Welding electrode for use in resistance spot welding workpiece stack-ups that include aluminum workpiece and steel workpiece

A technology for welding electrodes and workpieces, which is applied in the direction of resistance welding equipment, cooling electrodes, welding equipment, etc., and can solve the problems of high consumption cost and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

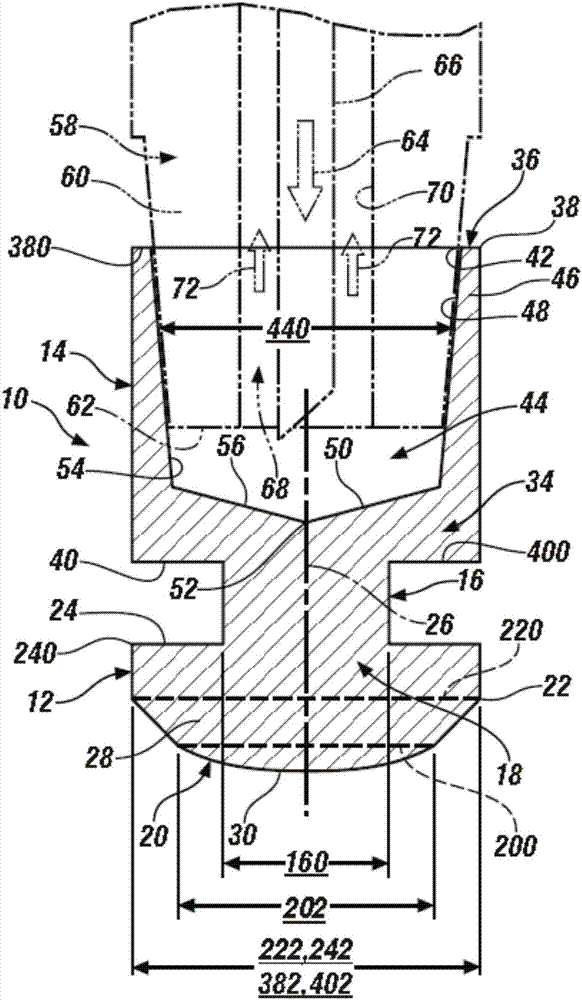

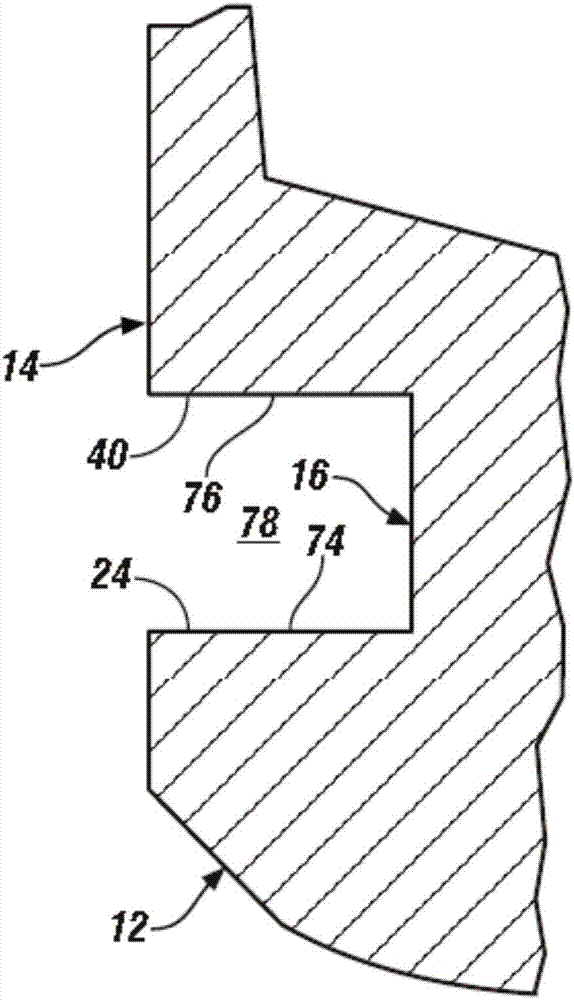

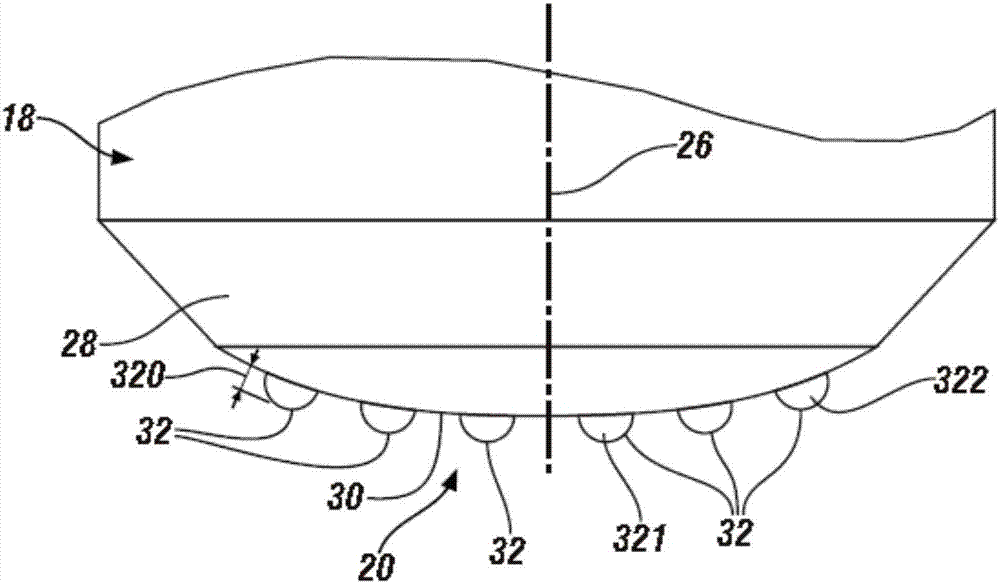

[0023] A welding electrode for resistance spot welding applications is indicated with reference numeral 10 in the figures. In particular, welding electrode 10 may be used to spot weld a workpiece stack comprising at least one aluminum workpiece and an overlapping adjacent steel workpiece, which will be hereinafter referred to as Figure 5-Figure 12for a more detailed description. For example, welding electrode 10 may be used to spot weld a "2T" workpiece stack that includes only adjacent and overlapping one aluminum workpiece and one steel workpiece (referred to as a pair) ( Figure 5 ). Other workpiece stacks can of course be spot welded in a similar manner. In fact, the welding electrode 10 can also be used to spot weld "3T" workpiece stacks ( Figure 6-Figure 7 ), which includes adjacent and overlapping pairs of aluminum and steel workpieces, plus either an additional aluminum workpiece or an additional steel workpiece, provided that two workpieces of the same base metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com