Preparation method of compound modified starch coal water slurry dispersing agent

A composite modification, coal-water slurry technology, which can be used in liquid carbon-containing fuels, petroleum industry, fuels, etc., and can solve problems such as the decline of petroleum energy competitiveness and coal utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

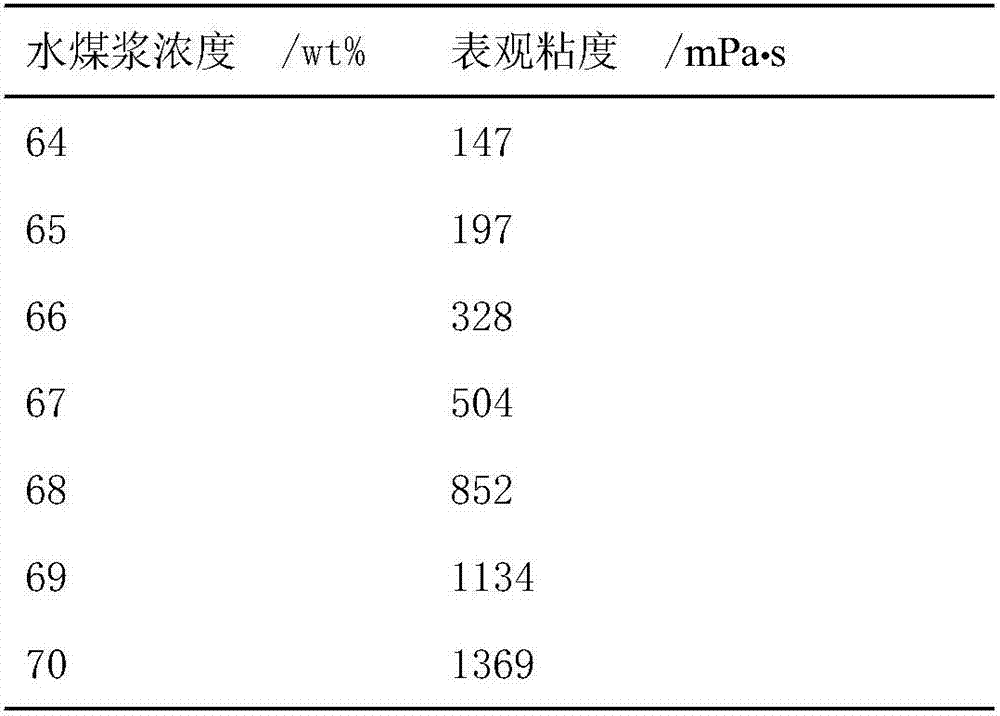

Embodiment 1

[0017] (1) The starch is made into a starch emulsion with a concentration of 35wt%, and then the sodium dodecylbenzenesulfonate solution with a concentration of 12wt% is added in a ratio of 0.07 by the molar ratio of sodium dodecylbenzenesulfonate to starch Mix in starch emulsion, adjust the pH value of the mixture to 11 with a sodium hydroxide solution with a concentration of 10wt%, pour it into a high-pressure reactor, and react for 2 hours at a temperature of 130°C and fully stirred to obtain dodecane Starch phenyl sulfonate;

[0018] (2) the starch dodecylbenzenesulfonic acid ester that step (1) obtains is cooled to 55 ℃ and after the pH value of the reaction system is adjusted to 11 with the sodium hydroxide solution of 10wt% or ammoniacal liquor, under stirring state Slowly add potassium permanganate solution with a concentration of 8wt% according to the addition of potassium permanganate as 6% of the dry weight of starch. After adding the potassium permanganate solution...

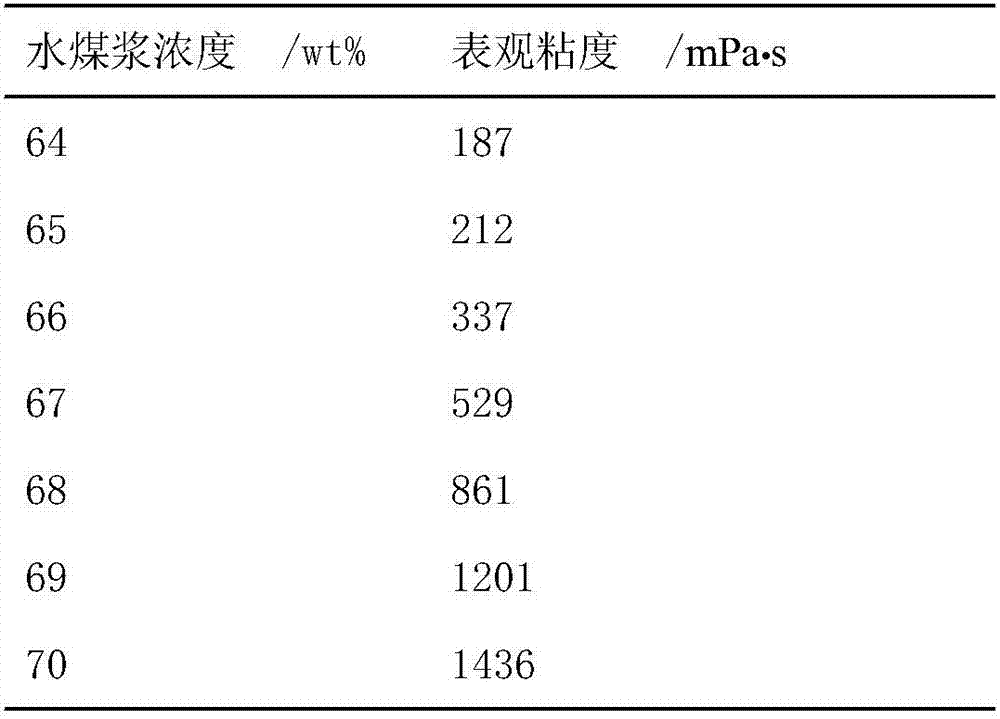

Embodiment 2

[0024] (1) The starch is made into a starch emulsion with a concentration of 30wt%, and then the menoctenyl succinic anhydride solution with a concentration of 10wt% is added to the starch emulsion at a ratio of 0.07 by the molar ratio of octenyl succinic anhydride and starch, and mixed, After adjusting the pH value of the mixture to 10 with a sodium hydroxide solution with a concentration of 8wt%, pour it into a high-pressure reactor, and react for 1.5 hours at a temperature of 120°C and in a fully stirred state to obtain starch octenyl succinate ;

[0025] (2) the octenyl succinic acid starch ester that step (1) obtains is cooled to 60 ℃ and after the pH value of the reaction system is adjusted to 10 with the sodium hydroxide solution of 20wt% or ammoniacal liquor, under stirring state, press Potassium permanganate is the add-on of 4% of starch dry basis weight and slowly adds concentration and is the potassium permanganate solution of 8wt%. After adding potassium permangana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com