Micro-carrier for cell culture and preparation method and application thereof

A cell culture and microcarrier technology, applied in general culture methods, microcarriers, biochemical equipment and methods, etc., to achieve the effect of simple and easy preparation process, non-toxic raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

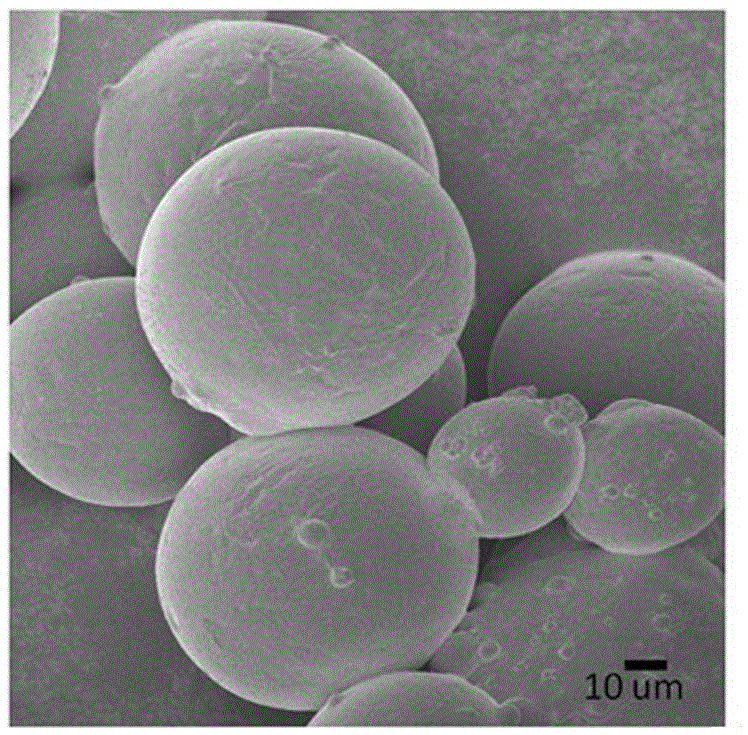

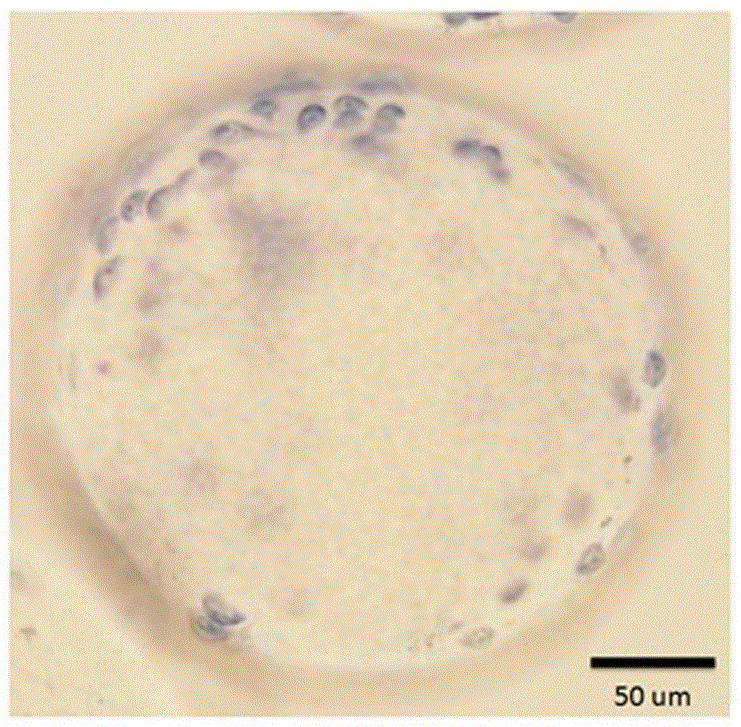

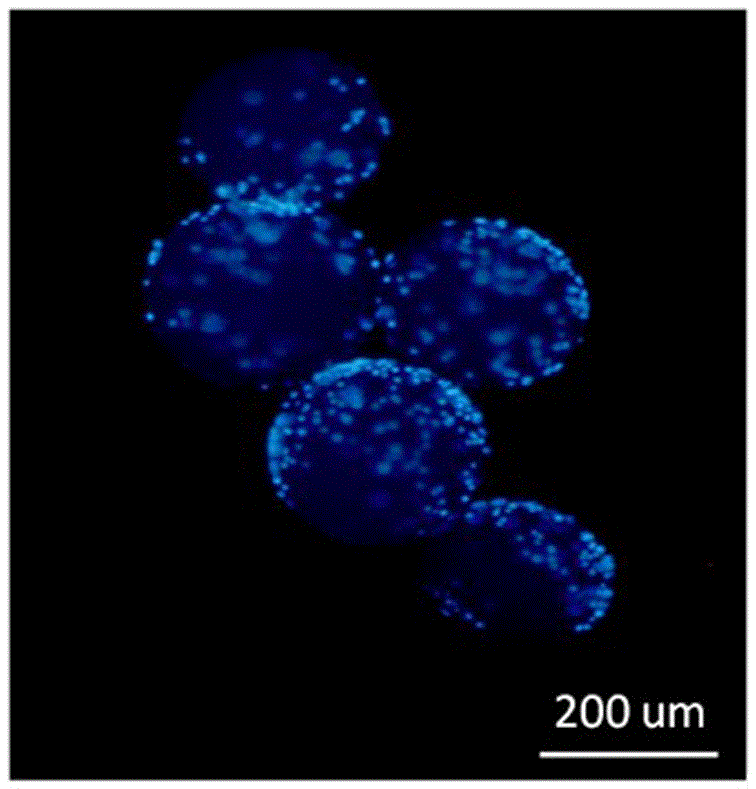

Image

Examples

preparation example Construction

[0064] A kind of preparation method step of microcarrier for cell culture of the present invention is as follows:

[0065] (1) First prepare gelatinized starch alkali solution: dissolve starch in deionized water, heat slowly until gelatinized while stirring, then add 0.5-2mol / L NaOH solution to continue stirring and mixing, cool and stand to form a uniform aqueous solution , in the aqueous phase solution, the mass volume percentage of starch is 0.1% to 15%;

[0066] (2) Mixing oil-water phase to make balls: Mix and stir non-toxic high-density oil, isooctane, dispersant and a certain amount of emulsifier to form a uniform oil phase solution, then slowly add the water phase solution in step (1), Stir to form a uniform and stable mixed phase; the sum of the volume concentration of the emulsifier and dispersant in the oil phase is 0.1% to 5%, and the volume ratio of the water phase solution to the oil phase solution is 1:1 to 10;

[0067] (3) Cross-linking and solidification into...

Embodiment 1

[0077] A kind of preparation method step of microcarrier for cell culture of the present invention is as follows:

[0078] (1) First prepare gelatinized starch alkali solution: weigh 10g of soybean starch and dissolve it in 200mL of deionized water, slowly heat to 80°C for gelatinization while stirring, then add 20mL of 0.5mol / L NaOH solution, continue to stir and mix, cool and stand into a uniform aqueous solution;

[0079] (2) Mix oil-water phase to make balls: Measure 500mL of soybean oil, 500mL of isooctane, 15mL of Span-8015mL and 10mL of Tween-8010mL and mix and stir for 20 minutes to form a uniform solution, then slowly add 220ml of water phase solution and stir for 30 minutes to form a uniform and stable mixed phase;

[0080] (3) Cross-linking and solidification into balls: slowly add 20 mL of polypropylene glycol diglycidyl ether into the mixed phase at a stirring speed of 500 rpm, and leave to stand after 6 hours of cross-linking reaction at room temperature;

[00...

Embodiment 2

[0088] A kind of preparation method step of microcarrier for cell culture of the present invention is as follows:

[0089] (1) First prepare gelatinized starch alkali solution: weigh 15g of potato starch and dissolve it in 500mL of deionized water, heat slowly to 80°C for gelatinization while stirring, then add 30mL of 1mol / L NaOH solution and continue to stir and mix, cool and stand still to form Homogeneous aqueous solution;

[0090] (2) Oil-water phase mixing balls: Measure 1000mL of engine oil, 1000mL of isooctane, Span-2050mL and Tween-8050mL, mix and stir for 20 minutes to form a uniform solution, slowly add 530ml of water phase solution, and stir for 30 minutes to form a uniform and stable mixture Mutually;

[0091](3) Cross-linking and solidification into balls: slowly add 60 mL of polyethylene glycol glycidyl ether into the mixed phase at a stirring speed of 700 rpm, and after 7 hours of cross-linking reaction at room temperature, let stand;

[0092] (4) Degreasing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com