Vacuum electron beam welding method for magnesium alloy component

A technology of vacuum electron beam and welding method, applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as inability to eliminate defects, and achieve good appearance, high welding quality consistency, and high welding yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

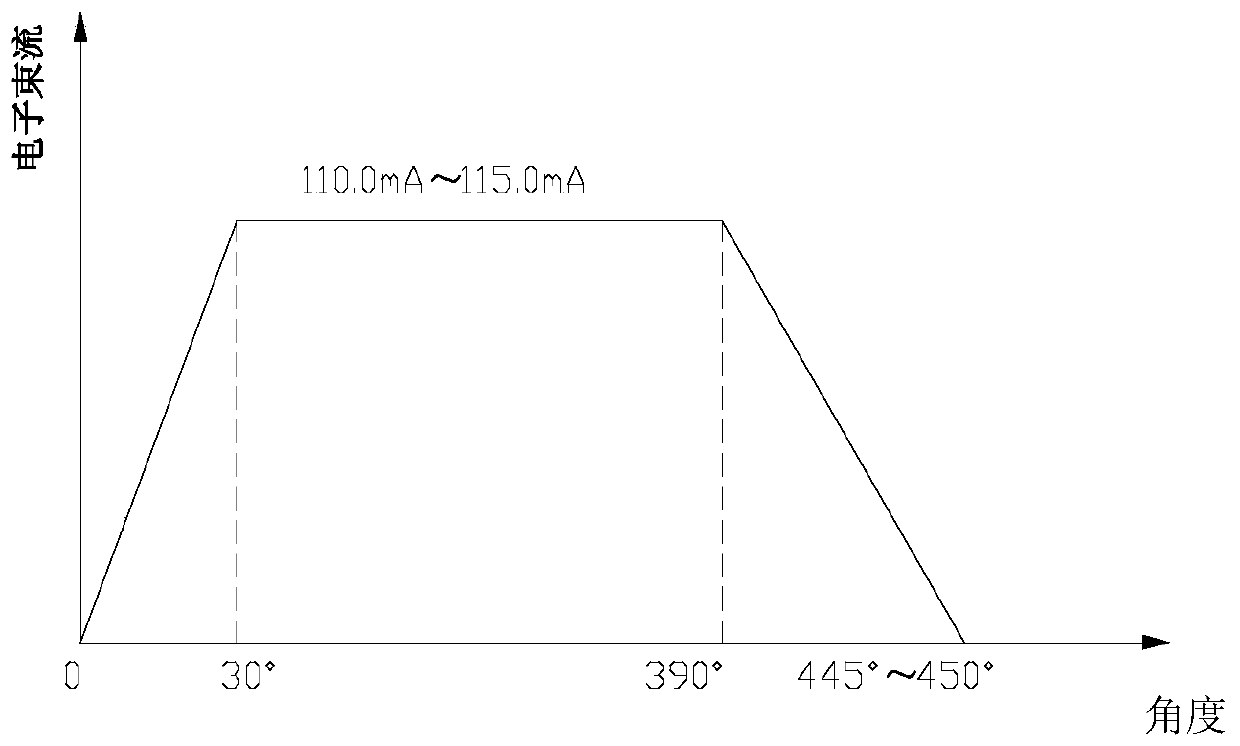

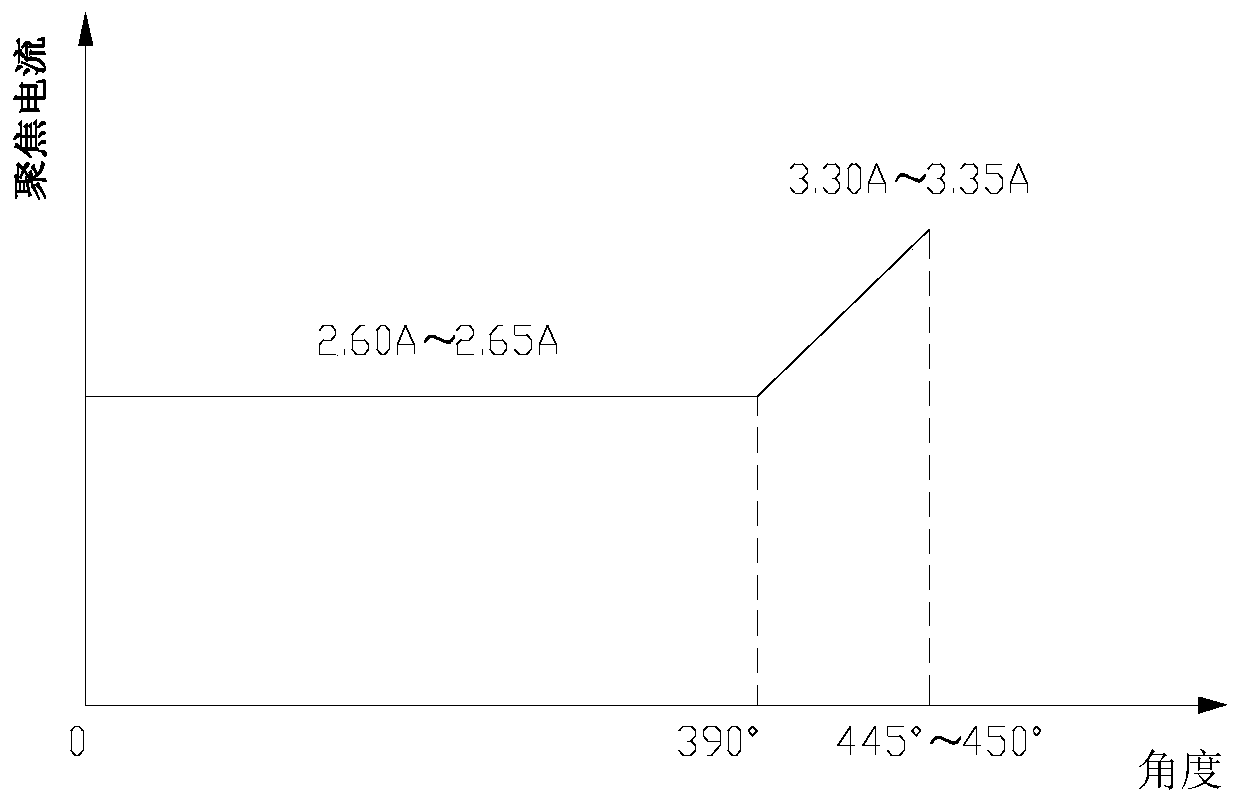

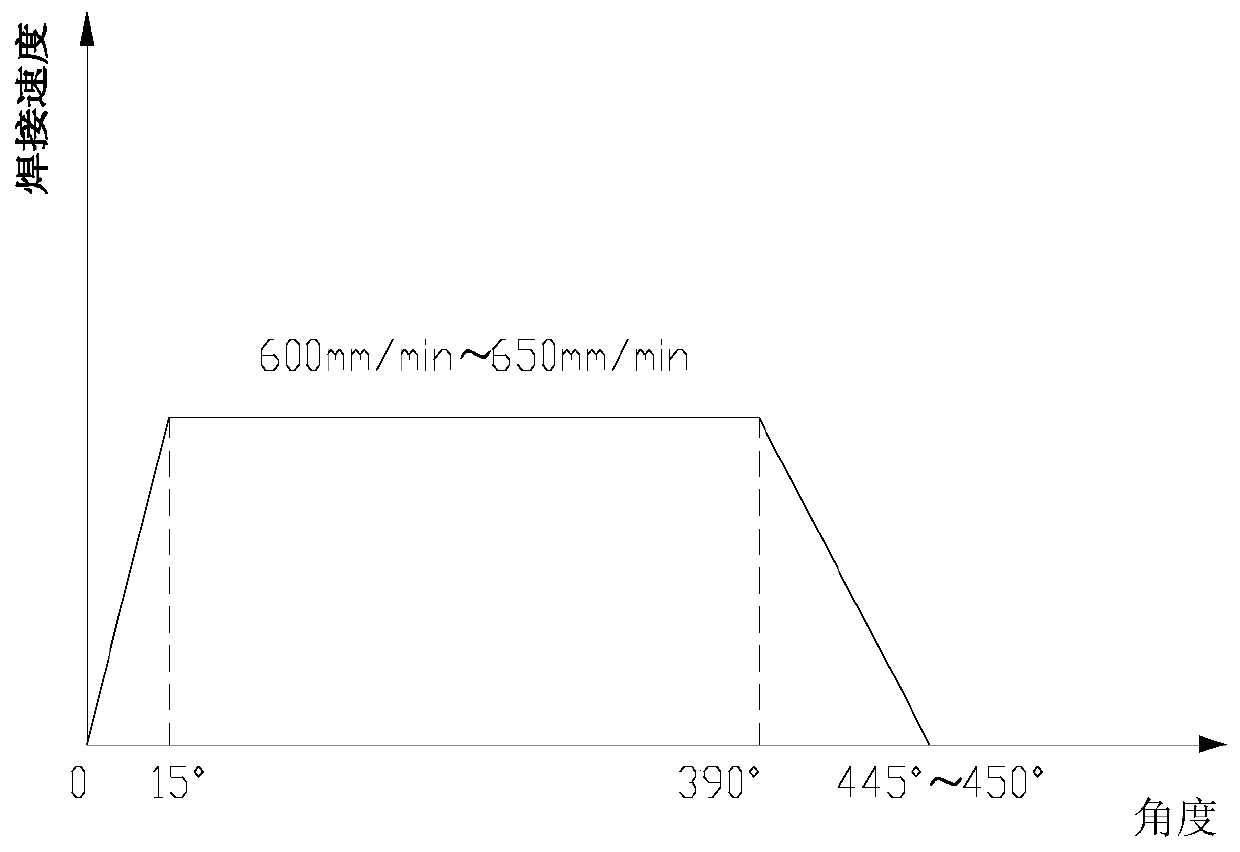

[0035] Such as Figure 1 to Figure 3 As shown, the vacuum electron beam welding method of the magnesium alloy component of the embodiment of the present invention comprises the following steps:

[0036] 1) Selection of welded parts: the welded joint adopts a complete butt joint, and adopts a circular magnesium alloy blank; in this embodiment, 20 pieces of circular magnesium alloy blanks with an outer diameter of 130mm and an inner diameter of 20mm are electron beam welded;

[0037] 2) Cleaning of welded parts: Wipe and clean the magnesium alloy blank and complete butt joints, use clean white gauze dipped in acetone to wipe and clean each part of the welded parts, remove the oil film, water film and organic impurities on the surface to be welded, and clean the The surface is also not allowed to touch and recontaminate with hands;

[0038]3) Assembly: After cleaning, assemble and weld each welding part, and use special fixtures for assembly during assembly. The assembly gap is ...

Embodiment 2

[0049] The difference between this embodiment and above-mentioned embodiment one is only: 1) select 20 outer diameters to be 140mm for use, inner diameter is the magnesium alloy blank of 20mm; 2) welding speed V 0 Using 600mm / min, electron beam current L 0 Using 115.0mA, focusing current I 0 With 2.65A, the focus current I 1 = 3.35A.

[0050] The weld penetration depth of the magnesium alloy component obtained by the above-mentioned vacuum electron beam welding method is 55 mm to 60 mm, and the surface and subsurface of the weld seam have no pores, and the pores inside the weld seam and the arc closing pores are diffusely distributed, and the diameter of a single pore is less than 1.2mm. There are no cracks, slag inclusions and other welding defects in the weld, that is, the welding quality is better while obtaining a larger penetration depth.

Embodiment 3

[0052] The difference between this embodiment and above-mentioned embodiment one is only: 1) select 20 outer diameters to be 140mm for use, inner diameter is the magnesium alloy blank of 20mm; 2) welding speed V 0 Using 650mm / min, electron beam current L 0 Using 110.0mA, focusing current I 0 Using 2.60A, focus current I 1 = 3.30A.

[0053] The weld penetration depth of the magnesium alloy component obtained by the above-mentioned vacuum electron beam welding method is 55 mm to 60 mm, and the surface and subsurface of the weld seam have no pores, and the pores inside the weld seam and the arc closing pores are diffusely distributed, and the diameter of a single pore is less than 1.2mm. There are no cracks, slag inclusions and other welding defects in the weld, that is, the welding quality is better while obtaining a larger penetration depth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com