Polishing device for welding tip

A technology of grinding device and welding tip, applied in positioning device, grinding machine, grinding/polishing equipment, etc., can solve the problems of requiring movement and time-consuming, and achieve the effect of simple grinding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

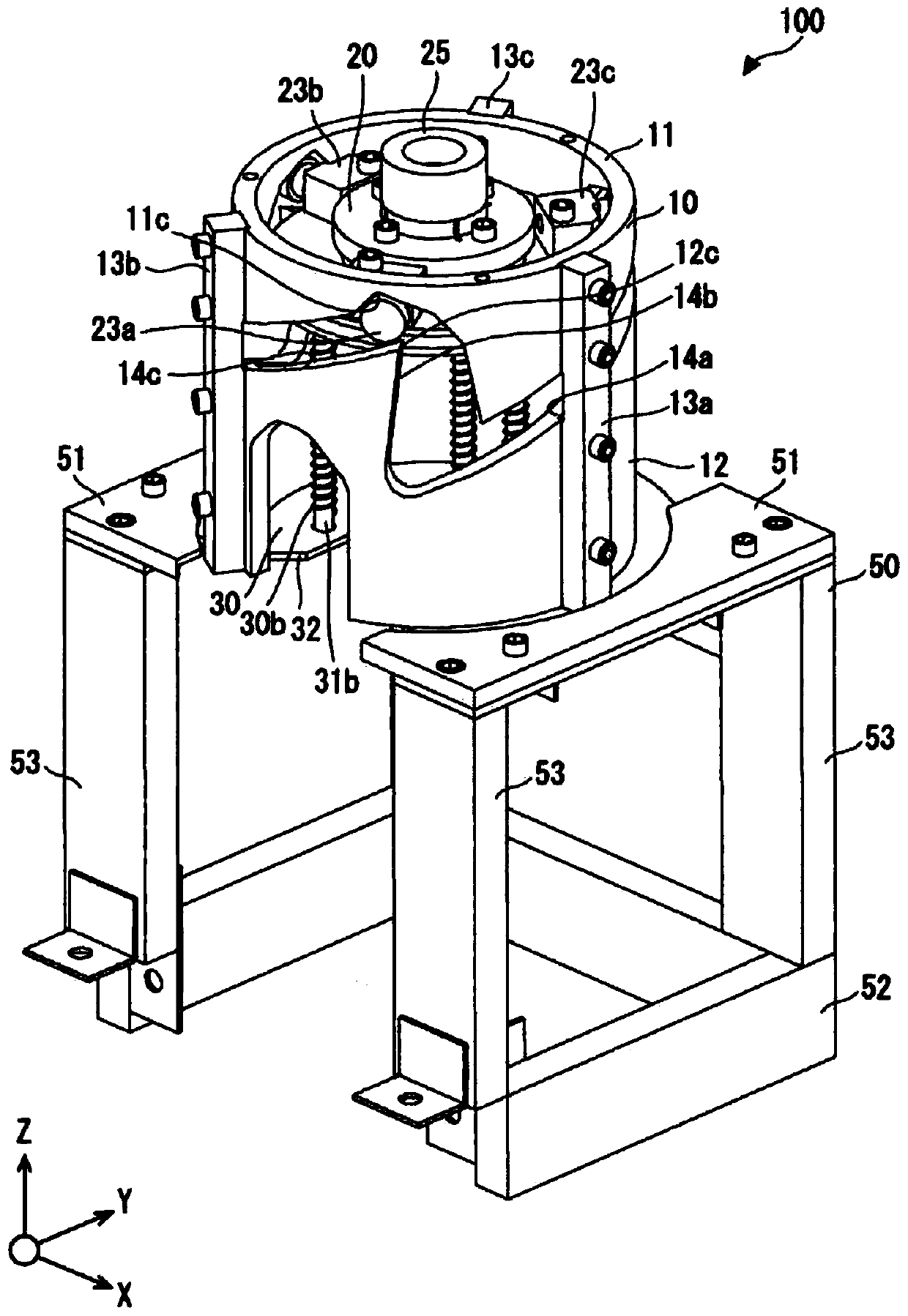

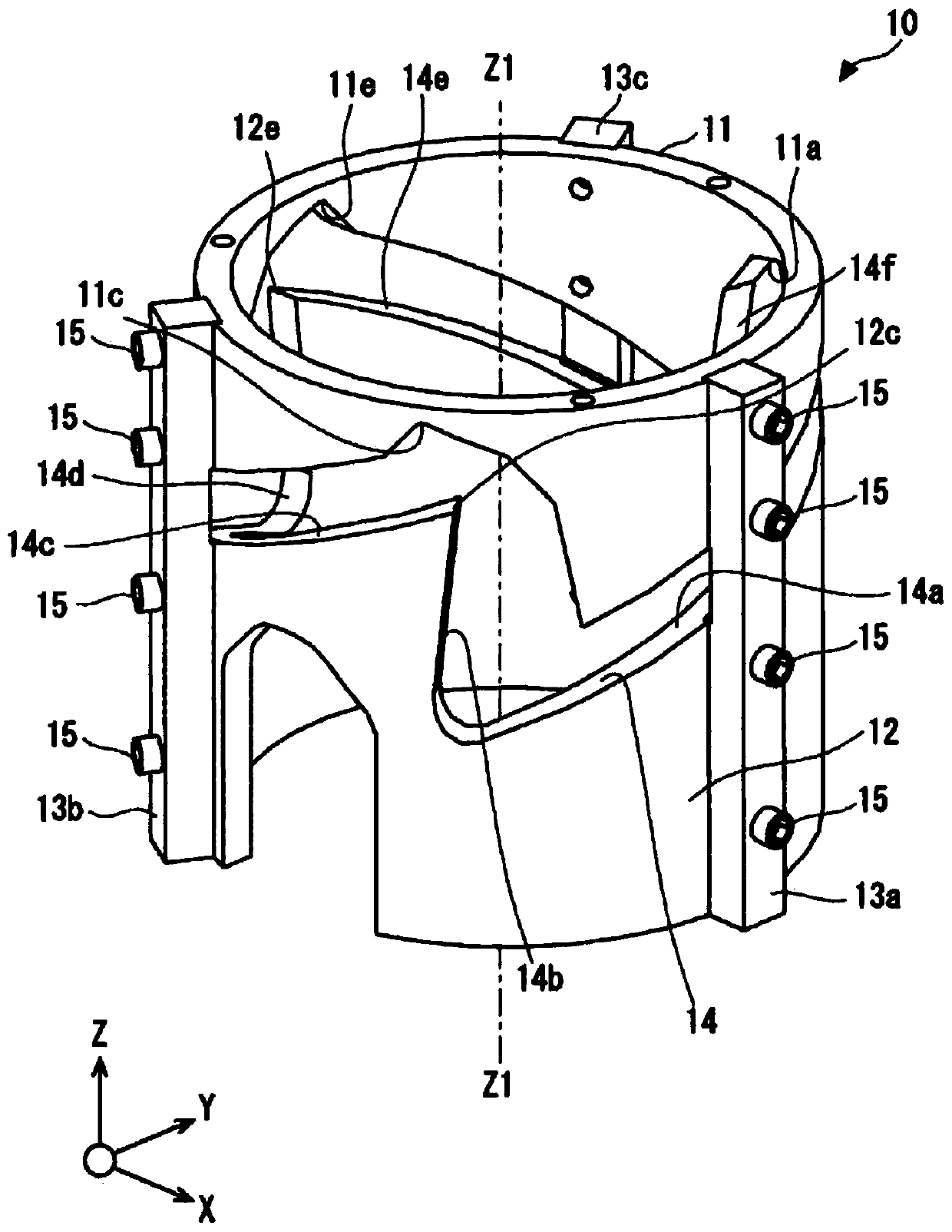

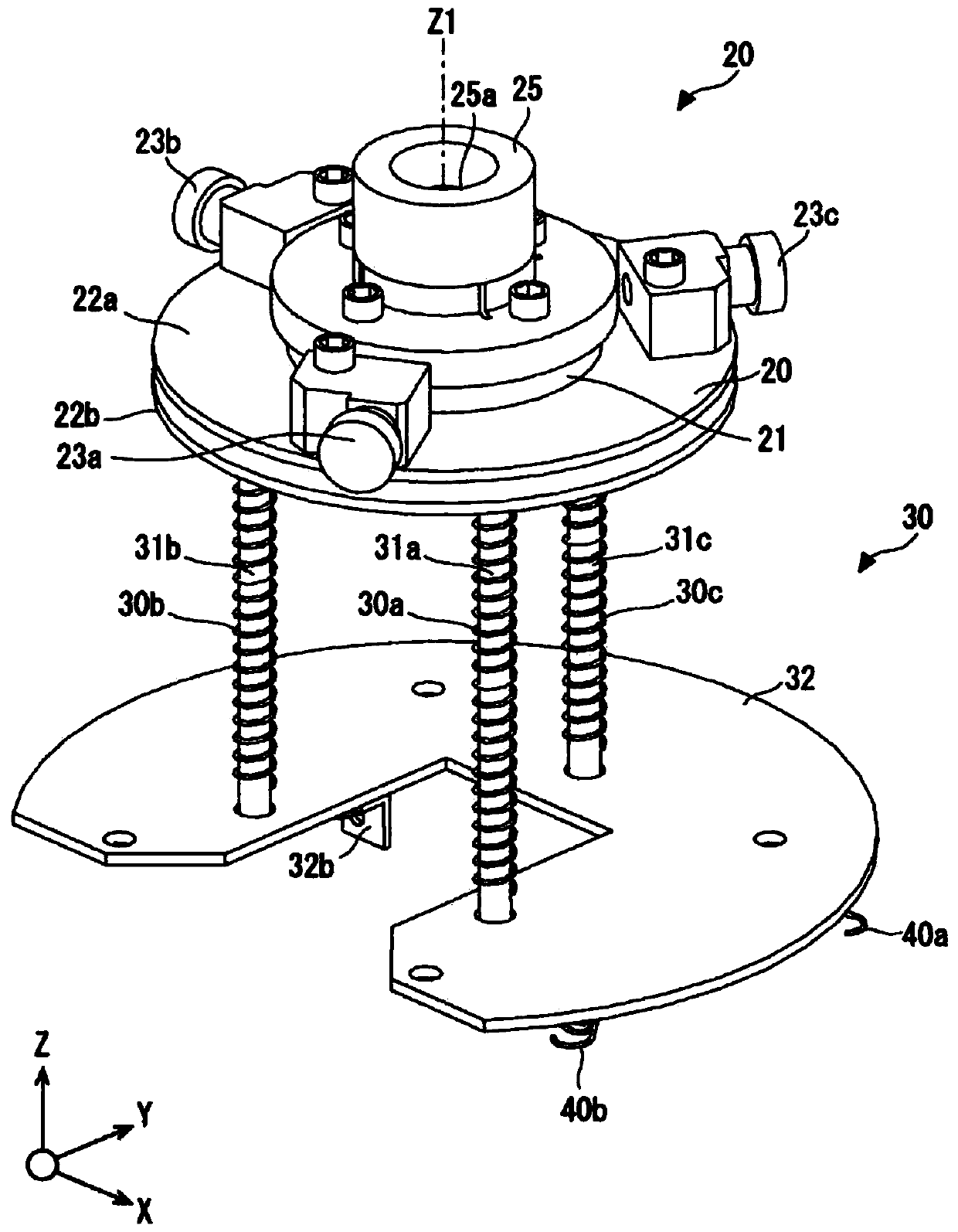

[0034] (Embodiment 1) Refer to Figure 1 to Figure 6 Embodiment 1 will be described. It should be noted that, of course, figure 1 and the right-handed xyz coordinates shown in the other drawings are coordinates for the convenience of describing the positional relationship of the constituent elements. Usually, the positive direction of the z-axis is vertically upward, and the xy plane is a horizontal plane, which are common among drawings. figure 1 It is a perspective view which shows the grinding|polishing apparatus of Embodiment 1. figure 2 It is a perspective view which shows the holder of the grinding|polishing apparatus of Embodiment 1. image 3 It is a perspective view which shows the grinding|polishing part etc. of the grinding|polishing apparatus of Embodiment 1. Figure 4 It is a plan view showing the polishing unit and the like of the polishing device according to the first embodiment. Figure 5 It is the perspective view which looked at the polishing apparatus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com