Patents

Literature

30results about How to "Easy to form industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing starch glue for lumber

InactiveCN1687279AHigh bonding strengthImprove water resistanceStarch derivtive adhesivesAdjuvantPlasticizer

The present invention relates to a preparation method of starch glue for wood. Said invention uses starch as main raw material, and adopts the following steps: firstly, making starch undergo the processes of acidolysis, oxidation and graft copolymerization, etc., then adding modifying agent and complexing agent to make cross-linking modification, then heating and gelatinizing, cooling and successively adding the adjuvants of diluent, plasticizer and defoaming agent so as to obtain a starch glue with excellent performance for wood.

Owner:JIANGNAN UNIV

Completely degradable plant protein wood adhesive and preparation thereof

ActiveCN101412899AAdd health stepsImprove water resistanceProtein adhesivesGlue/gelatin preparationAdhesivePreservative

The invention relates to a full biodegradable plant protein wood adhesive and a preparation method thereof, and belongs to the technical field of adhesive. The adhesive is prepared from the following components in weight portion: 100 portions of water, 5 to 20 portions of plant protein powder, 0 to 15 portions of acidity regulator, 0.05 to 20 portions of modifying agent, 0.05 to 10 portions of assistant, 0.1 to 10 portions of preservative, and 0 to 10 portions of stuffing. The preparation method comprises the following steps in turn: adding the water into a container, and dissolving the acidity regulator under a stirring state; adding the plant protein powder into the container under the stirring state; at the same time, complementing the acidity regulator according to change situations of pH values; heating a reaction system to a temperature needed by modification reaction, adding the modifying agent and the assistant into the container under the stirring state, and keeping the temperature to make the mixture reacted for 15 to 240 minutes at a temperature of between 5 and 60 DEG C; and in the last 2 to 5 minutes of the temperature keeping reaction, adding the preservative into the solution, and stirring the mixture evenly; and adding the stuffing into the reaction system, stirring evenly the mixture, and finally obtaining the wood adhesive. The adhesive has the advantages that the adhesive is easy to process, good in adhering property, and degradable.

Owner:郑州佰沃科技发展有限公司

Method for preparing natural nontoxic adhesive for wood use

InactiveCN1462786ANovel ideaProcess specificationStarch adhesivesSodium polyacrylateBuilding material

A natural non-toxic adhesive for wood used as building material or decorative material contains main material which is prepared from corn or cassava starch, water and assistant through emulsifying, oxidizing, etherifying, esterifying and cross-linking, polyvinyl alcohol as intensifer, solution of sodium polyacrylate as stabilizer, assistant and water. Its advantages are no poison and irritation, good water-proof nature, high drying speed and adhesion.

Owner:武汉正轩宇生物科技有限公司

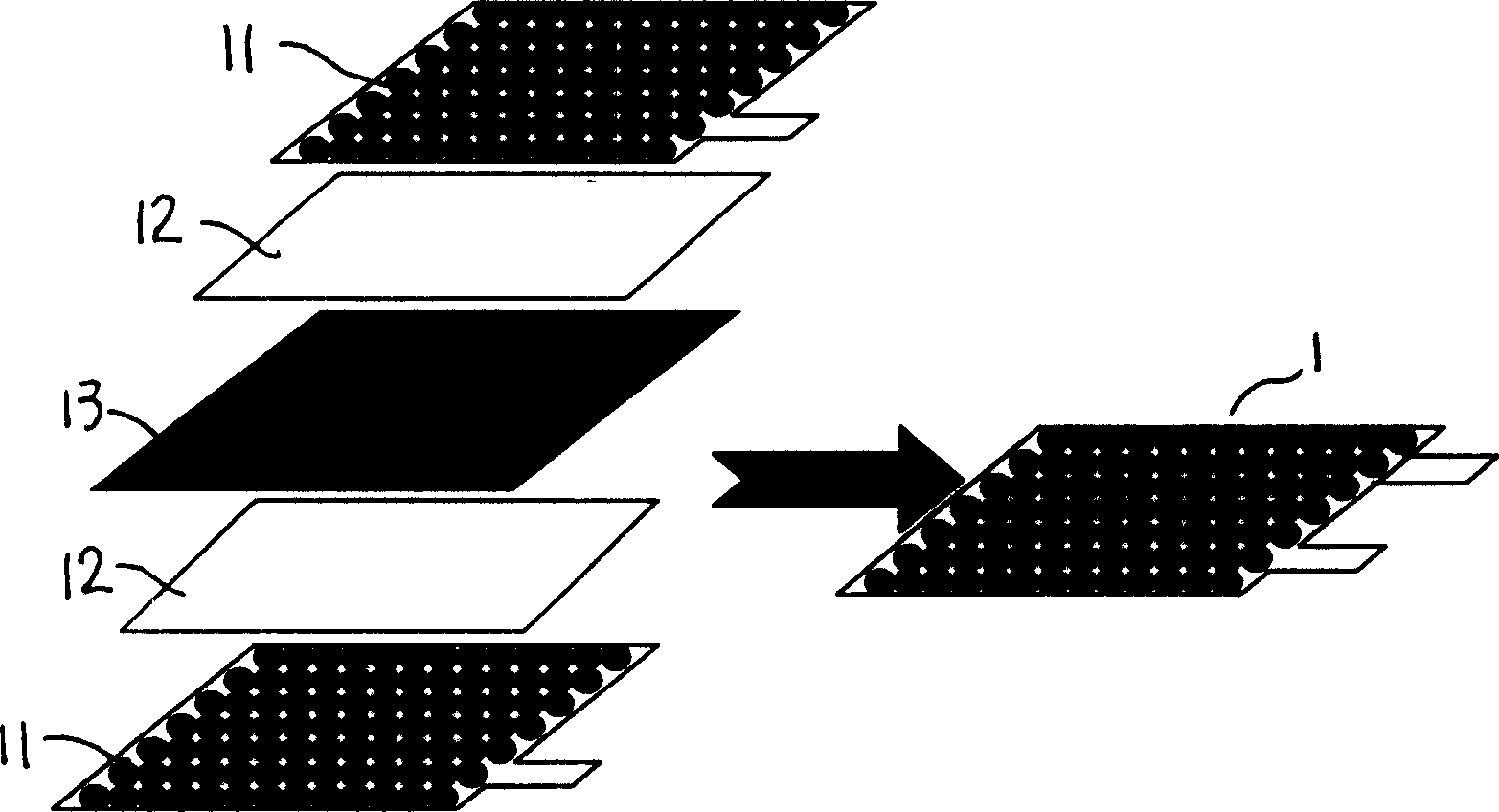

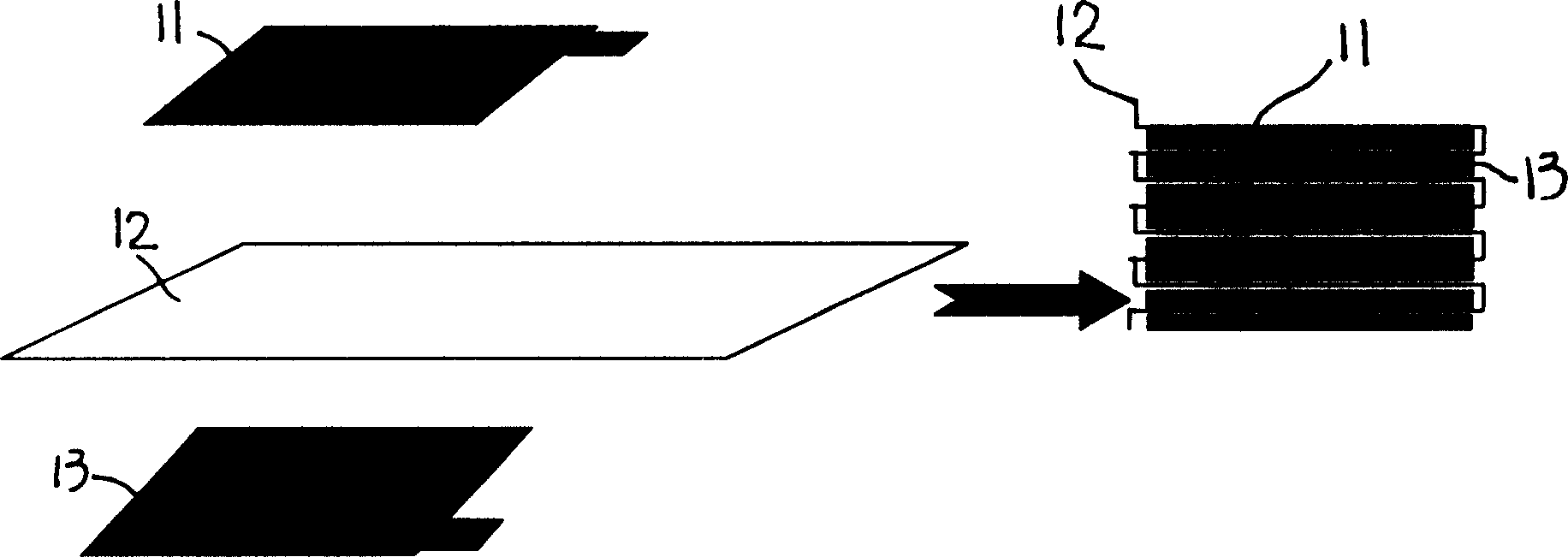

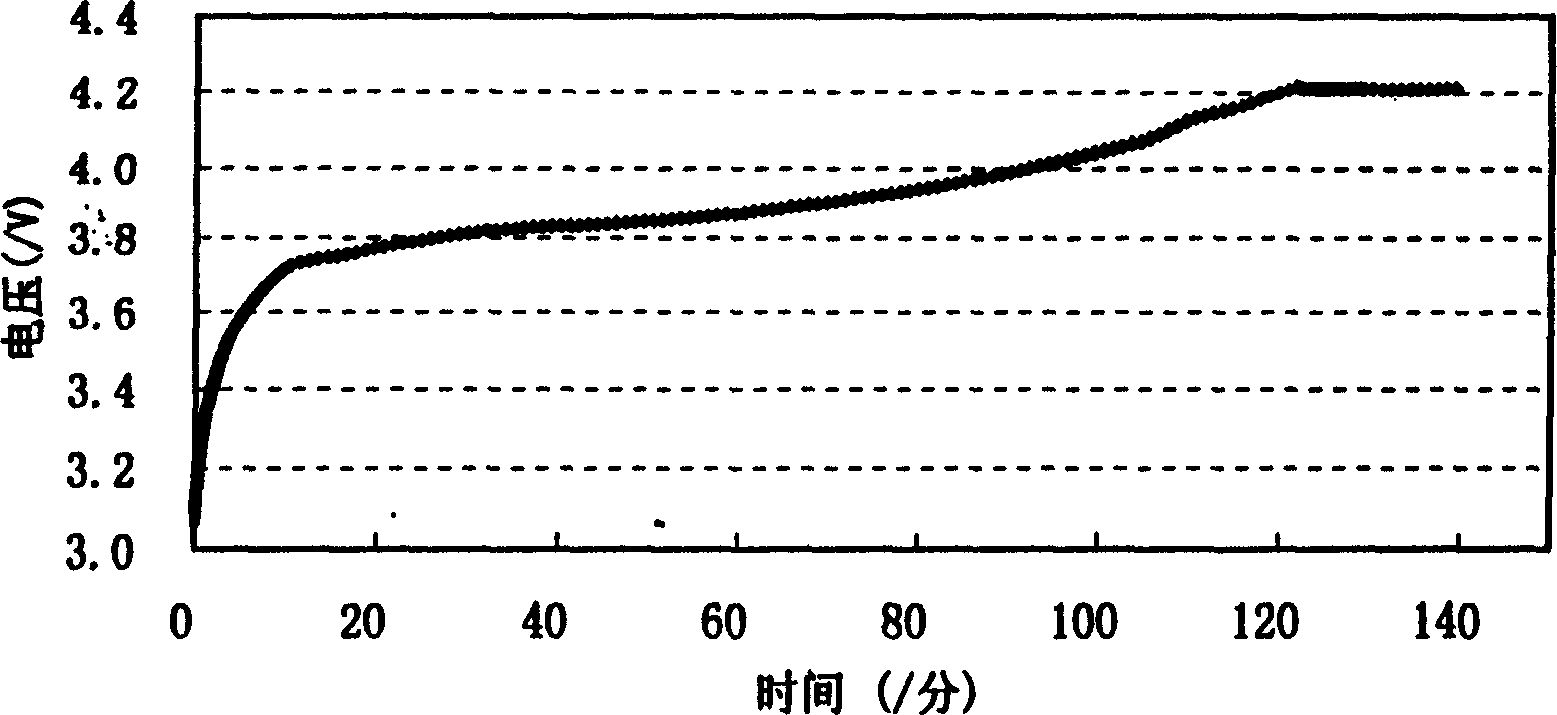

Isolation diaphragm for secondary polymer lithium cell and its making method

This invention discloses a method for using the multipolymer of PVDF or VDF with hexafluoropropylene as the host and utilizing phase separation, polymer alloy and cross-link technology to prepare a new type of porous isolation membrane and its manufacturing method. The thickness of the isolation membrane is 15-50 mum with the advantage of high strength, uniform slots, high conductivity, which is well immersed into the electrolyte and not necessary to be extracted.

Owner:DONGGUAN NEWPOWER ELECTRIC SCI & TECH

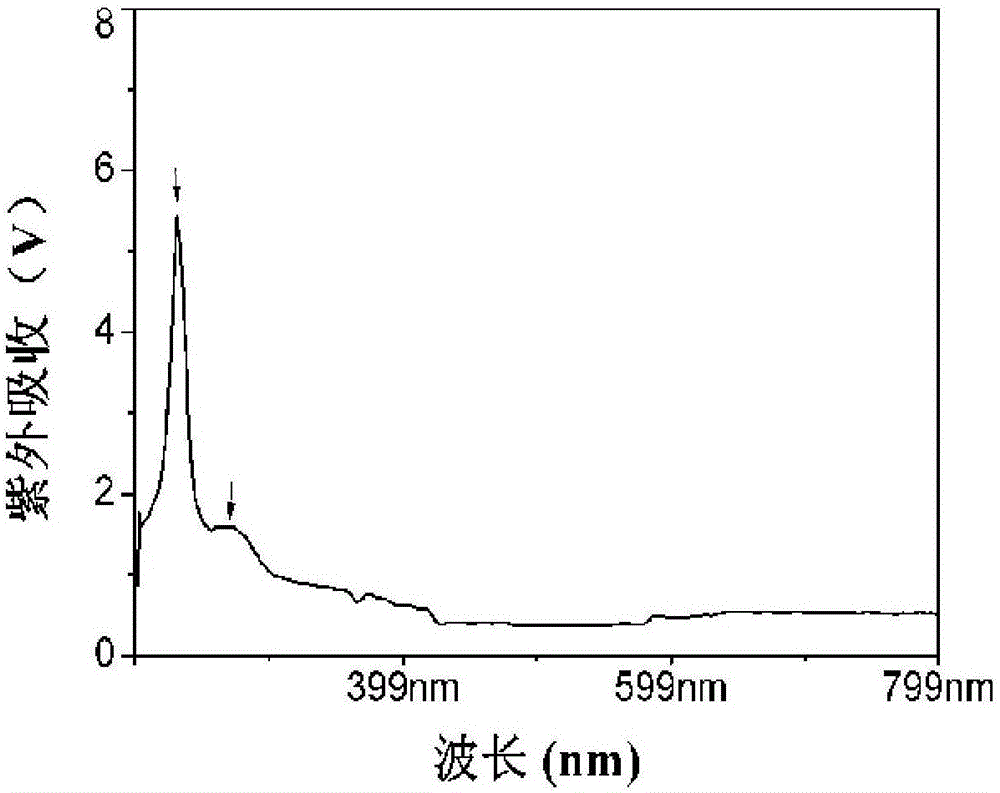

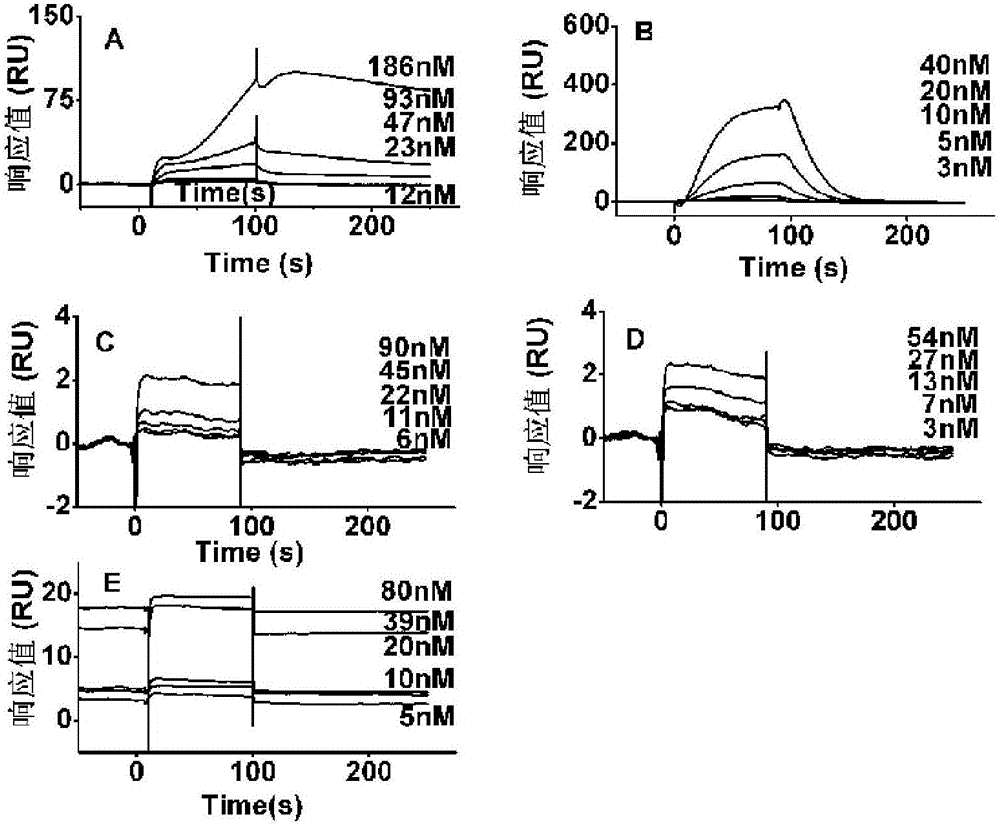

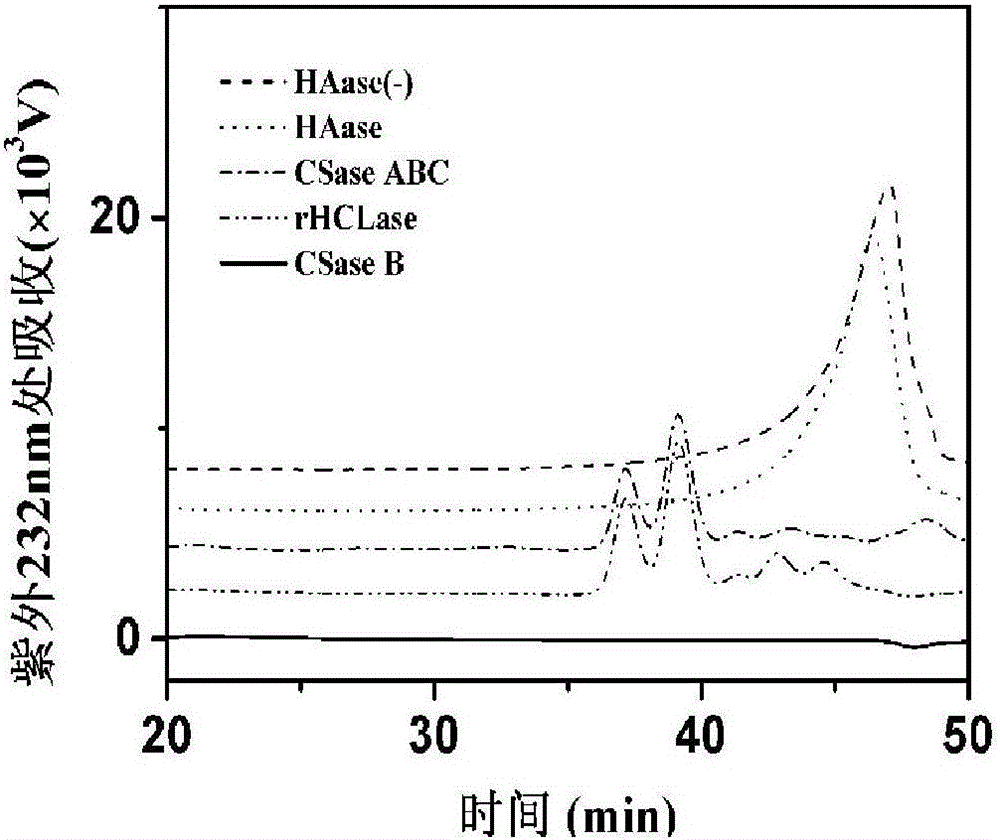

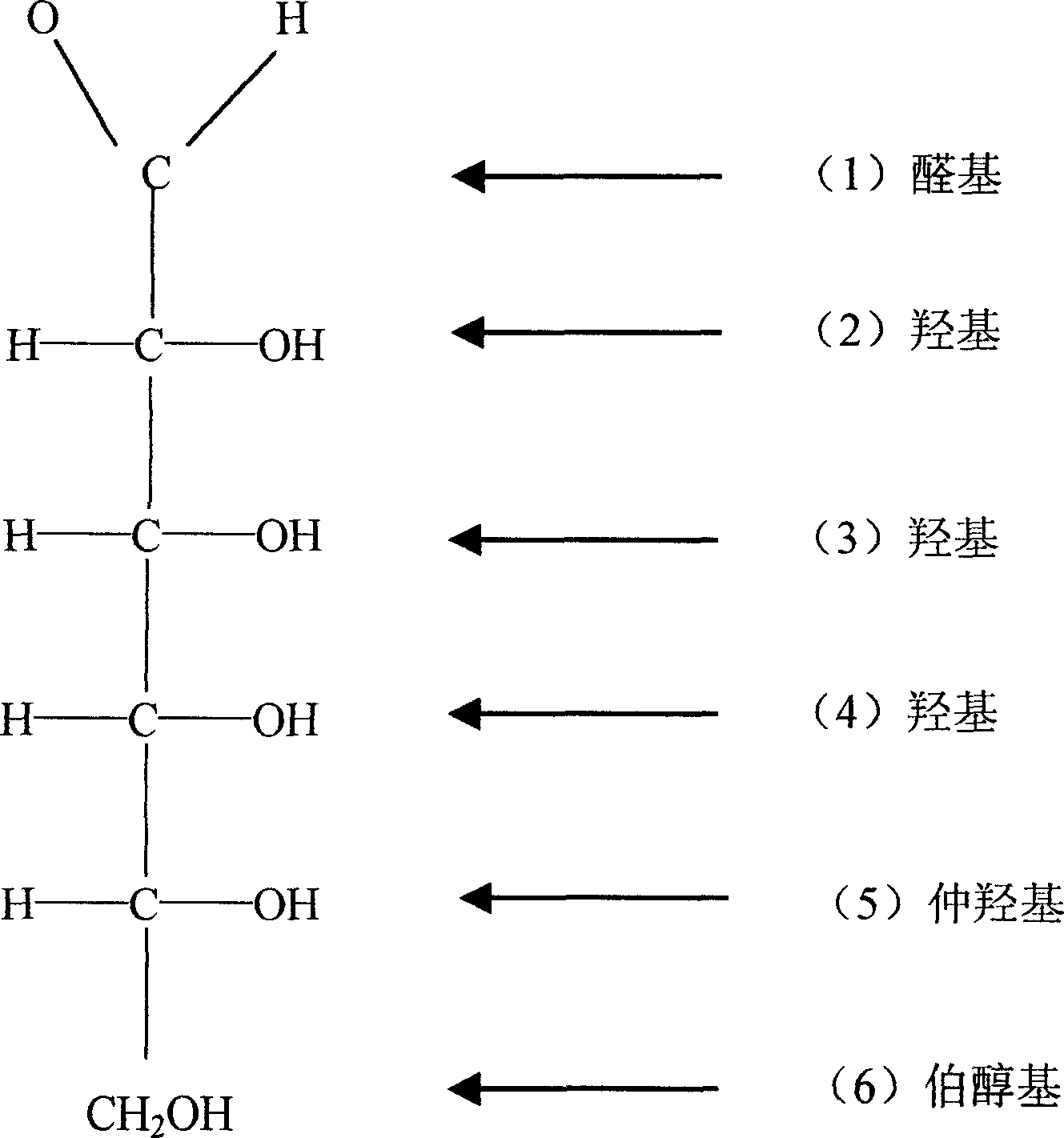

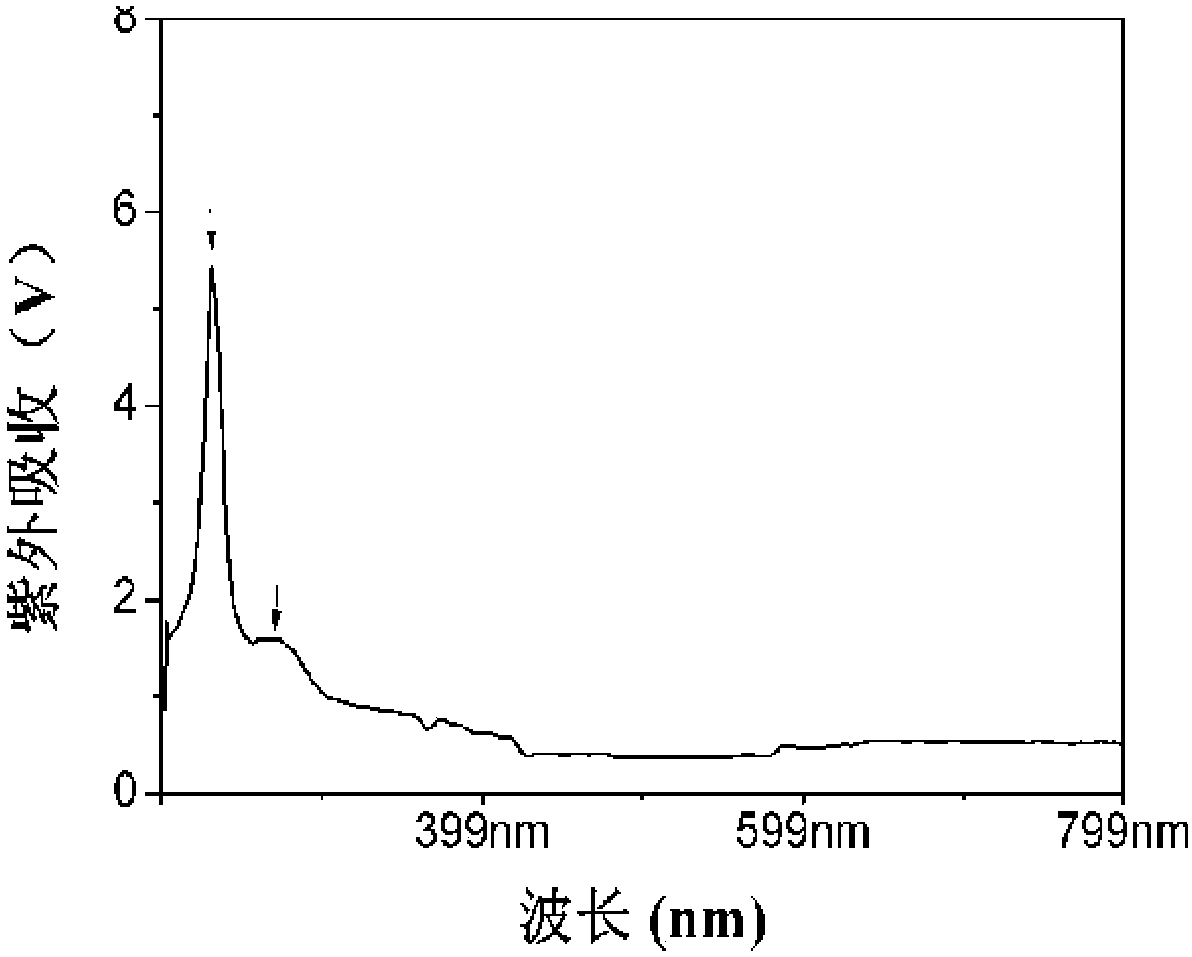

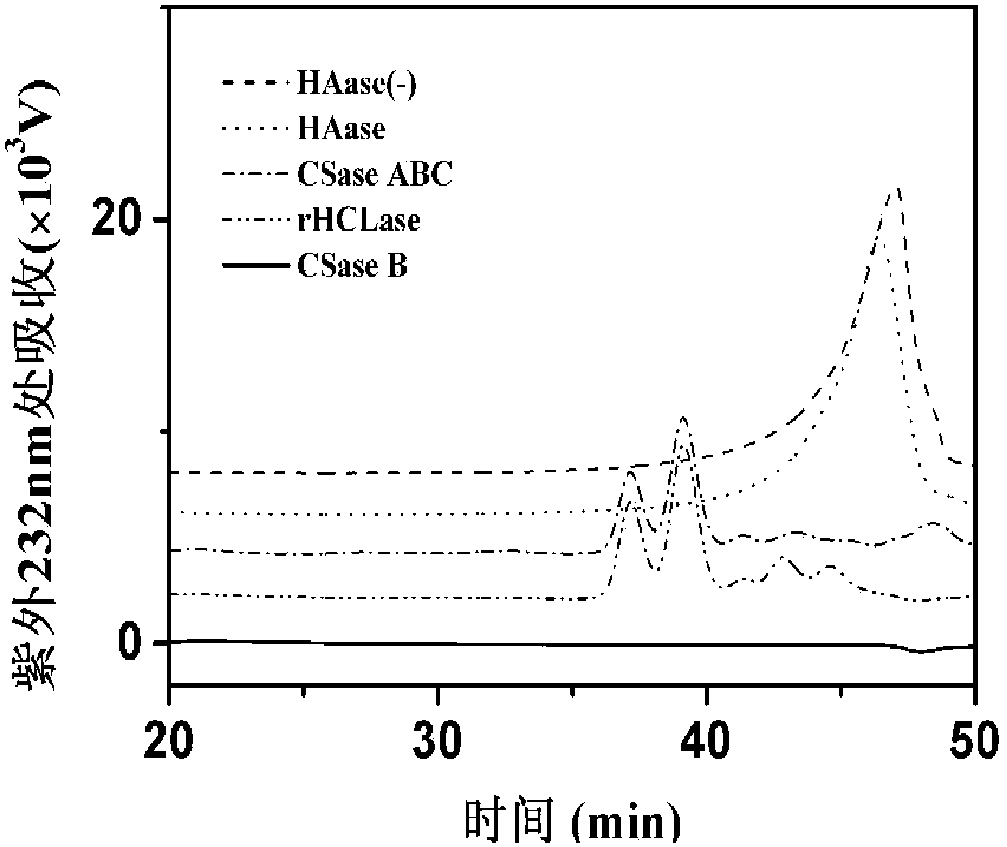

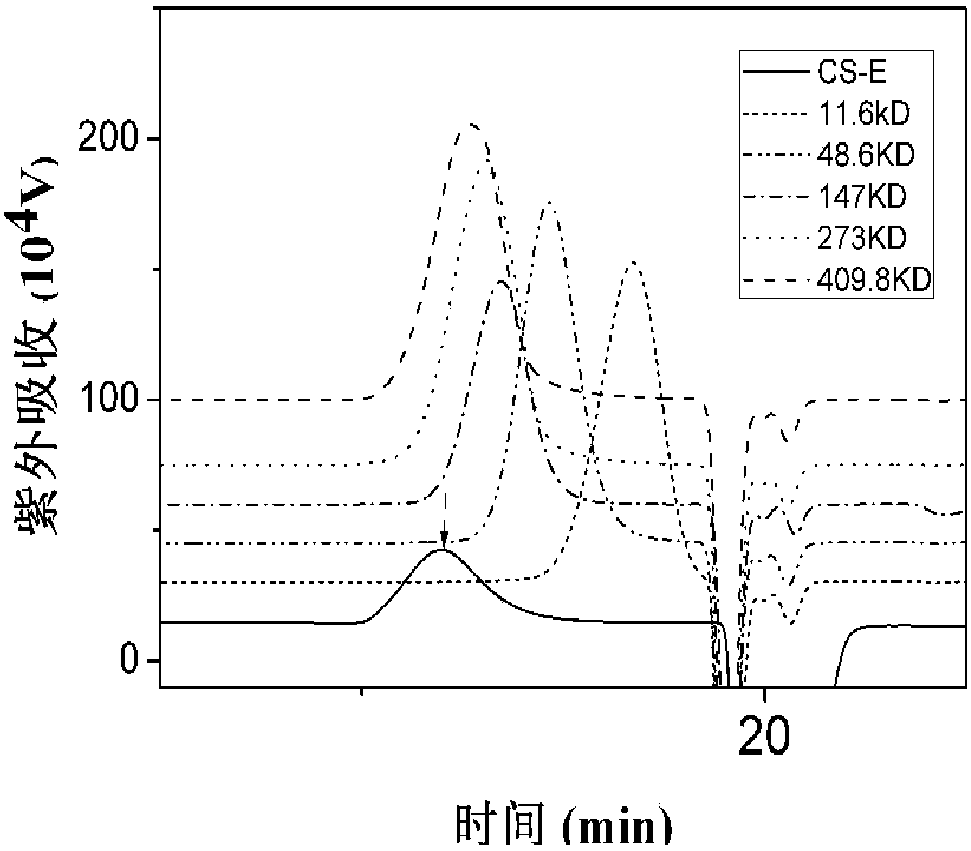

High-sulfating chondroitin sulfate (CS) and preparing method and application thereof

ActiveCN105924544AShorten the growth cycleIncrease productionOrganic active ingredientsAntineoplastic agentsSulfationChondroitin

The invention relates to a high-sulfating chondroitin sulfate (CS) and a preparing method and application thereof. According to the high-sulfating CS, the molecular weight is 100 KDa to 800 KDa, the sulfating degree is 0.7 to 1.43, and disaccharide compositions are O-units, C-units, A-units and E-units. The high-sulfating CS is a CS which is extracted from cartilage of dosidicus gigas and is rich in E-unit, and is a DG-CS with the specific disaccharide compositions, specific carbohydrate chain arranging and the specific molecular weight. An experiment proves that the high-sulfating CS has quite good anti-tumor metastasis activity.

Owner:SHANDONG UNIV

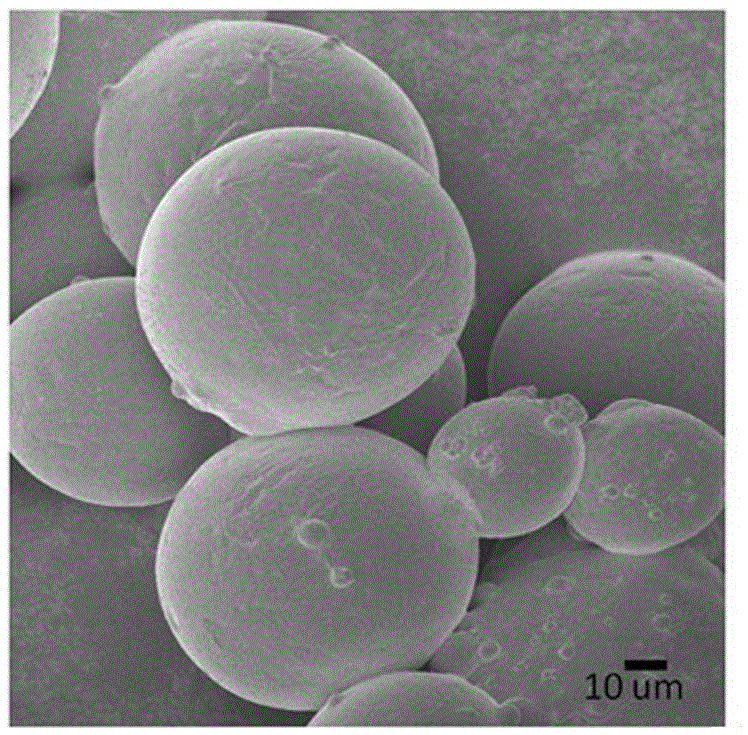

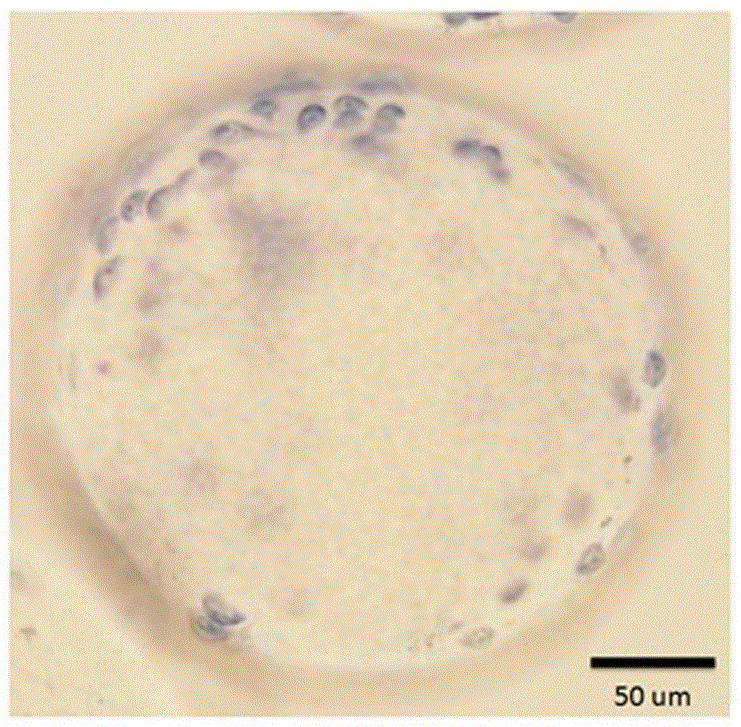

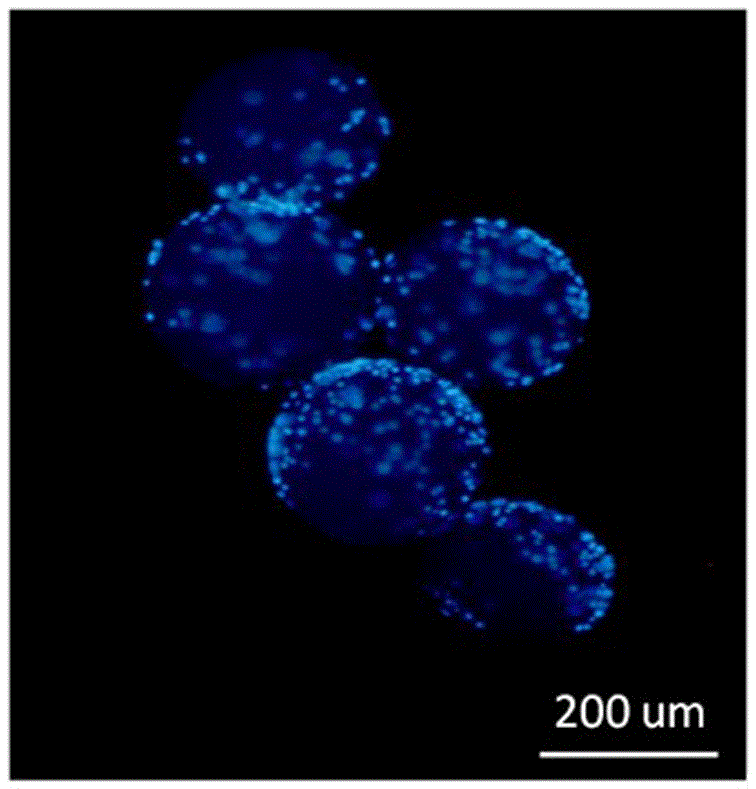

Micro-carrier for cell culture and preparation method and application thereof

InactiveCN105567626ASuitable for large-scale suspension cultureEasy to manufactureMicrocarriersGeneral culture methodsBiotechnologyEngineering

The invention provides a preparation method of a micro-carrier for cell culture. The preparation method includes the following steps that 1, a gelatinized starch alkali solution is prepared firstly; 2, an oil phase and a water phase are mixed for pelleting; 3, crossing-linking and curing are conducted at normal temperature for pelletizing; 4, oil-out cleaning is conducted; 5, DEAE coupling is conducted; 6, washing is conducted. The invention further provides the micro-carrier prepared through the method and an application of the micro-carrier to cell culture. Common edible starch is adopted, the raw material is free of toxicity and wide in source, and the whole preparation process is simple and feasible; the method is controllable, cost is low, and industrial production is easy. By means of the micro-carrier, suspension culture can be conducted in a stirring state, the micro-carrier is suitable for large-scale suspension culture of multiple anchorage-dependent cells, and the micro-carrier can be widely applied to the field of biological pharmacy.

Owner:冯玉萍 +1

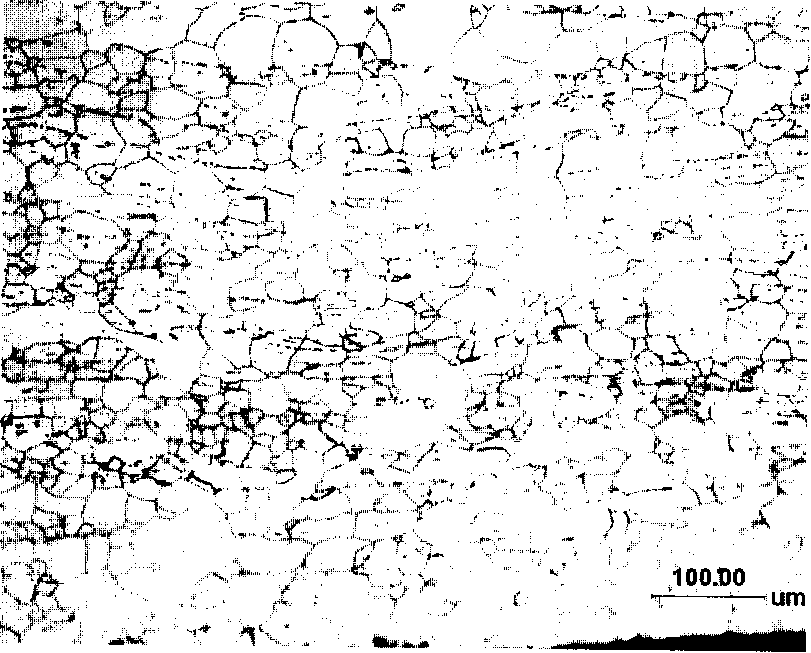

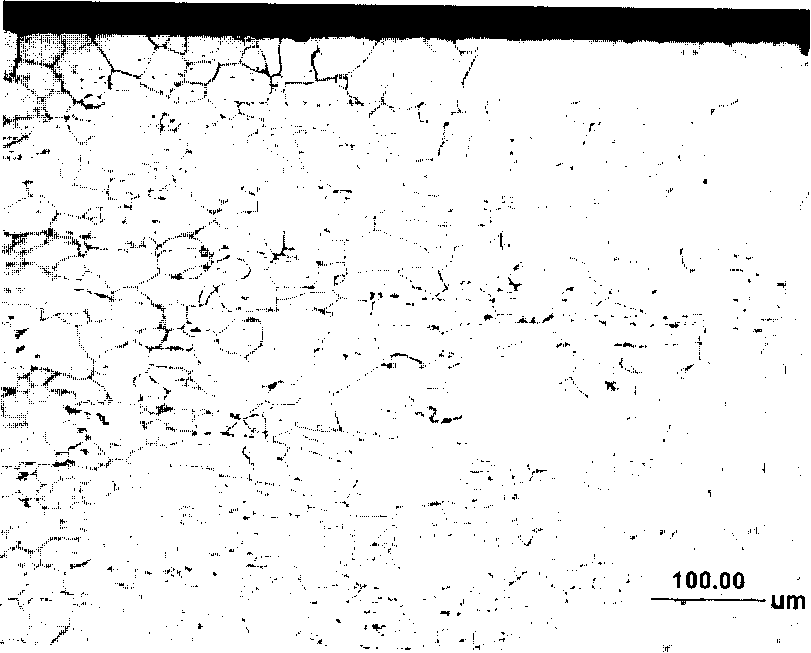

Soft ferritic stainless steel and manufacture method thereof

InactiveCN101205589AHigh hardnessWith wear resistanceTemperature control deviceHeat treatment process controlAlloyWear resistance

The invention discloses soft ferritic stainless steel and a method for manufacturing the same, wherein the mass percentage compositions of the stainless steel are: 0.01 to 0.03 percent by mass of C, 0.2 to 0.4 percent by mass of Mn, 0.2 to 0.4 percent by mass of Si, 15 to 17 percent of Cr, less than or equal to 0.025 percent of N, less than or equal to 0.020 percent of P, less than or equal to 0.0030 percent of S and the balance Fe and unavoidable impurities; the method comprises the following: 1) a step of smelting and continuous casting, in which molten iron and alloy material are subject to treatment by an AOD furnace and a VOD furnace, making the content of each composition with in the required range and then to continuous casting to be formed into blanks; 2) a step of heating plate blanks, in which the plate blanks are heated to between 1050 and 1100 DEG C for no less than 180 minutes; 3) a step of hot rolling, in which the finishing temperature is between 860 and 880 DEG C, the coiling temperature is 750+-20 DEG C; 4) a step of heat treatment after rolling, in which the annealing temperature is between 860 and 900 DEG C, with acid cleaning; 5) a step of cold rolling, in which the total draft is more than or equal to 70 percent; 6) a step of heat treatment after rolling, in where the annealing temperature is between 880 and 920 DEG C. The stainless steel manufactured by the invention is low in cost, moderate in flexibility and has certain anti-corrosion and wear-resistance properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Black allium chinensis vinegar and preparation method thereof

InactiveCN103060166ARetain physiological functionIncrease umamiVinegar preparationFlavorFermentation

The present invention provides a preparation method for black allium chinensis vinegar prepared by blending brewed fermented black allium chinensis concentrated juice and ordinary vinegar. The black allium chinensis vinegar is obtained by grinding allium chinensis into pulp for fermentation, then concentrating into a concentrated black allium chinensis juice, and blending with the existing vinegar with a blending ratio of fermented black allium chinensis juice to vinegar being 1:5. The obtained product not only retains physiological functions of the allium chinensis, but also adds a flavor of vinegar, enabling people to get beneficial health effects during the process of enjoying seasoning. The product of the invention is rich in flavor and good in taste, and enriches range of applications of the allium chinensis in diet fields and meets people's gourmet needs.

Owner:徐州绿之野生物食品有限公司

Preparation method of vinyl ether by direct schizolysis of acetal liquid phase

InactiveCN101597215ALow equipment requirementsReduce manufacturing costOrganic chemistryOrganic compound preparationHigh pressureLiquid phase

A preparation method of vinyl ether by direct schizolysis of acetal liquid phase comprises the following steps: adding dehydrant into alcohol and aldehyde under acidic condition to prepare the acetal, adding acidic catalyst into the acetal in the absence of any liquid phase medium, taking alkyl compound containing amidogen as a cocatalyst, the dosage of which is 1-10% of the acetal, and then carrying out reaction at the temperature of 180-200 DEG C to obtain a product, fractionating the obtained product to obtain the vinyl ether, wherein, the catalyst dosage is 0.1-1% of the acetal. The method dose not need high pressure, has low requirements on the equipment, can carry out schizolysis without adding any liquid phase medium, thus lowering the production cost; the temperature is within 200 DEG C, the reaction conditions are easily controlled; the production process is simple, thereby being easy to form industrial production.

Owner:湖北新景新材料有限公司

Combination of medication for antivirus in use for eye region and preparation method

InactiveCN1626090AReduce pollutionReduce contentPharmaceutical delivery mechanismAntiviralsSustained-Release PreparationsMethyl cellulose

The invention provides a pharmaceutical composition and a preparation method thereof, specifically, an ophthalmic sustained-release preparation containing ganciclovir and a preparation method thereof. It is an ophthalmic sustained-release preparation made from ganciclovir, carbomer, hydroxypropylmethylcellulose and commonly used pharmaceutical ophthalmic preparation auxiliary materials. The eye drops prepared by the in-situ gelation technology of the present invention have stable quality, less content of main drug ganciclovir, can maintain effective drug concentration for a long time, improve bioavailability, and reduce eye irritation. The drug administration frequency is reduced, the use is convenient, the preparation process is highly controllable, the industrial production capacity is easy to form, the production cost is reduced, and a new drug selection is provided for clinical use.

Owner:成都三明药物研究所

Method for preparing natural nontoxic adhesive for wood use

InactiveCN1183217CNon-toxic and irritating odorImprove water resistanceStarch adhesivesPolyvinyl alcoholAdhesive

A natural non-toxic adhesive for wood used as building material or decorative material contains main material which is prepared from corn or cassava starch, water and assistant through emulsifying, oxidizing, etherifying, esterifying and cross-linking, polyvinyl alcohol as intensifer, solution of sodium polyacrylate as stabilizer, assistant and water. Its advantages are no poison and irritation, good water-proof nature, high drying speed and adhesion.

Owner:武汉正轩宇生物科技有限公司

A kind of highly sulfated chondroitin sulfate and its preparation method and application

ActiveCN105924544BShorten the growth cycleIncrease productionOrganic active ingredientsAntineoplastic agentsHumboldt squidDisaccharide

Owner:SHANDONG UNIV

Preparation technology of panax pseudoginseng ultrafine powder granular decoction pieces

ActiveCN103054922BKeep natural propertiesSimple preparation processNervous disorderAntinoxious agentsGranularityMedical prescription

The invention relates to a preparation technology of panax pseudoginseng ultrafine powder granular decoction pieces. The preparation technology comprises the following steps of: (S1) cleaning: removing impurities and airing; (S2) slicing or primary grinding; (S3) drying: drying to control the water content at 3-8%; (S4) cooling and ultrafine grinding: controlling temperature at (-50)-(-20) DEG C, and grinding until the granularity is 10-1,000 meshes; (S5) mixing; (S6) granulation: granulating with a granulator, wherein the granularity ranges from 12 meshes to 24 meshes; (S7) total mixing; and (S8) sub-packing. The preparation technology provided by the invention has the advantages that no excipient is added, all natural characteristics of the traditional Chinese medicine are effectively maintained, the standard is uniform, difference in quality is little, and the medicine can be independently used or compounded with other traditional Chinese medicine decoction pieces; the prescription by a doctor, the fetching in a drugstore and the use by a patient are convenient; and the advantage in co-decoction and taking of a traditional Chinese medicine is kept, thus being favorable for realizing synergistic effect of multiple formulas of traditional Chinese medicine decoction pieces.

Owner:四川国强中药饮片有限公司

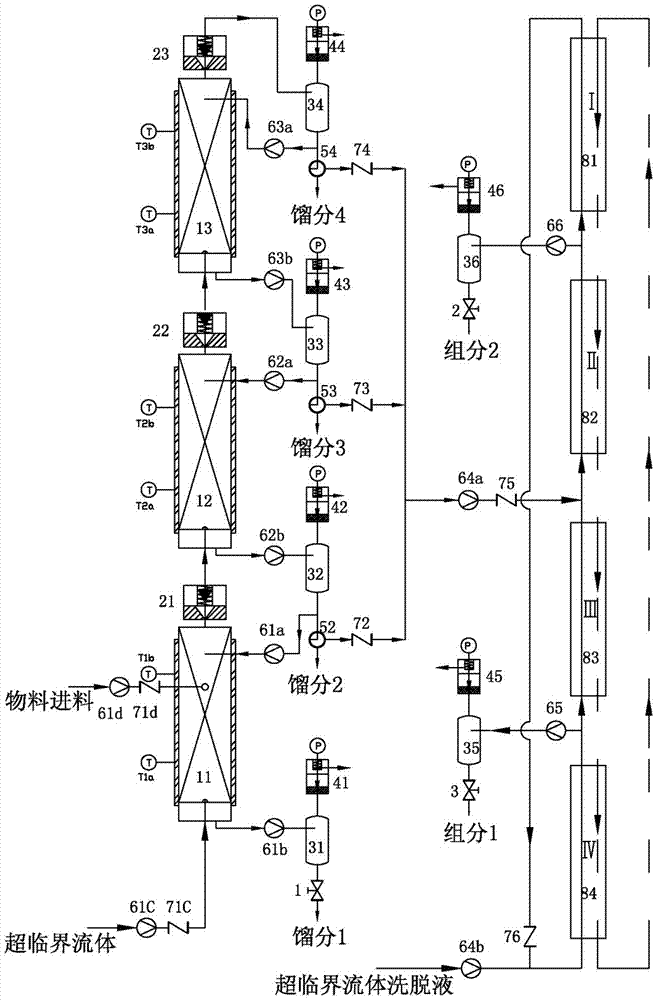

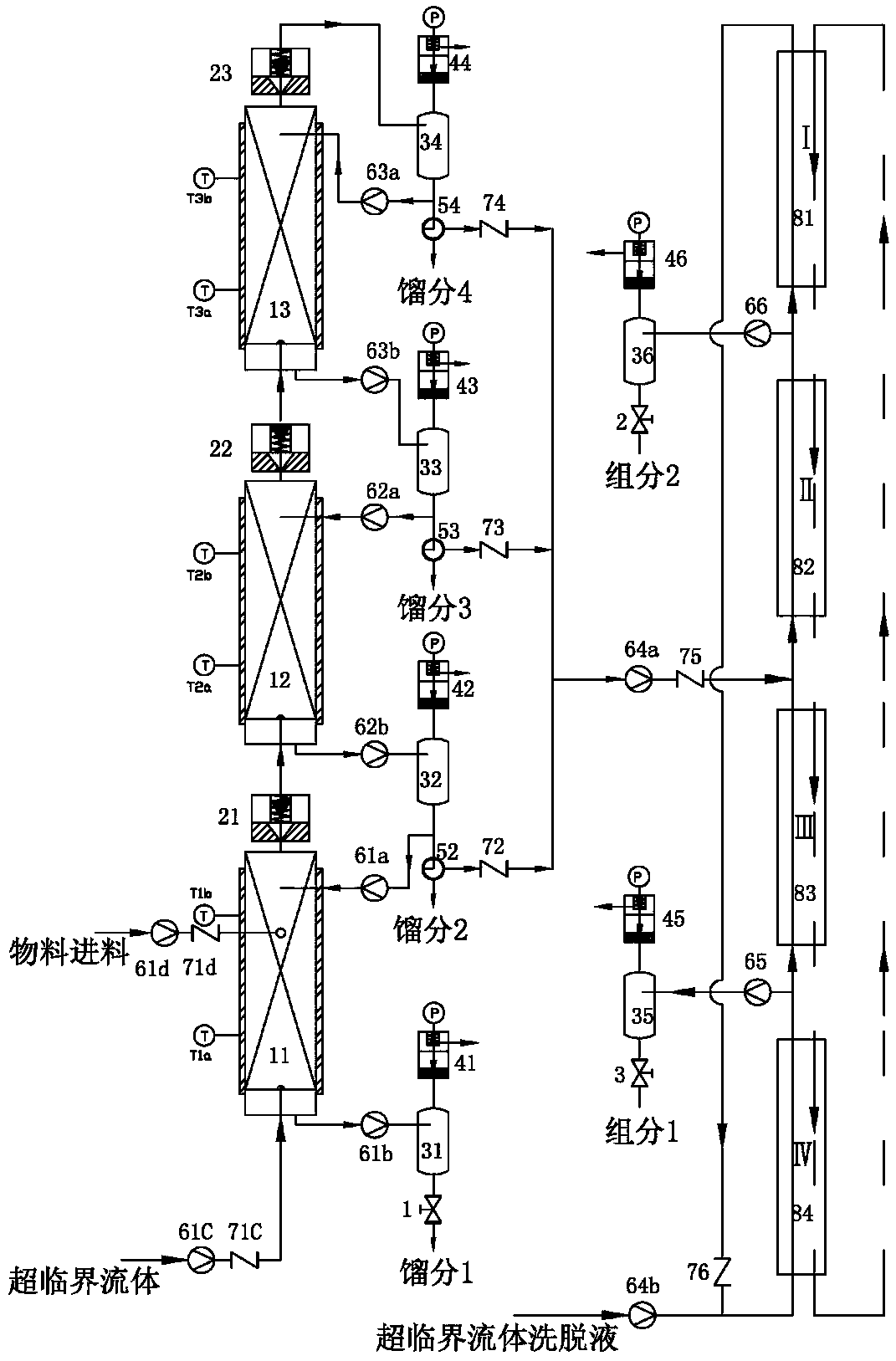

Multi-stage supercritical fluid rectification separation and continuous flow elution preparative chromatography separation device

ActiveCN107096251ALarge adjustment rangeWide adjustment range and more preciseDistillation regulation/controlSolid sorbent liquid separationChromatographic separationSolubility

A multi-stage supercritical fluid rectification separation and continuous flow elution preparative chromatography separation device consists of a supercritical fluid rectification separation mechanism and a supercritical continuous flow elution preparative chromatography separation mechanism; and supercritical fluid rectification separation mechanism consists of three stages of rectification units and has pressure gradient and temperature gradient. By the device, supercritical fluid rectification can operate and run under the pressure gradient and the temperature gradient simultaneously, the adjusting range of properties such as solubility, permeability and volatility of supercritical fluid is wide, the properties are adjusted accurately, and the rectification separation effect is improved; pressure gradient controlled adjustment is added, and the defects that materials overflow easily when the temperature of the bottom of a supercritical fluid rectification tower is low and the materials are caked easily when the temperature of the top of the tower is high due to pure temperature adjustment can be avoided; and compared with temperature adjustment, pressure adjustment has the characteristics of timely response and zero lagging, and intelligent control is easy to realize.

Owner:厦门昊琦科学仪器有限公司

Method for preparing starch glue for lumber

InactiveCN1293159CHigh bonding strengthImprove water resistanceStarch derivtive adhesivesAdjuvantPlasticizer

The present invention relates to a preparation method of starch glue for wood. Said invention uses starch as main raw material, and adopts the following steps: firstly, making starch undergo the processes of acidolysis, oxidation and graft copolymerization, etc., then adding modifying agent and complexing agent to make cross-linking modification, then heating and gelatinizing, cooling and successively adding the adjuvants of diluent, plasticizer and defoaming agent so as to obtain a starch glue with excellent performance for wood.

Owner:JIANGNAN UNIV

Medicinal composition for treating bacterial conjunctivitis and keratitis and preparation and preparation method

InactiveCN1579402AEasy to useImprove inner qualityOrganic active ingredientsSenses disorderUse medicationMedicine

The invention provides a medicine compound and its manufacturing method, concretely, it is slow released eye preparation containing hydrochloric acid levo ofloxacin and its manufacturing method. The invention uses in situ gelling technology to produce the eye drip, the quality is stable, and it can maintain effect medicine density in a long time, upgrades the biological utilization rate, reduces the stimulation to eyes, reduces the medicine feeding frequency, the producing process is high controlled, the cost is low, it provides a new medicine for clinic.

Owner:成都三明药物研究所

Adjuvant of slow release agent used for eye and medicine containing said adjurant and its preparation method

InactiveCN1785431AEasy to useImprove inner qualityOrganic active ingredientsSenses disorderUse medicationAdjuvant

An adjuvant for the slow-release eye medicine is prepared from carbomer and hydroxypropyl methylcellulose. Said slow-release eye medicine is prepared from levo-ofloxacin hydrochloride and said adjuvant. Its advantages are high biological utilization rate and low irritation to eye.

Owner:成都三明药物研究所

Grinding and polishing synthetic fiber material preparation method

The invention discloses a grinding and polishing synthetic fiber material preparation method. The fiber synthetic material preparation method includes and is characterized by including preliminarily processing fiber materials, penetrating thin glue, pressing a composite material uniformly mixed with polishing agent, strengthening plasticizer and adhesive, and integrally drying at constant temperature to enable the fiber materials, the polishing agent, the strengthening plasticizer and the like to be firmly solidified to form a uniform and elastic integral body. The synthetic materials have the advantages that the synthetic materials are quick polished, low in consumables, durable, wear-resisting, low in production cost, simple in technique, easy to realize industrial lives, and the like.

Owner:WUHAN INST OF GEOLOGICAL MINERALS

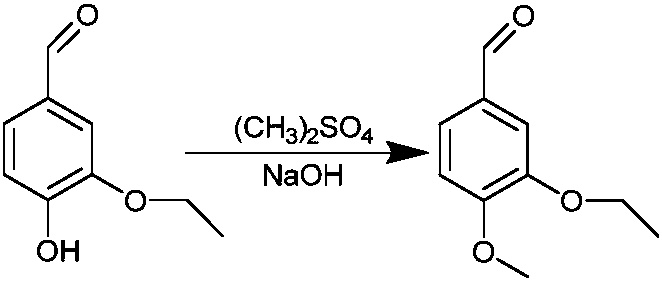

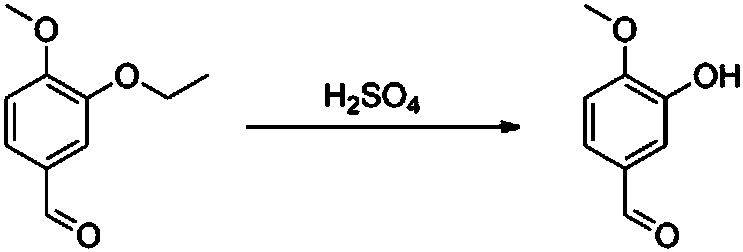

Preparation method of isovanillin

InactiveCN108084000ALower conversion rateLow costOrganic compound preparationCarbonyl compound preparationEthyl vanillinProduct gas

The invention provides a preparation method of isovanillin, and belongs to the technical field of isovanillin production. The preparation method of isovanillin comprises the following steps: dimethylsulfate and an ethyl vanillin solution are subjected to reaction in an alkaline environment at temperature of 5-40 DEG C for 4-8h, filtering is performed, filter residues are taken, and an intermediate is obtained; the intermediate and concentrated sulfuric acid are subjected to reaction for 2-7 hours in an inert gas atmosphere at temperature of 40-70 DEG C and under negative pressure. According to the preparation method, ethyl vanillin, dimethyl sulfate, concentrated sulfuric acid and the like are used as raw materials and are easily available and low in cost, the process is simple to controland easy to operate, industrial production is easy to realize, the yield is high, little waste water is produced, and the method is environmentally friendly.

Owner:CHONGQING THRIVE CHEM

Medicine for treating scalds

InactiveCN110522837AGood curative effectQuick resultsHydroxy compound active ingredientsDermatological disorderRadix AconitiCurative effect

The invention discloses a medicine for treating scalds. The medicine comprises the following components in parts by weight: 1-5 parts by weight of rheum officinale, 7-11 parts by weight of sanguisorbaofficinalis, 5-9 parts by weight of cistanche deserticola, 4-6 parts by weight of Suberect Spatholobus Stem, 10-20 parts by weight of lumbricus, 12-16 parts by weight of achyranthis bidentatae, 3-5 parts by weight of angelica sinensis, 5-7 parts by weight of bulbus fritillariae cirrhosae, 6-8 parts by weight of cassia twig, 10-15 parts by weight of ephedra, 4-8 parts by weight of dark plum, 14-18parts by weight of raw radix aconiti and 15-19 parts by weight of radix aconiti. The traditional Chinese medicine components in the medicine supplement each other, clear away heat and toxic materials, have a good effect on I-degree and II-degree scalds or burns, are good in curative effect, take effect quickly, and can stop bleeding and relieve pain, and scars are not likely to be left after wounds are healed. The use range is wide, carrying is convenient, the price is low, and popularization is facilitated.

Owner:李兴夫

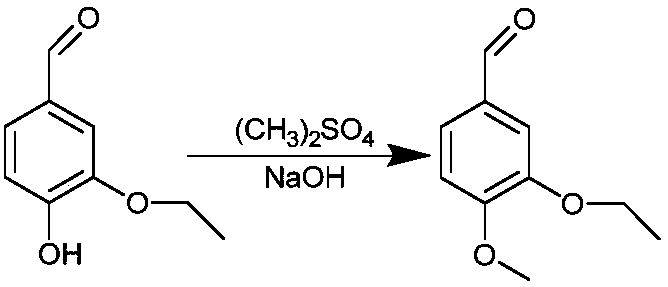

Water-based conductive graphite emulsion for alkaline zinc-manganese battery and preparation method of water-based conductive graphite emulsion

InactiveCN110885597AFix security issuesSolve protection problemsAnti-corrosive paintsElectrically-conductive paintsCelluloseCarboxymethyl cellulose

The invention discloses a water-based conductive graphite emulsion for an alkaline zinc-manganese battery and a preparation method of the water-based conductive graphite emulsion, and relates to the technical field of zinc-manganese batteries, wherein the water-based conductive graphite emulsion is prepared by mixing water as a solvent, graphite and carbon black as main conductive base materials,and water-based resin as a bonding base material and auxiliary agents for supplementing; the emulsion comprises the mixed components by weight: 10-40 parts of a water-based resin solution, 0.3-1 partof sodium carboxymethyl cellulose, 1-3 parts of a wetting dispersant, 0.1-2 parts of a leveling agent, 1-8 parts of a coalescing agent, 10-40 parts of graphite and carbon black, 1-3 parts of an anti-flash rust agent, 0.1-2 parts of an antifoaming agent, 0.1-1 part of ammonia water, 30-80 parts of water and 1-3 parts of propylene glycol monomethyl ether. According to the water-based conductive graphite emulsion for the alkaline zinc-manganese battery, the problems that an existing solvent conductive graphite emulsion is severe in production field environment, insufficient ability of a dry filmto conduct electricity and poor in corrosion resistance are solved.

Owner:山东润辉石墨制品有限公司

Silver-based brazing paste and preparation method and application thereof

InactiveCN112756842AEasy to operateImprove liquidityWelding/cutting media/materialsSoldering mediaSolderingMetal powder

The invention discloses silver-based brazing paste and a preparation method and application thereof. According to the technical scheme, the silver-based brazing paste comprises 35 wt%-40 wt% of a binder and soldering flux based on the total amount, the mass ratio of the binder to the soldering flux is 1:(1-1.2), and silver-based solder metal powder accounts for 60 wt%-65 wt% of the total amount; and alloy welding powder is composed of AgCu alloy powder and CuZn alloy powder, and the mass ratio of the AgCu alloy powder to the CuZn alloy powder is AgCu:CuZn=(0.5:1)-(2:1). The silver-based brazing paste and the preparation method and application thereof have the advantages of being low in cost, simple in operation and good in brazing effect.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Fresh peony flower enzyme and preparation method thereof

The invention relates to the technical field of biological enzymes, and particularly relates to a fresh peony flower enzyme and a preparation method thereof. The fresh peony flower enzyme is preparedfrom the following ingredients: 10-15 parts of fresh peony flowers, 65-105 parts of sterilized mineral water, 6-10 parts of honey, 0.02-0.06 part of koji, 0.02-0.05 part of acetobacter, 0.03-0.06 partof edible yeast, 0.3-0.7 part of lactobacillus bulgaricus, 0.2-0.6 part of streptococcus thermophilus, 0.2-0.5 parts of bifidobacterium longum, and 0.01-0.03 part of bacillus subtilis. The preparation method of the fresh peony flower enzyme comprises the following steps: (1) picking the fresh peony flowers; (2) sterilizing production utensils; (3) preparing a culture solution; and (4) sealing thecontainer, and carrying out normal-temperature fermentation in a cool and dark place. The fresh peony flower enzyme prepared by the preparation method preserves original nutrients of the fresh peonyflowers, and is capable of producing a large amount of probiotics beneficial to human health; and moreover, the preparation method is convenient to operate, and liable to realize industrial production.

Owner:宇凌

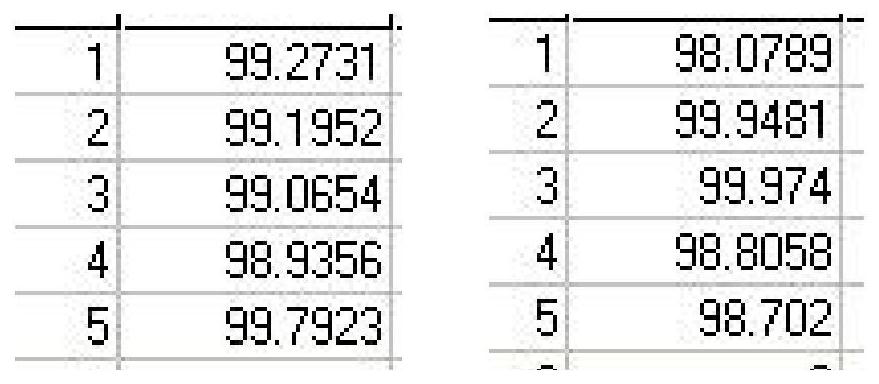

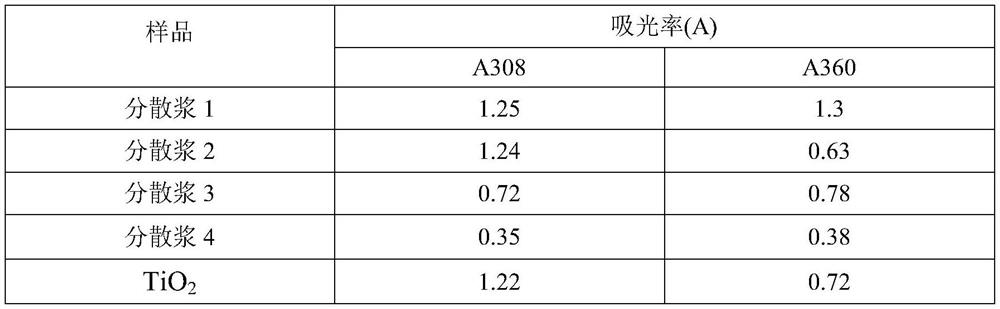

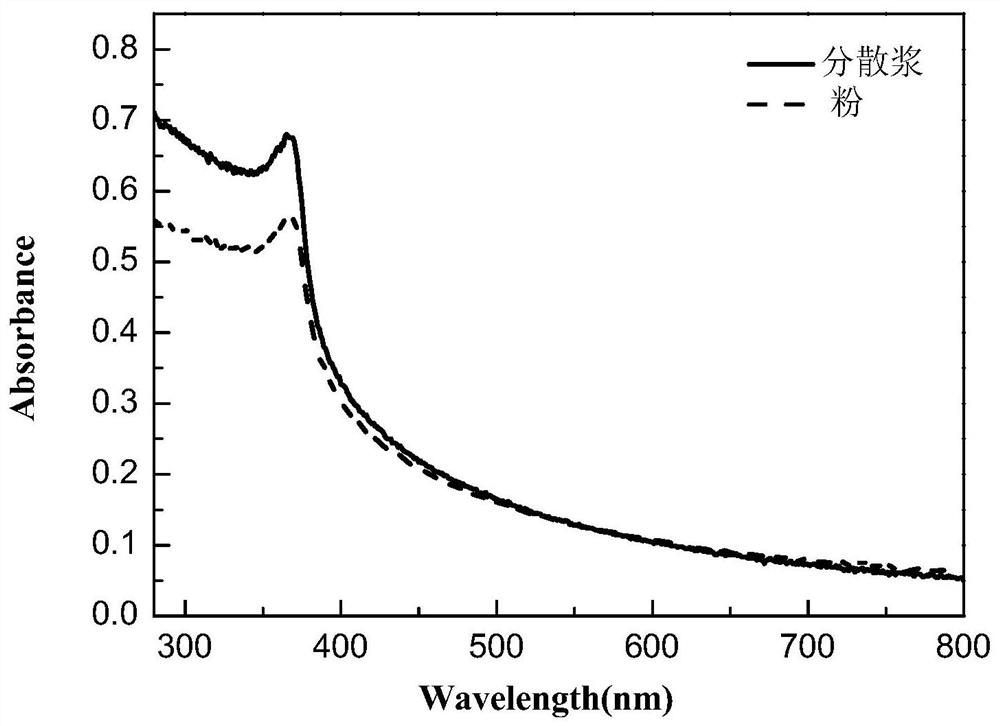

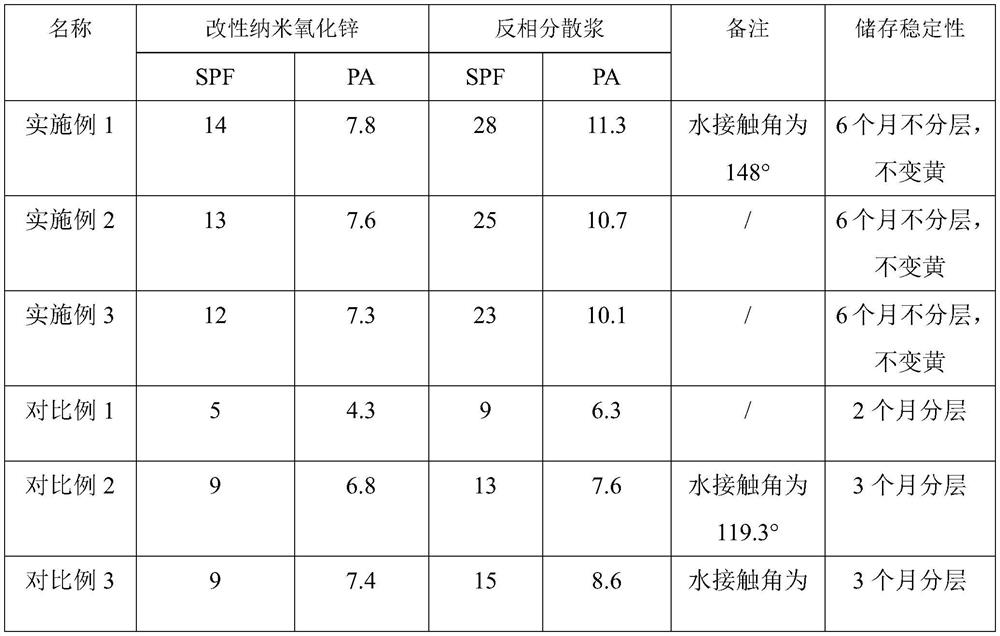

a kind of added tio 2 mbbt water-based dispersion paste

ActiveCN110946774BGood dispersionUniform and stable dispersionCosmetic preparationsToilet preparationsPreservativePhysical chemistry

The invention discloses a TiO-added 2 MBBT water-based dispersion slurry, including MBBT powder, TiO 2 Powder, dispersant, deionized water and preservative; MBBT and TiO 2 The total weight of the powder is 20 to 70 parts, of which TiO 2 The mass ratio to MBBT is 1:1-5, the weight part of dispersant is 1-10 parts; the weight part of deionized water is 30-80 parts; the weight part of preservative is 0.1-5 parts; the TiO 2 The particle size is 50-100nm, and the MBBT particle size is 100-300nm. The method has the advantages of simple process, convenient operation and low cost, and is easy to form industrialized production. Moreover, the paste prepared in cosmetic formulations is fine and grain-free, with good stability and high sun protection index.

Owner:江苏纳欧新材料有限公司

Completely degradable plant protein wood adhesive and preparation thereof

ActiveCN101412899BAdd health stepsImprove water resistanceProtein adhesivesGlue/gelatin preparationPreservativeAdhesive

The invention relates to a full biodegradable plant protein wood adhesive and a preparation method thereof, and belongs to the technical field of adhesive. The adhesive is prepared from the following components in weight portion: 100 portions of water, 5 to 20 portions of plant protein powder, 0 to 15 portions of acidity regulator, 0.05 to 20 portions of modifying agent, 0.05 to 10 portions of assistant, 0.1 to 10 portions of preservative, and 0 to 10 portions of stuffing. The preparation method comprises the following steps in turn: adding the water into a container, and dissolving the acidity regulator under a stirring state; adding the plant protein powder into the container under the stirring state; at the same time, complementing the acidity regulator according to change situations of pH values; heating a reaction system to a temperature needed by modification reaction, adding the modifying agent and the assistant into the container under the stirring state, and keeping the temperature to make the mixture reacted for 15 to 240 minutes at a temperature of between 5 and 60 DEG C; and in the last 2 to 5 minutes of the temperature keeping reaction, adding the preservative into the solution, and stirring the mixture evenly; and adding the stuffing into the reaction system, stirring evenly the mixture, and finally obtaining the wood adhesive. The adhesive has the advantages that the adhesive is easy to process, good in adhering property, and degradable.

Owner:郑州佰沃科技发展有限公司

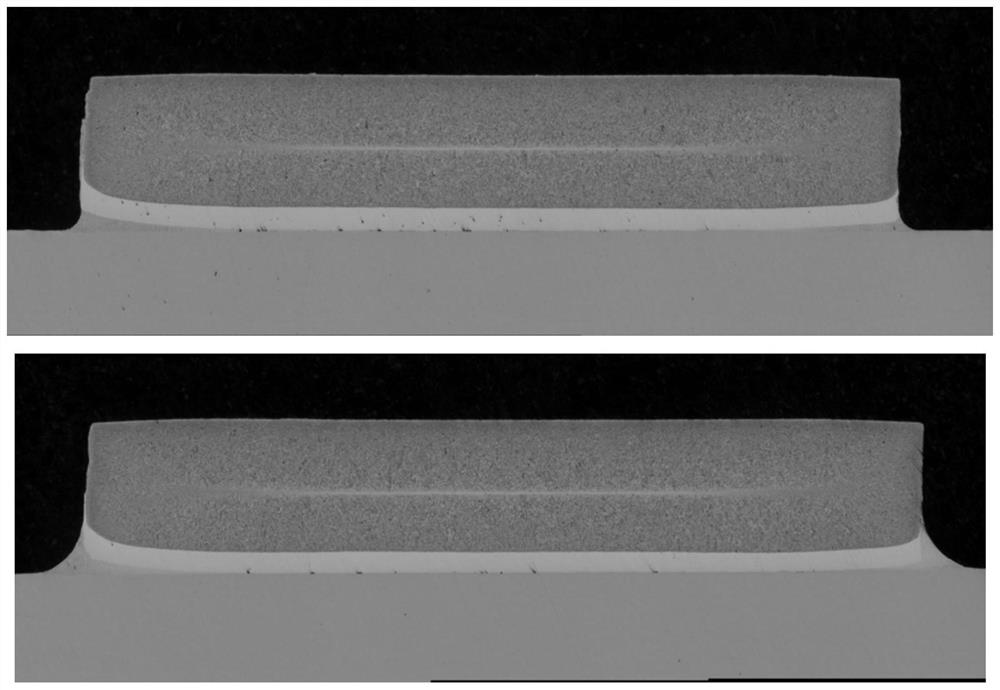

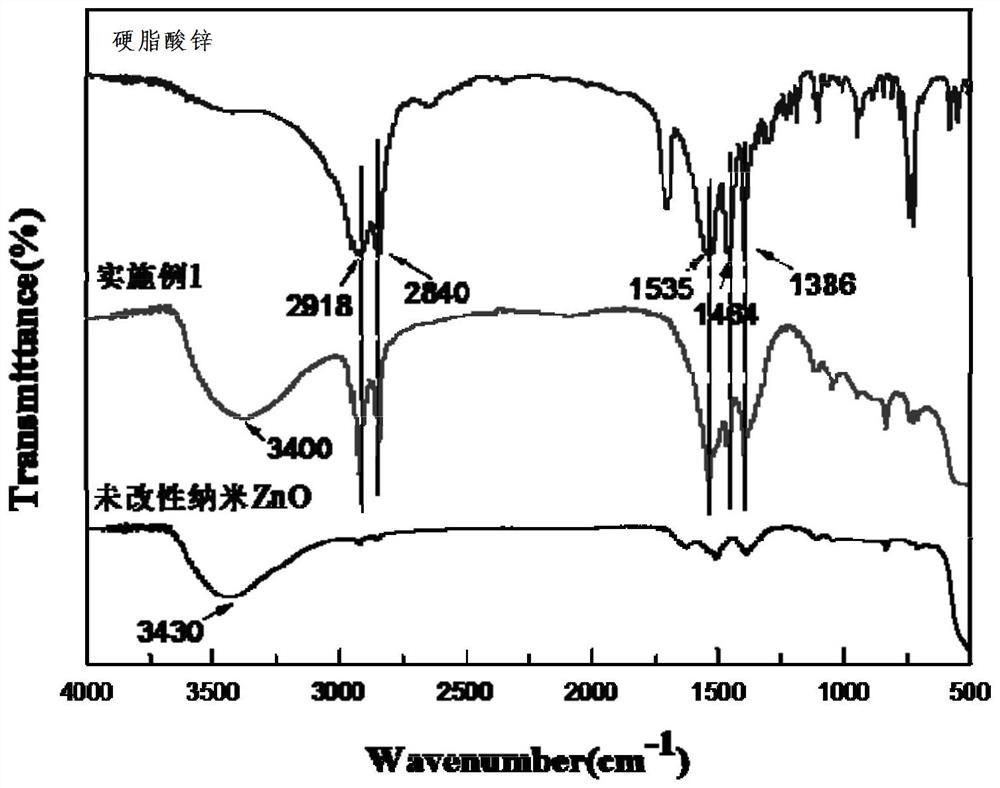

A kind of nanometer zinc oxide surface modification and the preparation method of reverse phase dispersion slurry

ActiveCN111084727BChange hydrophobicityImprove stabilityCosmetic preparationsZinc oxides/hydroxidesChemical reactionSilanes

The invention belongs to the field of inorganic nanometer material and fine chemical industry, and relates to a preparation method of nanometer zinc oxide surface modification and reverse phase dispersion slurry. The present invention weighs nano-zinc oxide and dilute hydrochloric acid and grinds it to obtain a mixed solution of nano-zinc oxide, then moves it to the reaction kettle, heats up, adds the mixed solution of stearic acid and organic alcohol dropwise, and continues to add the silane coupling agent dropwise after stirring. Organic alcohol mixed solution to obtain filter cake of modified nanometer zinc oxide composite material. The modified nano-zinc oxide filter cake and dispersant are added into the sand mill barrel, dispersed and ground to obtain nano-zinc oxide reversed-phase dispersion slurry. In the present invention, while a part of zinc oxide is generated into zinc stearate to form a dinuclear coordination structure, the exposed hydroxyl group on the surface of zinc oxide is used to chemically react with the hydrophilic group amino group in the silane coupling agent to change the nano-zinc oxide powder. Hydrophobic and improves the stability and UV shielding properties of nanoparticles.

Owner:常州纳欧新材料科技有限公司

Combination of medication for antivirus in use for eye region and preparation method

InactiveCN100360132CLess irritatingImprove quality controllabilityPharmaceutical delivery mechanismAntiviralsUse medicationAntiviral drug

The present invention provides a combination of medication and preparation method thereof, particularly, provides an antivirus in use for eye region and preparation method thereof. The combination of medication is antivirus in use for eye taking Ganciclovir, Carbomer, hydroxypropylmethyl cellulose, and common preparation accessories in sue for eye as material. The invention prepares eye drops with in-situ gelatinizing technology.

Owner:成都三明药物研究所

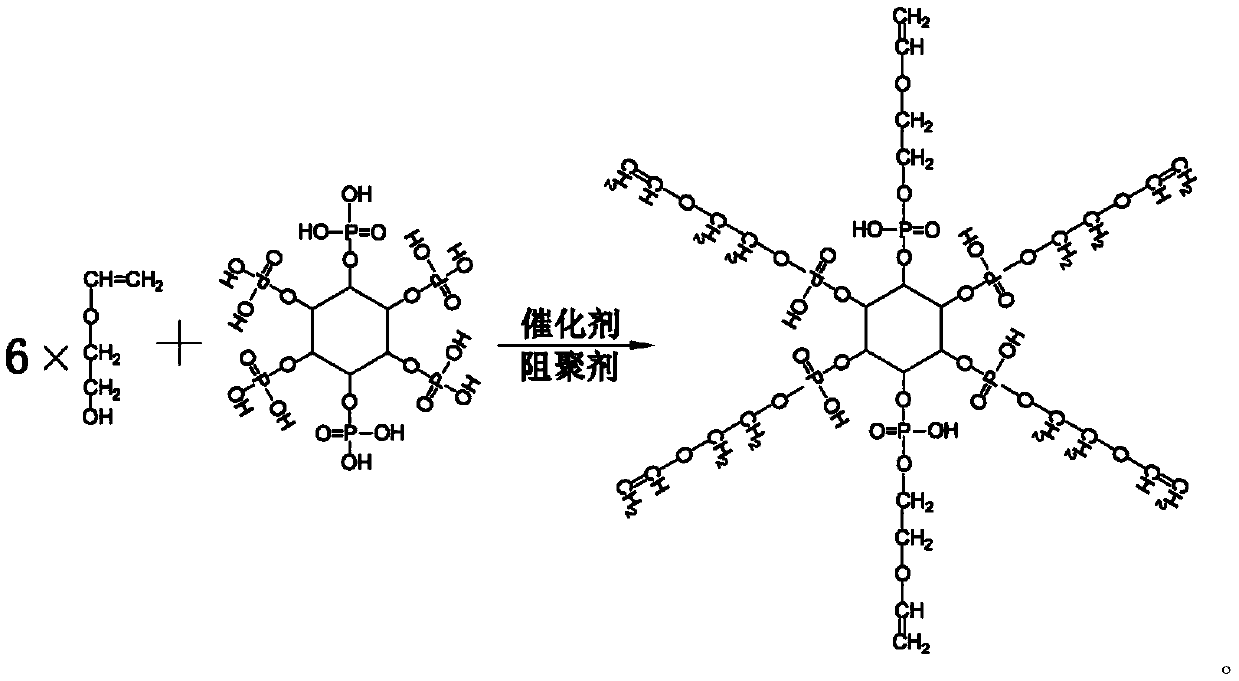

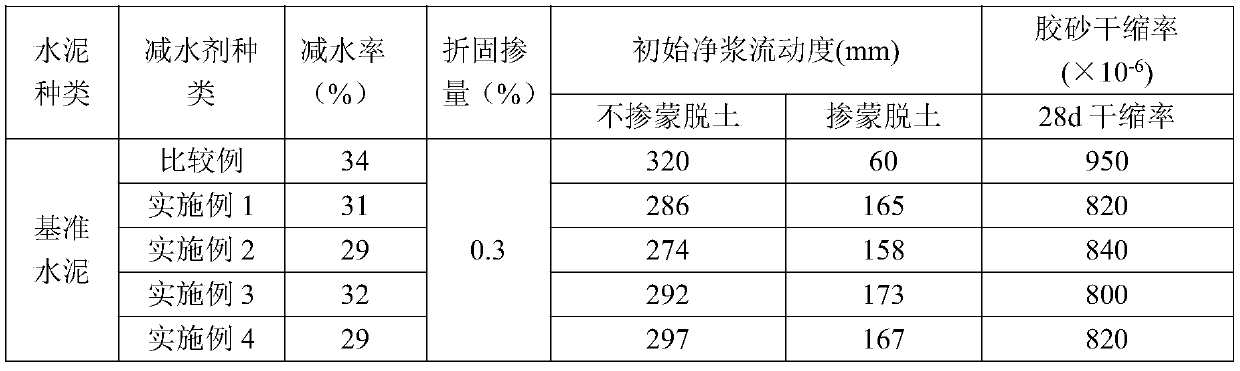

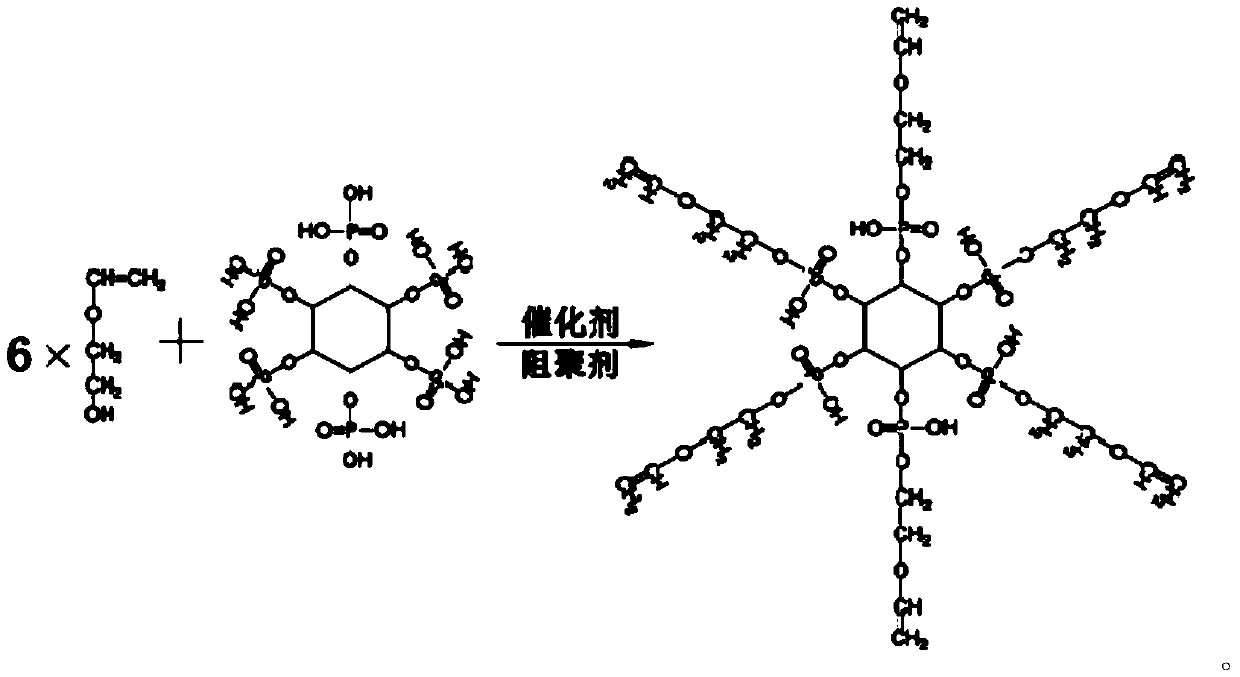

A kind of preparation method of anti-mud-shrinkage polycarboxylate superplasticizer

ActiveCN108047390BEnlarging the structure space sizeEasy to shrinkGroup 5/15 element organic compoundsPtru catalystPhytic acid

The invention discloses a preparation method of an anti-clay and shrinkage-reducing type polycarboxylate superplasticizer. Phytic acid, unsaturated alcohol ether, a polymerization inhibitor and a catalyst are added to a reaction vessel, uniformly stirred, heated to 80-200 DEG C and subjected to an esterification reaction for 1-12 h, a product I obtained after the reaction is cooled to room temperature, and a snowflake-like anti-clay macromonomer is obtained; the snowflake-like anti-clay macromonomer and solvent water are added to the reaction vessel, then a polyether macromonomer, unsaturatedcarboxylic acid, an unsaturated derivative and an initiator are added to the reaction vessel, uniformly stirred, heated to 50-100 DEG C and subjected to a reaction for 1-12 h, a product II obtained after the reaction is cooled to room temperature, alkali is added to regulate pH to 6.5-7.5, and the polycarboxylate superplasticizer is obtained. The polycarboxylate superplasticizer has excellent anti-clay, water-reducing and shrinkage-reducing effects and good dispersity, thereby having good application prospect and market competitiveness in the field of water reducers. The preparation method further has the advantages that the synthesis process is simple, safe, environmentally friendly, non-toxic, harmless, clean and pollution-free, industrial production is realized easily, and the method has good social benefits and economic benefits.

Owner:广西壮族自治区水利科学研究院

Multistage supercritical fluid rectification separation and continuous flow elution preparation chromatographic separation device

ActiveCN107096251BLarge adjustment rangeWide adjustment range and more preciseDistillation regulation/controlSolid sorbent liquid separationSolubilityChromatographic separation

A multi-stage supercritical fluid rectification separation and continuous flow elution preparative chromatography separation device consists of a supercritical fluid rectification separation mechanism and a supercritical continuous flow elution preparative chromatography separation mechanism; and supercritical fluid rectification separation mechanism consists of three stages of rectification units and has pressure gradient and temperature gradient. By the device, supercritical fluid rectification can operate and run under the pressure gradient and the temperature gradient simultaneously, the adjusting range of properties such as solubility, permeability and volatility of supercritical fluid is wide, the properties are adjusted accurately, and the rectification separation effect is improved; pressure gradient controlled adjustment is added, and the defects that materials overflow easily when the temperature of the bottom of a supercritical fluid rectification tower is low and the materials are caked easily when the temperature of the top of the tower is high due to pure temperature adjustment can be avoided; and compared with temperature adjustment, pressure adjustment has the characteristics of timely response and zero lagging, and intelligent control is easy to realize.

Owner:厦门昊琦科学仪器有限公司

A kind of preparation method of fiber composite material for grinding and polishing

ActiveCN103240681BNot easy to damageImprove permeabilityAbrasion apparatusMaterials preparationAdhesive

The invention discloses a grinding and polishing synthetic fiber material preparation method. The fiber synthetic material preparation method includes and is characterized by including preliminarily processing fiber materials, penetrating thin glue, pressing a composite material uniformly mixed with polishing agent, strengthening plasticizer and adhesive, and integrally drying at constant temperature to enable the fiber materials, the polishing agent, the strengthening plasticizer and the like to be firmly solidified to form a uniform and elastic integral body. The synthetic materials have the advantages that the synthetic materials are quick polished, low in consumables, durable, wear-resisting, low in production cost, simple in technique, easy to realize industrial lives, and the like.

Owner:WUHAN INST OF GEOLOGICAL MINERALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com