Spot welder electrode part

A technology of electrode part and spot welding machine, applied in the direction of cooling electrodes, electrode features, pressure electrodes, etc., can solve problems such as poor power supply, overheating of small contacts 195, insufficient cooling of protrusions 191a, etc., and achieve the effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

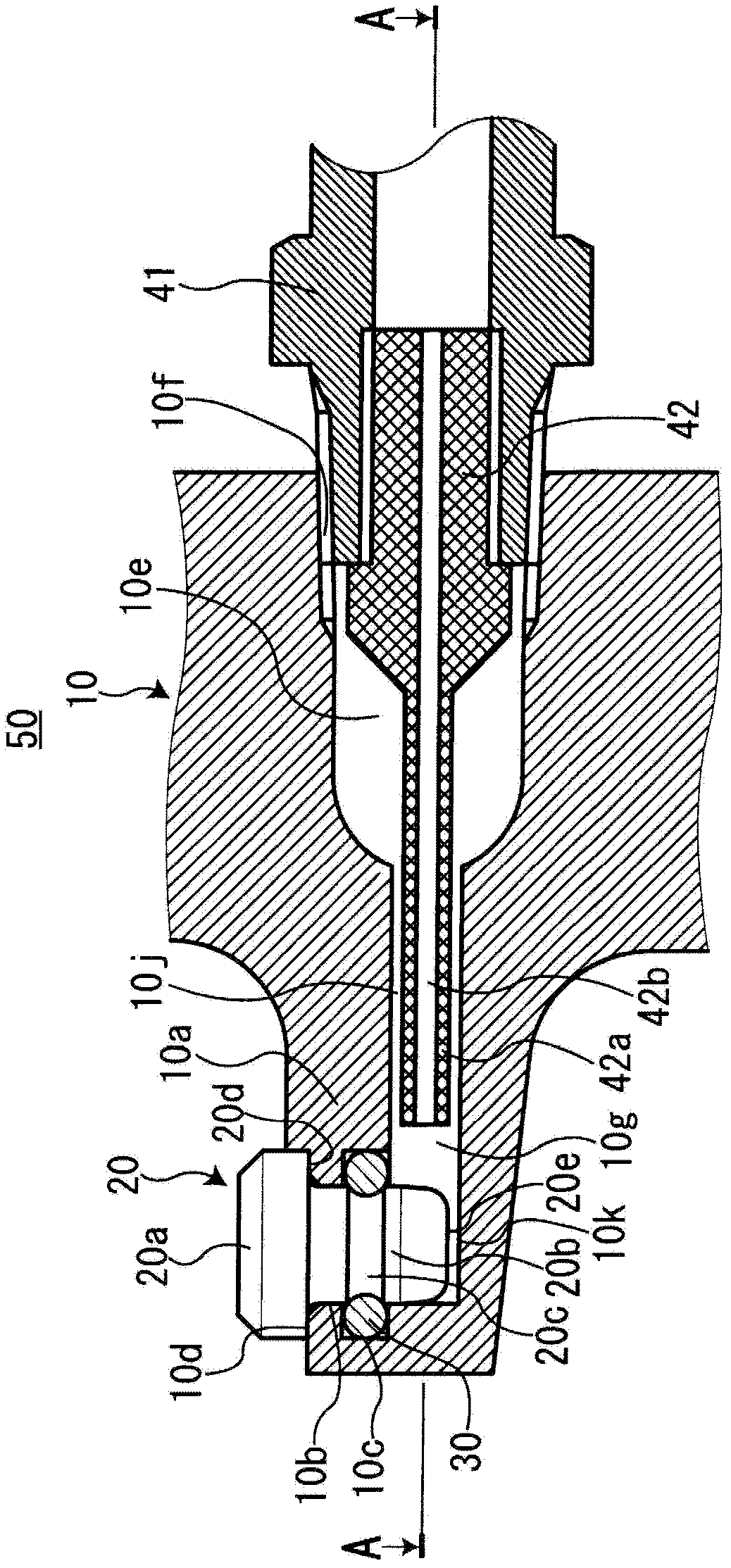

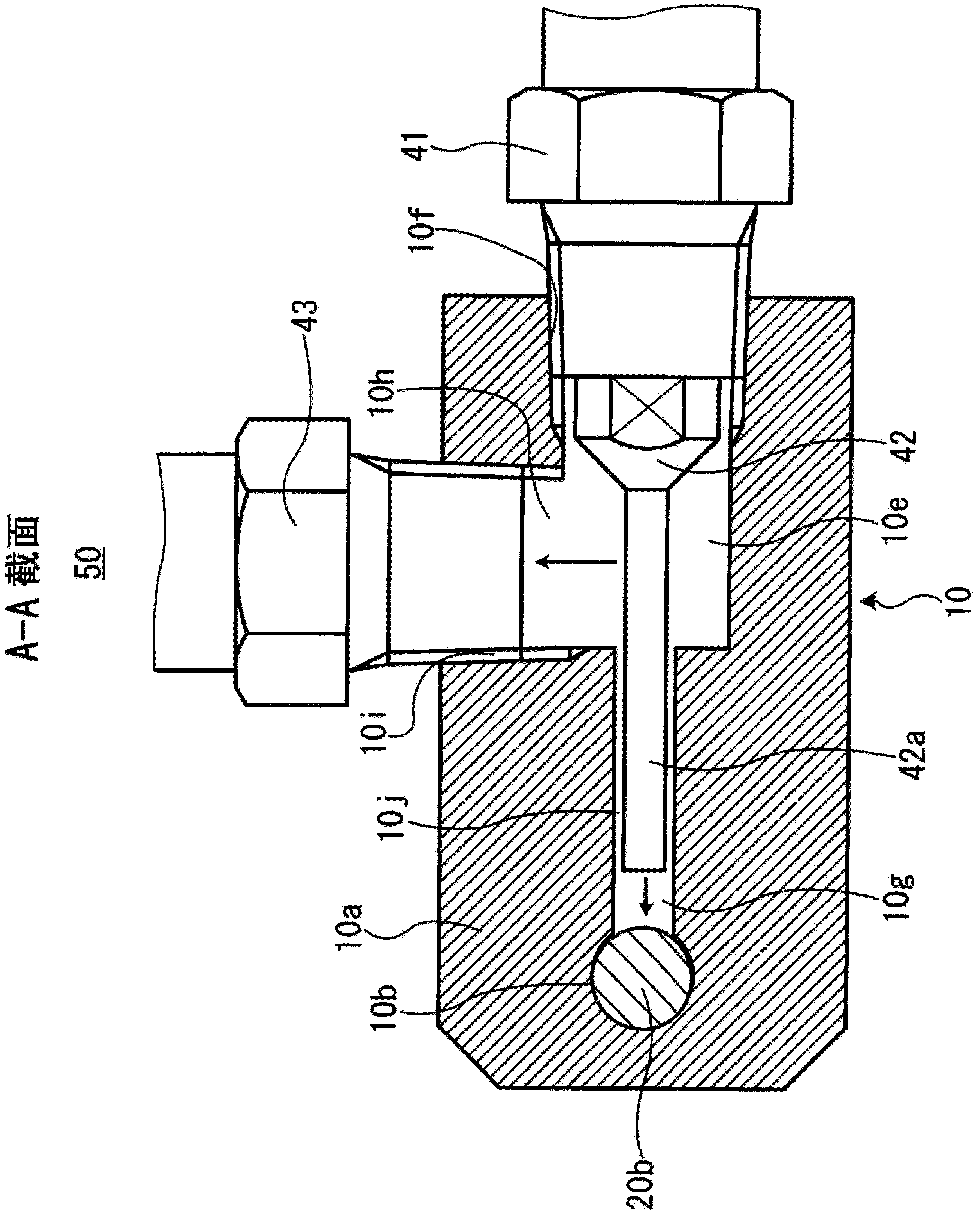

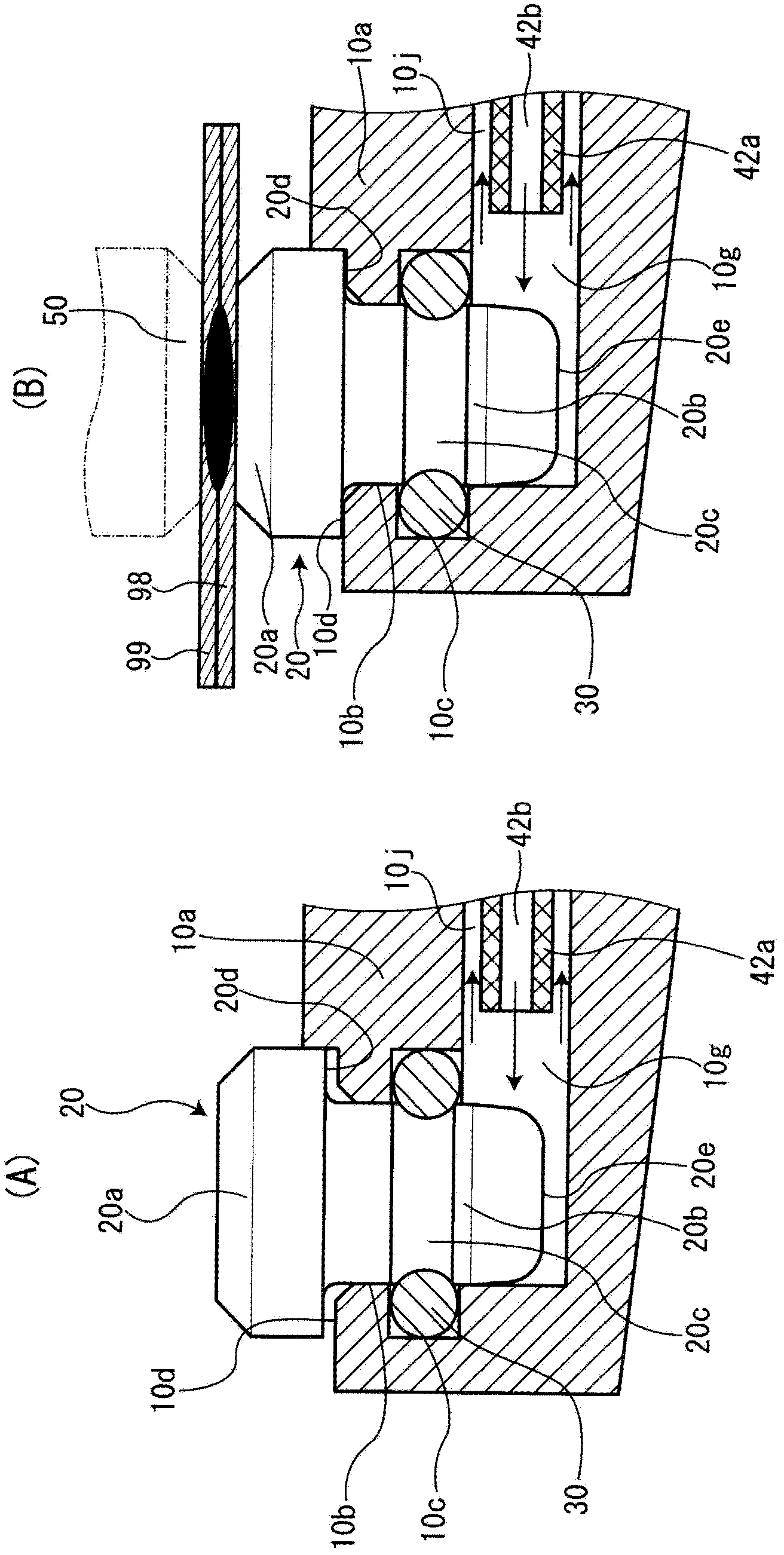

[0050] Below, with reference to accompanying drawing, accompanying drawing shows preferred embodiment of the present invention. 10 is an electrode frame, which is installed in the power supply part of the spot welding machine. The electrode holder 10 is supplied with welding current from the power supply unit described above. The electrode frame 10 is made of a tough copper alloy such as chromium copper and beryllium copper with good electrical conductivity. The electrode holder 10 is protrudingly formed with a plate-shaped protruding portion 10a. The surface of the protrusion 10a is recessed to form a mounting recess 10b. The cross-sectional shape of the mounting recess 10b is circular. The mounting recess 10b is not inclined with respect to the surface of the protrusion 10a, but is formed to perpendicularly intersect with the surface of the protrusion 10a. A first O-ring groove 10c is recessed and formed over the entire circumference of the inner peripheral surface of th...

no. 2 approach

[0061]The electrode part of the spot welding machine of 2nd Embodiment is demonstrated about the point which differs from 1st Embodiment. The electrode holder 110 of the second embodiment has a cylindrical shape. Such an electrode holder 110 is generally called a rod body. A cooling water passage 110 d is formed inside the electrode holder 110 . The top end of the electrode holder 110 is formed with a mounting recess 110a communicating with the cooling water passage 110d. The cross-sectional shape of the mounting recess 110a is circular. The mounting recess 110 a is not inclined with respect to the length direction of the electrode holder 110 . A first O-ring groove 110b is recessed and formed over the entire circumference of the inner peripheral surface of the mounting recessed portion 110a. A flat power supply surface 110 c is formed around the opening of the mounting recess 110 a at the tip of the electrode holder 110 . The power supply surface 110c perpendicularly int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com