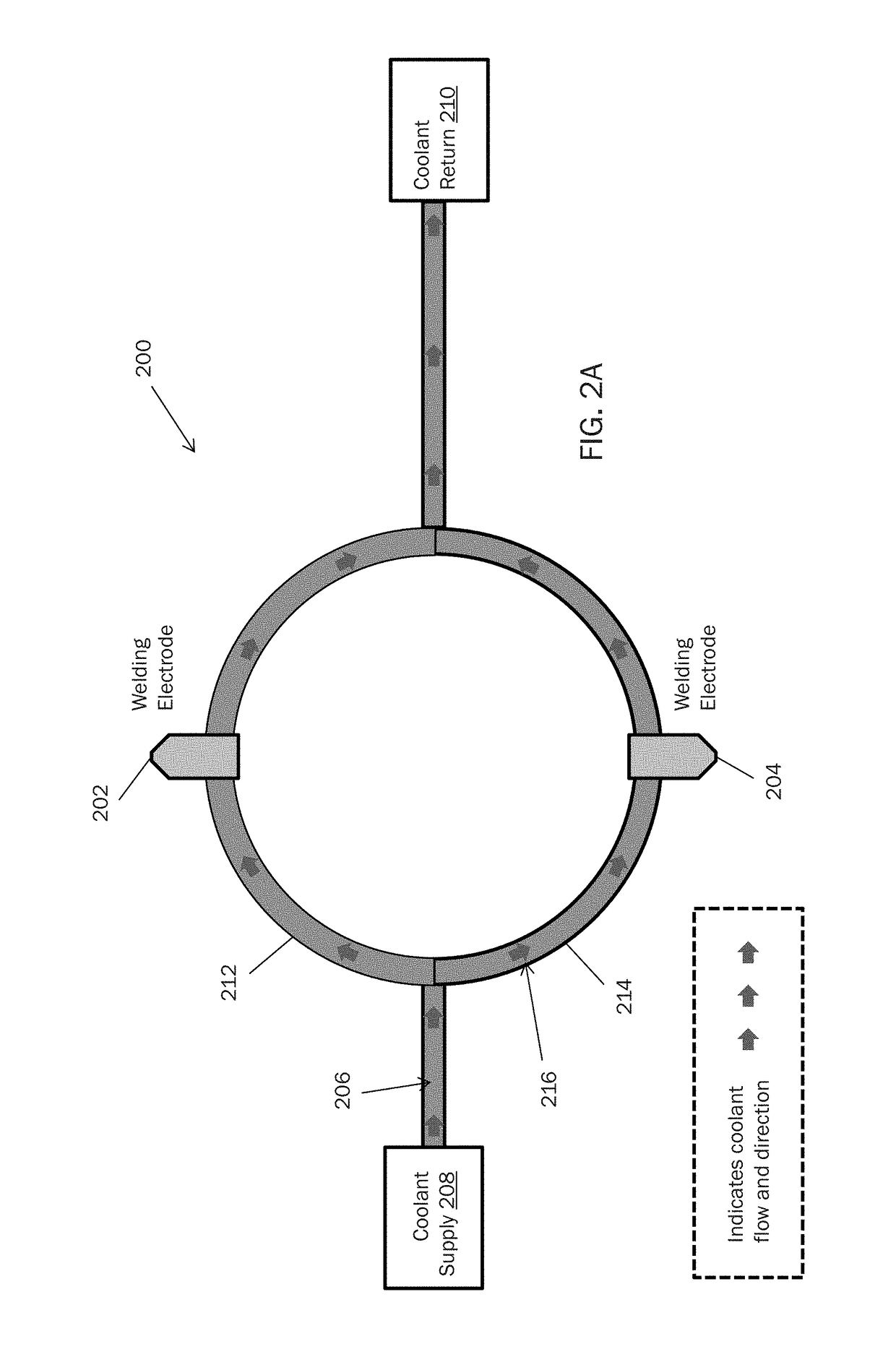

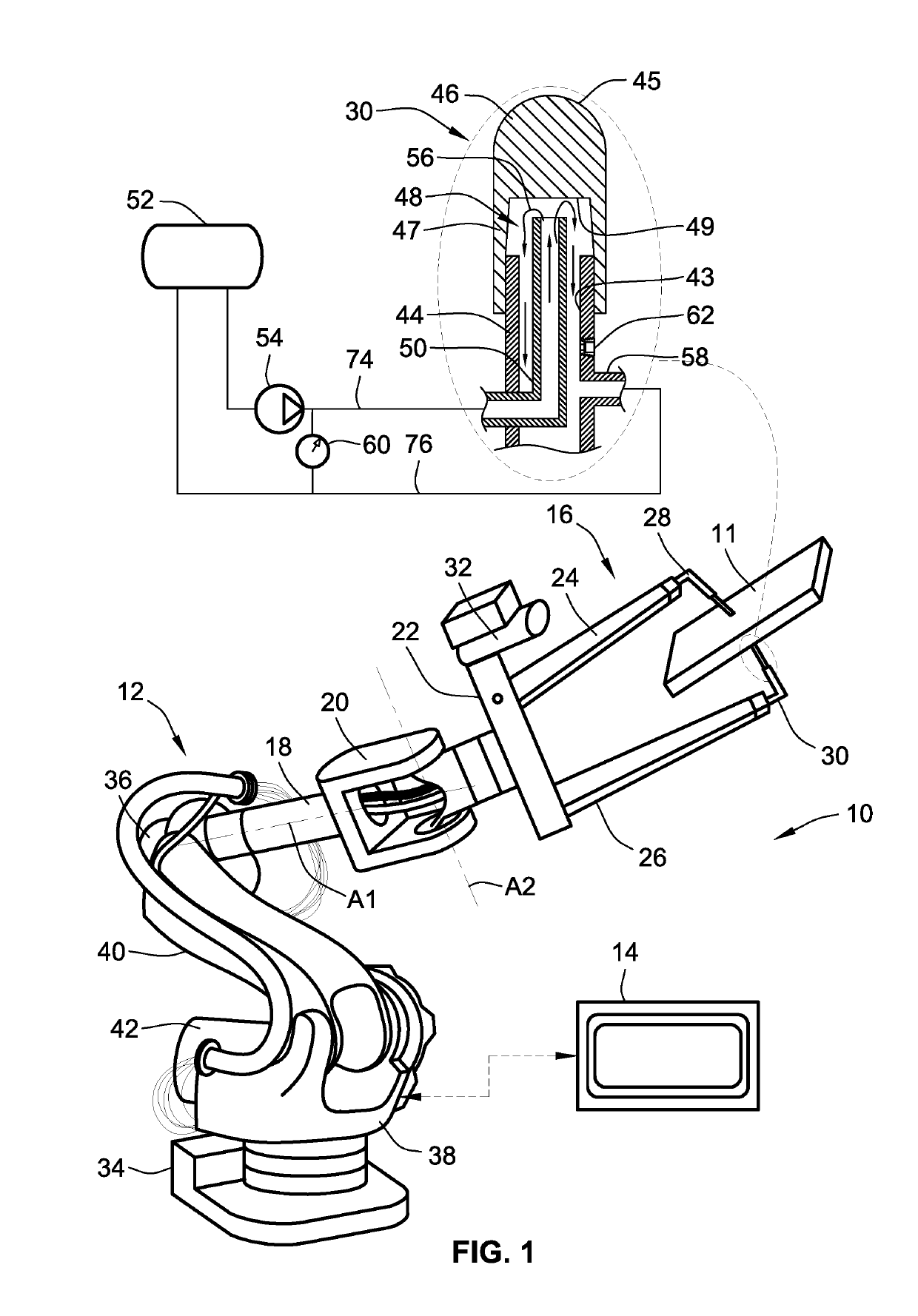

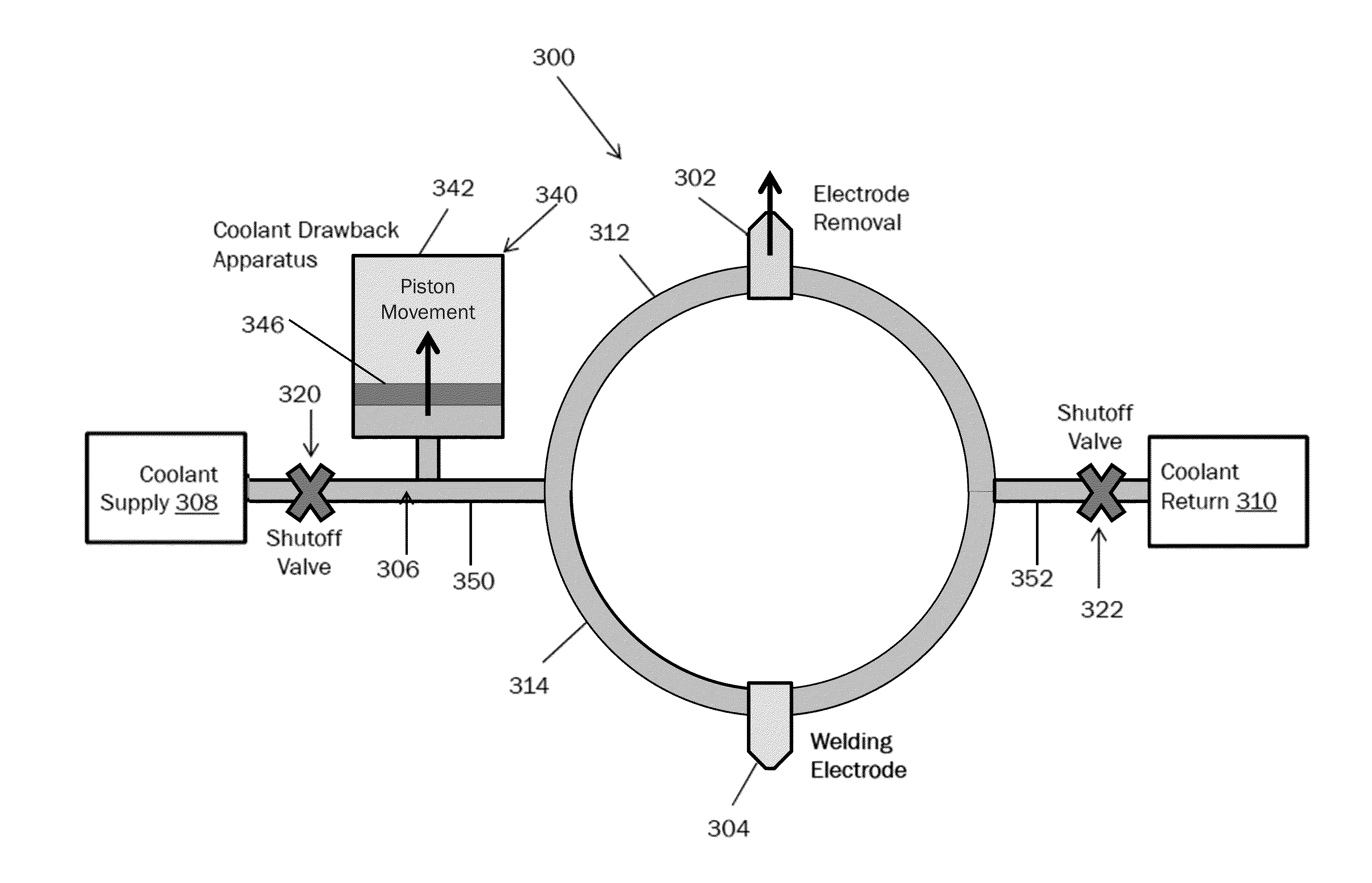

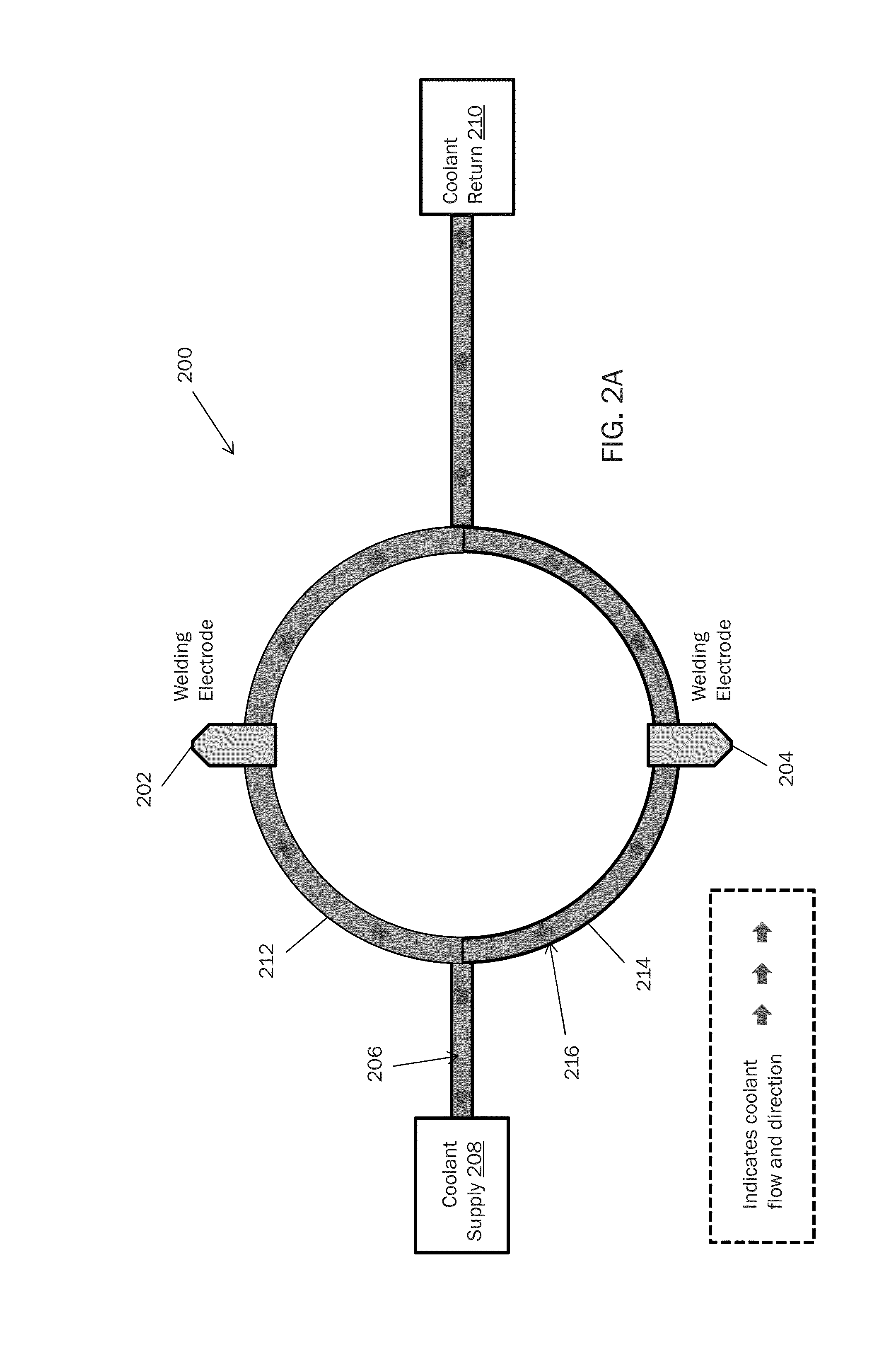

Systems and methods for coolant drawback

ActiveUS20160067815A1Reduce or eliminate liquid lossReduce and stop flowEngine diaphragmsFlexible member pumpsSuction forceCoolant flow

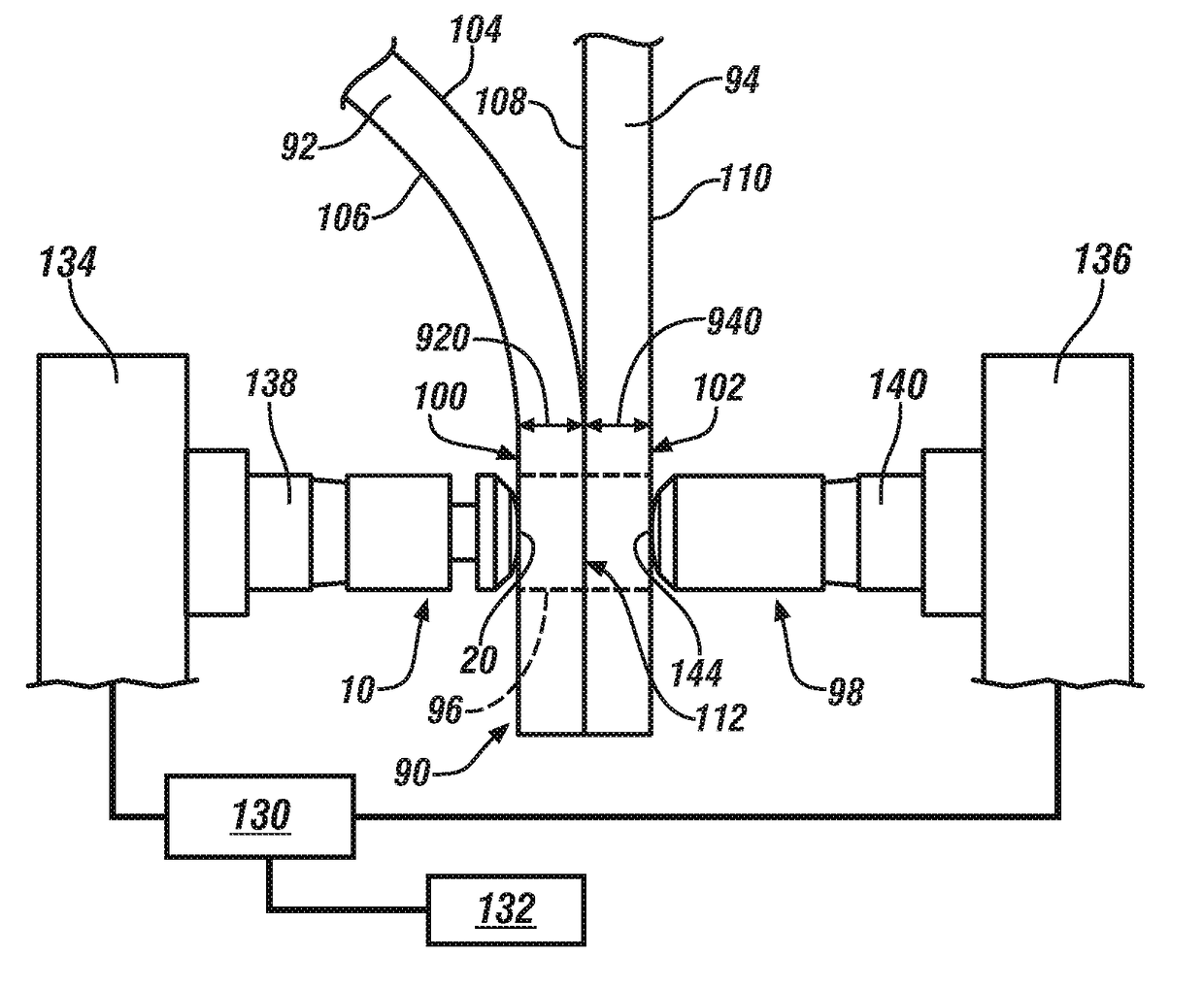

A first electrode coolant path is configured to cool a first welding electrode by liquid coolant flowing from a supply path through the first electrode coolant path to a return path. A second electrode coolant path is configured to cool a second welding electrode by liquid coolant flowing from the supply path through the second electrode coolant path to the return path. Three or more valves are configured to stop or reduce liquid coolant flow through the first or second electrode coolant path and configured to stop or reduce liquid coolant backflow from the return path when the first or second welding electrode is at least partially detached. At least one valve is coupled in the first or second electrode coolant path. A drawback apparatus generates a suction force to draw liquid coolant away from a gap formed when the first or second welding electrode is at least partially detached.

Owner:PROTEUS INDUSTRIES INC

Electrode for projection welding

InactiveUS7291801B2Prevent thermal degradationCut surfaceWelding/cutting auxillary devicesElectrode supporting devicesBiomedical engineeringElectrode

In an electrode for projection welding, an end cover (10) of metal having a through hole (19) is attached to the end of a main body (6) of metal having a cylindrical shape, a guide sleeve (12) of insulation material is disposed in the main body (6), the end of the guide sleeve (12) being formed with a receiving hole (18) for a part (2) in a state in which the receiving hole (18) communicates with the through hole (19) in the end cover (10), and a cooling passage (32) for fluid which cools the guide sleeve (12) is formed.

Owner:AOYAMA YOSHITAKA

Welding electrodes and adapter therefor

ActiveUS20150336199A1Improve the immunityReduce resistanceResistance electrode holdersOhmic-resistance electrodesEngineeringElectrode

Owner:PRUCHER BRYAN

Welding electrode for use in resistance spot welding workpiece stack-ups that include aluminum workpiece and steel workpiece

A welding electrode suitable for resistance spot welding applications includes a first portion, a second portion, and a reduced diameter portion that extends between and connects the first and second portions. The first portion includes a weld face and the second portion includes a mounting base that opens to an internal recess having a cooling pocket. The reduced diameter portion extends between a back surface of the first portion and a front surface of the second portion such that a gap separates the back and front surfaces from each other. The gap may be vacant or filled with a low conductivity material. The disclosed welding electrode may be used in conjunction with another welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum workpiece and an adjacent overlapping steel workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

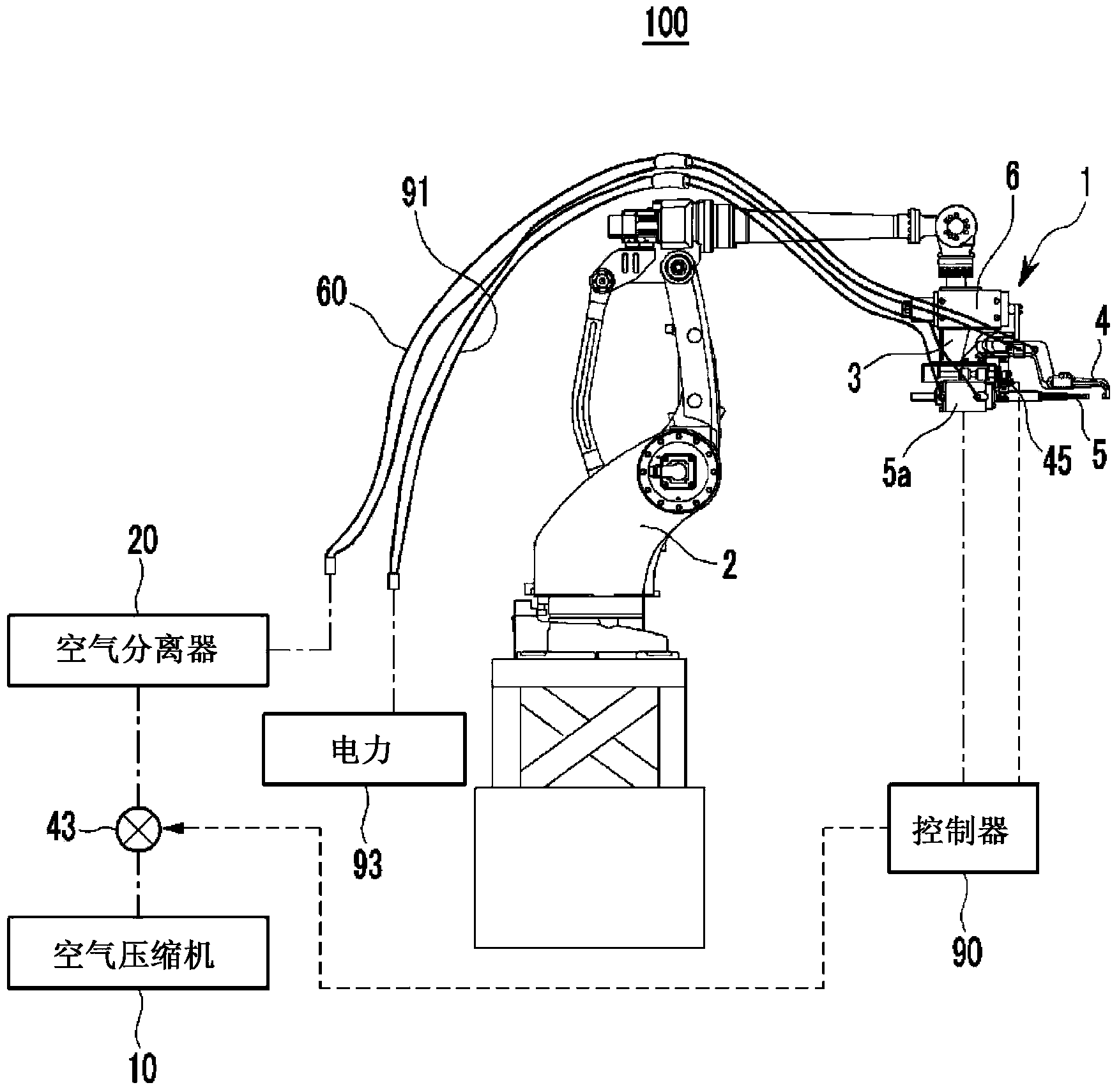

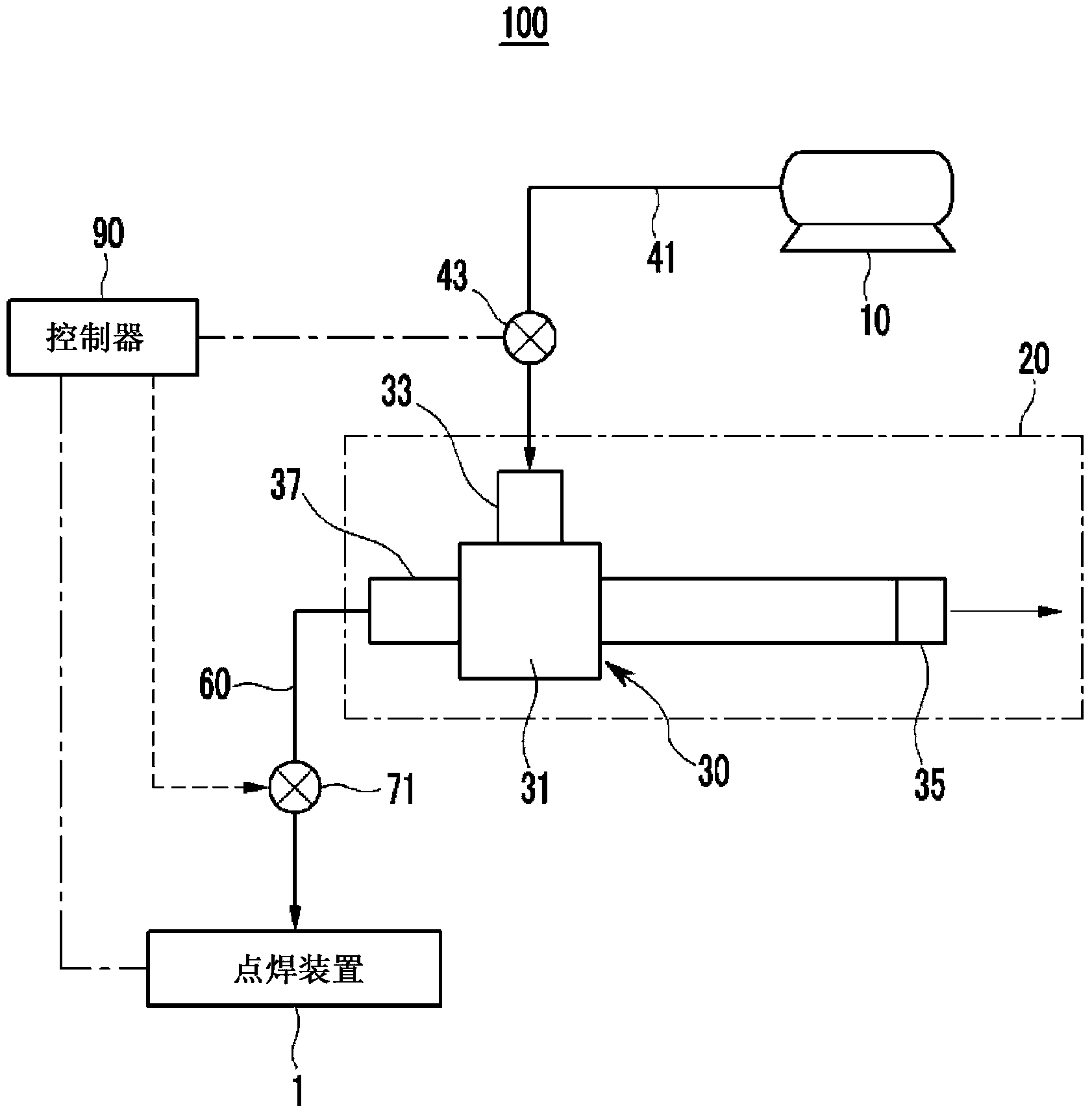

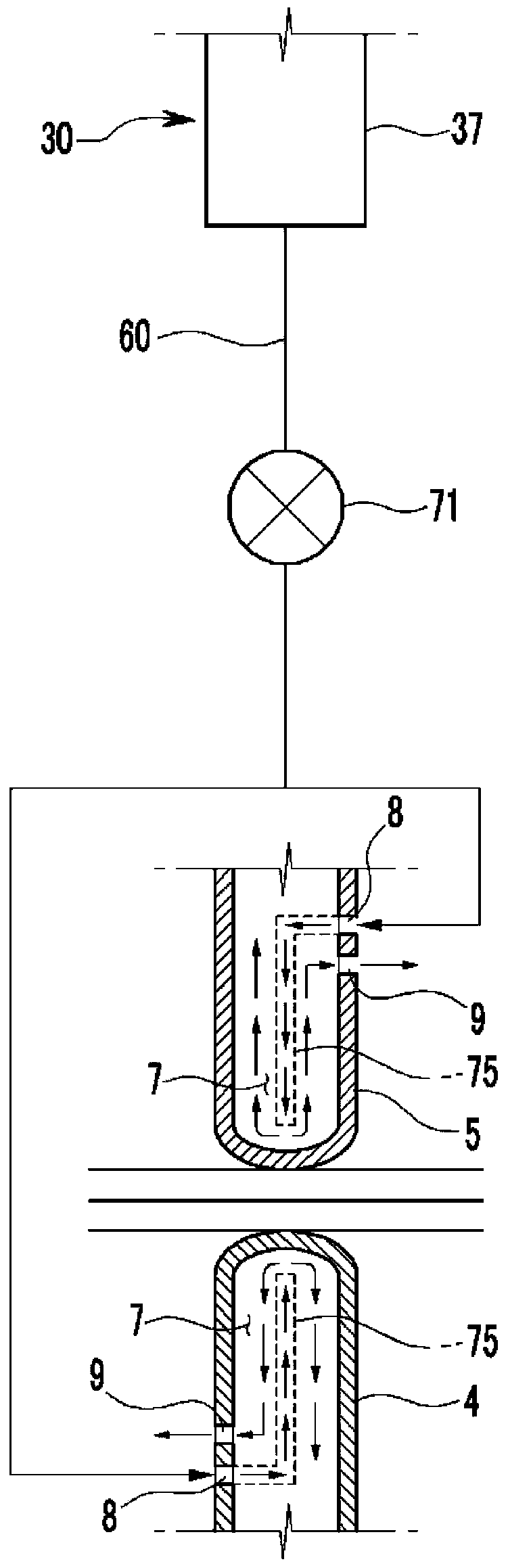

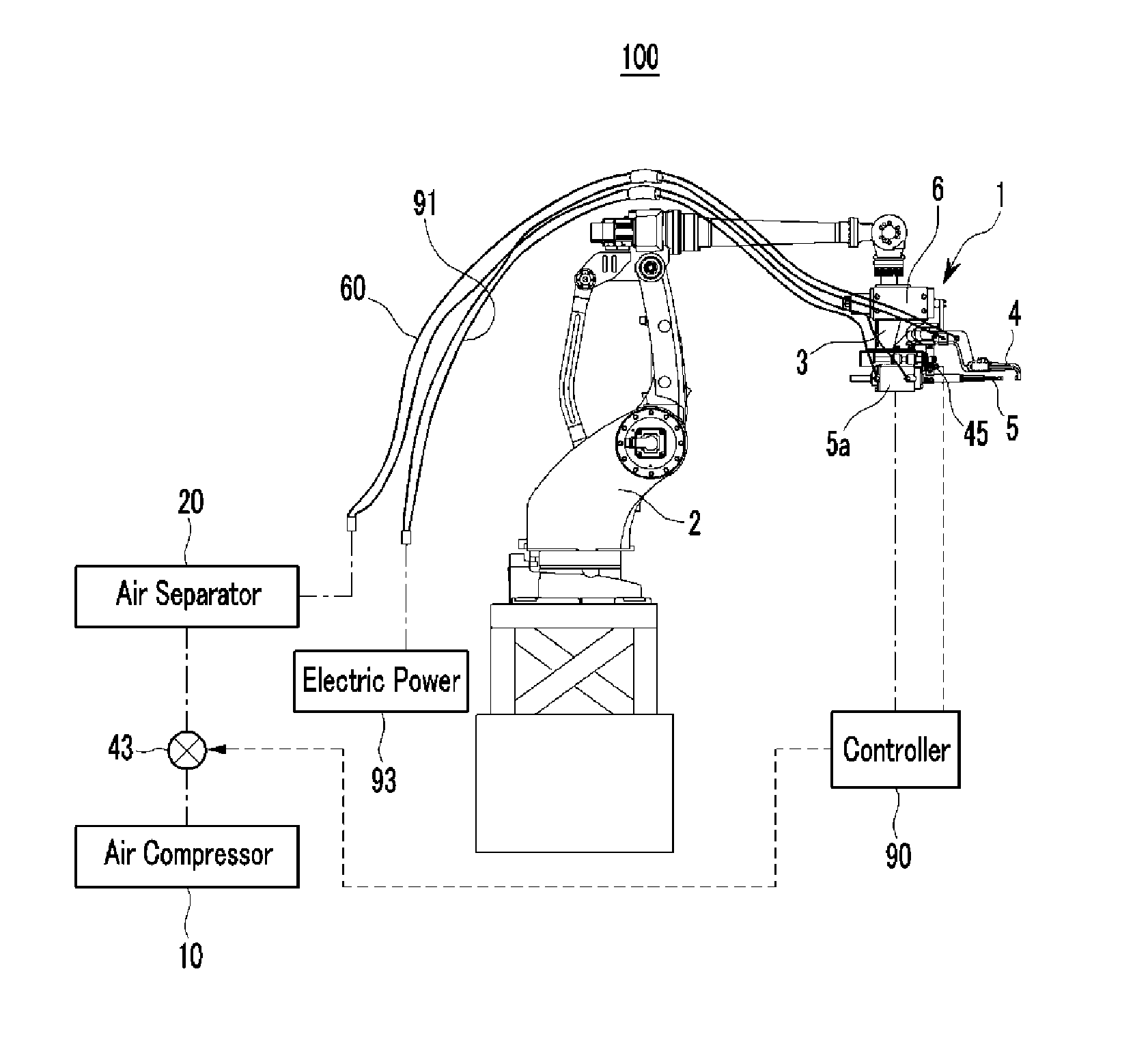

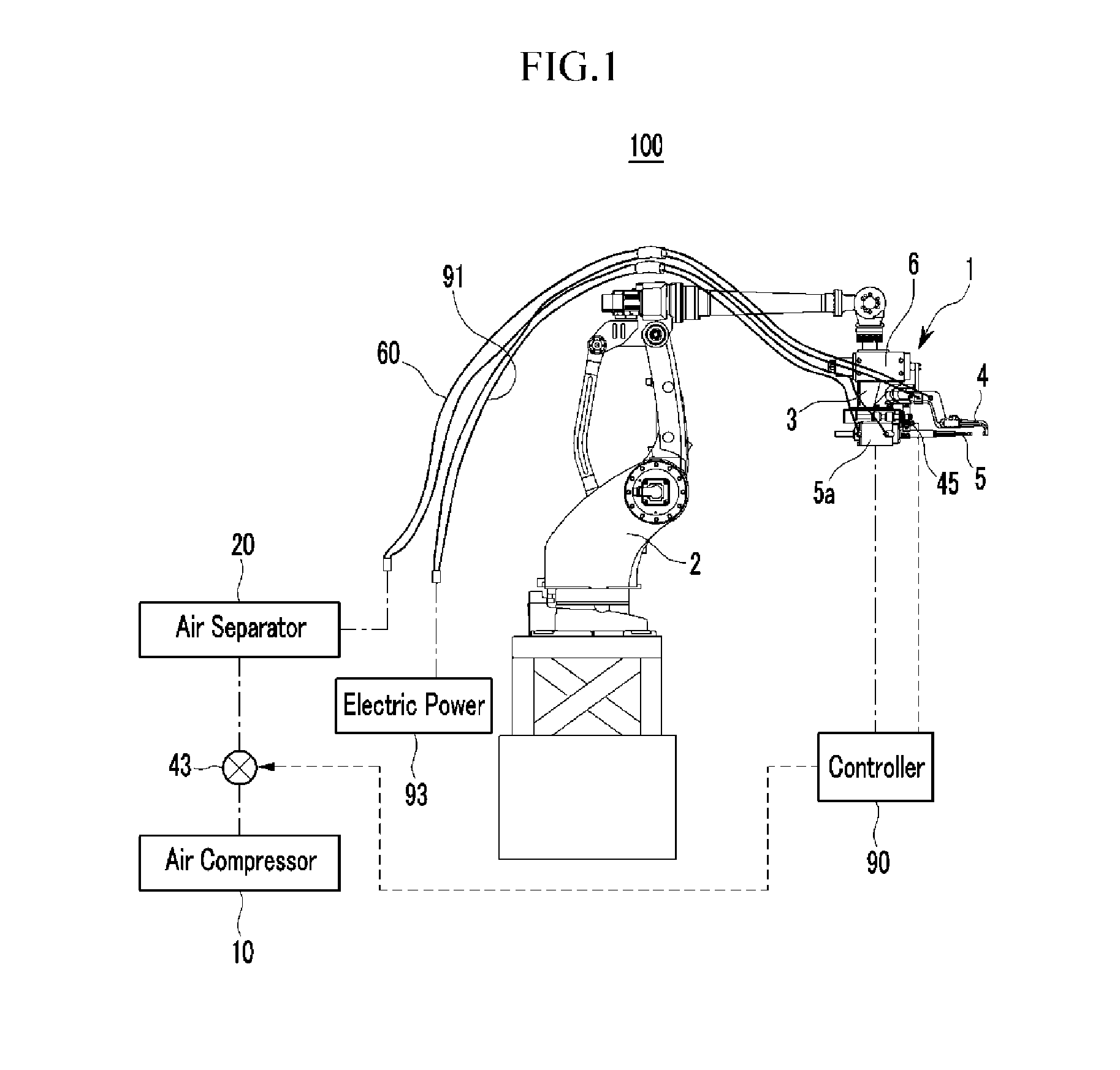

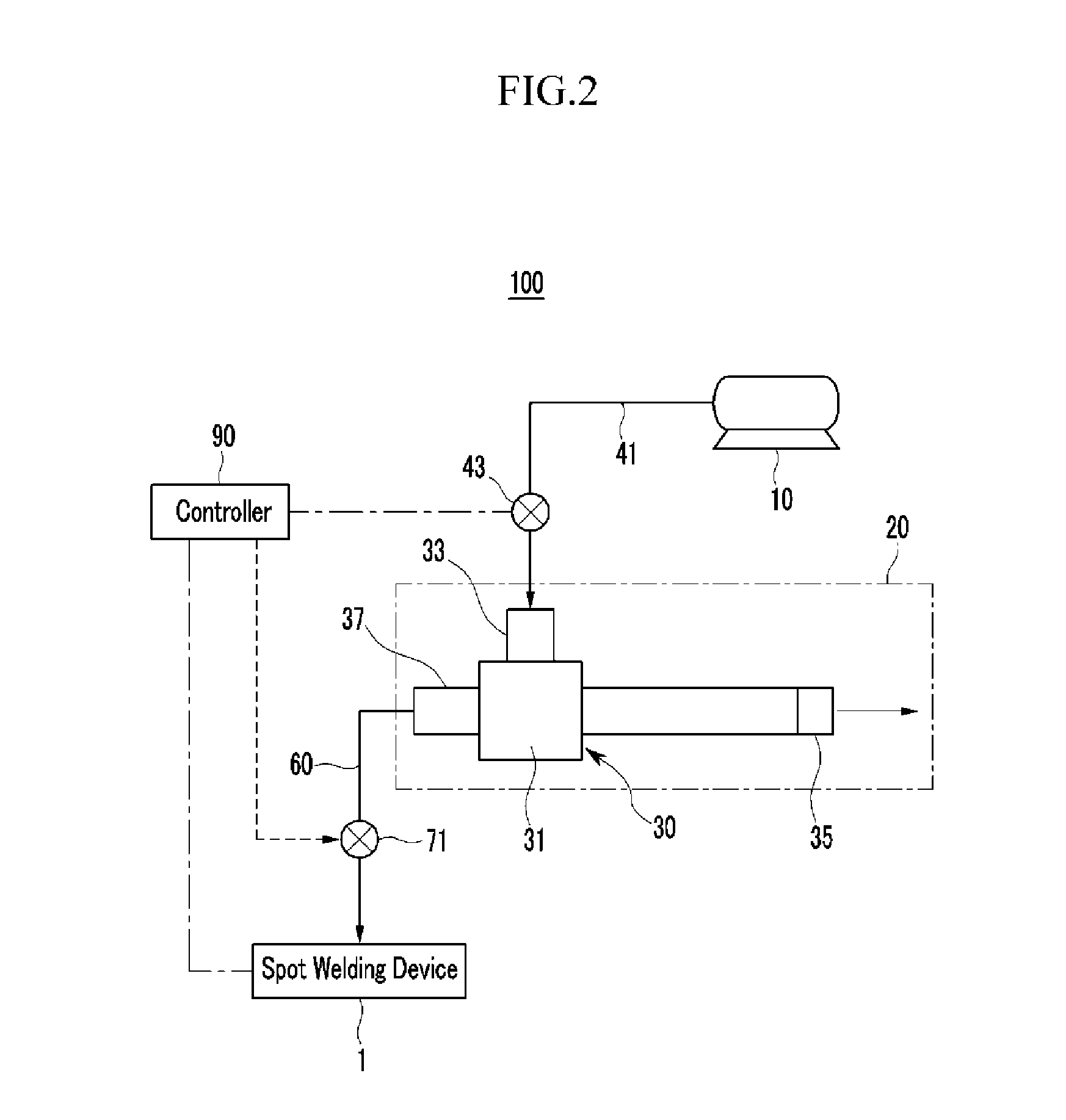

Cooling system for spot welding device

InactiveCN104070281AResistance electrode holdersWelding/cutting auxillary devicesTransformerEngineering

A cooling system for a spot welding device which cools heating parts of a spot welding device including two electrodes, a gun body, and a transformer, may include an air compressor, an air separator connected with the air compressor and separating compressed air supplied from the air compressor into hot air and cooling air, and a connection line supplying the cooling air separated by the air separator to a heating part of the spot welding device.

Owner:HYUNDAI MOTOR CO LTD

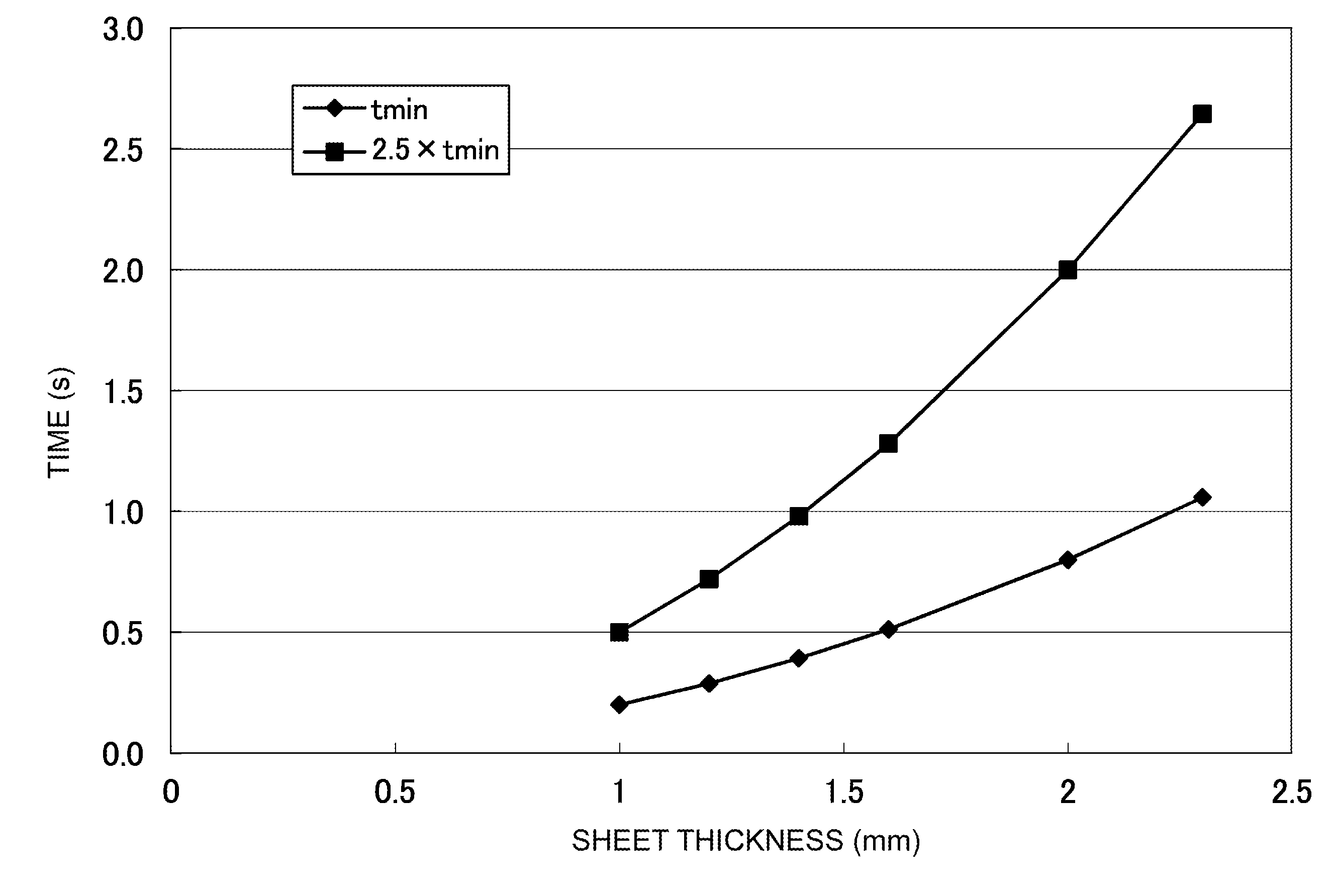

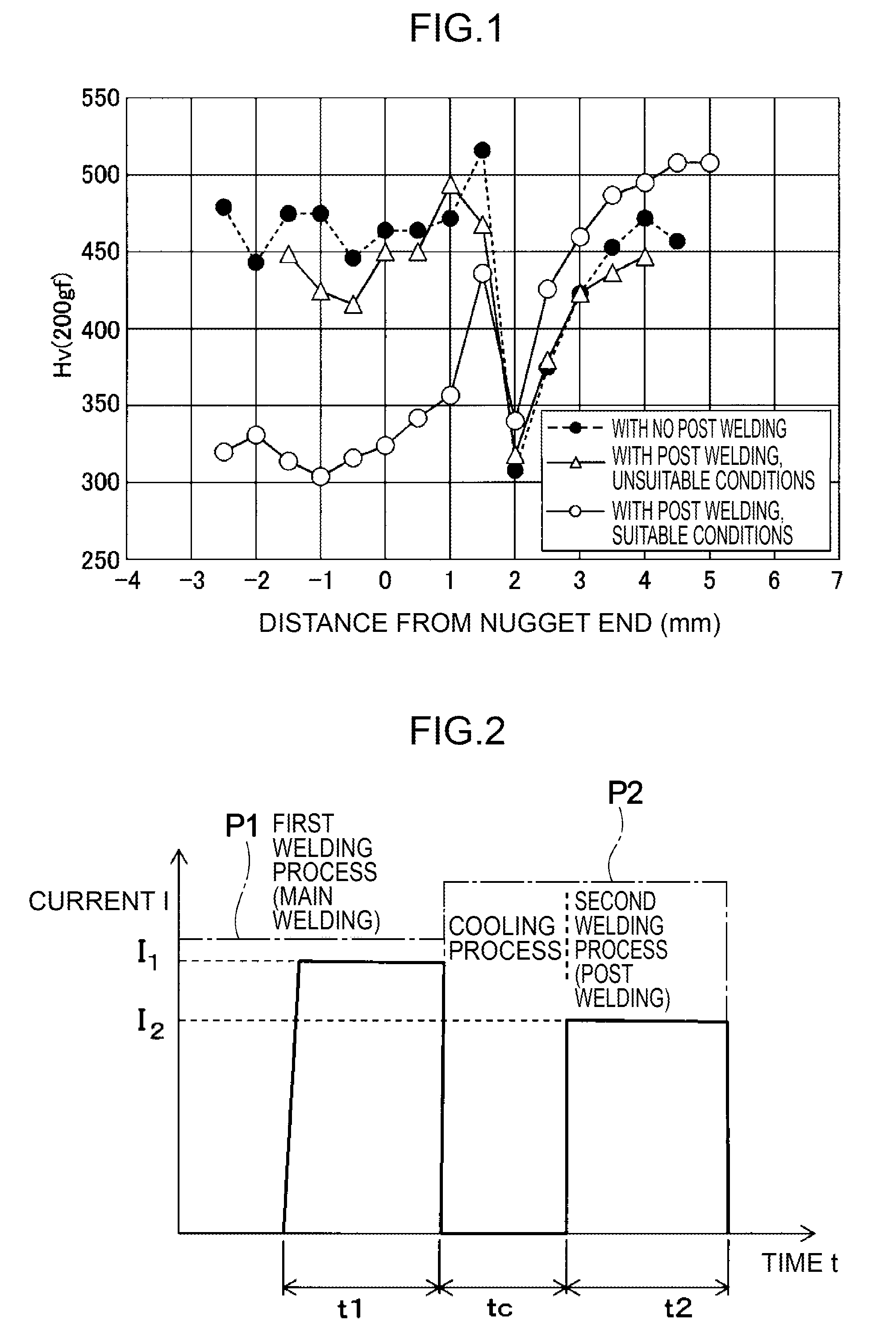

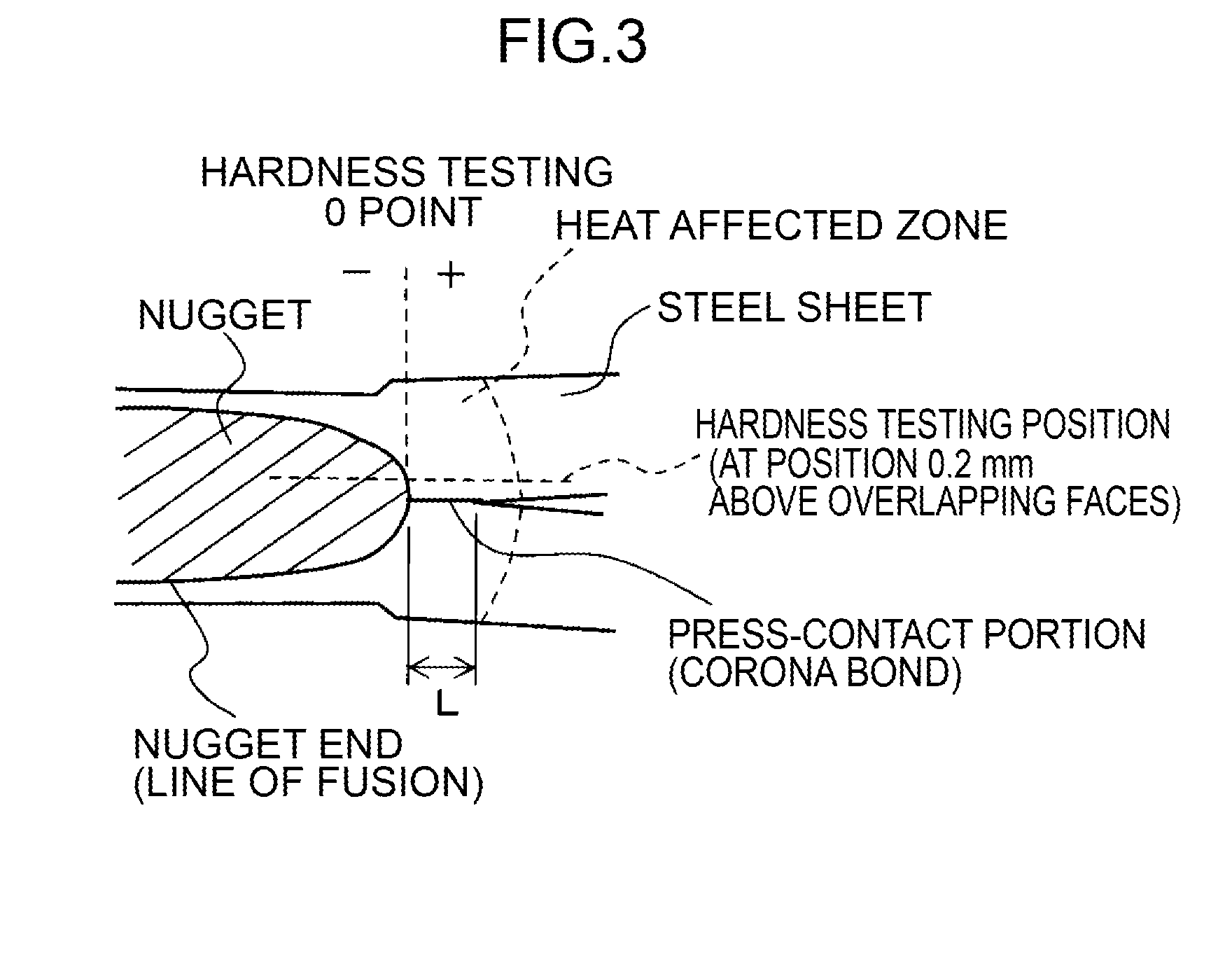

Spot welding method

InactiveUS20160067814A1High strengthVariation can be suppressedWelding/cutting auxillary devicesWelding electric suppliesPower flowEngineering

A spot welding method is a method of performing spot welding to obtain a spot welded joint, the method including a spot welding with two-stage welding, setting a ratio (I2 / I1) of a current I2 of a second welding process to a current I1 of a first welding process to from 0.5 to 0.8, setting a time tc of a cooling process within a range of from 0.8×tmin to 2.5×tmin wherein tmin is calculated using the equation (0.2×H2) according to a sheet thickness H of the steel sheets, setting an welding time t2 of a second welding process within a range of from 0.7×tmin to 2.5×tmin, and setting a pressure from the cooling process onward to greater than a pressure until the first welding process.

Owner:NIPPON STEEL CORP

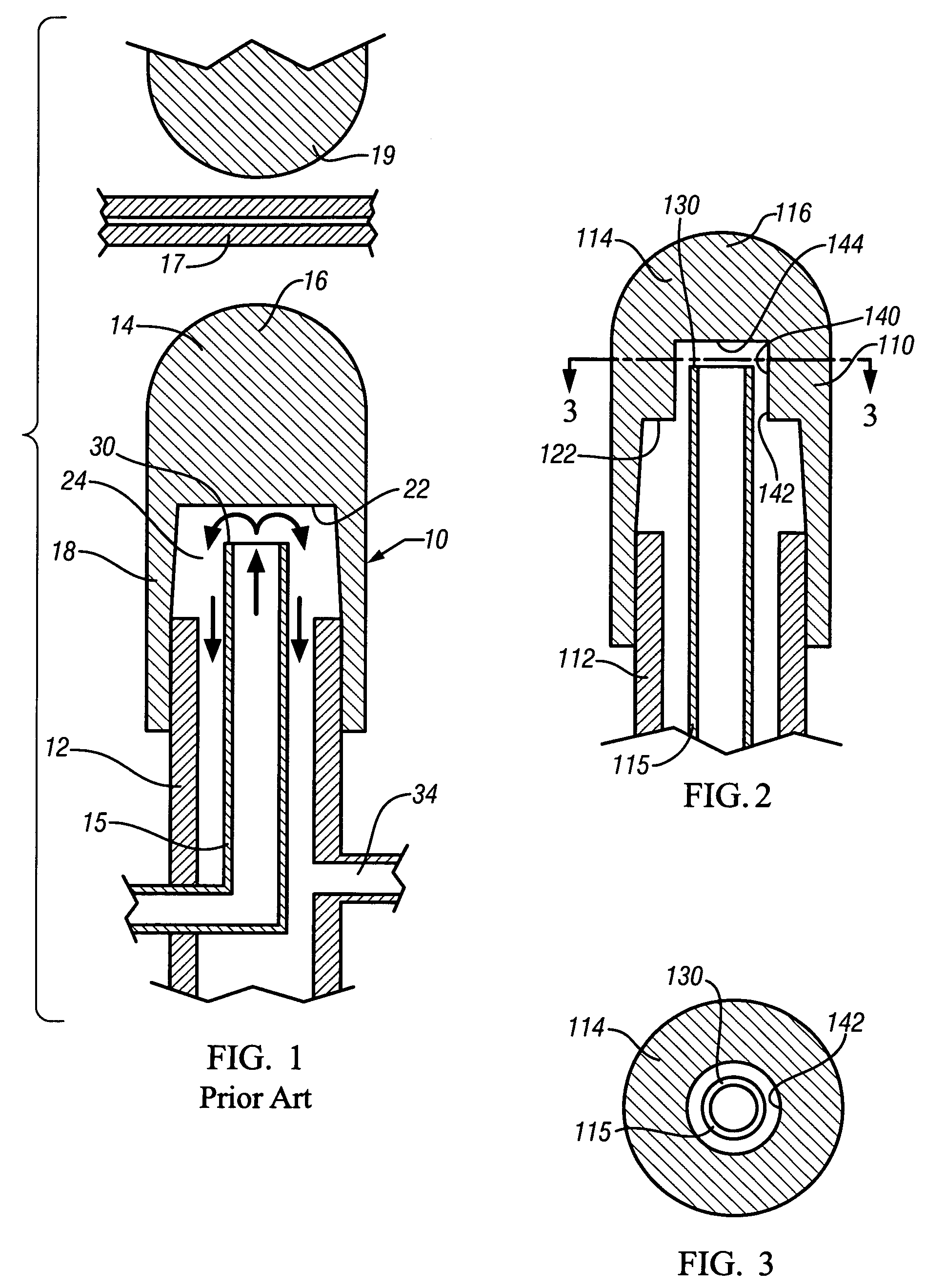

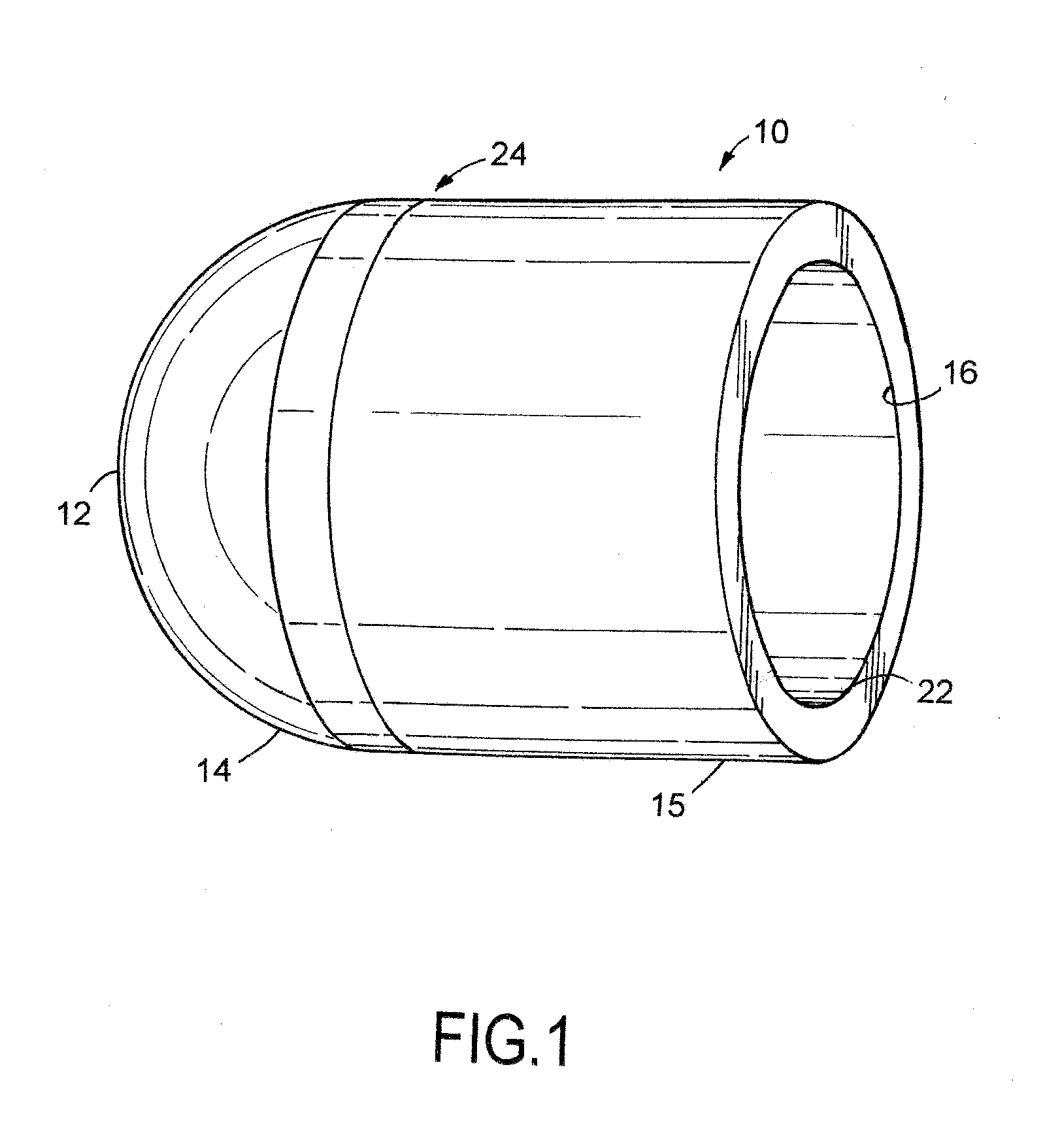

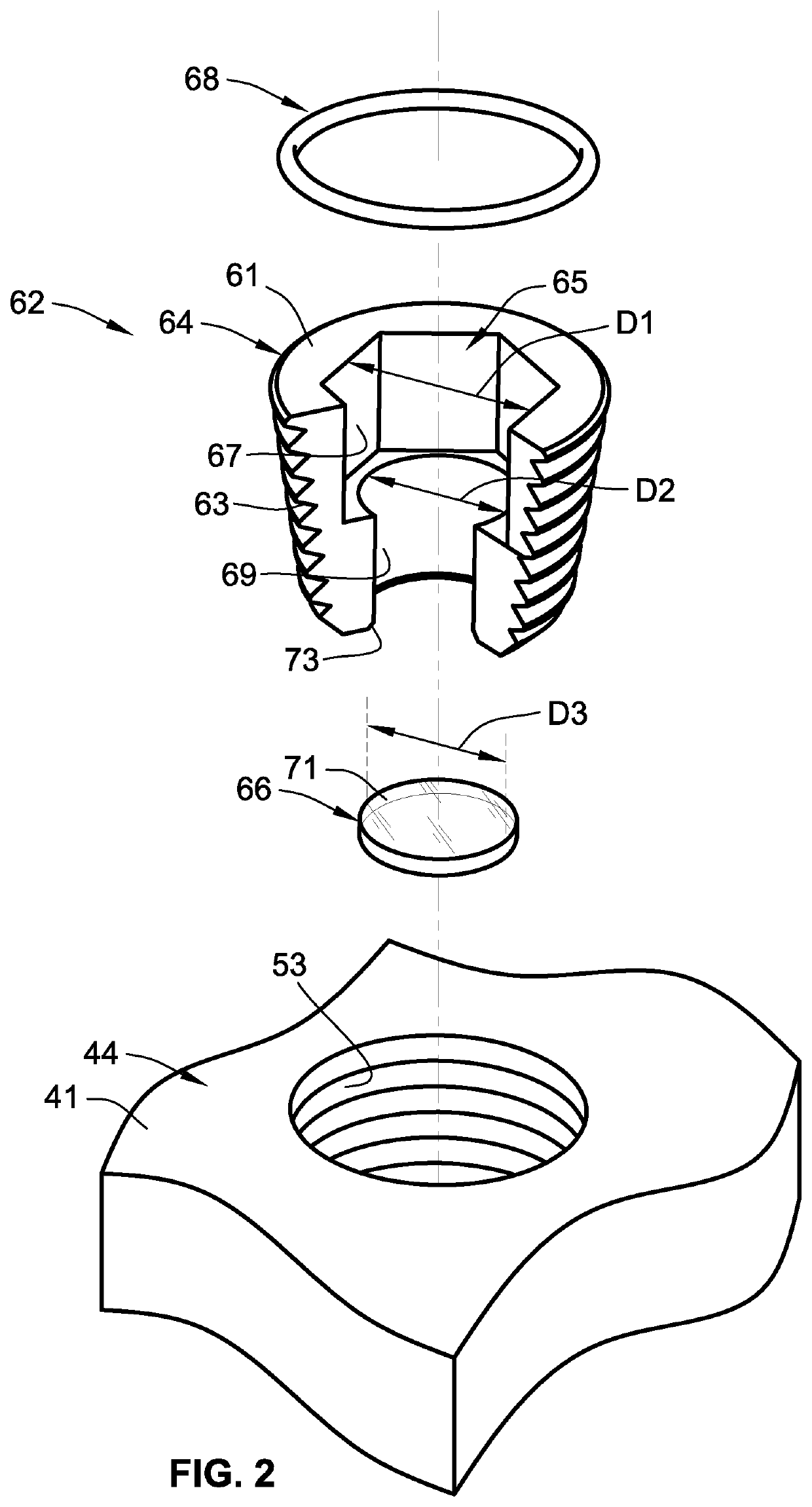

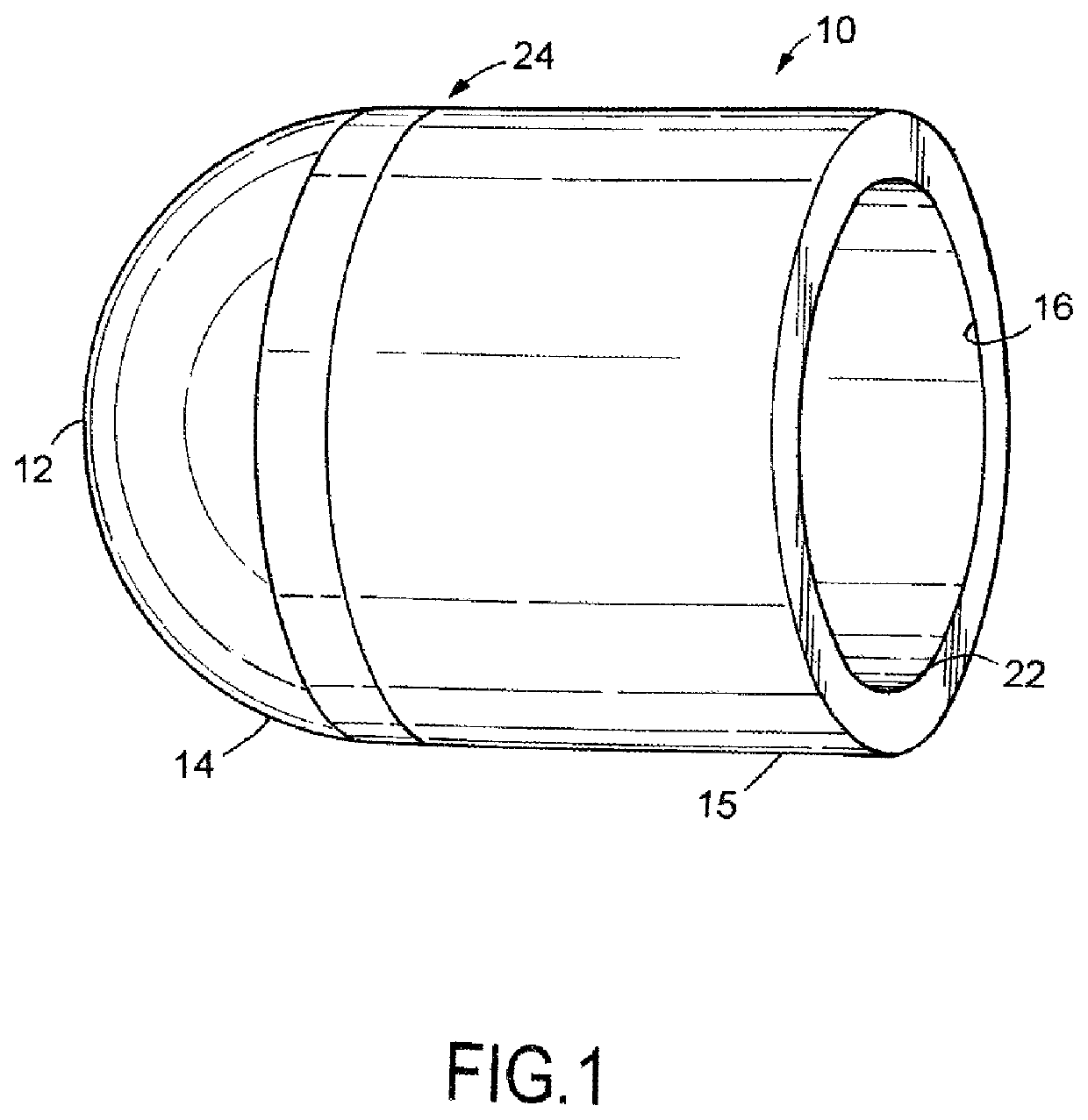

Resistance welding tip with improved cooling system

ActiveUS7238911B2Increase reduction rateImprove effectivenessOhmic-resistance electrodesWelding/cutting auxillary devicesElectrical resistance and conductanceScrew thread

Owner:GM GLOBAL TECH OPERATIONS LLC

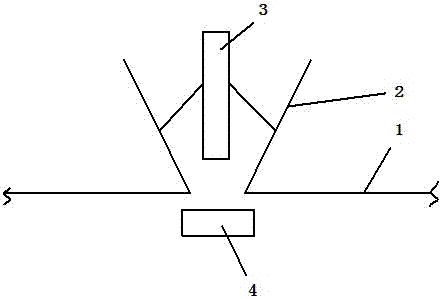

Resistance welding tip with improved cooling system

ActiveUS20060108329A1Increase reduction rateIncrease ratingsOhmic-resistance electrodesWelding/cutting auxillary devicesElectrical resistance and conductanceEngineering

An improved cooling system for adapting to a two-component welding electrode device having a shank and cap, includes a retractable nozzle tube, a manifold, and an adjustment element for adjustably interconnecting the tube and manifold. A threaded bushing or plunger is attached to the tube and operable to adjust the distance between the interior surface of the cap and the outlet of the tube to a preferred distance. A threaded sleeve interconnects the tube and bushing for additional adjustability. The tube defines an elastically compressible bellows section, and a spacer is removably attached to the distal end of the tube for automatic adjustment of the outlet position by the cap.

Owner:GM GLOBAL TECH OPERATIONS LLC

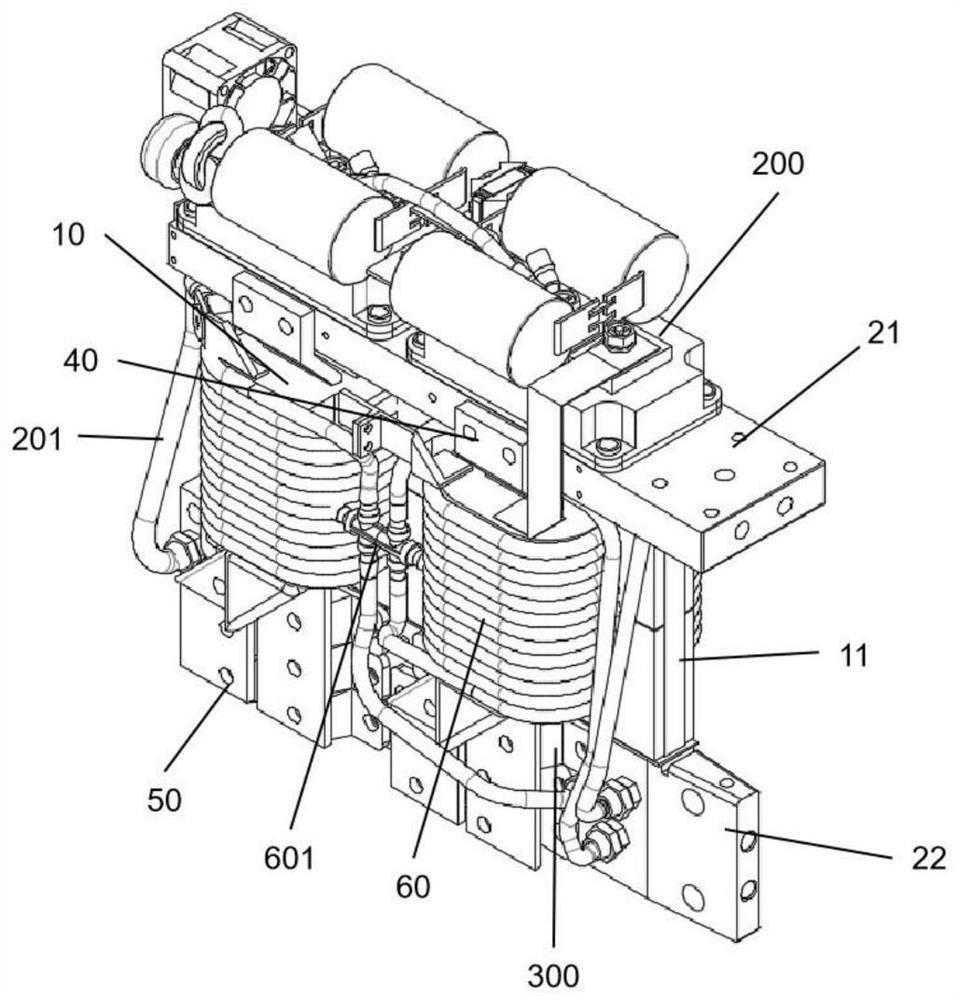

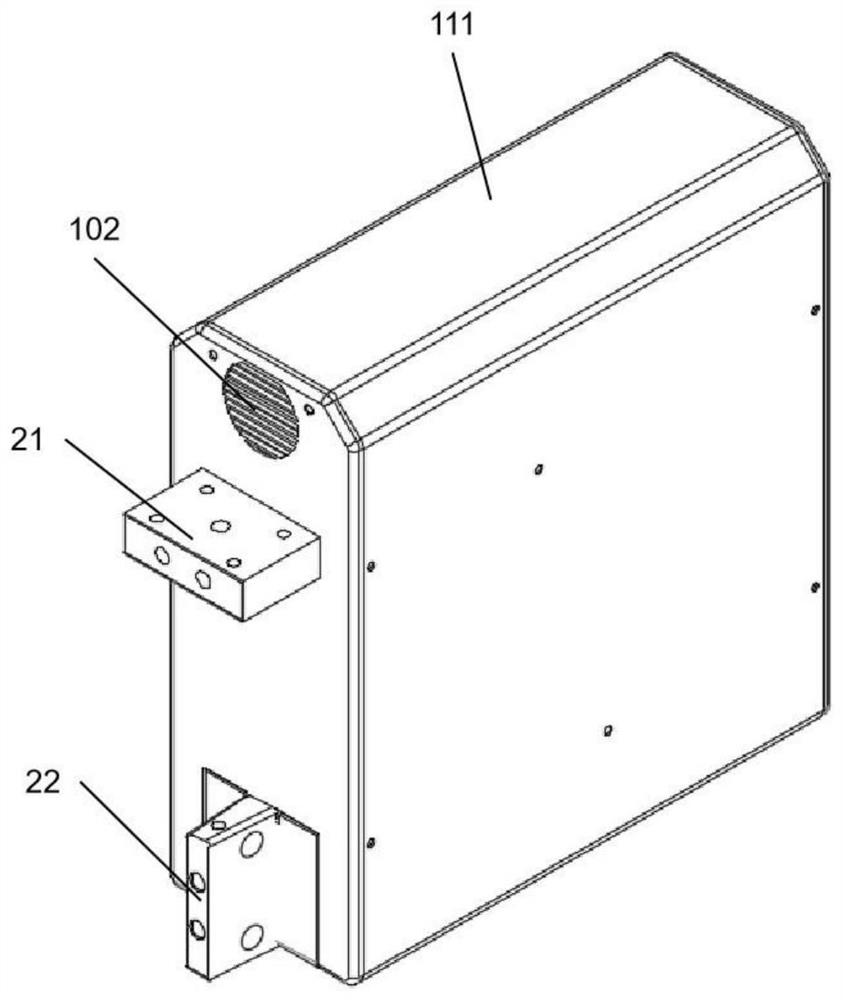

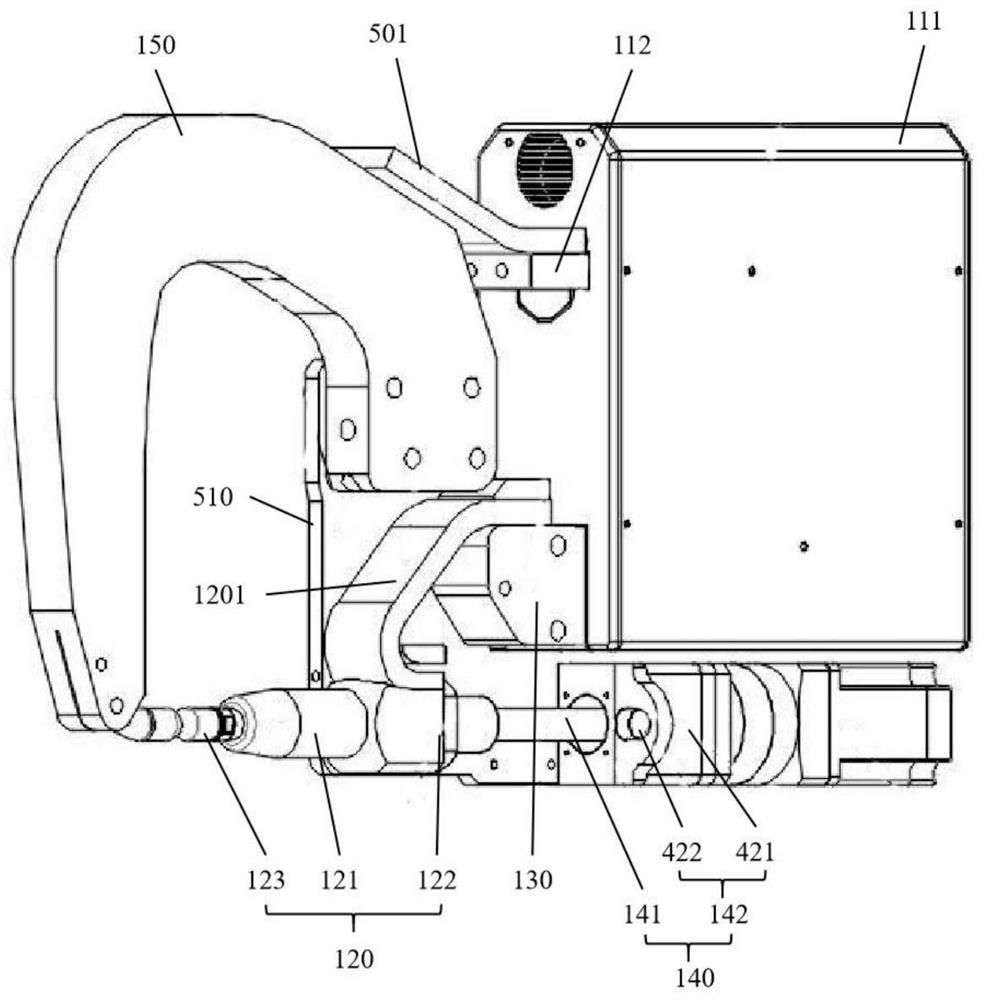

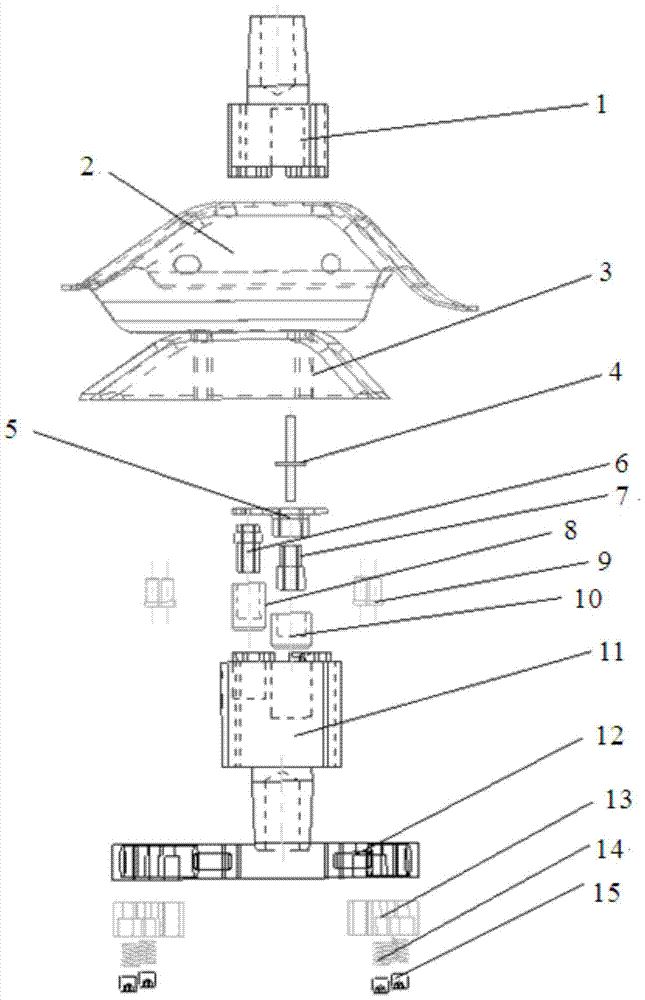

Low-voltage large-current light-weight spot welding machine

PendingCN112756758ARealize modular assemblyMiniaturizationResistance electrode holdersCooled electrodesElectrically conductiveEngineering

The invention provides a low-voltage large-current light-weight spot welding machine. The low-voltage large-current light-weight spot welding machine comprises a welding power source which comprises a box body, a first electrode and a second electrode, wherein the first electrode and the second electrode partially extend out of the box body; a movable arm structure which comprises a movable arm and a nut flange, wherein one end of the movable arm is connected with the nut flange; a connecting block which is arranged between a first conductive bridge and the first electrode; a driving device, wherein a driving rod of the driving device is connected with the nut flange and located at the bottom of the box body; and a stationary arm which is connected with the movable arm through a side connecting plate, wherein the side connecting plate is fixedly connected with the stationary arm and the connecting block through a plurality of fastening bolts, the side connecting plate is rotatably connected to the flange structure, and the movable arm structure, the connecting block, the driving device and the fixed arm are fixedly connected into an electrode holder stress connecting mechanism through the side connecting plate. The electrode holder stress connecting mechanism and the welding power source are mounted integrally. The movable arm structure and the stationary arm structure are compact, so that miniaturized design of an electrode holder is achieved, and the electrode holder and the welding power source are easy to disassemble, so that two electrode holders are switched rapidly.

Owner:HEFEI SANYU ELECTRIC

Method and apparatus for improved cooling of resistance welding cap

ActiveUS20070075049A1Ohmic-resistance electrodesWelding electrode featuresBiomedical engineeringCoolant

According to the invention a hollow cylindrical shank of electrically conducting metal is connected to a resistance welder. A coolant supply tube passes through the shank and has an interior coolant supply passage. The coolant supply tube has an outer diameter less than the inner diameter of the hollow cylindrical shank. A weld cap seats on the shank and has a cap tip and a cap skirt that depends from the cap tip and is attached to the shank. An underside of the cap tip faces the shank and the supply tube. A coolant receiving bore formed into the underside of the weld cap extends into the cap tip to receive the coolant supply tube part way into the bore. The bore formed into the underside of the cap tip defines a bore sidewall that provides added area of heat transfer contact between the coolant and the cap tip.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Fluid transfer of suction force between drawback apparatuses

ActiveUS20170203382A1Reduce or eliminate liquid lossReduce and stop flowEngine diaphragmsFlexible member pumpsSuction forceCoolant flow

A first electrode coolant path is configured to cool a first welding electrode by liquid coolant flowing from a supply path through the first electrode coolant path to a return path. A second electrode coolant path is configured to cool a second welding electrode by liquid coolant flowing from the supply path through the second electrode coolant path to the return path. Three or more valves are configured to stop or reduce liquid coolant flow through the first or second electrode coolant path and configured to stop or reduce liquid coolant backflow from the return path when the first or second welding electrode is at least partially detached. At least one valve is coupled in the first or second electrode coolant path. A drawback apparatus generates a suction force to draw liquid coolant away from a gap formed when the first or second welding electrode is at least partially detached.

Owner:PROTEUS INDUSTRIES INC

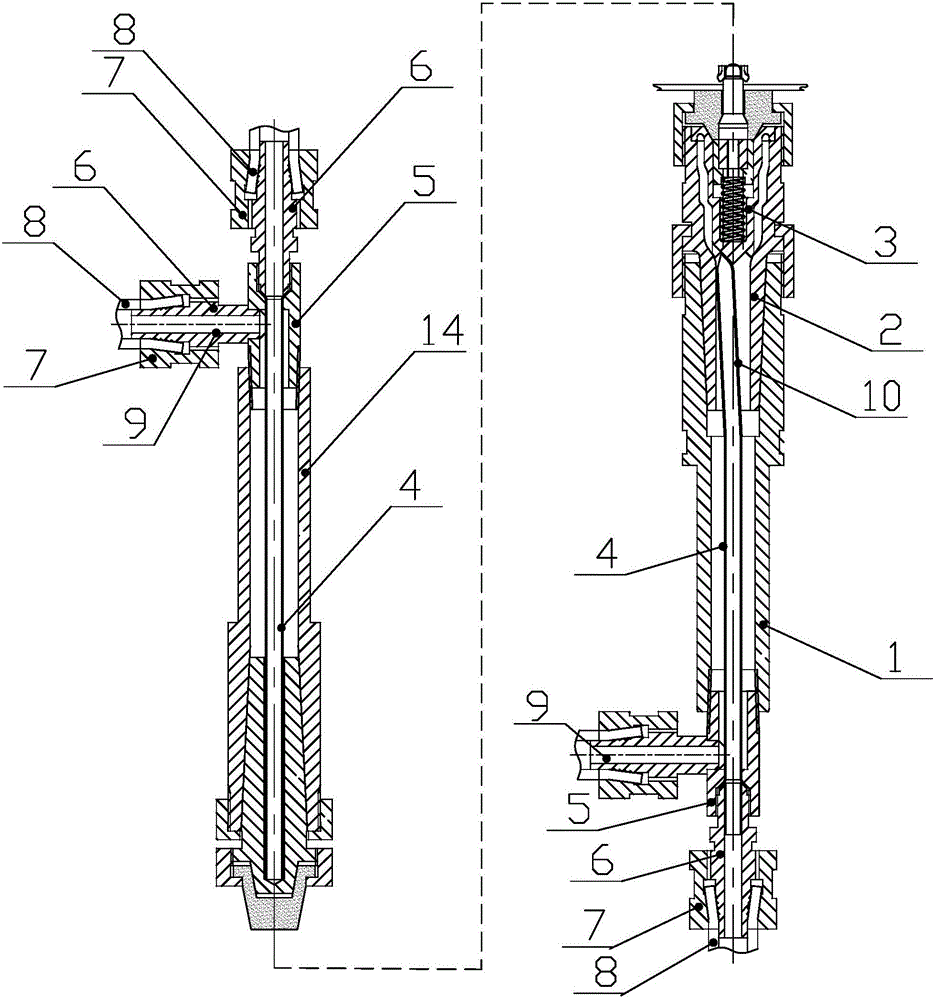

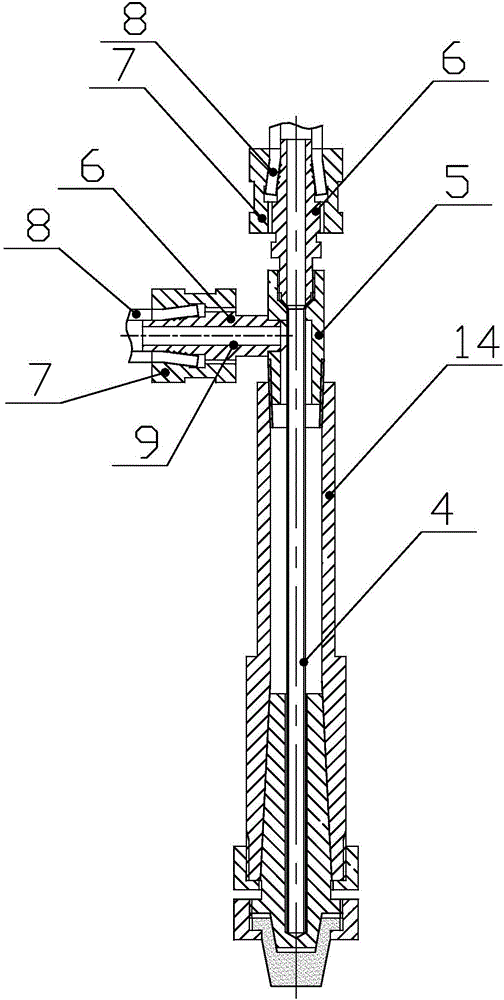

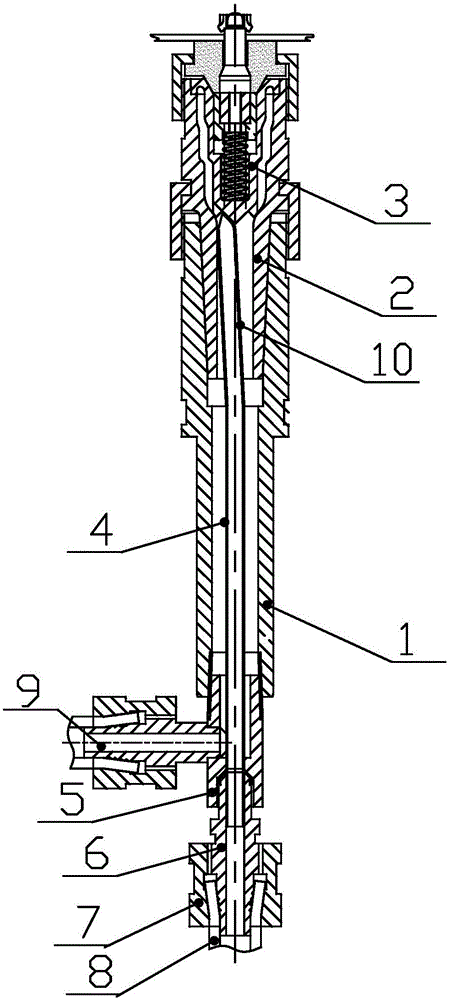

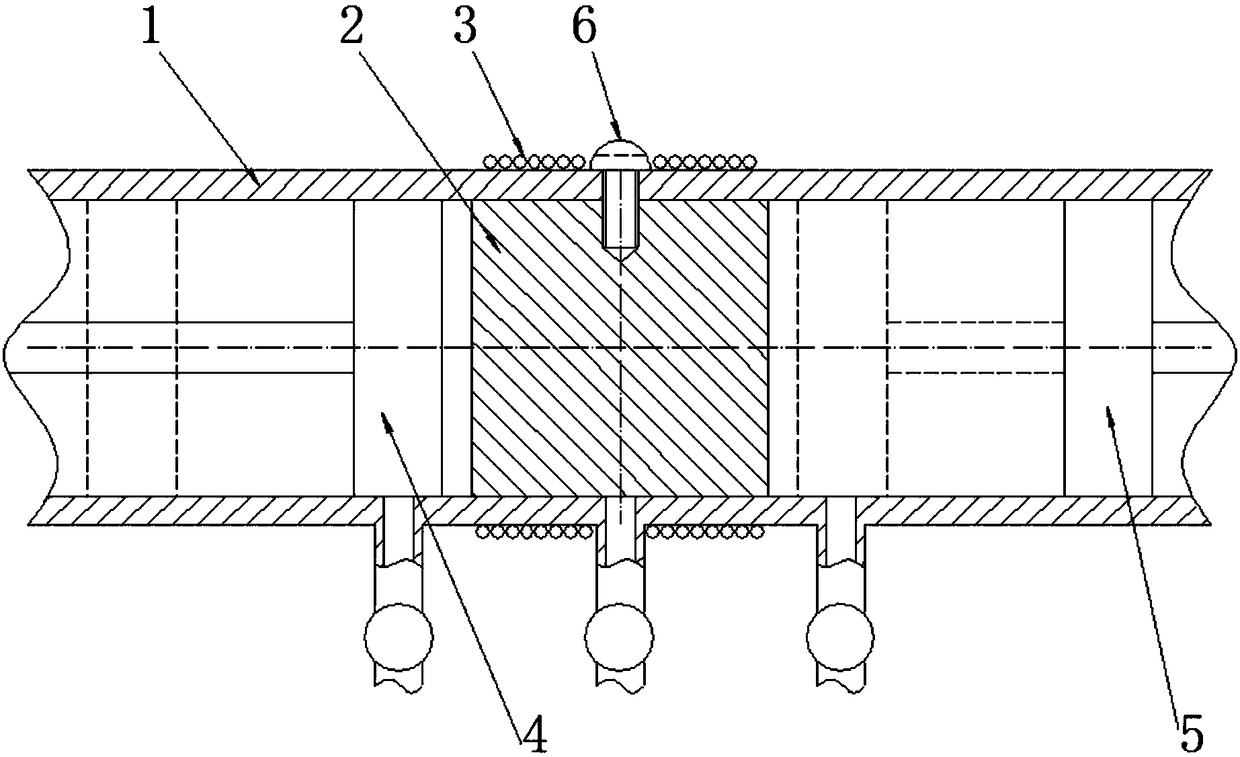

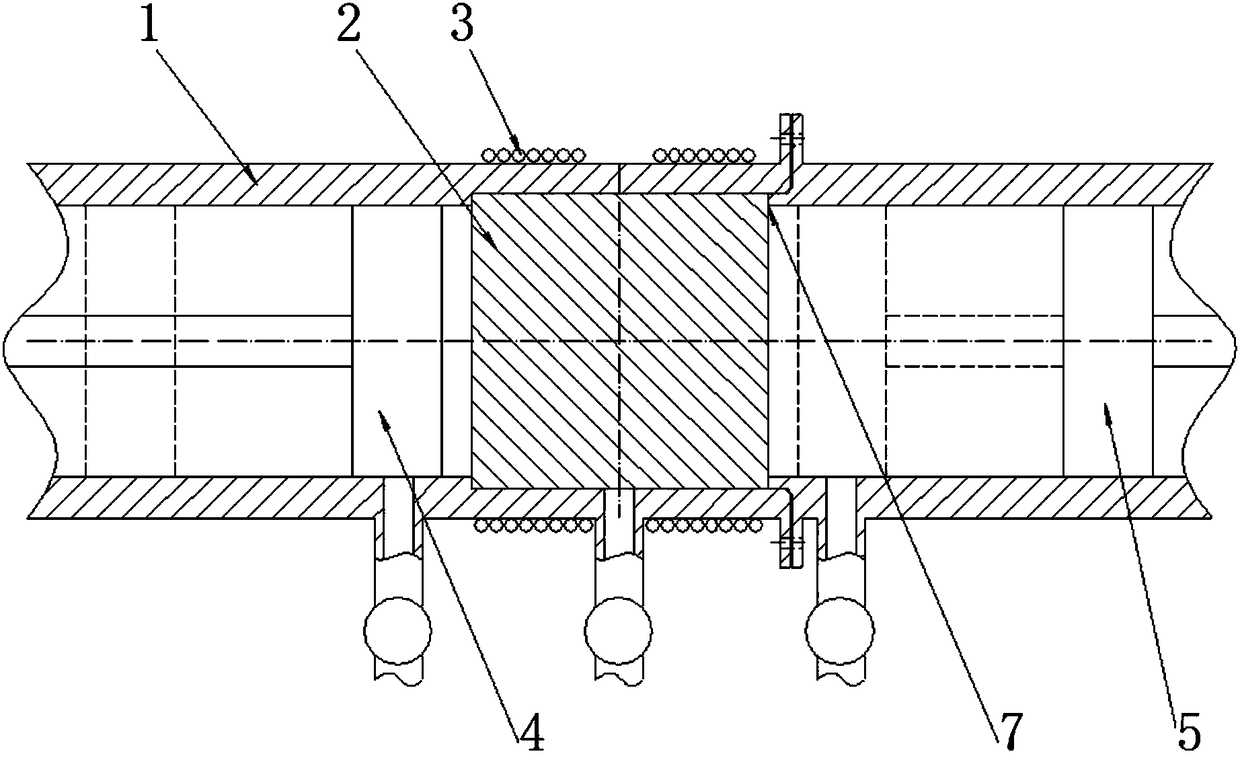

Cooling system of device special for welding of projection welding nut

PendingCN106735822AExtend the life cycleExtended service lifeCooled electrodesEngineeringCooling efficiency

The invention provides a cooling system of a device special for welding of a projection welding nut. The cooling system comprises an upper electrode body cooling system and a lower electrode body cooling system, wherein the upper electrode body cooling system comprises an upper water inlet mechanism and an upper water outlet mechanism; the upper water inlet mechanism and the upper water outlet mechanism are connected with a hollow upper holding rod of an upper electrode body; the lower electrode body cooling system comprises a lower water inlet mechanism and a lower water outlet mechanism; and the lower water inlet mechanism and the lower water outlet mechanism are connected with a hollow lower holding rod of a lower electrode body. According to the cooling system, the water inlet / outlet mechanisms and direct pipelines are added in the electrode bodies, cold water can enter the electrode bodies through the water inlet / outlet mechanisms and the direct pipelines to cool the electrode bodies, water cooling cycle operation is carried out through the water inlet / outlet mechanisms and the direct pipelines, the cooling efficiency is improved, the welding process is stable and reliable, the continuous working time is effectively prolonged, the production efficiency is improved, the tooling maintenance cost is reduced, and the utilization cycle and service life of electrodes are prolonged.

Owner:重庆太乙机械有限公司

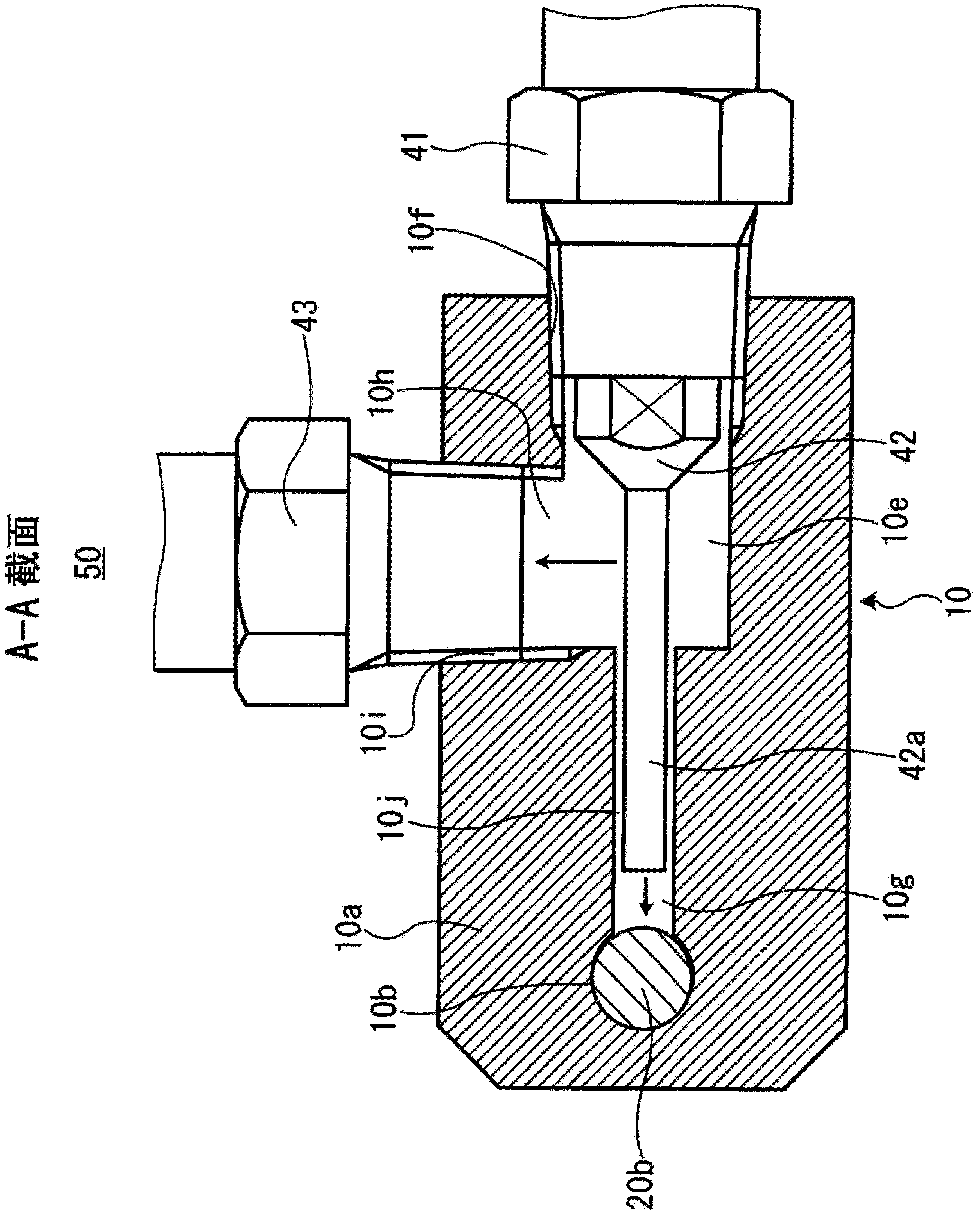

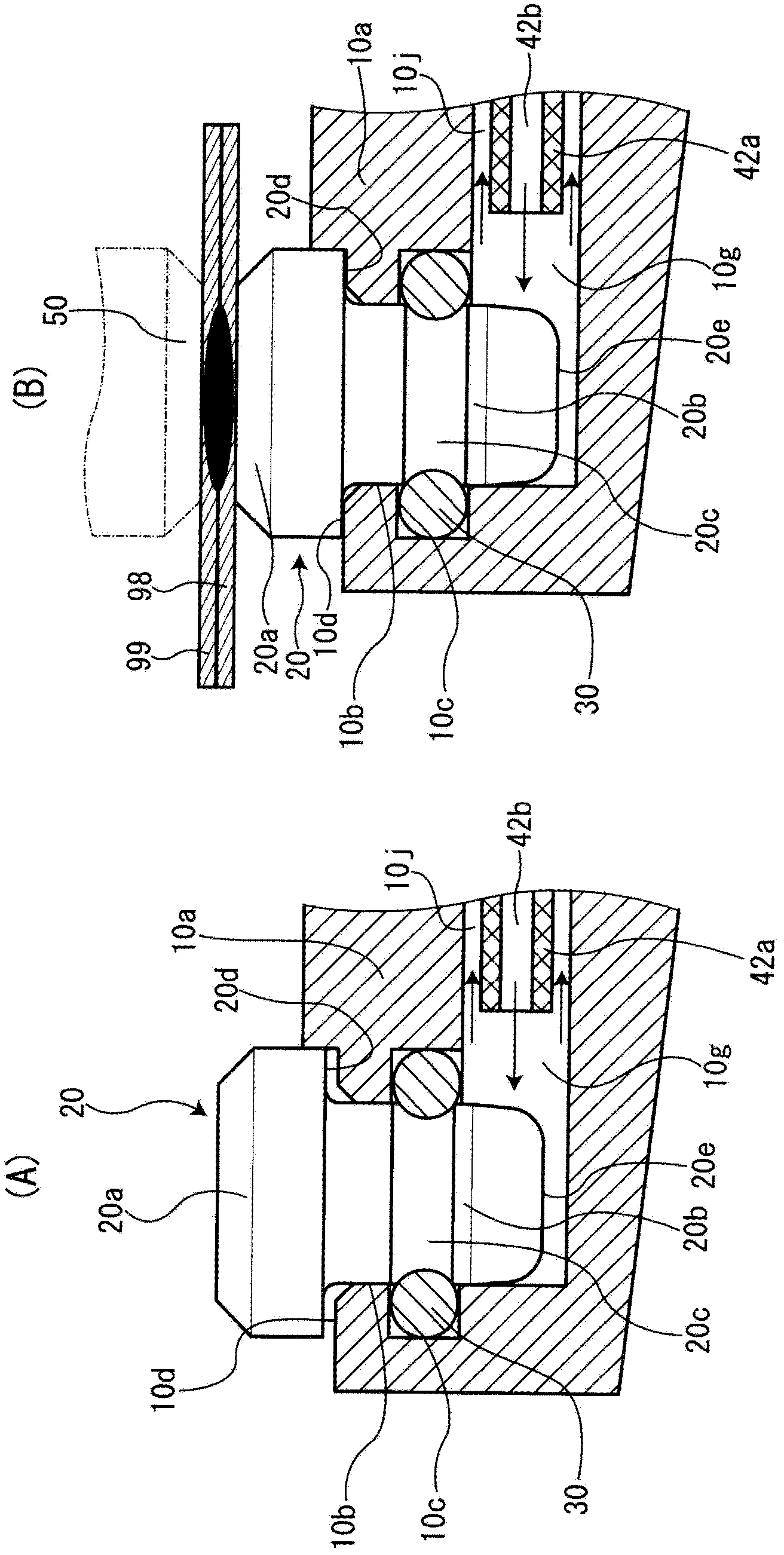

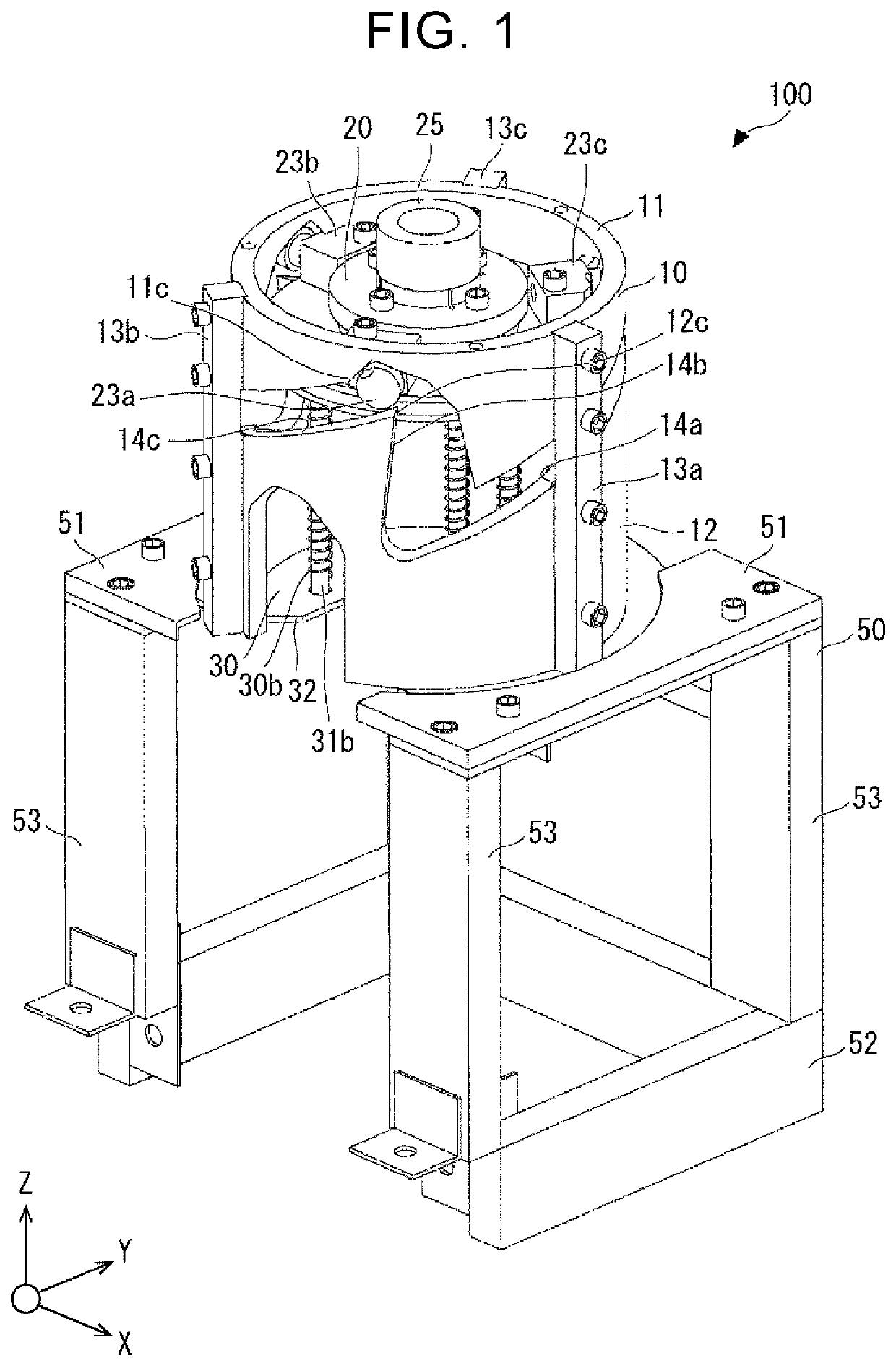

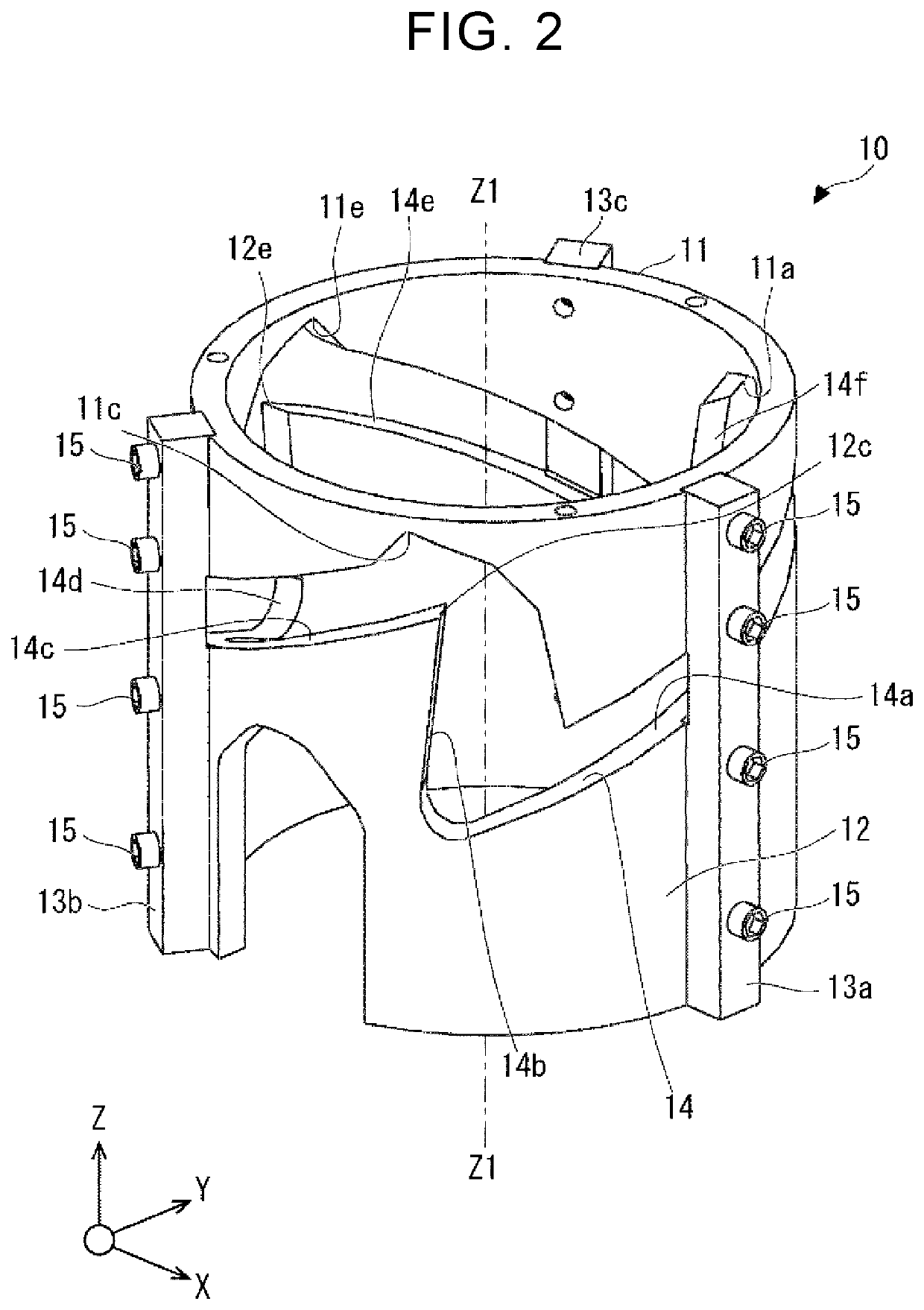

Spot welder electrode part

InactiveCN102427908AAvoid overall overheatingImprove cooling effectResistance electrode holdersPressure electrodesWater flowElectrical and Electronics engineering

Provided is a spot welder electrode part that can prevent overheating of an electrode holder and a small tip. A recessed mounting part (10b) with a circular cross-sectional shape is formed as a depression in the surface of a projecting part (10a) of an electrode holder (10), a first O-ring groove (10c) is formed in the inner circumferential surface of the recessed mounting part (10b), a cooling water channel (10g) connecting to the recessed mounting part (10b) is formed in the electrode holder (10), and a cylindrically-shaped mounting part (20b) is formed at the base end of a contact part (20a) of an electrode (20). A second O-ring groove (20c) is also formed in the outer circumferential surface of the mounting part (20b), the mounting part (20b) is connected to the inside of the recessed mounting part (10b), and an O-ring (30) is fit into the first O-ring groove (10c) and the second O-ring groove (20c) to mount the electrode (20) at the projecting part (10a). The electrode (20) and the projecting part (10a) are cooled by cooling water flowing inside the cooling water channel (10g).

Owner:SHINKOKIKI CO LTD +1

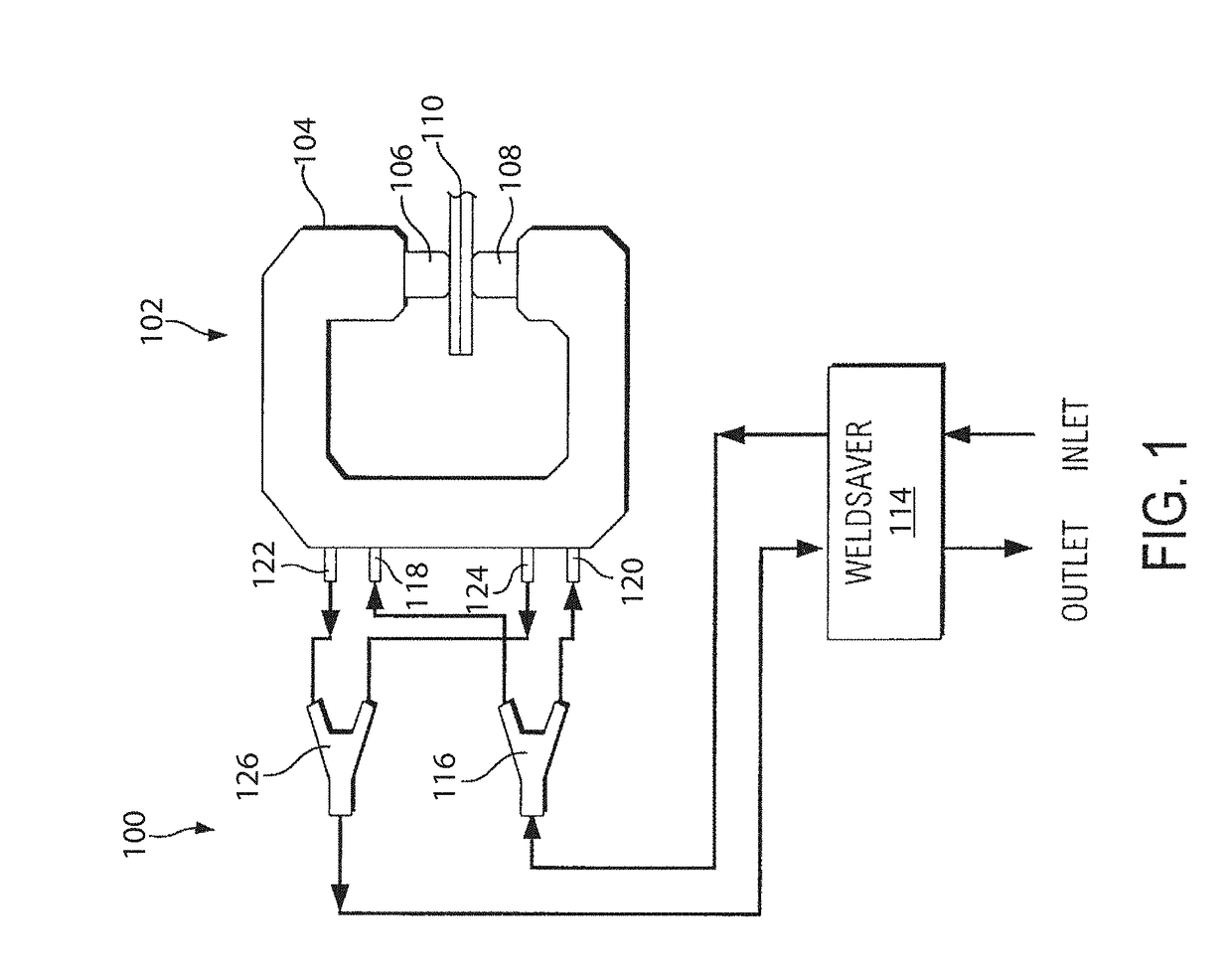

Weld electrode plugs with polymeric inserts for loss-of-cooling detection in welding systems

ActiveUS20190099830A1Efficient and rapid detectionAbate electrode damageResistance electrode holdersOperating means/releasing devices for valvesPhysical propertyCoolant

Disclosed are weld electrode plugs with polymeric inserts for loss-of-cooling detection, methods for making or for using such weld electrode plugs, and electric welding systems equipped with loss-of-cooling detection plugs. A disclosed loss-of-cooling detection assembly includes a plug that attaches to the weld shank of a welding system such that the plug fluidly couples to a coolant bore within the shank. The plug includes a plug body with a clearance hole extending therethrough. An insert detachably mounts to the plug such that the insert fluidly seals the clearance hole. This insert is fabricated from a polymeric material, such as a shape memory polymer, that alters a physical property, such as shape / size, of the insert responsive to changes in temperature and / or pressure of coolant fluid in the shank's bore. When this physical property is altered, the insert unseals the clearance hole causing a detectable leak of fluid from the shank.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cooling system for spot welding device

InactiveUS20140290291A1Low costImprove usabilityLighting and heating apparatusWelding/cutting auxillary devicesTransformerEngineering

A cooling system for a spot welding device which cools heating parts of a spot welding device including two electrodes, a gun body, and a transformer, may include an air compressor, an air separator connected with the air compressor and separating compressed air supplied from the air compressor into hot air and cooling air, and a connection line supplying the cooling air separated by the air separator to a heating part of the spot welding device.

Owner:HYUNDAI MOTOR CO LTD

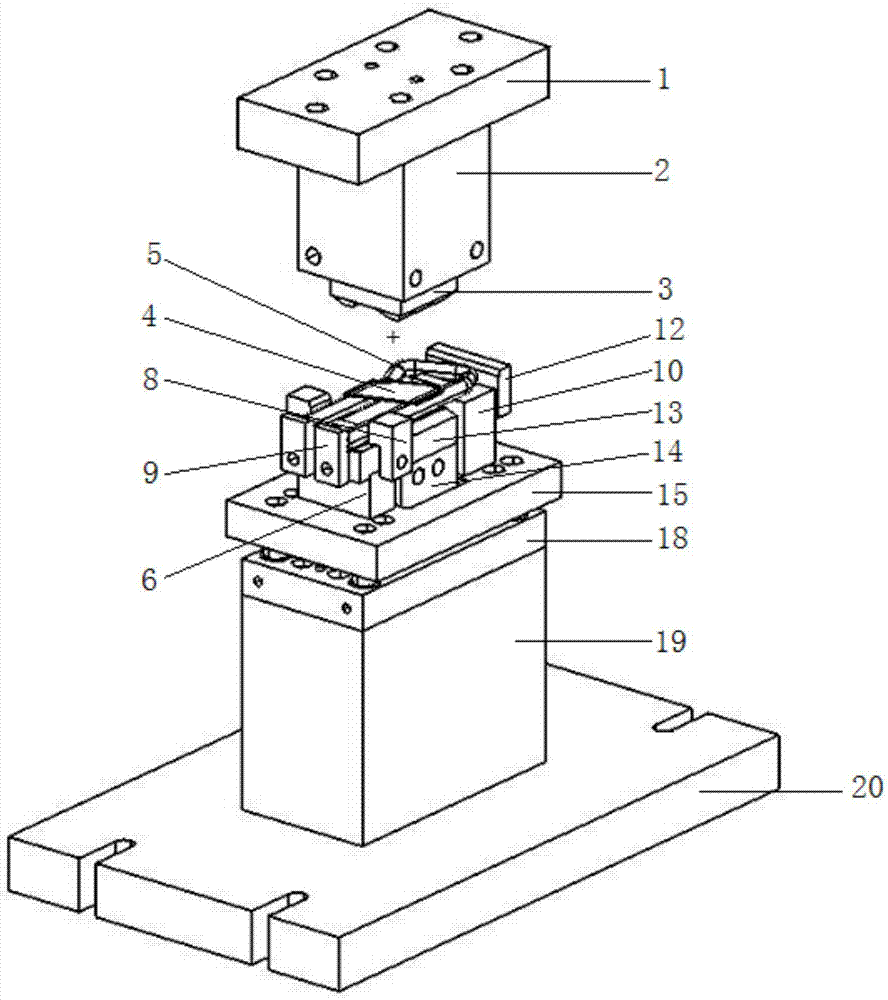

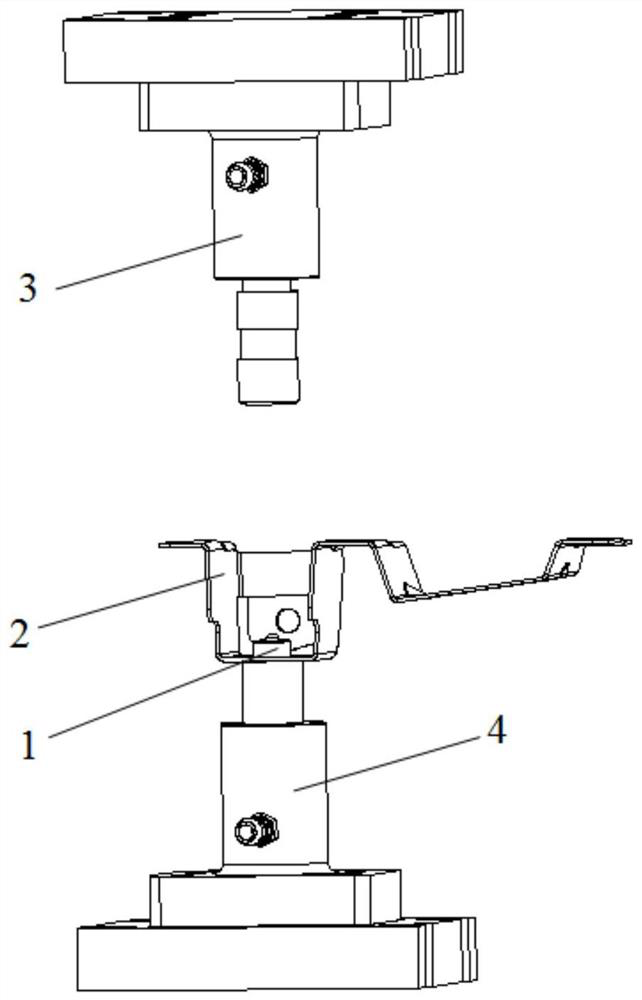

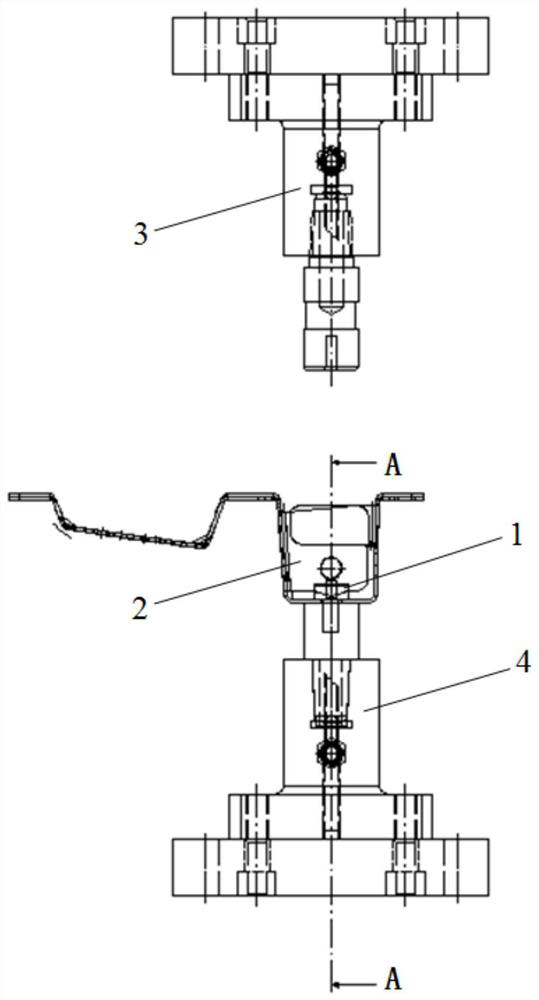

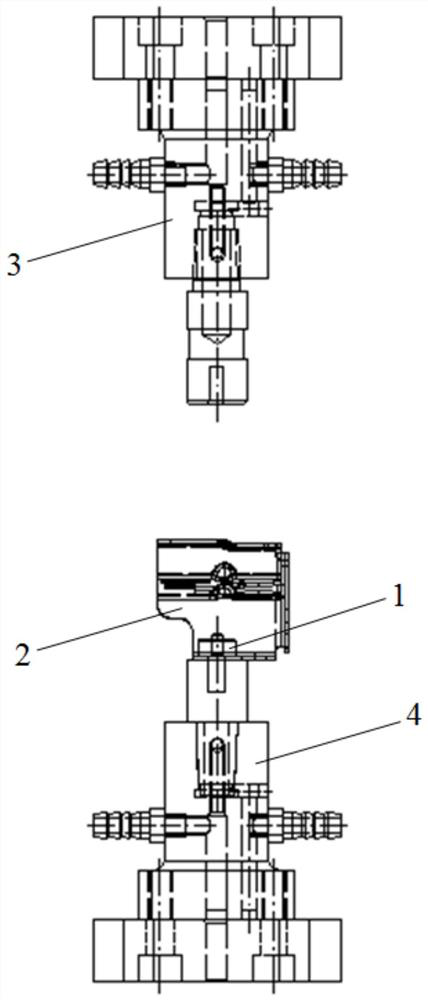

Positioning welding electrode for welding of automobile positioning hook

ActiveCN107457477ARapid positioningEasy to adjustVehicle componentsMetal working apparatusRebarClose contact

The invention relates to a positioning welding electrode for welding of an automobile positioning hook. The positioning welding electrode comprises an upper electrode and a lower electrode. The upper electrode and the lower electrode are fixed to a welding machine correspondingly. The lower electrode is provided with a floating positioning mechanism. The floating positioning mechanism comprises a main positioning unit, a mistake-proof positioning unit and a floating unit. During welding, a bending galvanized plate and a bending steel bar are combined and placed on the floating positioning mechanism for positioning. The upper electrode and the lower electrode are matched to weld the bending galvanized plate and the bending steel bar together. Compared with the prior art, welding parts can be rapidly positioned through the main positioning unit; the mistake-proof positioning unit can conduct accurate adjustment; the floating unit has the buffering effect during welding; it is guaranteed that the parts can make close contact with the lower electrode all the time to prevent suspension, so that the parts to be welded are accurately positioned and rapidly welded during welding. The positioning welding electrode is easy to operate, clear in step, convenient to disassemble and assemble and high in welding quality, welding stability and production efficiency.

Owner:SHANDONG AOLIN CAR FITTINGS

Gas-protection precision cold welding system with intermittent demagnetizing cooling device

PendingCN108213675AHigh consistency of welding qualityAchieve constant temperature controlCooled electrodesSustainable buildingsTemperature controlEngineering

The invention relates to the technical field of a cold welding machine, in particular to a gas-protection precision cold welding system with an intermittent demagnetizing cooling device. the gas-protection precision cold welding system comprises a cooling piston cylinder, a magnetic cold core, a magnetic cold core driving coil group, a cold end piston and a hot end piston, wherein the cooling piston cylinder is a cylindrical ceramic tube, and a cold exhaust hole, an air inlet hole and a hot exhaust hole are formed in the side face of the cooling piston cylinder from left to right in order; themagnetic cold core is a loose and porous paramagnetic material cylinder and is arranged at the center of the cooling piston cylinder, and the magnetic cold core driving coil group is twined on the area, corresponding to the magnetic cold core, of the outer side of the middle segment of the cooling piston cylinder; and the cold end piston is arranged on the left side of the cooling piston cylinder, and the hot end piston is arranged on the right side of the cooling piston cylinder. As a design of protecting-gas magnetic refrigeration is added, under the condition of refrigeration without adding a liquid channel and adopting a compressor, the gas-protection precision cold welding system realizes constant-temperature control for precision cold welding workpieces and improves the consistencyof welding quality of precision cold welding.

Owner:NINGXIA WUZHONG HAOYUN WELDER

Polishing device for welding tip

ActiveUS20200094366A1Simple configurationSimplify workEdge grinding machinesOther manufacturing equipments/toolsPolishingEngineering

A polishing device for a welding tip includes a cylindrical holder; and a polishing unit. The polishing unit includes a blade configured to polish a welding tip. The blade polishes the welding tip due to rotation of the polishing unit. The holder includes a groove extending along an entire inner circumference of the holder. The groove includes axial groove portions each of which extends along an axis of the holder, and inclined groove portions each of which extends for a specified first distance and is inclined in one direction with respect to the axial groove portions. The axial groove portions and the inclined groove portions are alternately arranged. The polishing unit includes projected portions each of which extends to an inside of the groove, and the number of the projected portions is two or more and is equal to or less than the number of the axial groove portions.

Owner:TOYOTA JIDOSHA KK

Polishing device for welding tip

ActiveCN110936162AConvenient grinding operationLow costOther manufacturing equipments/toolsGrinding machinesPolishingEngineering

A polishing device for a welding tip includes a cylindrical holder; and a polishing unit. The polishing unit includes a blade configured to polish a welding tip. The blade polishes the welding tip dueto rotation of the polishing unit. The holder includes a groove extending along an entire inner circumference of the holder. The groove includes axial groove portions each of which extends along an axis of the holder, and inclined groove portions each of which extends for a specified first distance and is inclined in one direction with respect to the axial groove portions. The axial groove portions and the inclined groove portions are alternately arranged. The polishing unit includes projected portions each of which extends to an inside of the groove, and the number of the projected portionsis two or more and is equal to or less than the number of the axial groove portions.

Owner:TOYOTA JIDOSHA KK

Drawback valve systems and methods for coolant drawback

ActiveUS20160067816A1Reduce and eliminate liquid lossReduce or eliminate liquid lossEngine diaphragmsFlexible member pumpsSuction forceCoolant flow

A first electrode coolant path is configured to cool a first welding electrode by liquid coolant flowing from a supply path through the first electrode coolant path to a return path. A second electrode coolant path is configured to cool a second welding electrode by liquid coolant flowing from the supply path through the second electrode coolant path to the return path. Three or more valves are configured to stop or reduce liquid coolant flow through the first or second electrode coolant path and configured to stop or reduce liquid coolant backflow from the return path when the first or second welding electrode is at least partially detached. At least one valve is coupled in the first or second electrode coolant path. A drawback apparatus generates a suction force to draw liquid coolant away from a gap formed when the first or second welding electrode is at least partially detached.

Owner:PROTEUS INDUSTRIES INC

Weld electrode plugs with polymeric inserts for loss-of-cooling detection in welding systems

ActiveUS10632561B2Efficient and rapid detectionReduce in quantityResistance electrode holdersOperating means/releasing devices for valvesCoolantShape-memory polymer

Owner:GM GLOBAL TECH OPERATIONS LLC

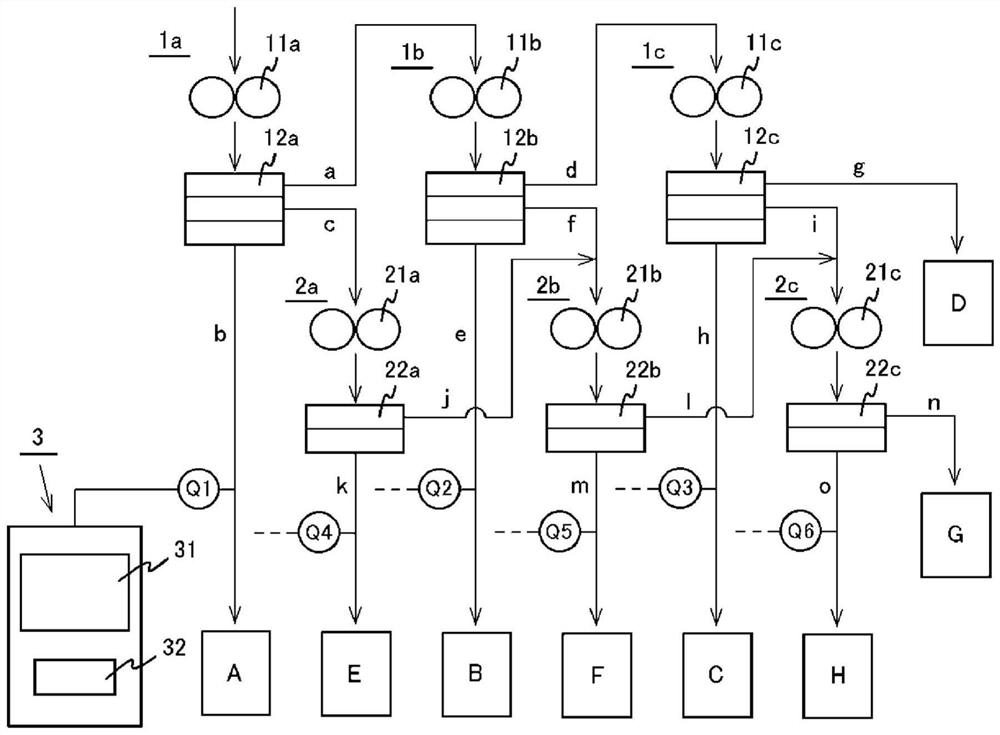

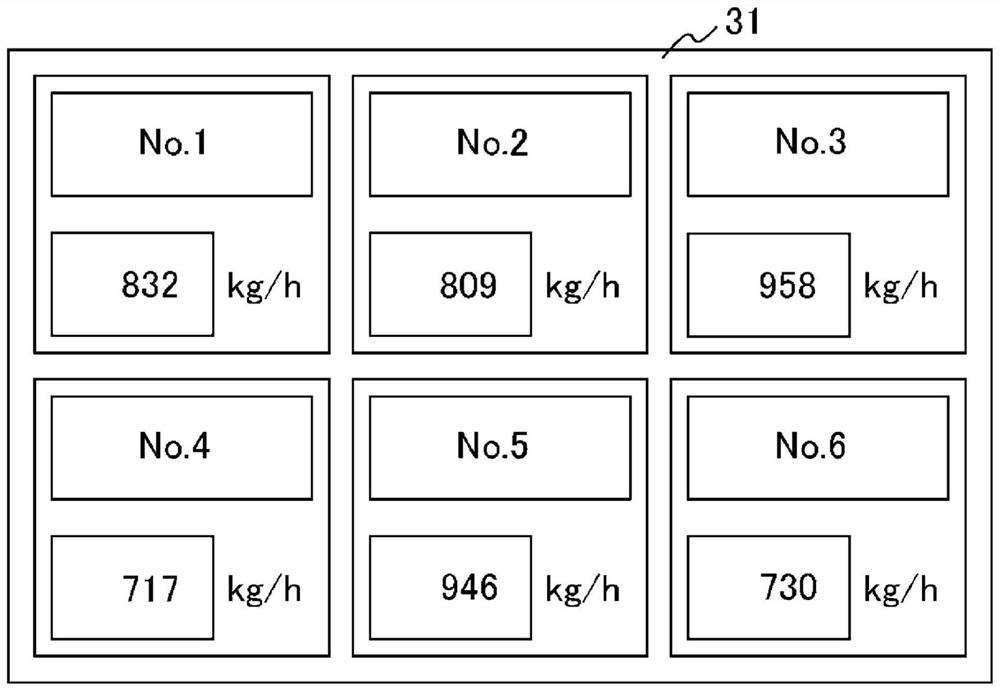

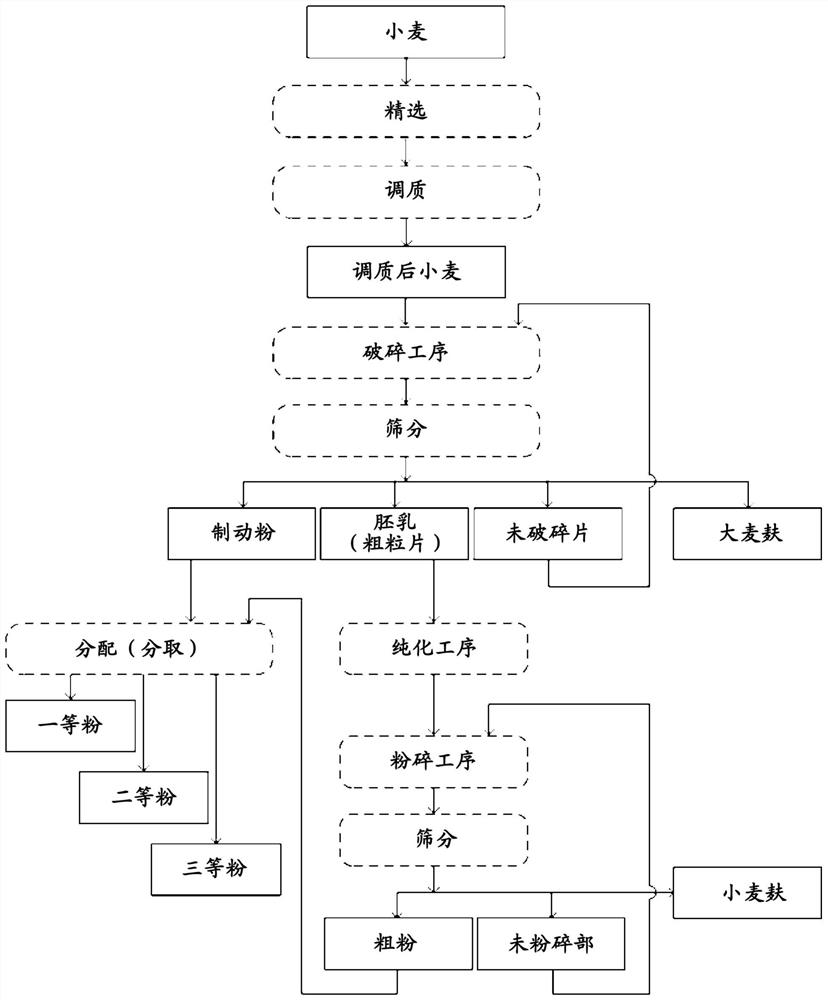

Monitoring system for milling equipment

ActiveCN113677437ASure easyImprove qualityGrain huskingGrain polishingMonitoring systemProcess engineering

Provided is a monitoring system for milling equipment that includes a plurality of crushing units each including a roll milling machine for crushing a material-to-be-milled and a sieving machine for sieving the material-to-be-milled crushed by the roll milling machine according to particle size, and a plurality of pulverizing units each including a roll milling machine for pulverizing the material-to-be-milled and a sieving machine for sieving the material-to-be-milled pulverized by the roll milling machine according to particle size, and that gradually mills the material-to-be-milled, which is a raw material, by means of the crushing units and the pulverizing units, the monitoring system comprising: a plurality of flow rate measuring devices each provided in each flow path of rising powder discharged from each sieving machine of each crushing unit and each pulverizing unit; and a monitoring device capable of monitoring the presence or absence of an abnormality. The monitoring device is capable of monitoring the presence or absence of an abnormality, on the basis of the measurement result of each flow rate of the rising powder by each flow rate measuring device.

Owner:SATAKE CORP

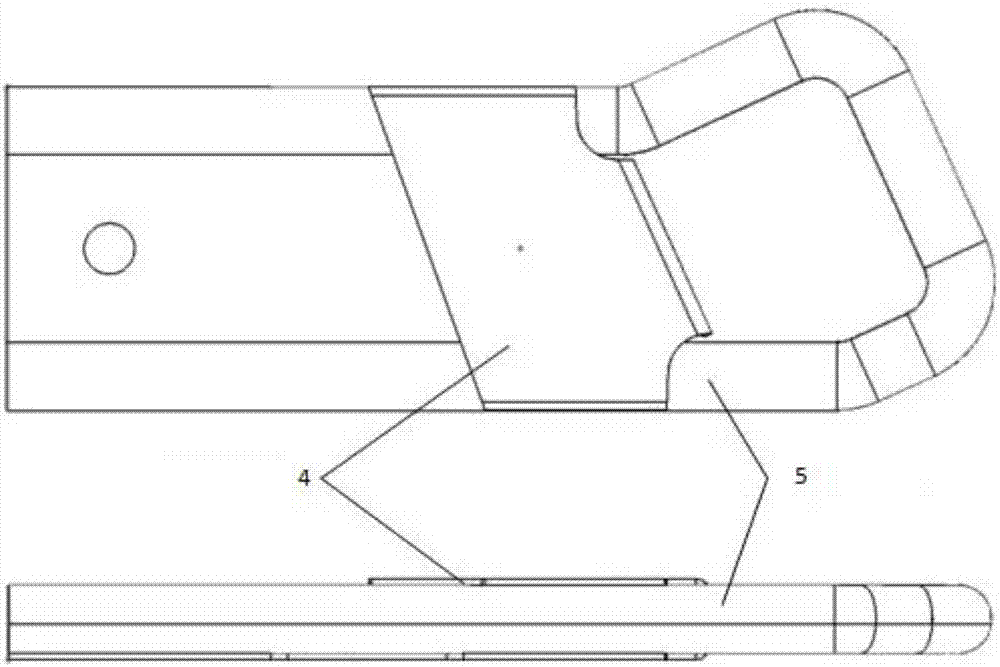

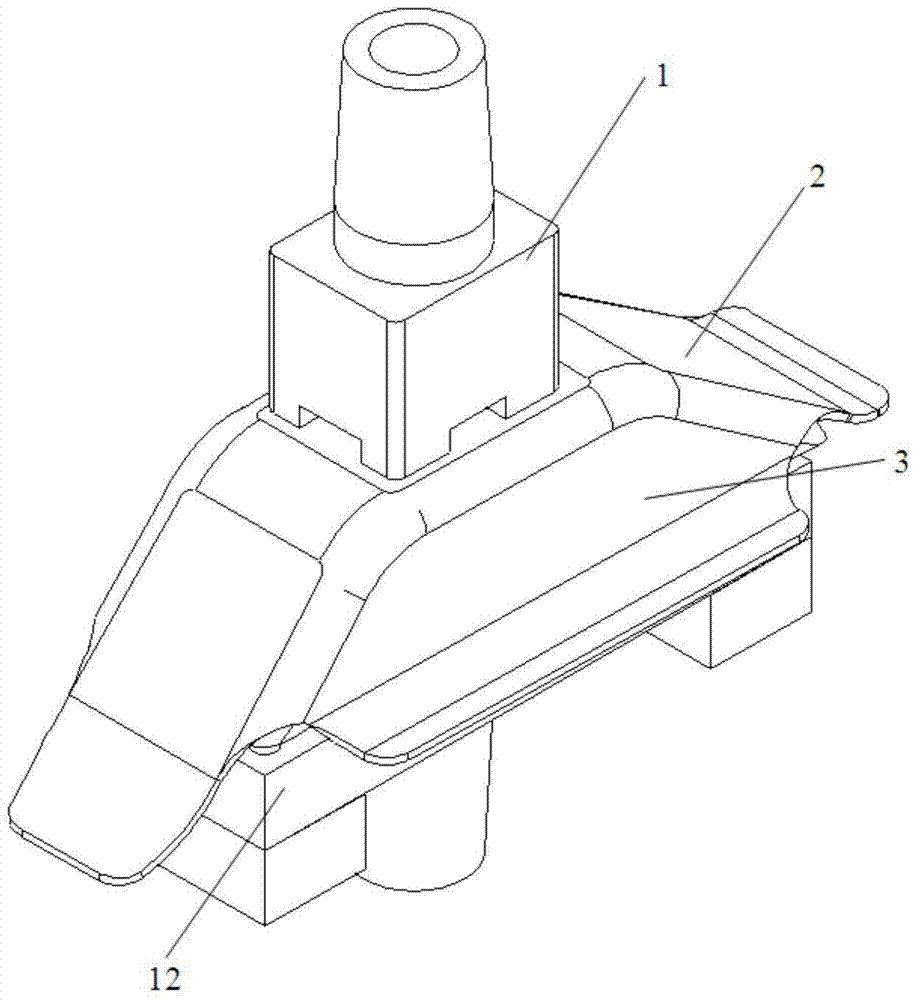

A positioning welding tool electrode for automobile reinforcement plate

ActiveCN105057866BEasy to disassemble and overhaulImprove stabilityResistance electrode holdersWelding/cutting auxillary devicesElectrical resistance and conductanceMechanical engineering

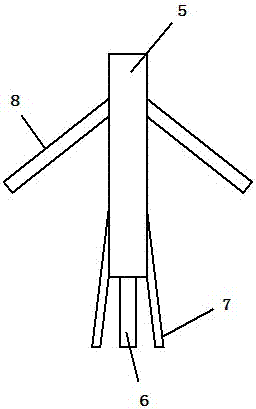

The invention relates to a positioning and welding tool electrode used for an automobile reinforcement plate. The electrode is fixed to a resistance welding machine and used for welding a to-be-welded accessory (5) to the automobile reinforcement plate (2). The positioning and welding tool electrode comprises an upper electrode (1), a lower electrode (11) and a positioning mechanism. The upper electrode (1) and the lower electrode (11) are both fixed to the resistance welding machine. When the reinforcement plate (2) and the to-be-welded accessory (5) are welded, the reinforcement plate (2) and the to-be-welded accessory (5) are positioned and fixed through the positioning mechanism. The to-be-welded accessory (5) is welded to the reinforcement plate (2) through the upper electrode (1) and the lower electrode (11). Compared with the prior art, the positioning and welding tool electrode has the advantages of being easy and convenient to operate, convenient to overhaul, disassemble and assemble, high in error detection property, high in welding quality stability, high in production efficiency, and the like.

Owner:奥林汽车零部件(常熟)有限公司

Welding electrodes and adapter therefor

ActiveUS10730135B2Improve the immunityReduce resistanceResistance electrode holdersElectrode maintenanceEngineeringMechanical engineering

Owner:PRUCHER BRYAN

Improved welding robot and welding method thereof

PendingCN107042356AEfficient weldingImprove melting effectResistance electrode holdersCooled electrodesAgricultural engineeringEngineering

The invention discloses an improved welding robot comprising a rack. Die side plates are arranged on the rack. A gap is arranged between the die side plates. Electrowelding anodes are arranged above the die side plates. Electrowelding cathodes are arranged below the die side plates. The electrowelding anodes and the electrowelding cathodes are arranged on drive mechanisms correspondingly. Each electrowelding anode comprises an installation rod, wherein a first electrode is arranged at the bottom of the installation rod, second electrodes are arranged on the two sides of the first electrode, and two pneumatic support rods are further arranged on the installation rod. Each electrowelding cathode comprises an installation plate, wherein a third electrode is arranged on the installation plate, and a plurality of cooling water circulating tubes are arranged on the two sides of the third electrode. The invention further discloses a welding method of the welding robot. Through the improved welding robot and the welding method thereof, the deficiencies of the prior art can be overcome, and automatic welding of a weld joint in a narrow bent position is achieved.

Owner:赖连容

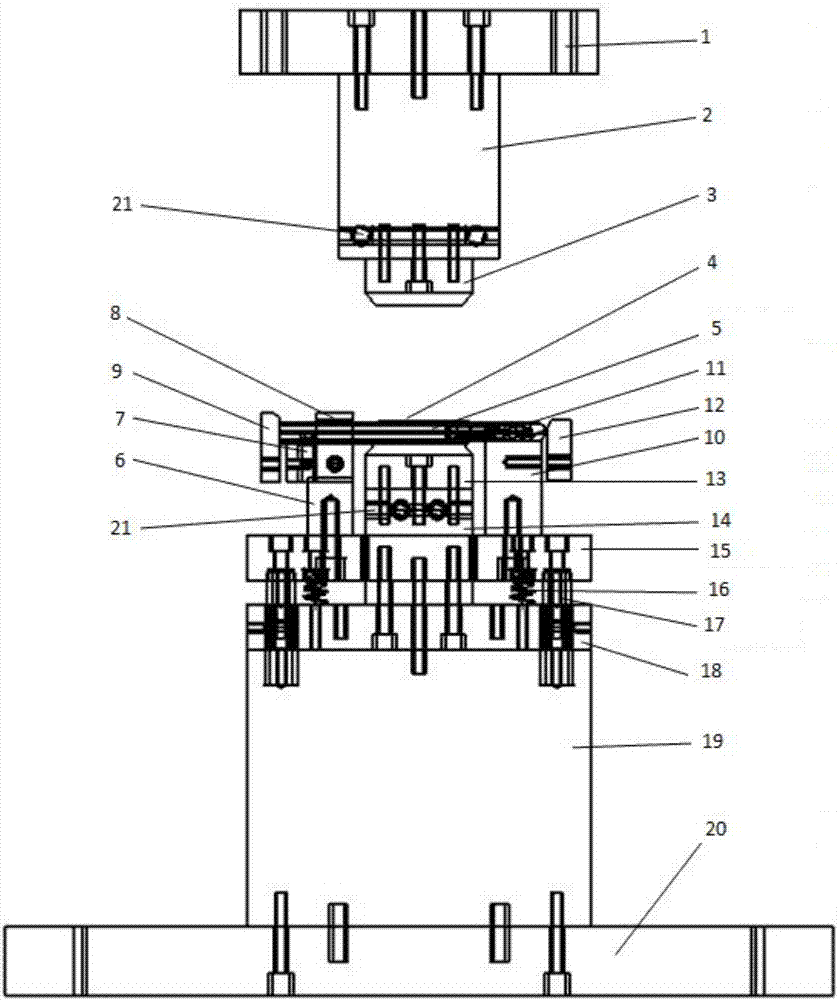

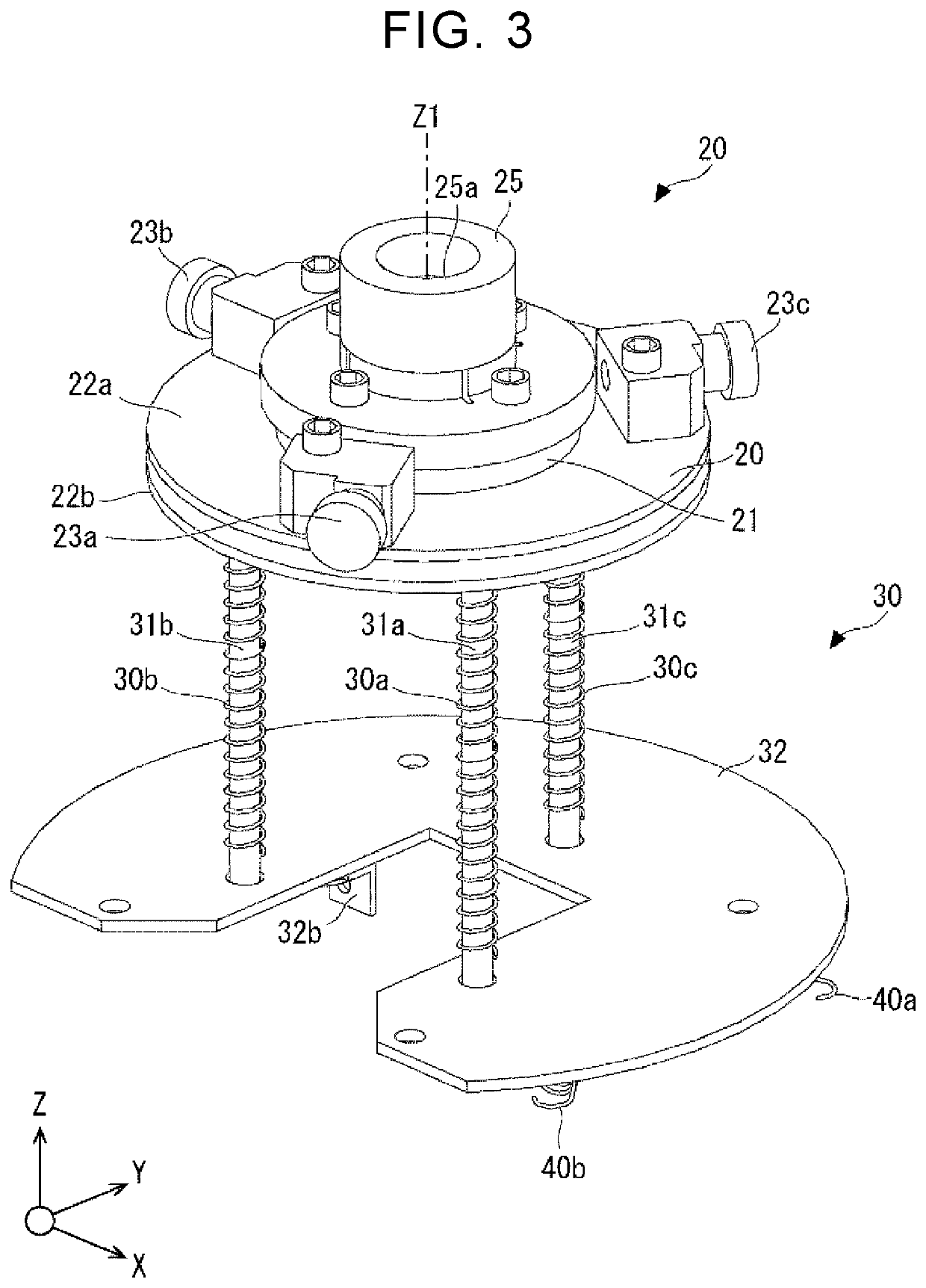

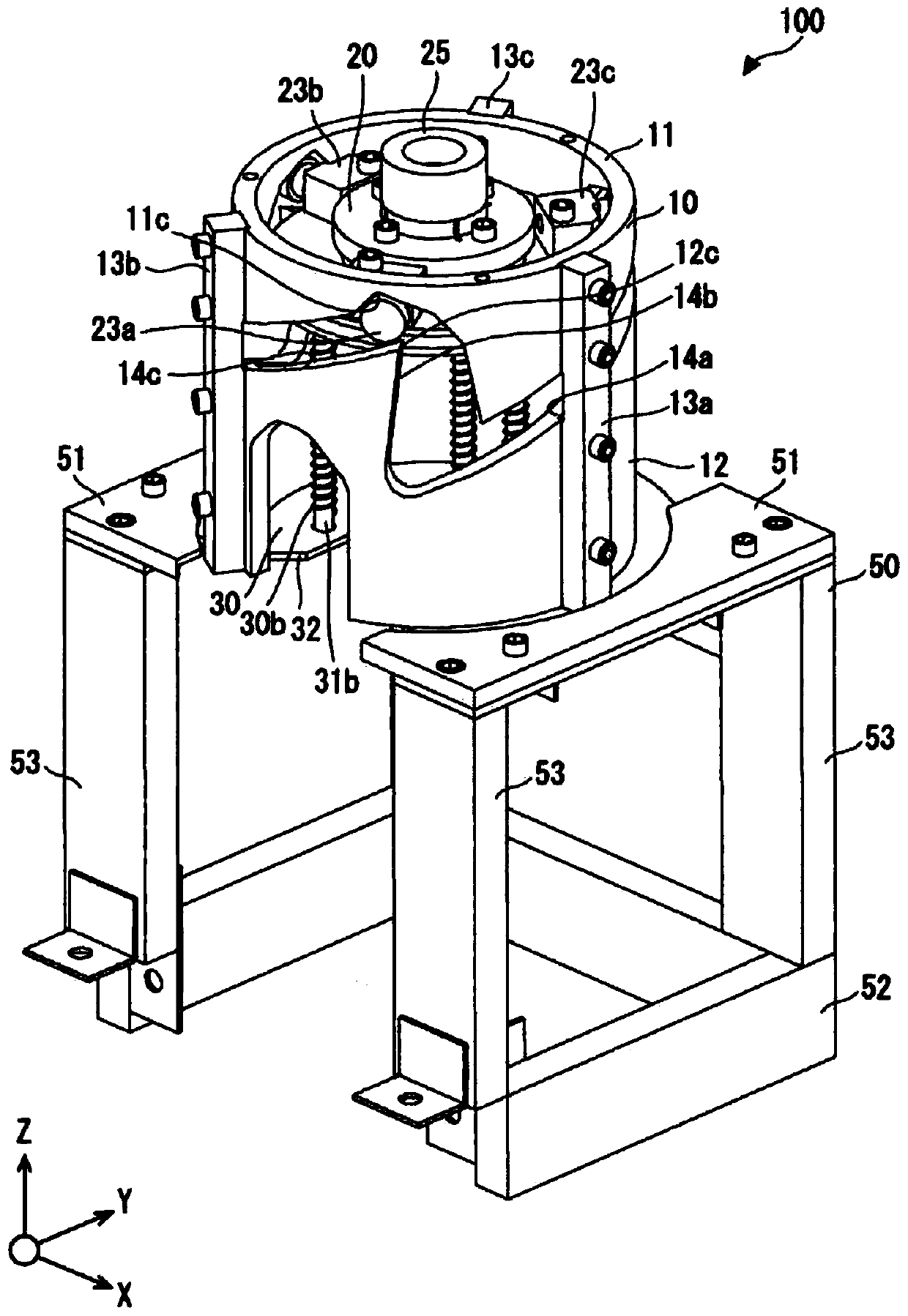

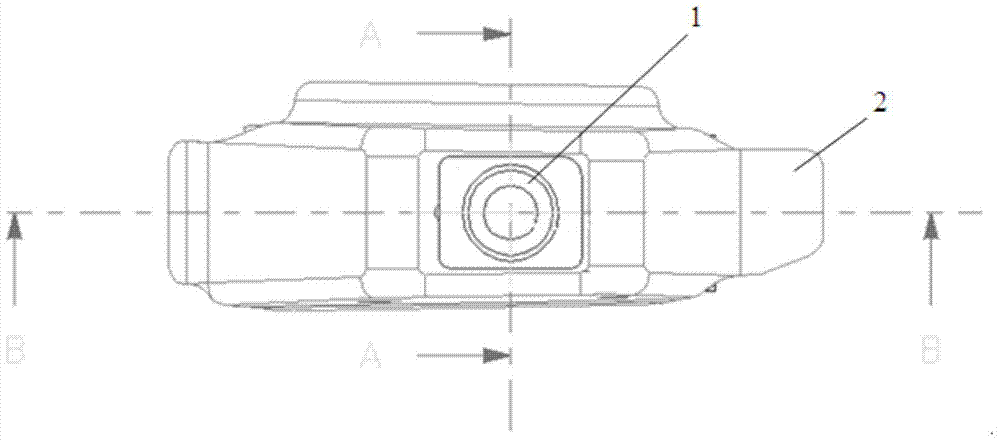

Positioning projection welding electrode

PendingCN111702314AEasy to realize installation positioningRealize installation positioningCooled electrodesSlag (welding)Heat resistance

The invention relates to a positioning projection welding electrode. The positioning projection welding electrode is used for welding a mounting nut to a part to be mounted and comprises an upper electrode and a lower electrode; the lower electrode comprises a lower electrode base, an electrode connecting rod, a lower electrode rod and an electrode positioning pin arranged at the top of the lowerelectrode rod which are sequentially arranged from bottom to top; and a mounting hole and the mounting nut on the part to be mounted are sequentially sleeved on the electrode positioning pin from bottom to top. Compared with the prior art, through a part fixing column body and a bolt fixing column body, mounting and positioning of the part to be mounted and the mounting nut are achieved conveniently, the problem of dislocation of the part to be mounted and the mounting nut is avoided, and the welding qualification rate is increased; in addition, the positioning pin is made of a KCF material, has the advantages of being high in insulation effect, good in heat resistance, high in production efficiency, excellent in toughness, abrasion resistance and fracture resistance and the like, and effectively solves the problems that an iron positioning pin is fast in abrasion, welding slag is likely to be generated, and a ceramic positioning pin is likely to be fractured.

Owner:SHANDONG AOLIN CAR FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com