Gas-protection precision cold welding system with intermittent demagnetizing cooling device

A technology of cooling device and gas protection, applied in the direction of cooling electrodes, welding equipment, resistance welding equipment, etc., can solve the problems of poor applicability, heavy weight, complex structure, etc., and achieve the effect of improving the consistency of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

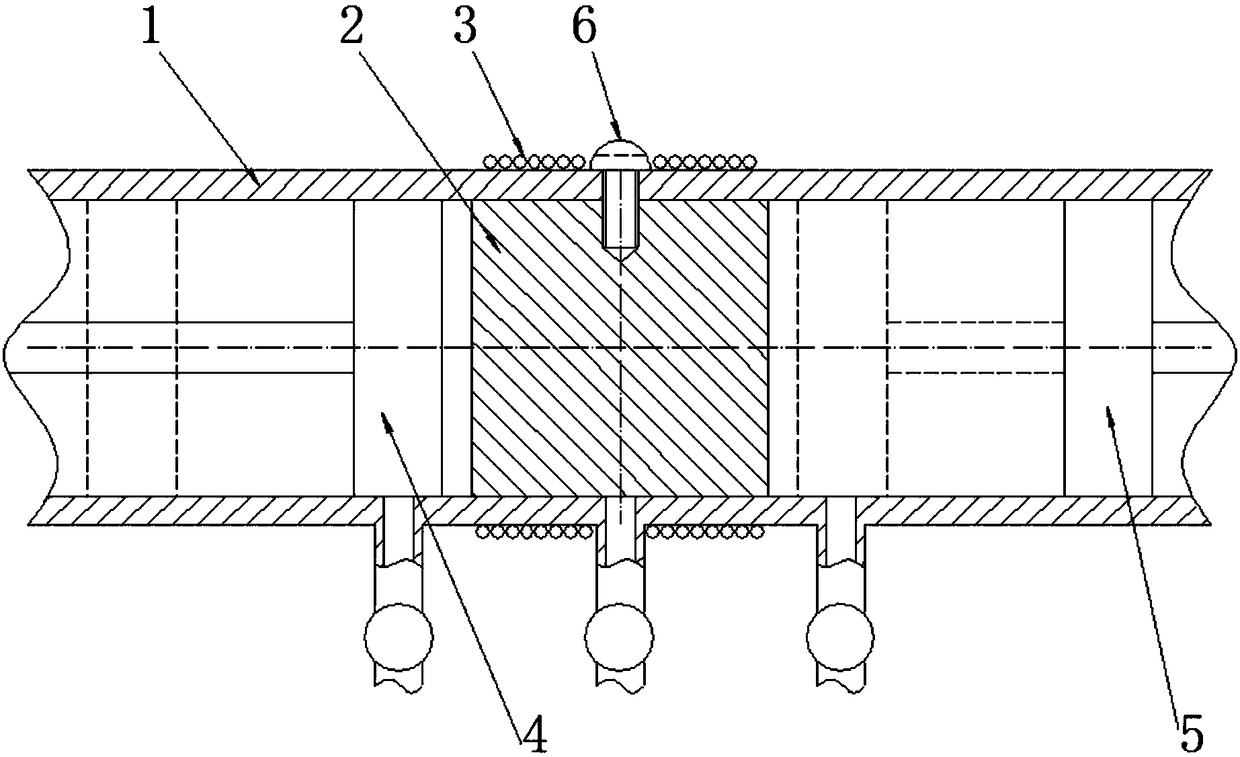

[0026] Specific embodiment one: a gas-shielded precision cold welding system with an intermittent demagnetization cooling device, including: a cooling piston cylinder 1 assembly and a cold welding electrode assembly.

[0027] Among them, the cooling piston cylinder 1 assembly includes a cooling piston cylinder 1, a magnetic cooling core 2, a magnetic cooling core driving coil group 3, a cold end piston 4, a hot end piston 5, and a magnetic cooling core fastening screw 6; the cooling piston cylinder 1 is a cylinder Shaped ceramic tube, its side from left to right according to open cold exhaust hole, air intake hole, hot exhaust hole; The air inlet fits together and is located between the cold exhaust hole and the hot exhaust hole; the magnetic cooling core fastening screw 6 passes through the cooling piston cylinder 1 cylinder wall and connects with the magnetic cooling core 2, and the magnetic cooling core 2 is tightened by the magnetic cooling core. The solid screw 6 is fixed...

specific Embodiment 2

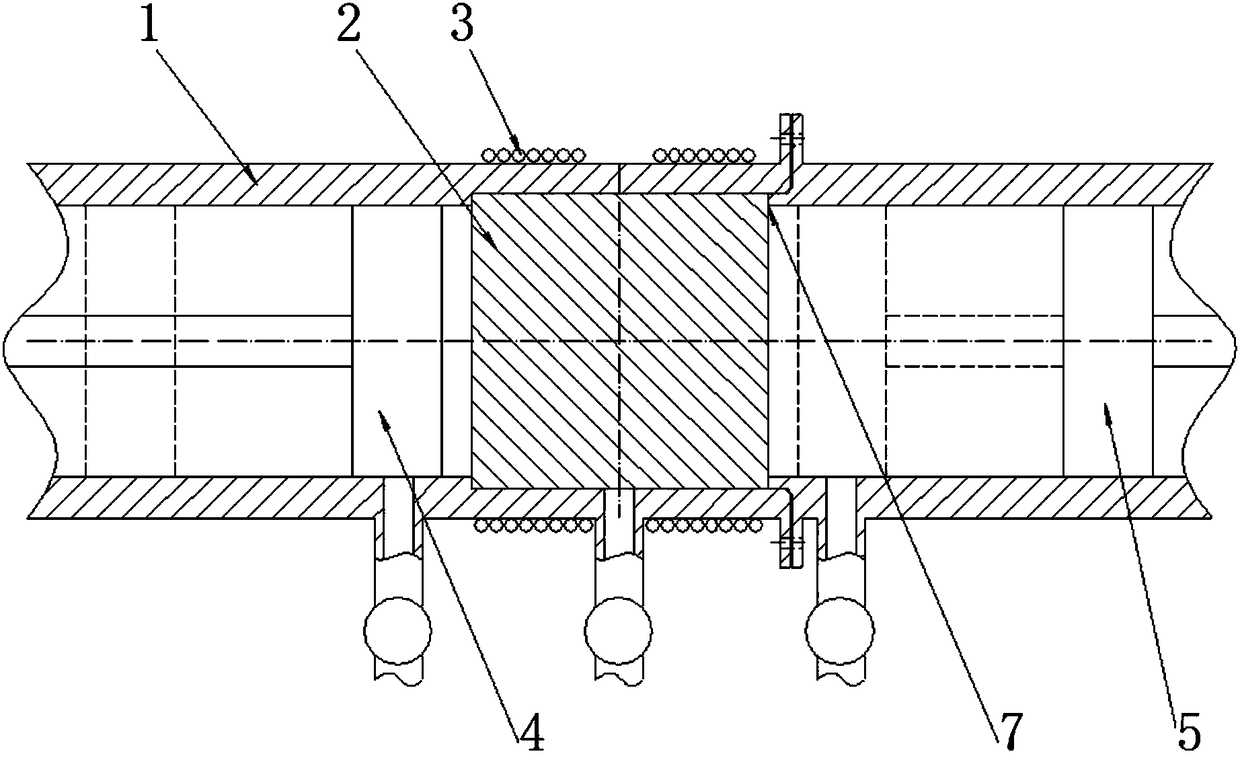

[0029] Specific embodiment 2: a gas-shielded precision cold welding system with an intermittent demagnetization cooling device, including: a cooling piston cylinder 1 assembly and a cold welding electrode assembly.

[0030] Among them, the cooling piston cylinder 1 assembly includes the cooling piston cylinder 1, the magnetic cooling core 2, the magnetic cooling core drive coil group 3, the cold end piston 4, and the hot end piston 5; the cooling piston cylinder 1 is a cylindrical ceramic tube, and its side is from the left To the right, open the cold exhaust hole, the air intake hole, and the hot exhaust hole; Between the exhaust hole and the hot exhaust hole; the piston cylinder is composed of left and right parts connected, the connection is located at one end of the magnetic cooling core 2, and the piston cylinder is provided with a magnetic cooling core slot 7 at the magnetic cooling core 2; the magnetic cooling core drives The coil group 3 is wound and installed in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com