Soft ferritic stainless steel and manufacture method thereof

A manufacturing method, ferrite technology, applied in the direction of manufacturing tools, temperature control, heat treatment process control, etc., can solve the problems of unfavorable commemorative coin embossing, insufficient wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

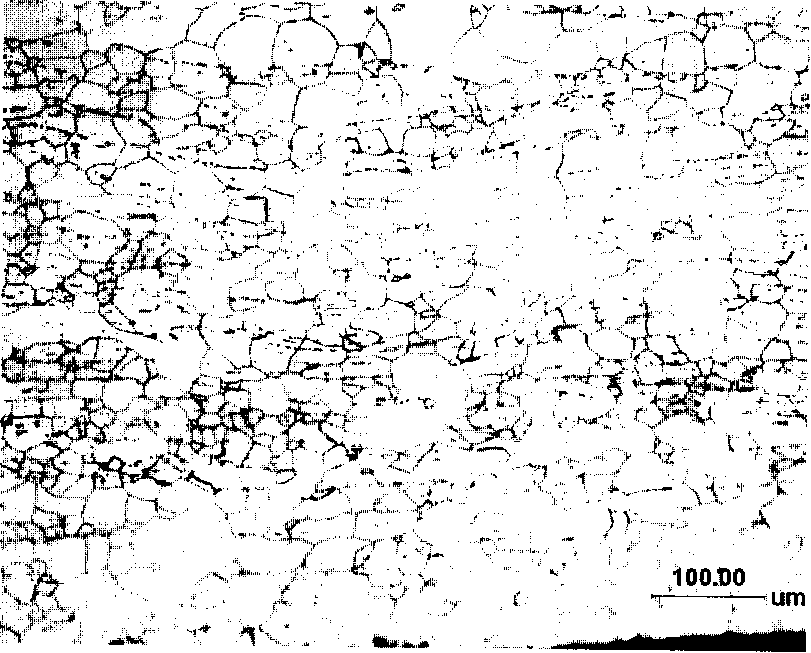

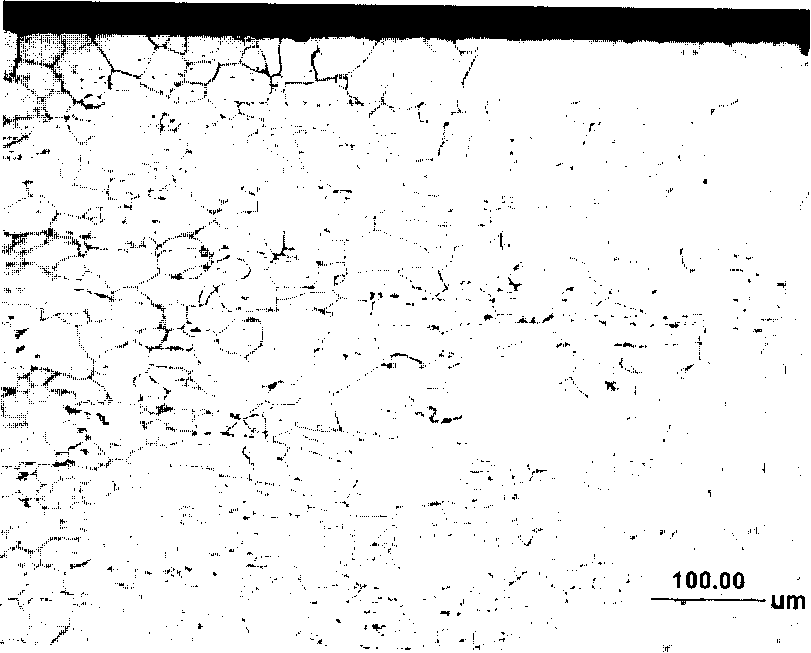

[0049] The composition of the embodiment is shown in Table 1, the manufacturing process is shown in Table 2, the mechanical properties are shown in Table 3, and the results of the corrosion resistance comparison test with SUS430 are shown in Table 4, using 10% FeCl 3 Solution carries out immersion test, and test solution temperature is 50 ℃, and immersion time is 5 hours, and sample size is 20mm (long) * 40mm (wide) * 1.7mm (thick), as can be seen from Table 4, the present invention is more resistant than SUS430 Chlorides are much more corrosive. The metallographic picture of the test steel cold-rolled and annealed is shown in Figure 1a , Figure 1b , the grain grade is 7.5. The finer the grain, the higher the strength of the steel and the higher the hardness, so the material does not need to pursue high grain size indefinitely.

[0050] Table 1

[0051] Unit: mass percentage

[0052] Example

[0053] Table 2

[0054]

[0055] 6

[0056] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com