Positioning welding electrode for welding of automobile positioning hook

A technology of positioning welding and positioning hook, which is applied in the direction of electrode features, cooling electrodes, vehicle parts, etc., can solve the problems that welding electrodes cannot be positioned and welded at the same time, the device cannot meet production and processing needs, and four welds are welded at the same time. The effect of avoiding parts burn, enhancing welding effect, and high stability of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

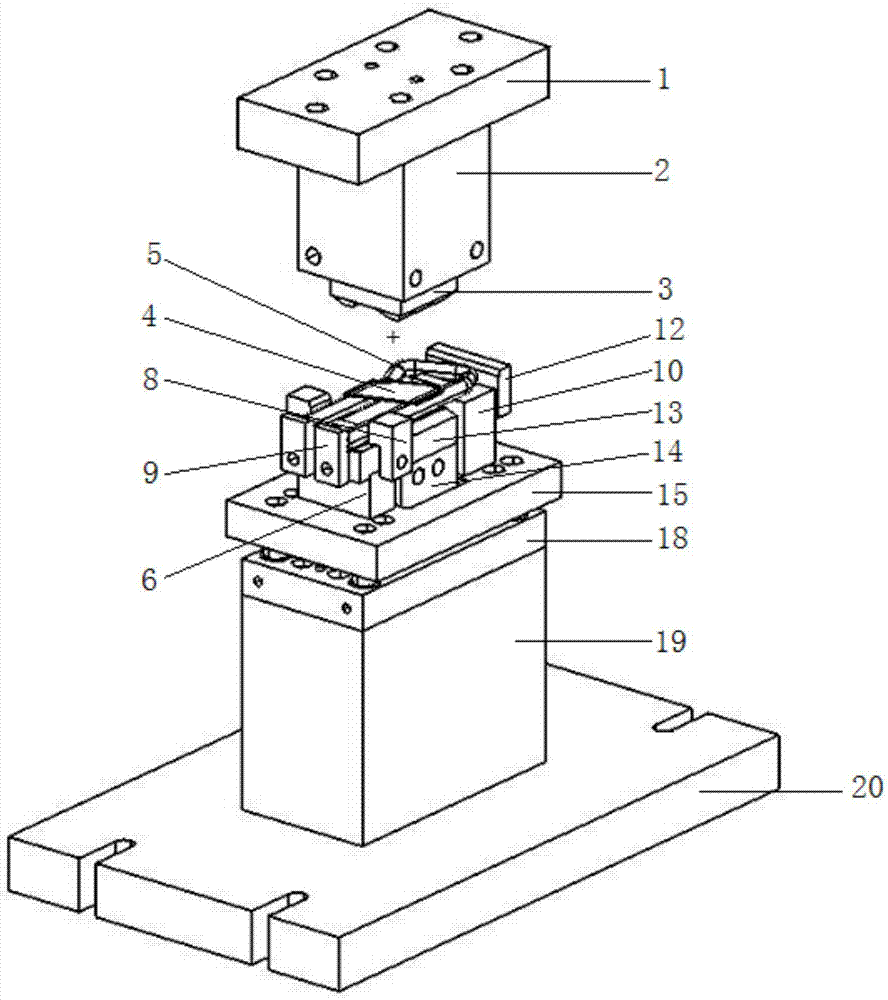

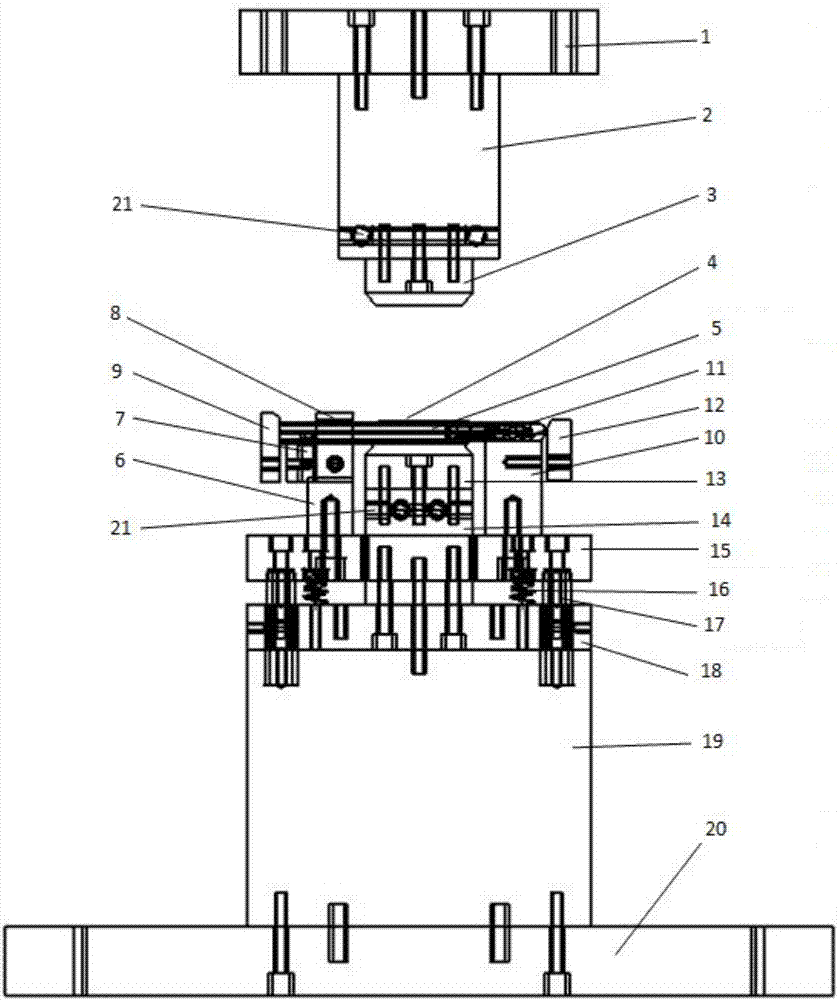

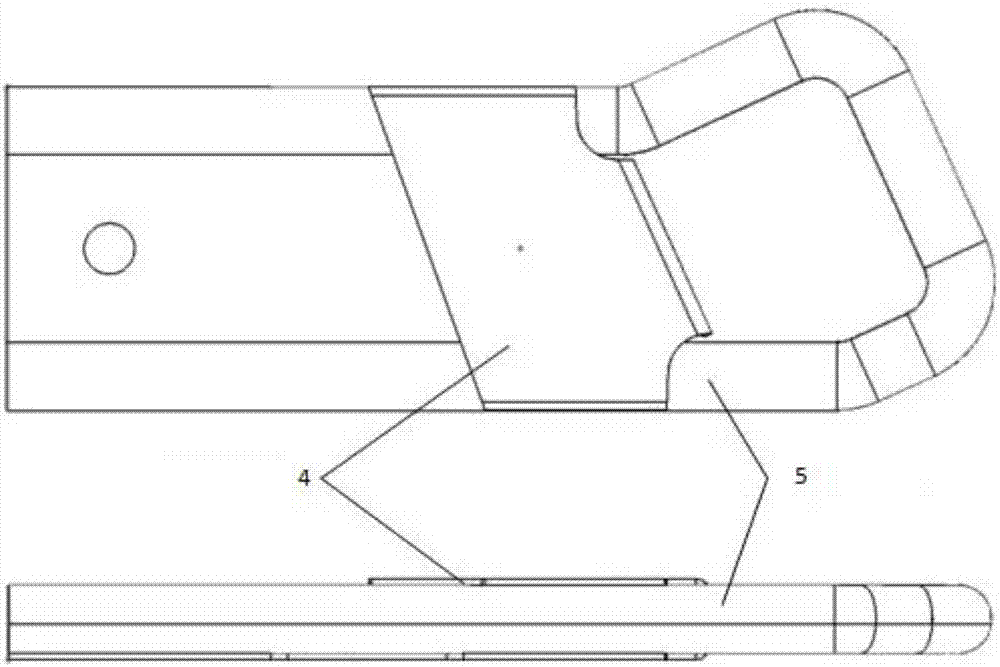

[0030] like figure 1 , 2 , a positioning welding electrode used for automotive positioning hook welding, such as image 3 , used to weld the bent galvanized sheet 4 of the positioning hook and the bent steel bar 5 together, including the upper electrode and the lower electrode, such as Figure 4 , 5 , the upper electrode and the lower electrode are respectively fixed on the welding machine, and the lower electrode is provided with a floating positioning mechanism, wherein the floating positioning mechanism includes a main positioning unit, an error-proof positioning unit and a floating unit. When welding, the bent galvanized sheet 4 is combined with the bent steel bar 5, placed on the floating positioning mechanism for positioning, the upper electrode and the lower electrode cooperate to weld the bent galvanized sheet 4 and the bent steel bar 5 together, and the lower electrode includes the lower electrode head 13 and the lower electrode block 14. The lower electrode head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com