Water-based conductive graphite emulsion for alkaline zinc-manganese battery and preparation method of water-based conductive graphite emulsion

A zinc-manganese battery, conductive graphite technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor corrosion resistance, harsh production site environment of conductive graphite emulsion, insufficient dry film conductivity, etc. Low, solve safety hazards and environmental protection problems, the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

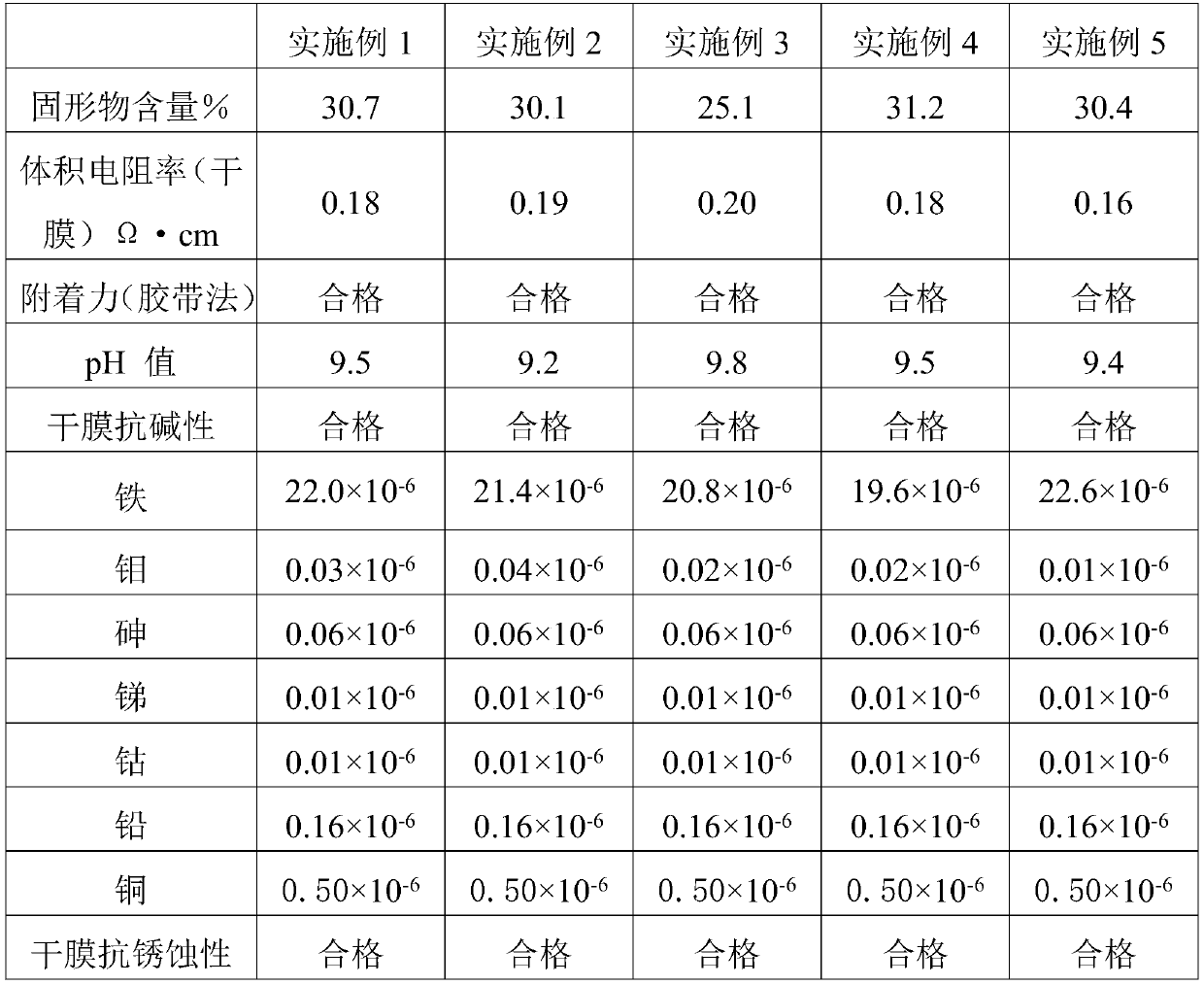

Examples

Embodiment 1

[0031] This embodiment provides a water-based conductive graphite emulsion for alkaline zinc-manganese batteries, which uses water as the solvent, graphite and carbon black as the main conductive base material, water-based resin as the bonding base material, and auxiliary additives. into; the weight ratio of its compounding components is: 20 parts of acrylic resin, 0.6 part of sodium carboxymethyl cellulose, 2 parts of succinate block copolymer, 1.0 part of silicone leveling agent, 2.5 parts of lauryl alcohol ester, graphite 18 parts, 2 parts of carbon black, 2 parts of amine chelate containing zinc salt, 1.0 part of polyether modified silicone oil, 0.5 part of ammonia water, 30 parts of water, 2 parts of propylene glycol methyl ether.

[0032] The preparation method of the water-based conductive graphite emulsion of the alkaline zinc-manganese battery of the present embodiment comprises the following steps:

[0033] (1) Disperse the sodium carboxymethyl cellulose evenly in wa...

Embodiment 2

[0039] This embodiment provides a water-based conductive graphite emulsion for alkaline zinc-manganese batteries, which uses water as the solvent, graphite and carbon black as the main conductive base material, water-based resin as the bonding base material, and auxiliary additives. into; the weight ratio of its mixing components is: 10 parts of amino resin, 1 part of sodium carboxymethyl cellulose, 2 parts of succinate block copolymer, 2 parts of silicone leveling agent, 1 part of lauryl alcohol ester, graphite 20 parts, 1 part of carbon black, 1 part of amine chelate containing zinc salt, 0.1 part of polyether modified silicone oil, 1 part of ammonia water, 80 parts of water, 3 parts of propylene glycol methyl ether.

[0040] The preparation method of the water-based conductive graphite emulsion of the alkaline zinc-manganese battery of the present embodiment comprises the following steps:

[0041] (1) Disperse the sodium carboxymethyl cellulose evenly in water to make an aq...

Embodiment 3

[0047] This embodiment provides a water-based conductive graphite emulsion for alkaline zinc-manganese batteries, which uses water as the solvent, graphite and carbon black as the main conductive base material, water-based resin as the bonding base material, and auxiliary additives. into; the weight ratio of its compounding components is: 40 parts of acrylic resin, 0.3 part of sodium carboxymethyl cellulose, 2 parts of acrylic block copolymer, 0.1 part of silicone leveling agent, 8 parts of lauryl alcohol ester, 8 parts of graphite 2 parts, 2 parts of carbon black, 1 part of amine chelate containing zinc salt, 2 parts of polyether modified silicone oil, 0.1 part of ammonia water, 52.5 parts of water, 1 part of propylene glycol methyl ether.

[0048] The preparation method of the water-based conductive graphite emulsion of the alkaline zinc-manganese battery of the present embodiment comprises the following steps:

[0049] (1) Disperse the sodium carboxymethyl cellulose evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com