Lithium battery monolithic film maker

A single-chip, lithium battery technology, applied in the manufacture of electrolyte batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of affecting battery quality, low efficiency, inconsistent tab exposure, etc., to achieve easy removal, The effect of improving yield and high consistency of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Combine below Figure 1 to Figure 6 , the present invention is further described:

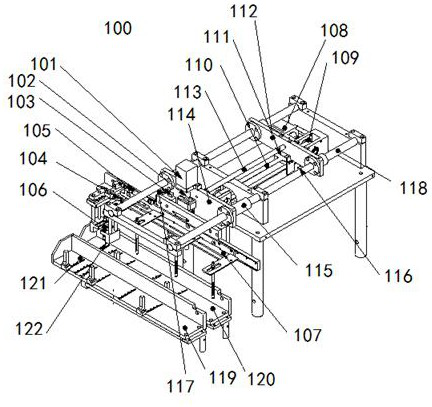

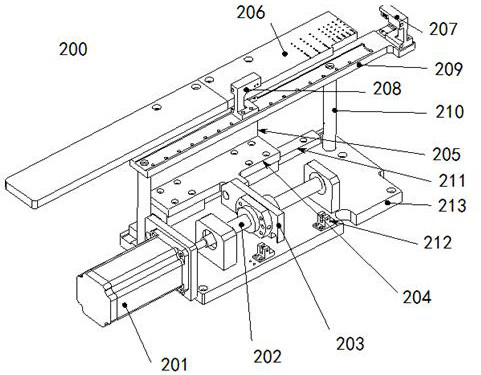

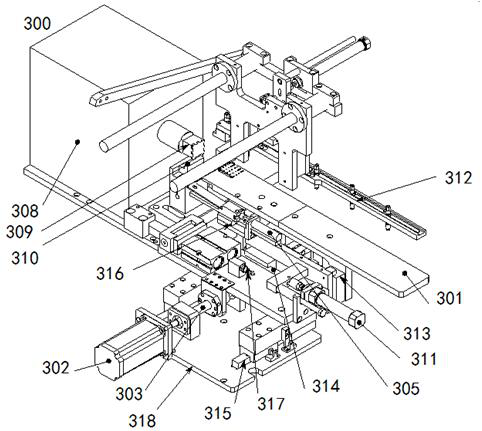

[0033] A lithium battery monolithic sheet making machine, comprising a pole piece feeding and flattening mechanism 100, a pole piece head positioning mechanism 200, and a pole piece positioning welding mechanism 300, the pole piece feeding and pushing mechanism 100 passes through the first vertical translation device And the first horizontal translation device moves the pole piece from the magazine on the Y-axis pole piece platform 206, and rolls up the pole piece head and pushes it flat; the pole piece head positioning mechanism 200 is used to complete the position of the pole piece head positioning; after the pole piece positioning welding mechanism 300 completes the positioning of the right side of the pole piece, the pole piece is welded and fixed through the pole piece.

[0034] Such as figure 1 As shown, the pole piece loading and flattening mechanism 100 moves the pole piece fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com