Silver-based brazing paste and preparation method and application thereof

A brazing paste, silver-based technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of complex preparation process and high processing cost, and achieve simple operation process, high welding quality consistency, and easy automatic welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

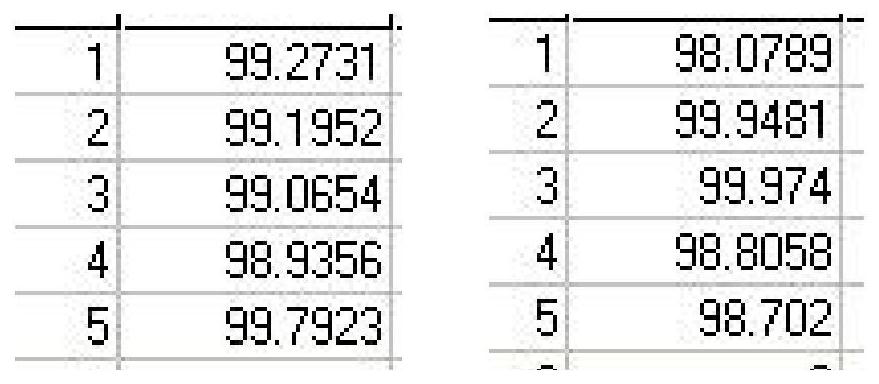

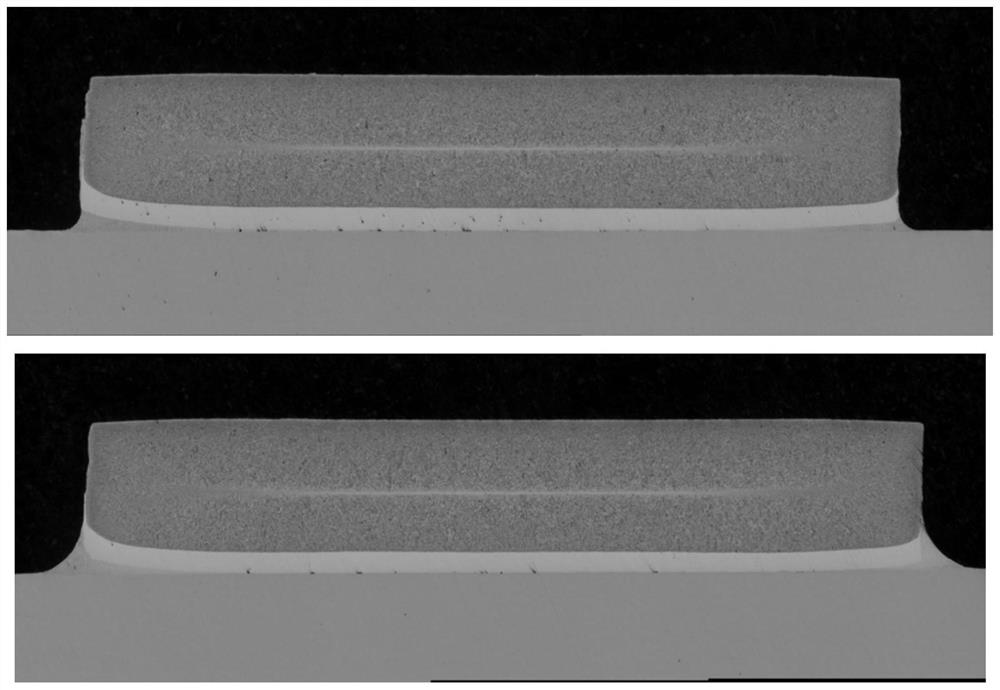

[0025] Such as Figure 1 to Figure 3 As shown, in the embodiment of the present invention, the present invention can obtain silver-based solder paste with low cost and high soldering quality through a simple preparation process. The present embodiment provides a kind of preparation method of the silver brazing paste of high soldering quality, and its implementation step is processed in the existing dispersing mixer;

[0026] Step 1: Preparation of binder. In this step, the binder is mixed and stirred with polyisobutylene, D80 solvent oil, surfactant, thixotropic agent and other materials. The specific operations are as follows:

[0027] Select a stainless steel container and mark the weight, weigh a certain amount of polyisobutylene with an electronic scale, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com