Isolation diaphragm for secondary polymer lithium cell and its making method

A manufacturing method and technology of separator, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of thickness not less than 50 microns, low mechanical strength of separator, poor wettability of electrolyte, etc. High energy density, good adhesion and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

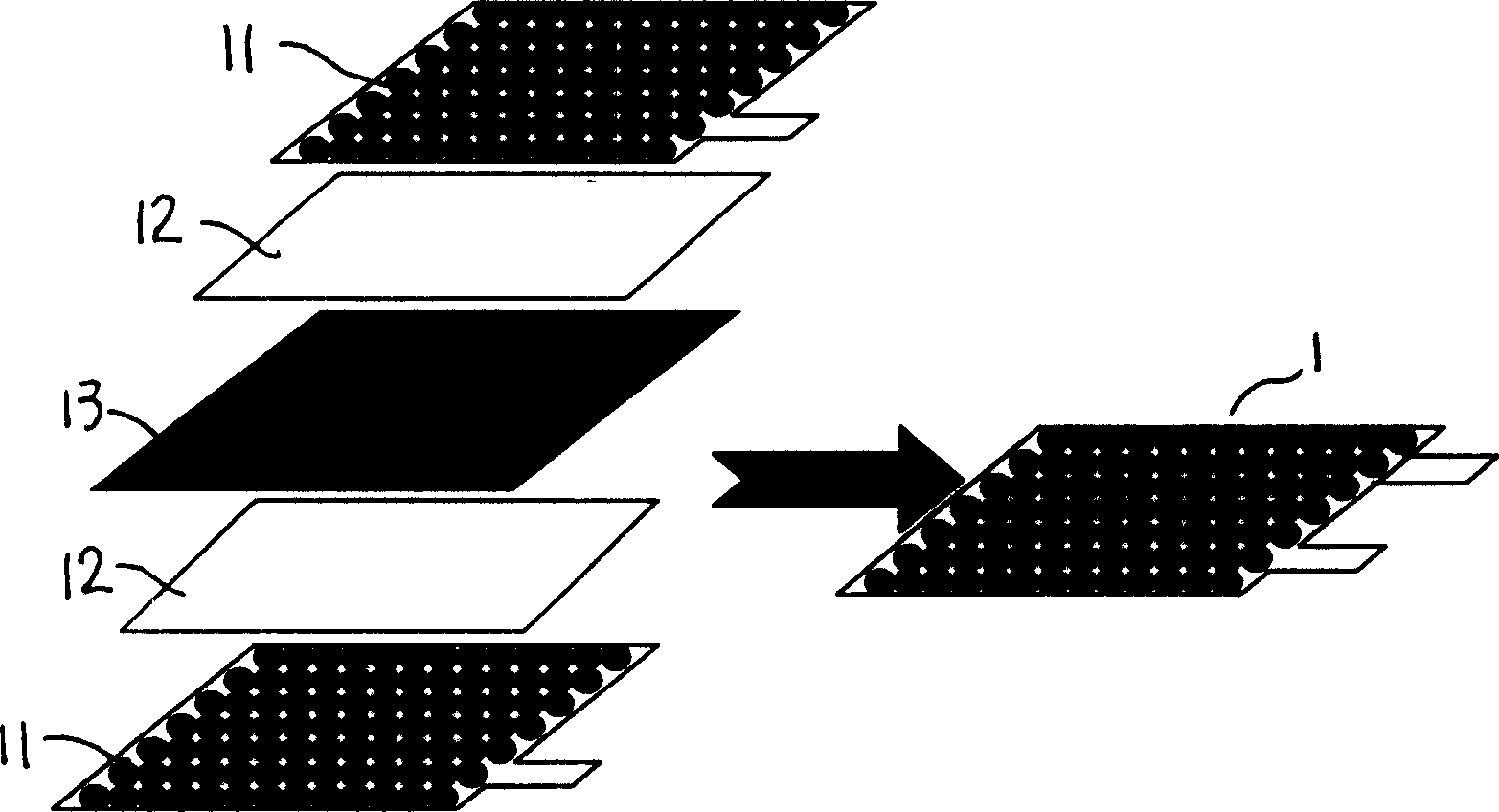

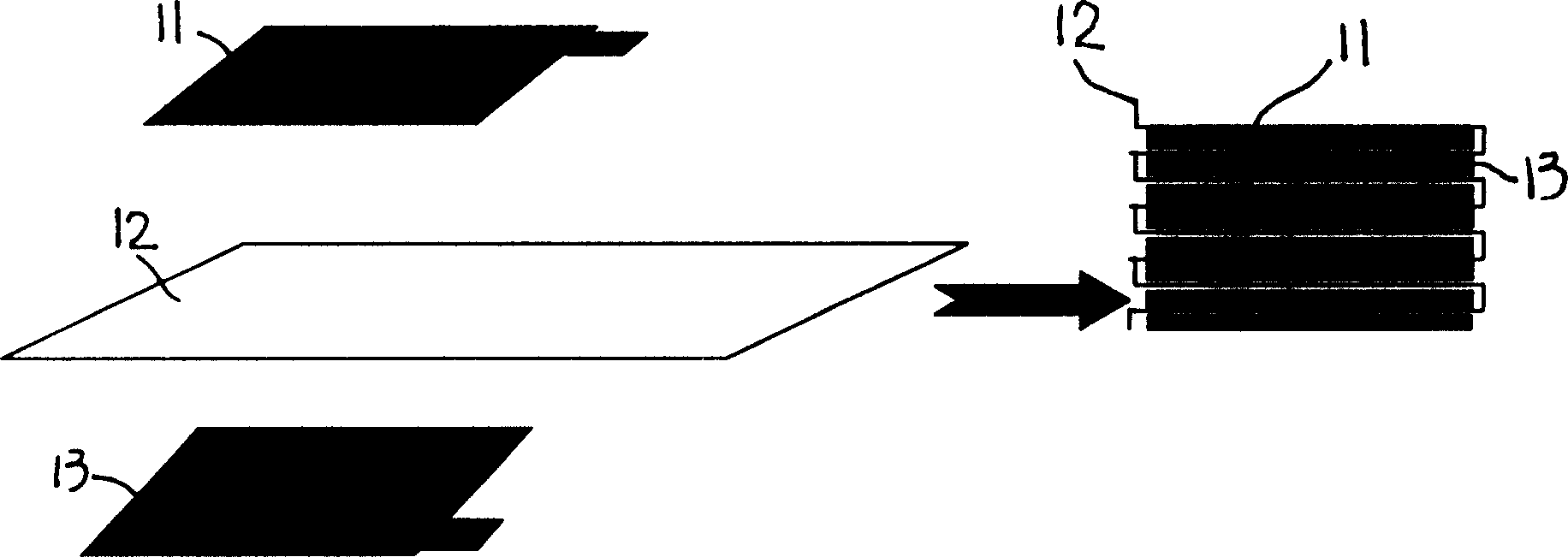

Method used

Image

Examples

Embodiment approach

[0029] One, the preparation method of phase separation porous isolation membrane:

[0030] (1) Prepare separator slurry: dissolve vinylidene fluoride and hexafluoropropylene copolymer (PVDF-HFP) or polyvinylidene fluoride (PVDF) (5-30%, mass percentage, the same below) in an organic solvent, Join Al 2 o 3 or SiO 2 Inorganic matter powder (1-20%), mix evenly, add phase separation agent after stirring evenly. Organic solvents can be composed of propenyl carbonate (PC), ethyl acetate (EtAc), ethyl methyl carbonate (EMC), dimethyl carbonate (DMC), diethyl carbonate (DEC), acetone (ACE), butyl One or more of organic polar solvents such as ketone, N, N-dimethylpyrrolidone (NMP), and cyclohexanone. The phase separation agent can be composed of one or more of water, methanol, ethanol, butanol, ethylene glycol, glycerol, and isobutanol.

[0031] (2) Evenly coat the isolation film slurry on the film made of PET, PE, PP, PVC, centrifugal paper and other materials according to the re...

Embodiment 1

[0046] Isolation film:

[0047] (1) Preparation of separator slurry: dissolve vinylidene fluoride and hexafluoropropylene copolymer (PVDF-HFP) (18%, mass percentage, the same below) in acetone, polystyrene (PS) (6%) In dimethyl carbonate (DMC). Mix the two solutions well, then add SiO 2 (5%), after stirring evenly, slowly add ethanol. After stirring, let stand for more than 30 minutes.

[0048] (2) Coat the isolation film slurry on the PET according to the required thickness, and then dry at a temperature of 75°C.

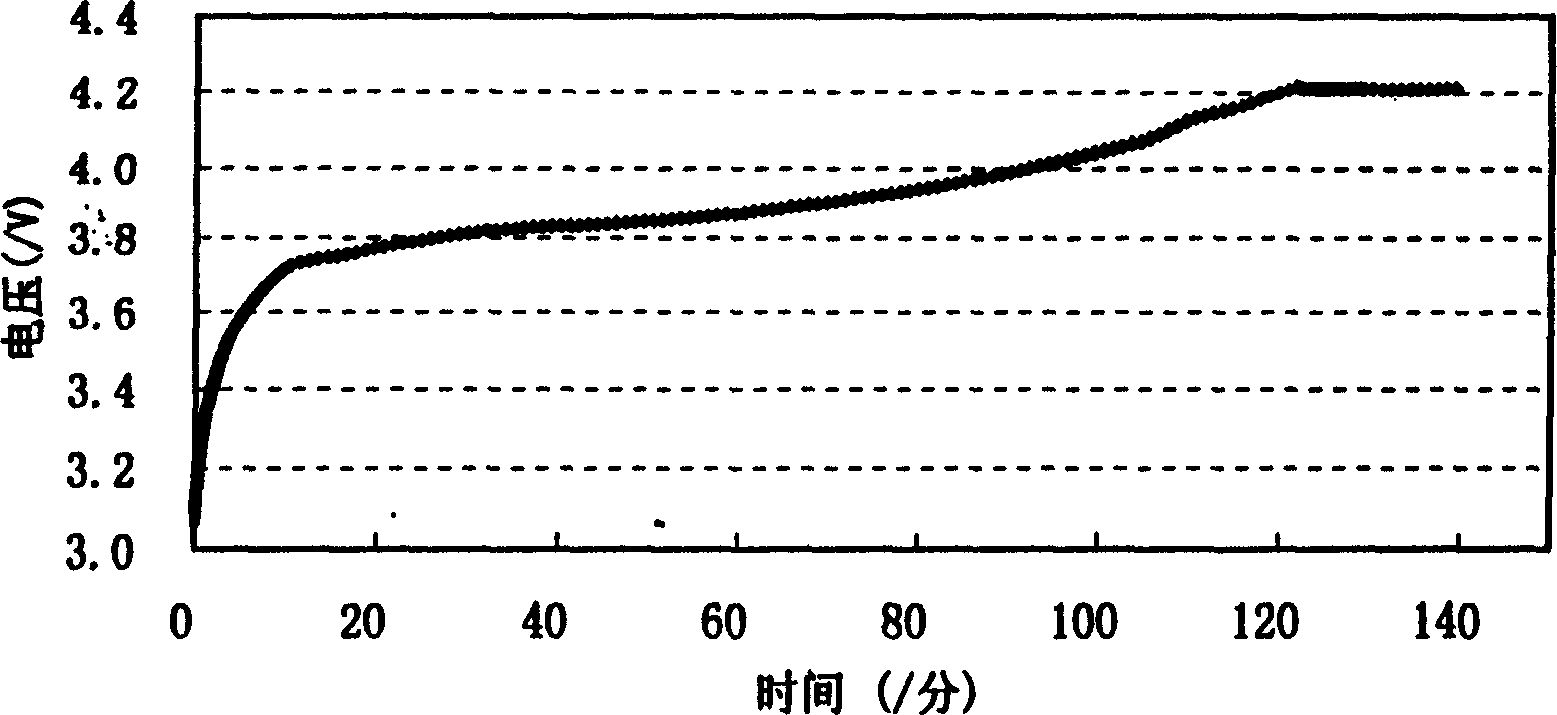

[0049] The main parameters and performance of the secondary polymer lithium battery made of this separator are as follows:

[0050] Capacity: 807mAh

[0051] Charging cut-off voltage: 4.2V

[0052] Discharge cut-off voltage: 3.0V

[0053] Its charging curve at 0.5C (C is the charge and discharge rate potential, indicating the number of charges and discharges per hour) is shown in image 3 , its discharge curves and cycle life curves at different rates are s...

Embodiment 2

[0055] Isolation film:

[0056] (1) Preparation of separator slurry: polyvinylidene fluoride (12%) was dissolved in N,N-dimethylpyrrolidone (NMP), and polystyrene (15%) was dissolved in dimethyl carbonate. Then mix the two solutions evenly and add SiO 2 (5%), after stirring evenly, slowly add ethanol, after stirring, let it stand for more than 30 minutes.

[0057] (2) Coat the separator slurry on the PET according to the required thickness, and then dry it at 95°C.

[0058] The main parameters and performance of the secondary polymer lithium battery made of this separator are as follows:

[0059] Capacity: 776mAh

[0060] Charging cut-off voltage: 4.2V

[0061] Discharge cut-off voltage: 3.0V

[0062] Its charging curve at 0.5C see Image 6 , the discharge curves at different rates are shown in Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com