A positioning welding tool electrode for automobile reinforcement plate

A technology for positioning welding tools and reinforcing plates, which is applied in the direction of cooling electrodes, electrode features, welding equipment, etc., can solve problems such as unstable positioning of welded parts and parts to be welded, reduced positioning accuracy and work efficiency, and single function of welding tools. Achieve the effect of improving welding efficiency, high production efficiency and ensuring welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

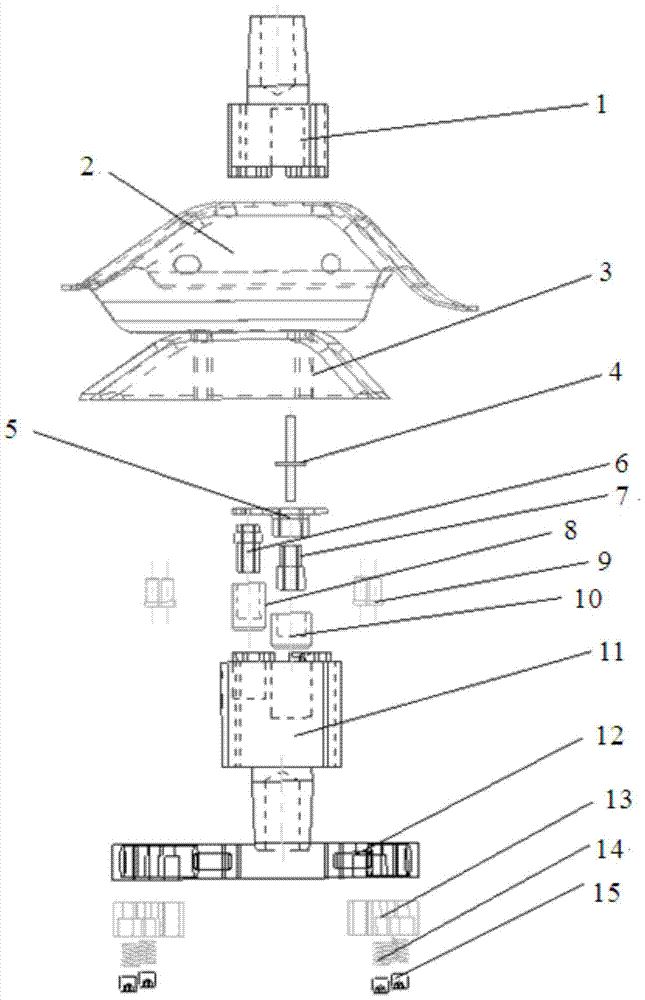

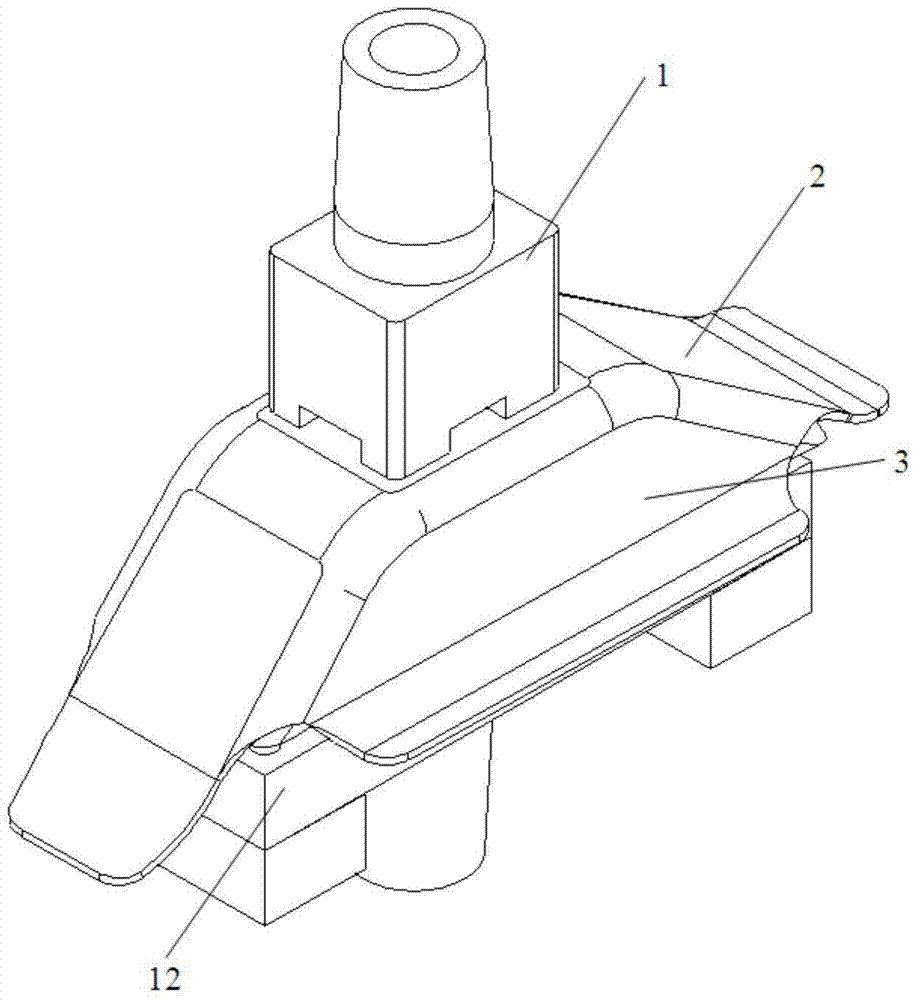

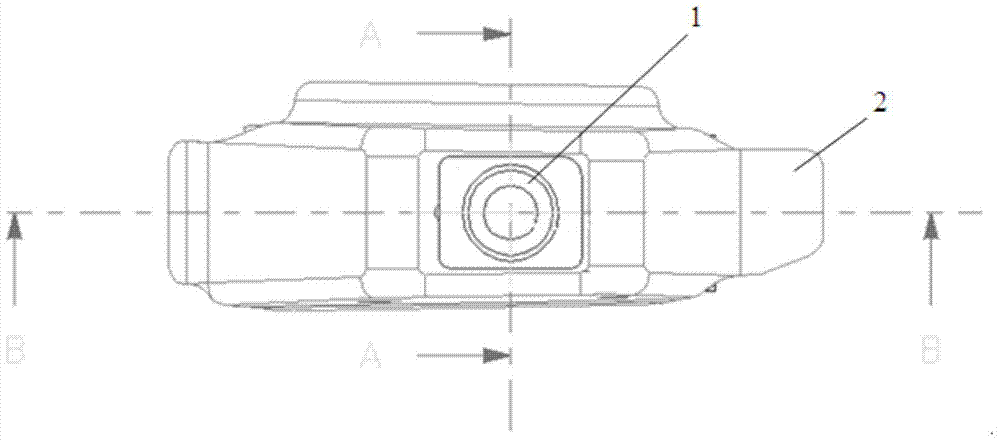

[0030] Such as Figure 1-5 As shown, a positioning welding tool electrode for automobile reinforcing plate, the electrode is fixed on a resistance welding machine, and is used to weld the accessory 5 to be welded on the automotive reinforcing plate 2, and the positioning welding tool electrode includes an upper electrode 1, a lower electrode The electrode 11 and the positioning mechanism, the upper electrode 1 and the lower electrode 11 are respectively fixed on the resistance welding machine, and when the reinforcing plate 2 and the fitting to be welded 5 are welded, the reinforcing plate 2 and the fitting to be welded 5 are positioned and fixed by the positioning mechanism, and the upper The electrode 1 and the lower electrode 11 weld the part 5 to be welded on the reinforcing plate 2 .

[0031] The positioning mechanism includes a baffle plate 13, an auxiliary support plate 12, a wire spring 14, a head screw 15, and a positioning block 3 located outside the lower electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com