A kind of nanometer zinc oxide surface modification and the preparation method of reverse phase dispersion slurry

A nano-zinc oxide and surface modification technology, which is applied in the direction of zinc oxide/zinc hydroxide, medical preparations containing active ingredients, cosmetic preparations, etc., can solve the problem of damaging the stability of the application system, reducing application efficiency, and limiting the scope of application and other problems, to achieve the effect of improving UV shielding performance, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

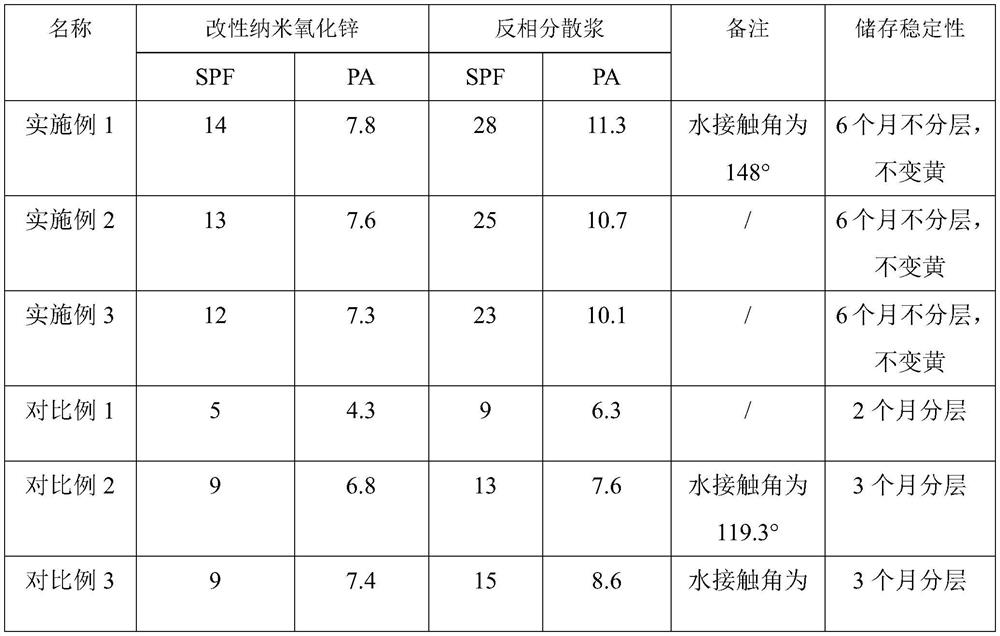

Embodiment 1

[0028] A surface modification method of nano-zinc oxide, comprising the following steps:

[0029] (1) take by weighing the nano zinc oxide of 100g and 400g distilled water and put it into the sand grinding barrel, add 0.1M dilute hydrochloric acid dropwise under the stirring state, adjust the pH of the solution to be 4-5, after the dispersion disc is evenly dispersed, use the grinding wheel at the rotating speed of Grinding at 4000r / min for 1h to obtain a mixed solution of nano-zinc oxide;

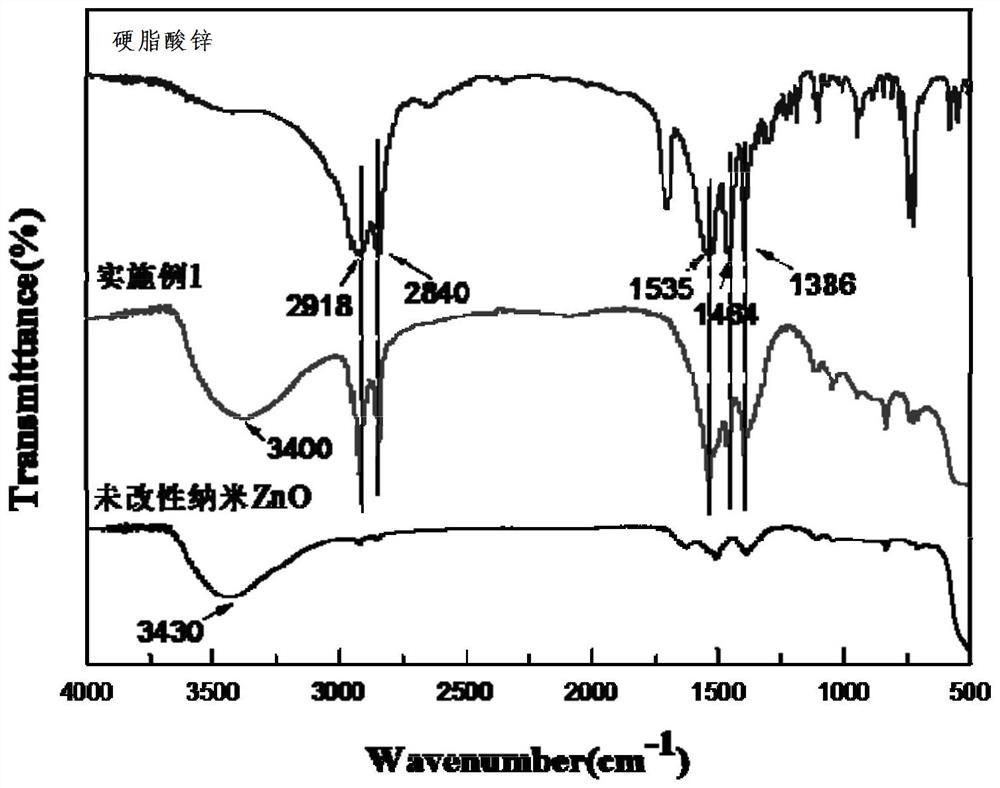

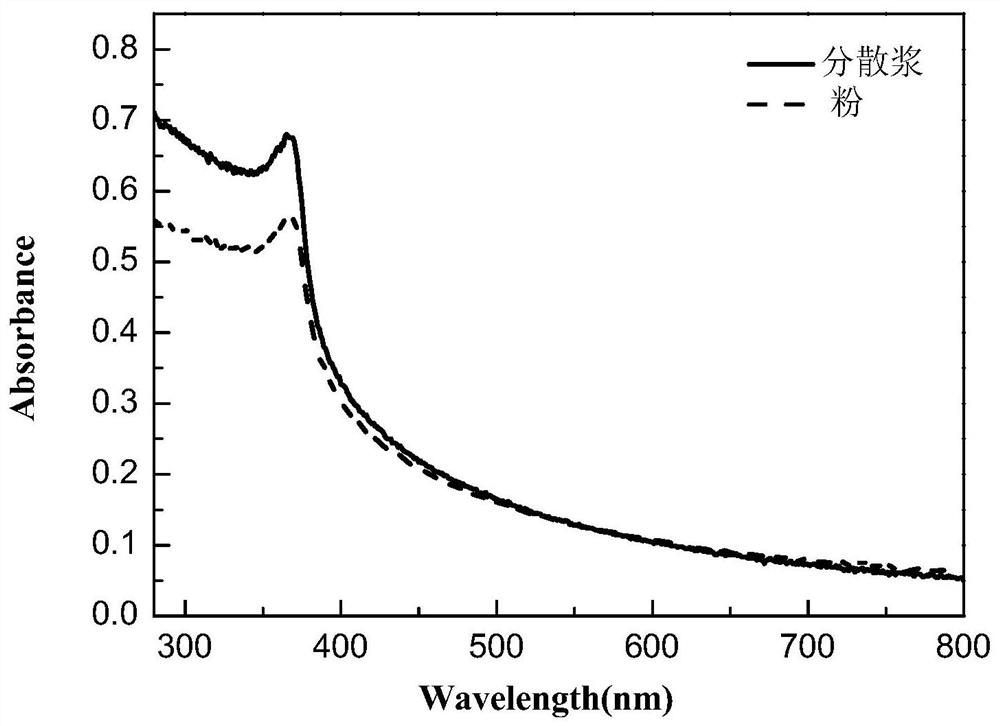

[0030] (2) the mixed solution of above-mentioned nano zinc oxide is moved to the reactor, the temperature is raised to 85 ℃, the mixed solution of 4%wt stearic acid and absolute ethanol is added dropwise, the pH of the adjustment reaction system is 6-7, and stirred for 1h; Maintain the reaction temperature, continue to add dropwise (bisaminosilane coupling agent) a mixed solution of 2%wt N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane and absolute ethanol, stir for 1h; Filtration and washi...

Embodiment 2

[0034] A surface modification method of nano-zinc oxide, comprising the following steps:

[0035] (1) take by weighing the nano zinc oxide of 50g and 450g distilled water and put it into the sand grinding barrel, add 0.01M dilute hydrochloric acid dropwise under the stirring state, adjust the pH of the solution to be 4-5, after the dispersion disc is uniformly dispersed, use the grinding wheel at the rotating speed of Grinding at 3000r / min for 2h to obtain a mixed solution of nano-zinc oxide;

[0036] (2) The mixed solution of the above-mentioned nano-zinc oxide is moved to the reaction kettle, and the temperature is raised to 55 ° C, and the mixed solution of 2%wt stearic acid and isopropanol is added dropwise, and the pH of the adjustment reaction system is 6-7, and stirred for 2h; Maintain the reaction temperature, continue to add dropwise (monoaminosilane coupling agent) a 1%wt mixed solution of 3-aminopropyltriethoxysilane and isopropanol, stir for 2h; filter and wash wit...

Embodiment 3

[0040] A surface modification method of nano-zinc oxide, comprising the following steps:

[0041] (1) take by weighing the nano zinc oxide of 150g and 350g distilled water and put it into the sand grinding barrel, add 0.3M dilute hydrochloric acid dropwise under the stirring state, adjust the pH of the solution to be 4-5, after the dispersion disc is uniformly dispersed, use the grinding wheel at the rotating speed of Grinding at 5000r / min for 0.5h to obtain a mixed solution of nano-zinc oxide;

[0042] (2) The mixed solution of the above-mentioned nano-zinc oxide was moved to the reaction kettle, the temperature was raised to 90 ° C, the mixed solution of 8%wt stearic acid and methanol was added dropwise, the pH of the reaction system was adjusted to be 6-7, and stirred for 0.5 h; At the reaction temperature, continue to add dropwise (polyaminosilane coupling agent) a 3%wt mixed solution of γ-aminoethylaminoethylaminopropyltrimethoxysilane and methanol, and stir for 0.5h; fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com