Monitoring system for milling equipment

A technology of milling equipment and monitoring system, which is applied in the field of monitoring system to achieve the effect of stable quality and automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, an embodiment of the monitoring system of the pulverizing equipment of the present invention will be described in detail with reference to the drawings.

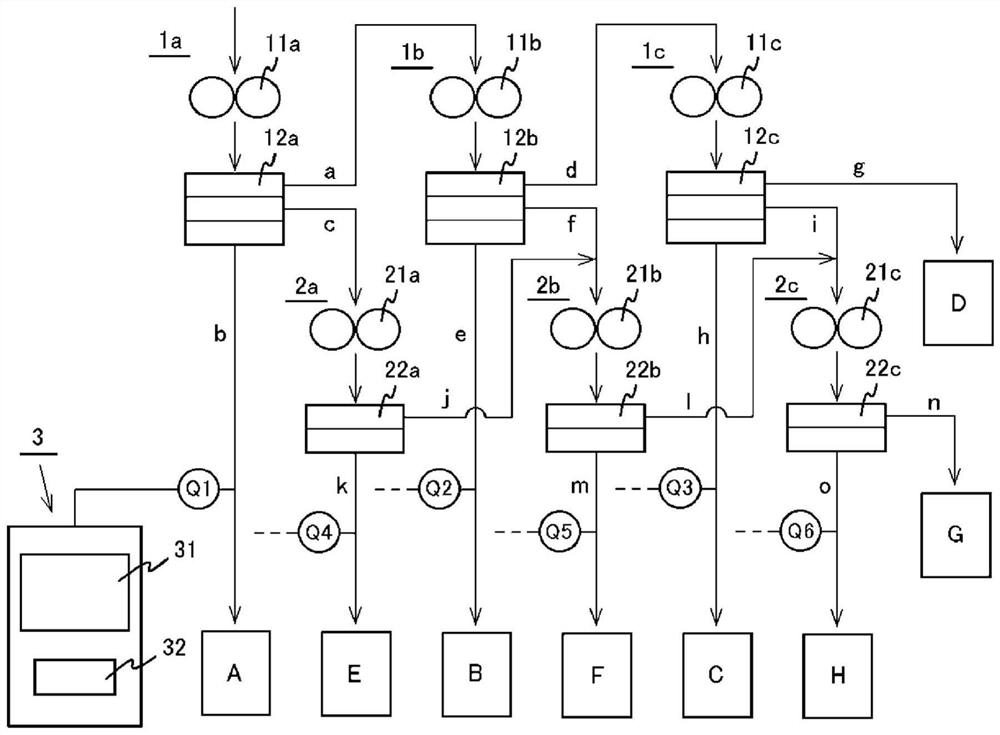

[0045] figure 1 It is a schematic explanatory diagram showing one embodiment of the pulverizing equipment used in the monitoring system of the present invention.

[0046] figure 1 The shown pulverizing equipment includes three sets of crushing units 1a to 1c and three sets of crushing units 2a to 2c arranged on the downstream side of the respective crushing units 1a to 1c.

[0047] The crushing units 1a to 1c include roller mills 11a to 11c for crushing wheat, respectively. The crushing units 1a to 1c further include sifters 12a to 12c installed immediately after the roller mills 11a to 11c, and to classify the wheat crushed by these mills 11a to 11c according to particle size. . That is, each crushing part 1a-1c mentioned above is comprised combining each roll mill 11a-11c and the sieve machine 12a-12c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com