Multi-stage supercritical fluid rectification separation and continuous flow elution preparative chromatography separation device

A technology of supercritical fluid and rectification separation, which is applied in the direction of distillation separation, solid adsorbent liquid separation, and separation methods. It can solve problems such as difficult to achieve industrial continuous production, limited application, and influence on separation effect, and achieve easy intelligence. The effect of control, efficient distillation and separation, and simple fraction composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

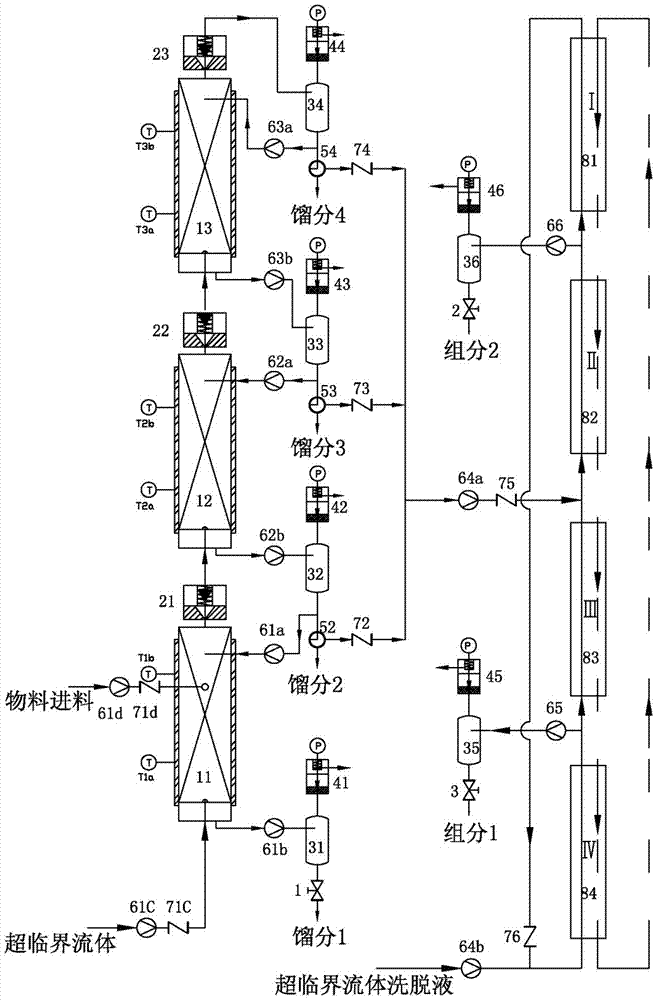

[0028] Attached below figure 1 The present invention is further described in detail with specific embodiments.

[0029] The multistage supercritical fluid rectification separation and continuous flow elution preparation chromatographic separation device of the present invention, its separation process comprises the following steps:

[0030] 1. First, make all the fluid transfer pumps, on-off valves, and switching valves in the closed state, and open all the pressure-limiting control valves and back-pressure control valves 21 and 22.

[0031] 2. Turn on the fluid delivery metering pump 61c to pump the supercritical fluid from the inlet of the lower end of the first-stage rectification column 11 into the rectification column, and make it fill the first-stage, second-stage, and third-stage rectification columns, then adjust The back pressure of the back pressure valve 23 is greater than 80MPa. 3. Turn on the heater power supply of the first-stage rectification column 11, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com