Lignosulfonic acid/polyaniline/poly(3,4-ethylenedioxythiophene) composite antistatic coating as well as preparation and application thereof

A technology of ethylenedioxythiophene and lignosulfonic acid, which is applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficult dispersion, high density, and easy agglomeration, and achieve low cost, simple preparation process, Realize the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

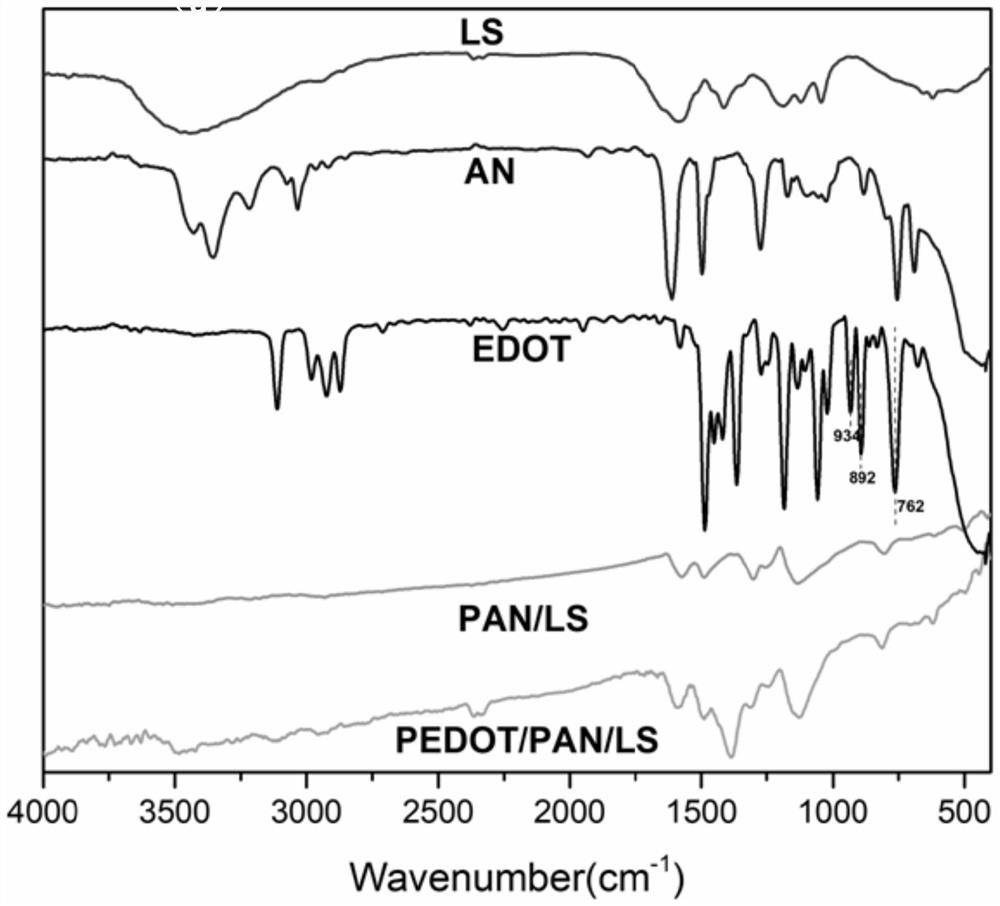

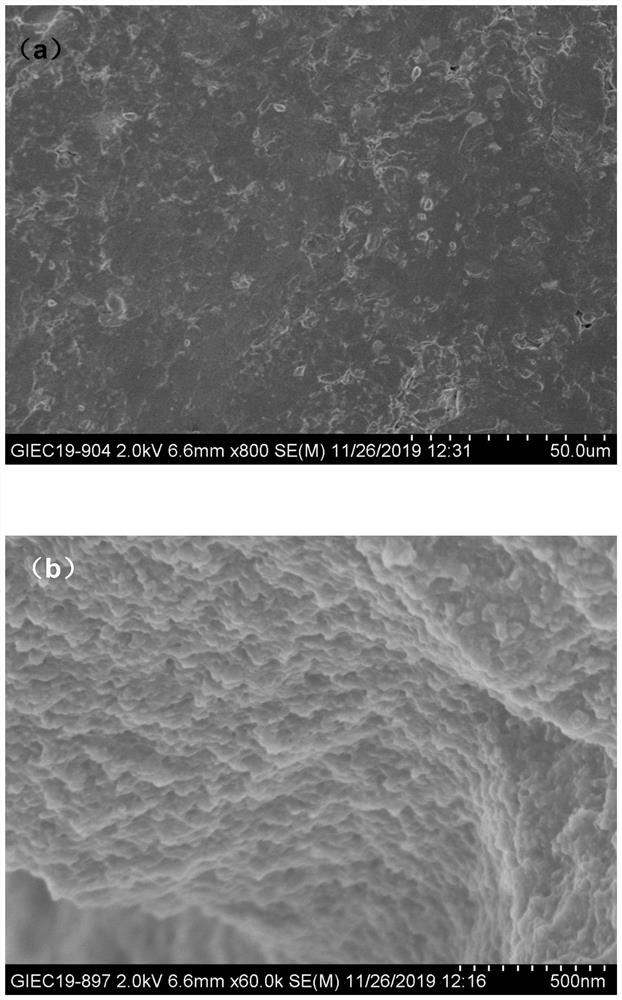

[0042] This embodiment provides a kind of lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) composite antistatic coating and lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) ) preparation method of composite antistatic coating.

[0043] (1) Add 5g of sodium lignosulfonate into a 500ml flask, add 200ml of 1mol / L hydrochloric acid solution, and stir until completely dissolved. Then 4.0ml of aniline was added thereto, and the mixture was placed in a water bath at 25°C for 30min. In addition, weigh 4.94g of ammonium persulfate into a 250ml flask, add 100ml of 1mol / L hydrochloric acid solution, keep the temperature at 25°C for 30min, stir until the ammonium persulfate is completely dissolved, then add it into the above mixture, and stir with a magnet (100rpm) 24h. The obtained dark green product was suction-filtered, washed with deionized water until the filtrate was colorless, and then vacuum freeze-dried for 48 hours with a freeze dryer to obtain so...

Embodiment 2

[0047] This example provides a method for preparing a lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) composite antistatic coating.

[0048] (1) The preparation of lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) composite takes the same method as in Example 1

[0049] (2) Disperse the ligninsulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) compound in acetone to obtain a dispersion, make the concentration of the dispersion 0.05mg / mL, and mix the dispersion with e- 51 epoxy resin is mixed according to the mass ratio of lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) compound and e-51 epoxy resin at 2:100, and ultrasonicated at 20kHz and 25°C for 30min, Stir at 100rpm for 1 hour, then add triethylenetetramine curing agent with a mass ratio of 7:100 to the epoxy resin, mix and stir for 15 minutes to obtain an antistatic coating, and in a vacuum oven, vacuum the air bubbles to obtain an antistatic coating; The coating instr...

Embodiment 3

[0051] This example provides a method for preparing a lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) composite antistatic coating.

[0052] (1) The preparation of lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) composite adopts the same method as in Example 1.

[0053] (2) Disperse the ligninsulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) compound in acetone so that the concentration of the dispersion is 0.05 mg / mL, and mix the dispersion with e-51 epoxy The resin was mixed according to the mass ratio of lignosulfonic acid / polyaniline / poly(3,4-ethylenedioxythiophene) compound and e-51 epoxy resin at 5:100, and then ultrasonicated at 20kHz and 25°C for 30min, 100rpm Stir for 1 hour, then add a triethylenetetramine curing agent with a mass ratio of 7:100 to the epoxy resin, mix and stir for 15 minutes to mix evenly, and under vacuum oven conditions, vacuum the air bubbles to obtain an antistatic coating; Electrostatic paint was applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com