A kind of preparation method of anti-mud-shrinkage polycarboxylate superplasticizer

A technology of water reducing agent and polycarboxylic acid, applied in the field of concrete additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

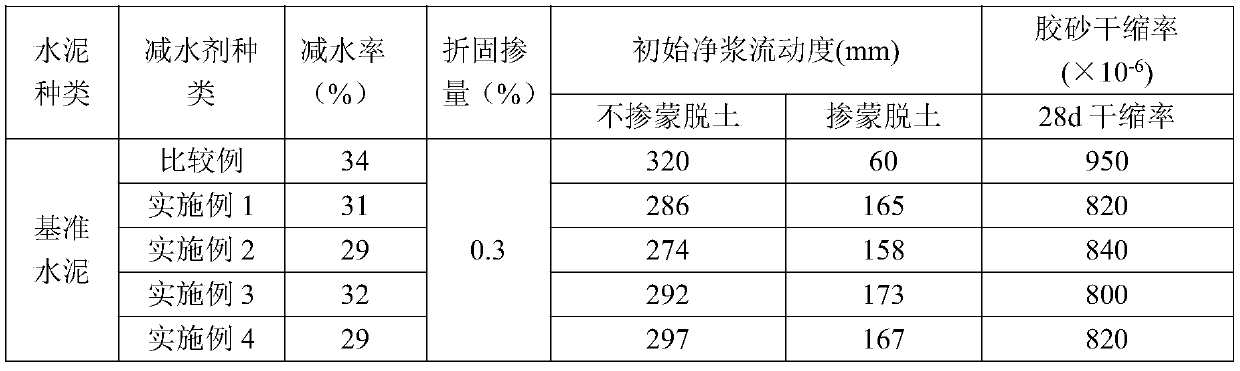

Examples

Embodiment 1

[0032] A preparation method of mud-resistant-shrinkage-reducing polycarboxylate water-reducer, comprising the following steps:

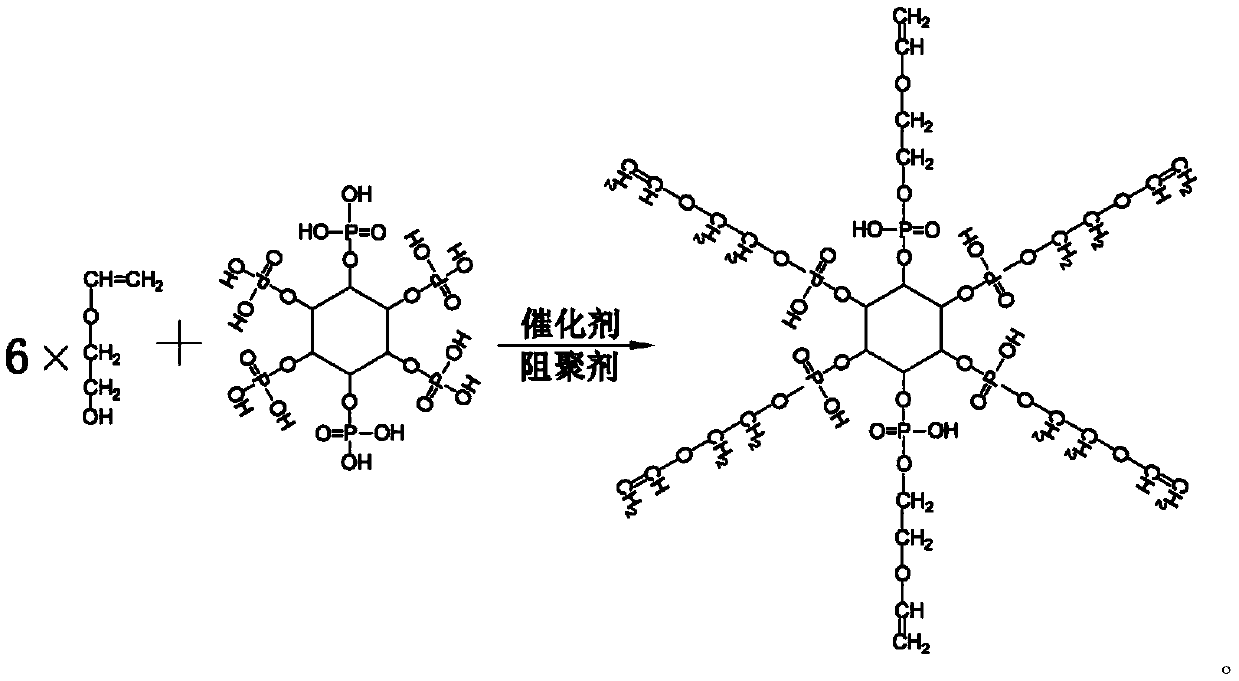

[0033] S1: Synthesis of snowflake-shaped anti-mud macromonomer: 100g of phytic acid solution with a concentration of 70%, 0.15g of hydroquinone polymerization inhibitor, and 3.64g of p-toluenesulfonic acid catalyst were added to the reaction vessel, stirred evenly, and heated to 50°C, add 51.33g of vinyl glycol ether into the reaction container dropwise in 4 times for 2 hours, stir well, when the temperature rises to 150°C, carry out the heat preservation reaction, the reaction time is 4h, and cool down after the reaction To normal temperature, the snowflake-shaped anti-mud macromonomer is obtained;

[0034] S2: Synthesis of anti-mud-shrinkage polycarboxylate water-reducer: 54.0 g of the product snowflake-shaped anti-mud macromonomer obtained in step S1, sodium methacrylate sulfonate 15.8 g, propylene polyoxyethylene ether (molecular weight= 1000) 1...

Embodiment 2

[0036] A preparation method of mud-resistant-shrinkage-reducing polycarboxylate water-reducer, comprising the following steps:

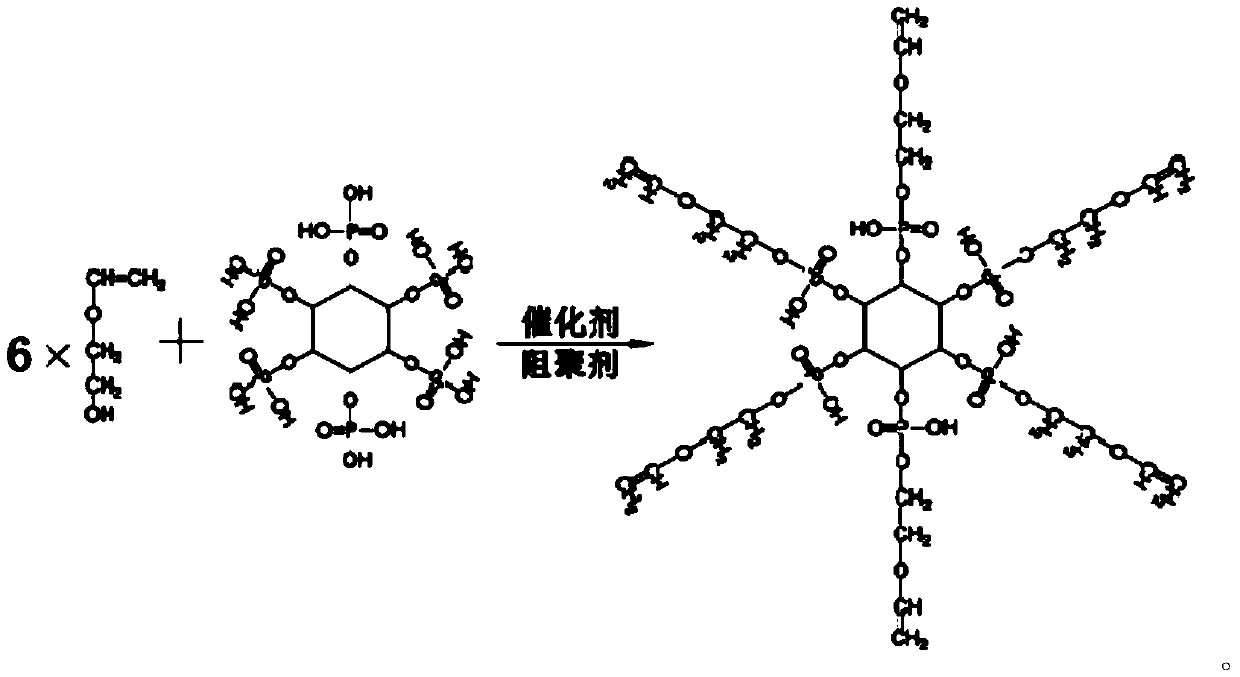

[0037] S1: Synthesis of snowflake-shaped anti-mud macromonomer: add 100g of phytic acid solution with a concentration of 70%, 0.56g of hydroquinone polymerization inhibitor, and 5.67g of concentrated sulfuric acid catalyst into the reaction vessel, stir evenly, and heat up to 50°C , add the weighed 56.0g vinyl glycol ether into the reaction vessel dropwise in 4 times for 2 hours, stir well, when the temperature rises to 140°C, carry out the heat preservation reaction, the reaction time is 5h, after the reaction, cool to room temperature , to obtain a snowflake-shaped anti-mud macromonomer;

[0038] S2: Synthesis of anti-mud-shrinkage polycarboxylate superplasticizer: 54.0 g of the product snowflake-shaped anti-mud macromonomer obtained in step S1, 11.85 g of allyl sodium sulfonate, and methallyl polyoxyethylene ether (Molecular weight = 2000) 200g, ...

Embodiment 3

[0040] A preparation method of mud-resistant-shrinkage-reducing polycarboxylate water-reducer, comprising the following steps:

[0041] S1: Synthesis of snowflake-shaped anti-mud macromonomer: 100g of phytic acid solution with a concentration of 70%, 1.21g of hydroquinone polymerization inhibitor, and 1.96g of p-toluenesulfonic acid catalyst were added to the reaction vessel, stirred evenly, and heated to 50°C, add 60.67g of vinyl glycol ether into the reaction vessel dropwise in 2 times for 2 hours, stir well, and when the temperature rises to 180°C, carry out the heat preservation reaction, the reaction time is 3h, and cool down after the reaction To normal temperature, the snowflake-shaped anti-mud macromonomer is obtained;

[0042] S2: Synthesis of anti-mud-shrinkage-reducing polycarboxylate superplasticizer: 54.0 g of the snowflake-shaped anti-mud macromonomer obtained in step S1, 3.95 g of sodium methacrylate, allyl block polyether+propylene Base polyoxyethylene ether (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com