a kind of added tio 2 mbbt water-based dispersion paste

An aqueous dispersion and dispersant technology, which can be applied to skin care preparations, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve the problems of difficult dispersion, poor absorption effect, application limitations, etc., and achieves easy operation and low cost. , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

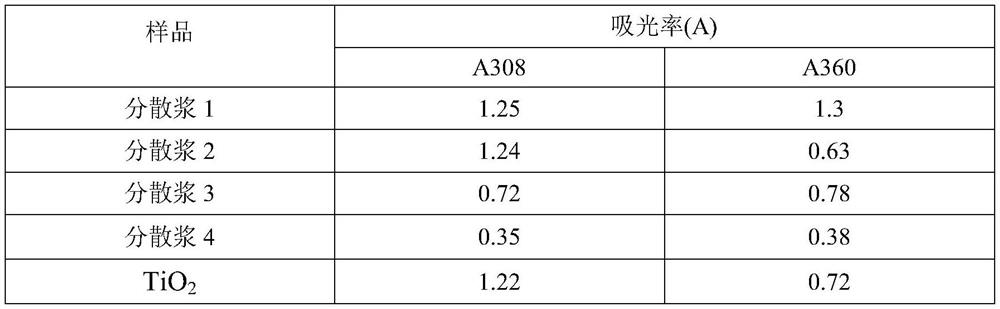

Examples

Embodiment 1

[0018] A kind of added TiO 2 MBBT water-based dispersion slurry, wherein the mass percentage of each component is: MBBT and TiO 2 Powder accounts for 50% and TiO 2 The mass ratio to MBBT is 1:2, the 731A dispersant is 10%, the phenoxyethanol is 3%, and the balance is deionized water. The specific preparation method is as follows:

[0019] Weigh MBBT and TiO according to the formula 2 Put the powder into the sand grinding barrel with deionized water, pre-disperse on the dispersing plate at a speed of 2000r / min for 10min, then add half of the 731A dispersant drop by drop, change the grinding wheel and re-disperse at a speed of 4000r / min Add the remaining 731A dispersant drop by drop. The purpose is to prevent a large number of bubbles from being added at one time and affect the use of the slurry. Add phenoxyethanol and grind for 1 hour to obtain the added TiO 2 MBBT water-soluble dispersion slurry, referred to as dispersion slurry 1.

Embodiment 2

[0021] A kind of added TiO 2 MBBT water-based dispersion slurry, wherein the mass percentage of each component is: MBBT and TiO 2 Powder accounts for 40% and TiO 2 The ratio to MBBT is 1:1, 731A dispersant is 5%, 1,2 hexanediol is 1%, and the balance is deionized water. The specific preparation method is as follows:

[0022] Weigh MBBT and TiO according to the formula 2 Put the powder into the sand grinding barrel with deionized water, pre-disperse on the dispersing plate at a speed of 2000r / min for 10min, then add half of the 731A dispersant drop by drop, change the grinding wheel and re-disperse at a speed of 4000r / min Add the remaining 731A dispersant drop by drop, add 1,2 hexanediol, and then grind for 1 h to obtain the added TiO 2 MBBT water-based dispersion slurry, referred to as dispersion slurry 2.

Embodiment 3

[0024] A kind of added TiO 2 MBBT water-based dispersion slurry, wherein the mass percentage of each component is: MBBT and TiO 2 Powder accounts for 30% and TiO 2 The ratio to MBBT is 1:5, polyglyceryl-10 oleate is 4%, 1,3 butanediol is 3.5%, and the balance is deionized water.

[0025] Weigh MBBT and TiO according to the formula 2 Add the powder to the sand grinding barrel with deionized water, and pre-disperse the dispersing disc at a speed of 2000r / min for 10 minutes. Add the remaining polyglycerol-10 oleate drop by drop at 4000r / min, add 1,3 butanediol, and then grind for 1h to obtain the added TiO 2 MBBT water-based dispersion slurry, referred to as dispersion slurry 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com