Patents

Literature

93results about How to "Realize modular assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

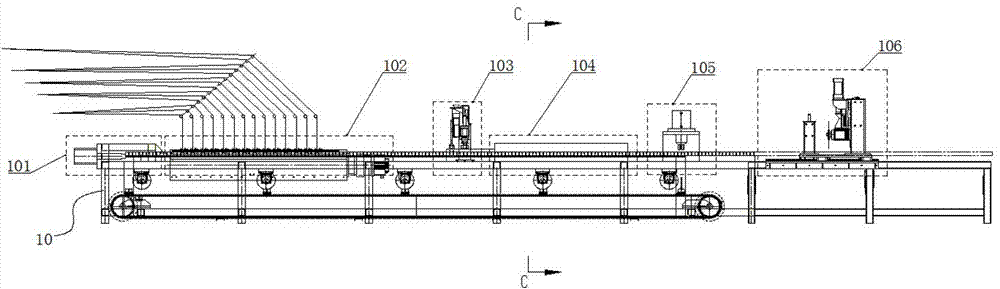

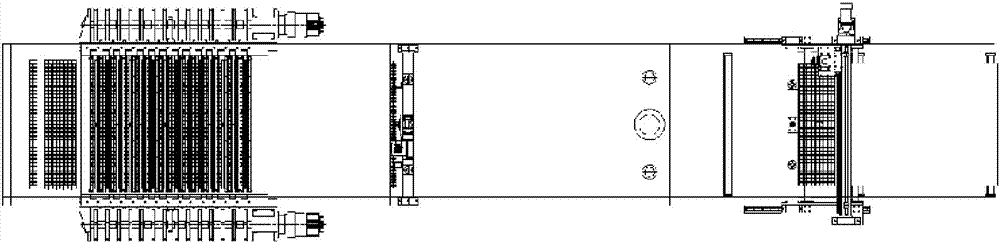

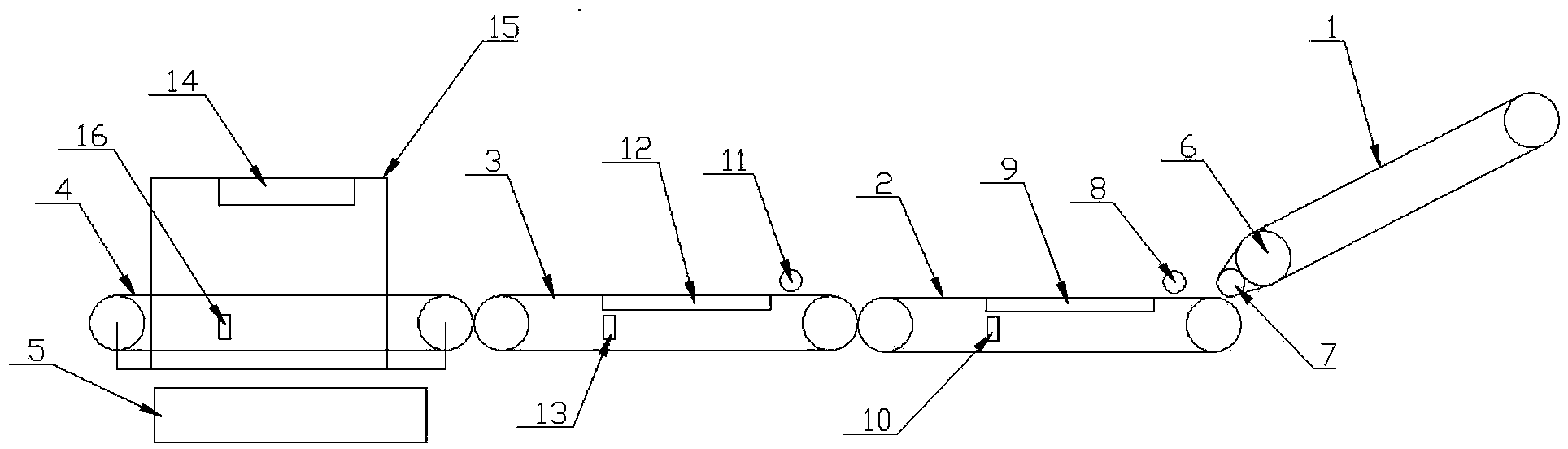

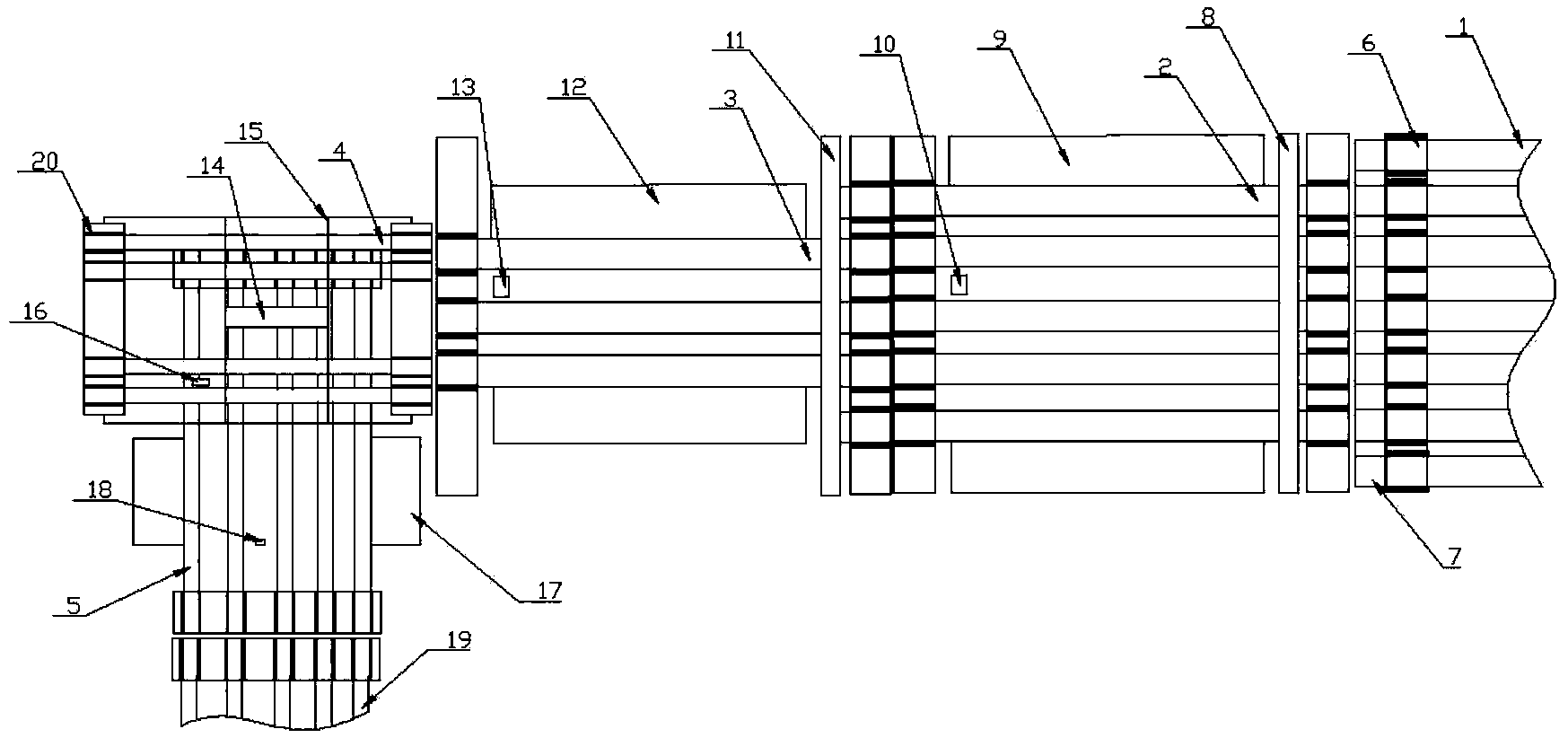

Fiberglass pultrusion grille continuous production line

The invention relates to a fiberglass pultrusion grille continuous production line which is characterized by comprising a rack, a core mould propulsion mechanism, automatic yarn laying mechanisms, a resin mixture injection mechanism, a heating solidification mechanism, a core mould demoulding mechanism, a grille cutting mechanism and a grille mould composed of fixed mould bodies and a plurality of moving core mould bodies; and the fixed mould bodies of the grille mould comprises a reinforcing fiber imbedding section fixed mould body, a resin mixture injection section fixed mould body and a heat solidification section fixed mould body which can be all matched with the moving core mould bodies in a core mould moving guide channel correspondingly to form a closed grille-shaped mold cavity. The fiberglass pultrusion grille continuous production line has the advantages that pultrusion manufacturing is conducted in a tunnel-type fixed mould cavity; the situations that each grille rib can allow more fibers to be placed in, steeping of matrix resin is more uniform and consistent, and materials are in the process state needed by pultrusion at the time of solidification and forming are guaranteed correspondingly, and accordingly continuous pultrusion production of fiber reinforced plastic is achieved finally.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

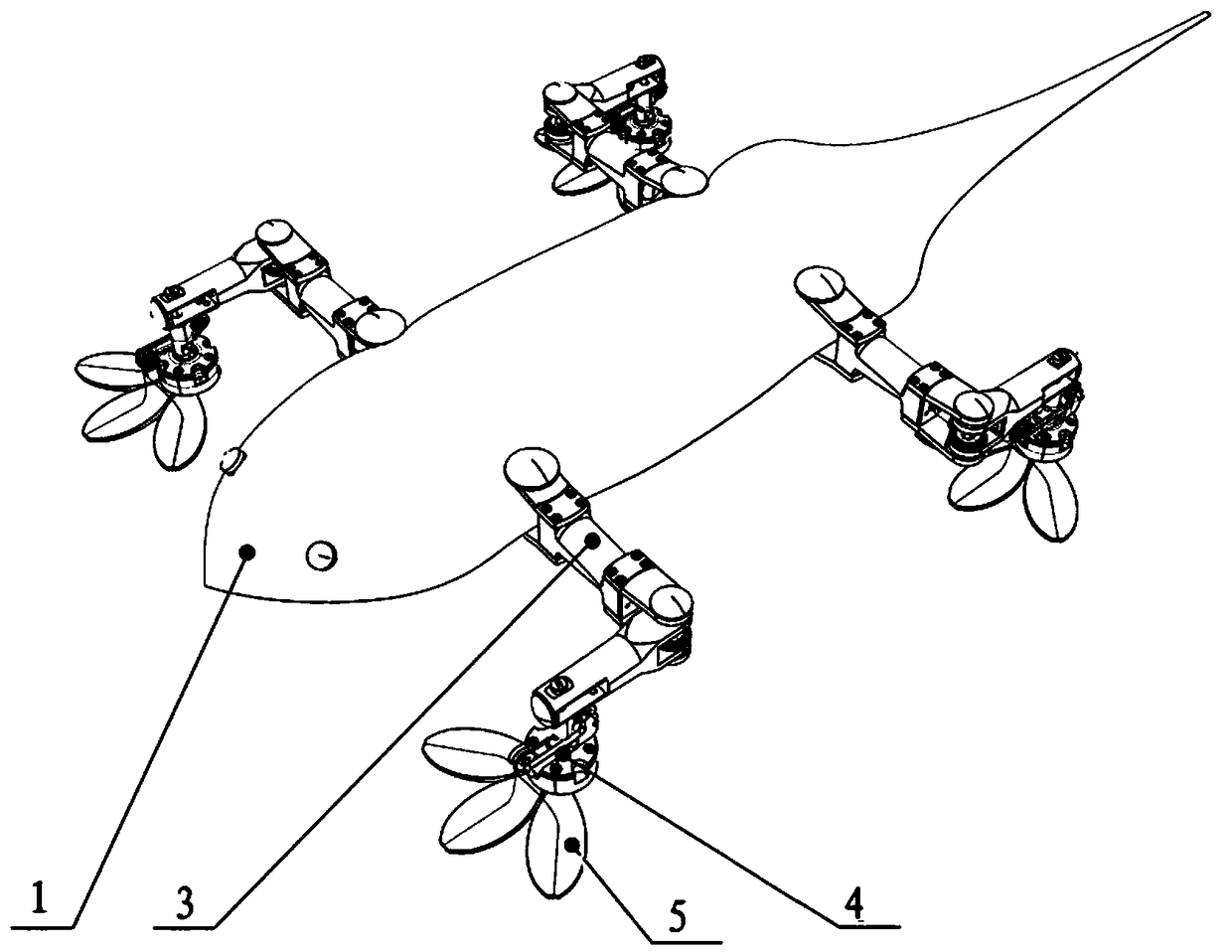

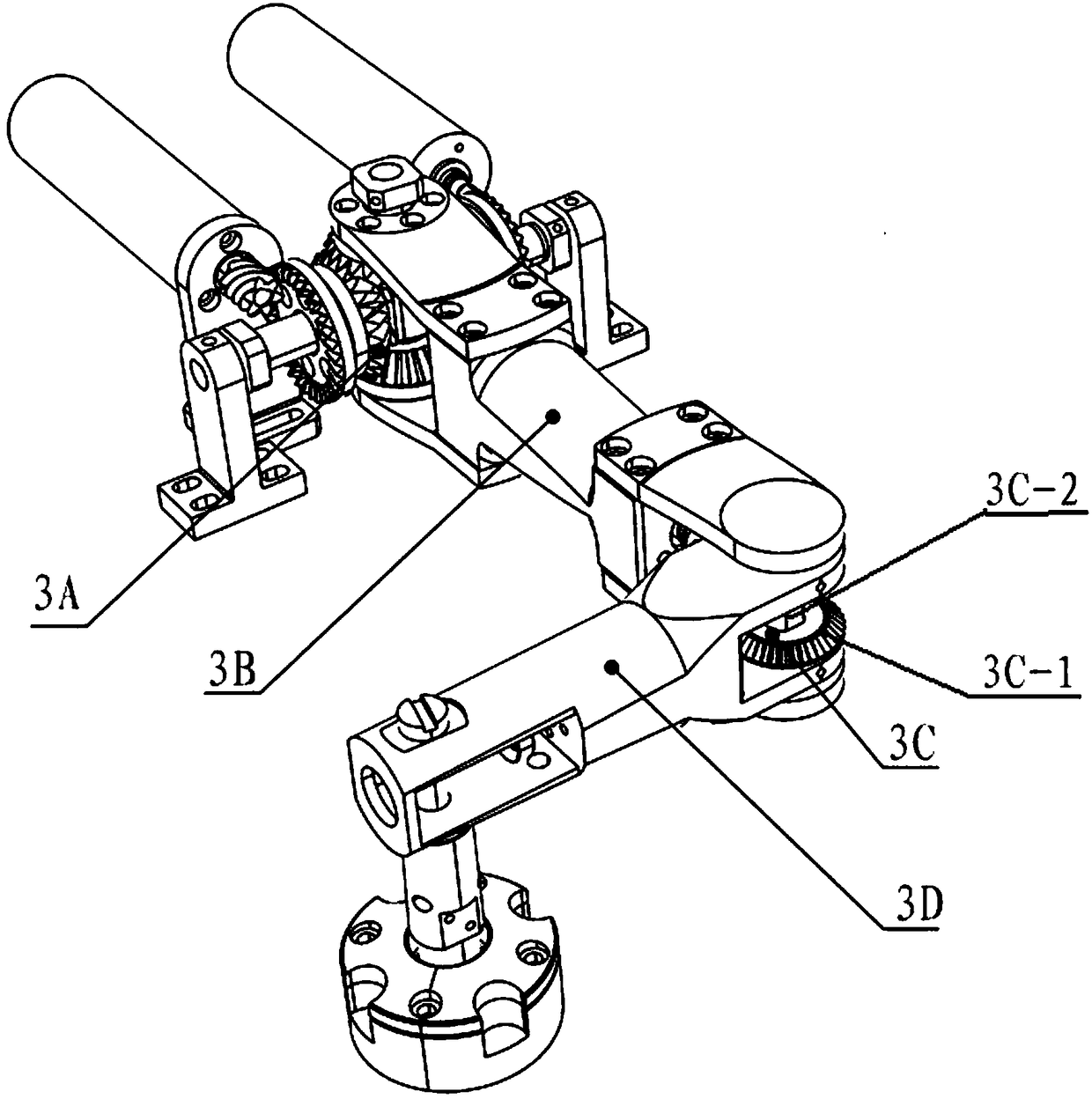

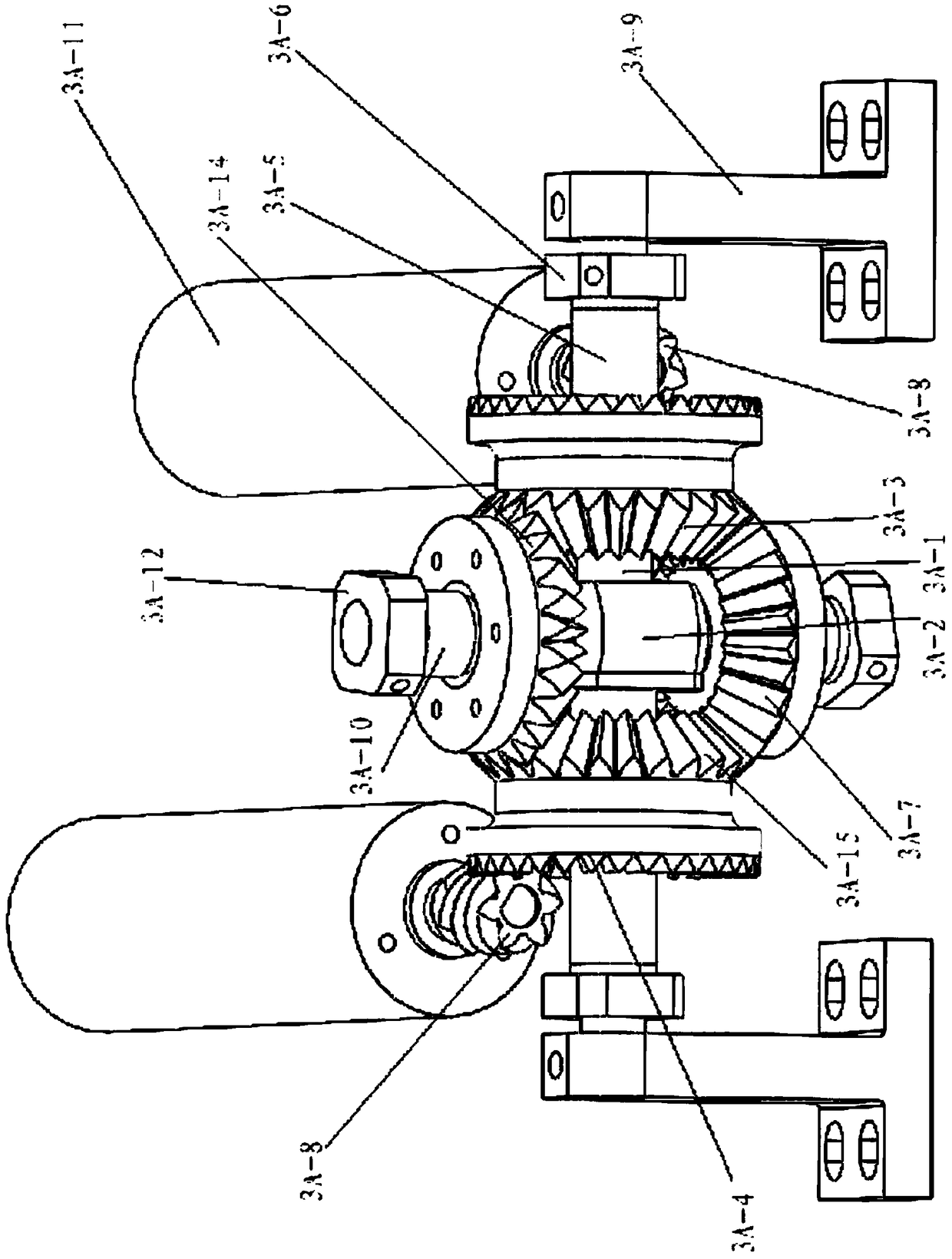

Bionic wall-climbing robot suitable for complicated narrow and small space in space station microgravity environment

The invention discloses a bionic wall-climbing robot suitable for a complicated narrow and small space in a space station microgravity environment. Technical problems to be solved are that the gait and trajectory planning of a traditional robot are restricted and it is hard for the traditional robot to pass through multiple complicated narrow and small spaces because the multiple complicated narrow and small spaces are available in the space station microgravity environment and the working space of the traditional robot is limited due to a mechanical structure in the background technology. According to the technical scheme, the bionic wall-climbing robot suitable for the complicated narrow and small space in the space station microgravity environment comprises a robot body, four multi-posefast conversion bionic single leg modules and four active adhesion and desorption paw mechanisms; and bionic toe adhesion units are arranged at the tail ends of the four active adhesion and desorption paw mechanisms. The bionic wall-climbing robot suitable for the complicated narrow and small space in the space station microgravity environment has the advantages that a multi-pose and gait conversion mechanism is realized by using a differential gear transmission mechanism; by combining a thigh rotation joint and a leg lifting joint, the flexibility of the leg motion of the robot is improved;by using the active adhesion and desorption paw mechanisms, rapid desorption and gait conversion are realized so that the bionic wall-climbing robot adapts to multiple special poses and motion gaits;and a passing and moving ability in the complicated narrow and small space is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

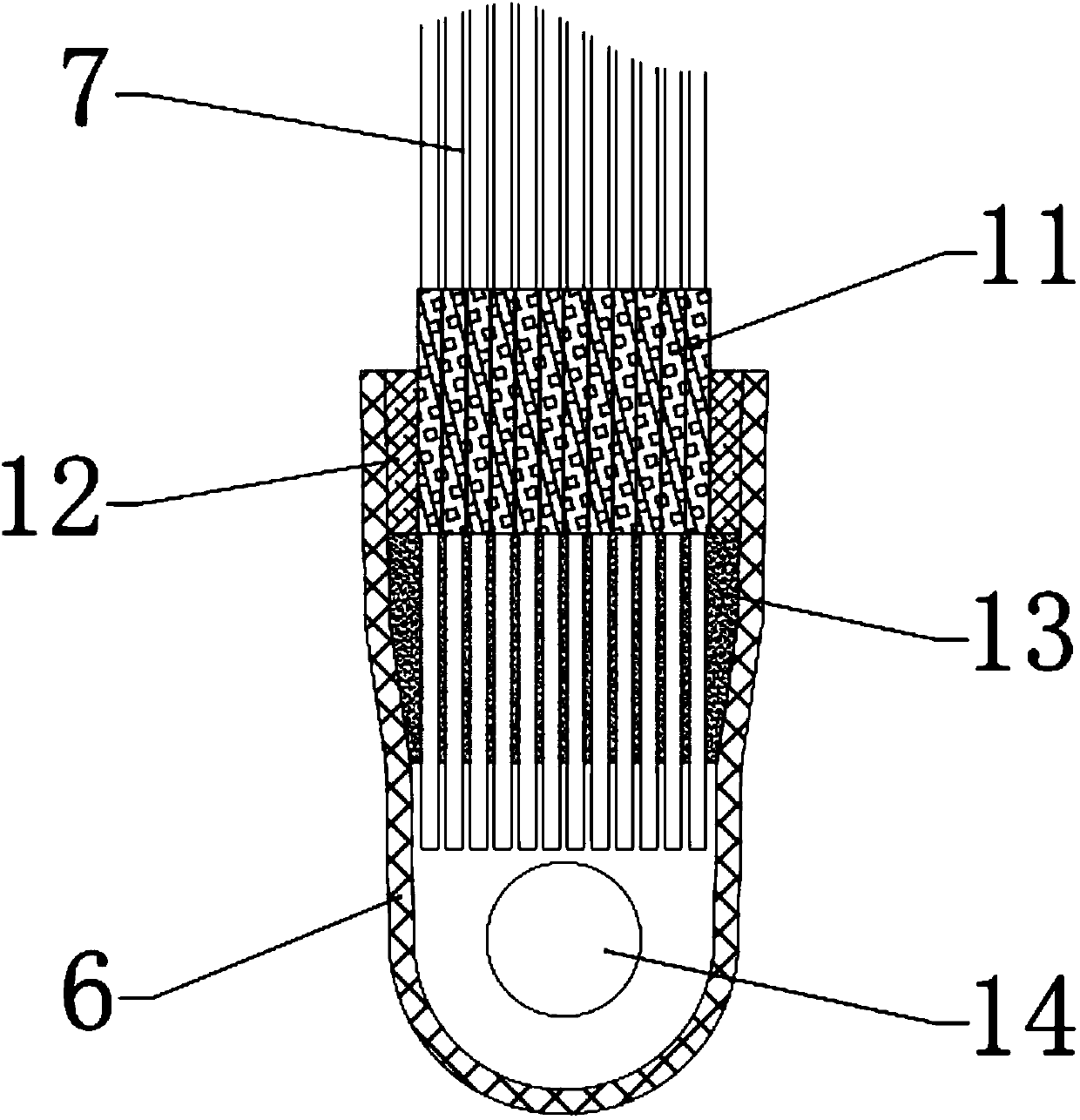

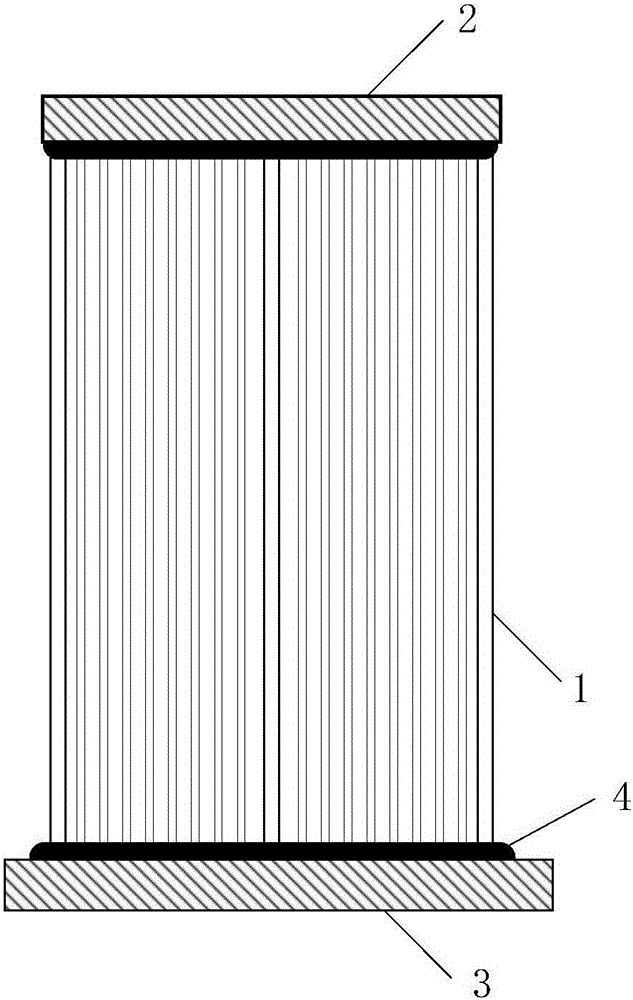

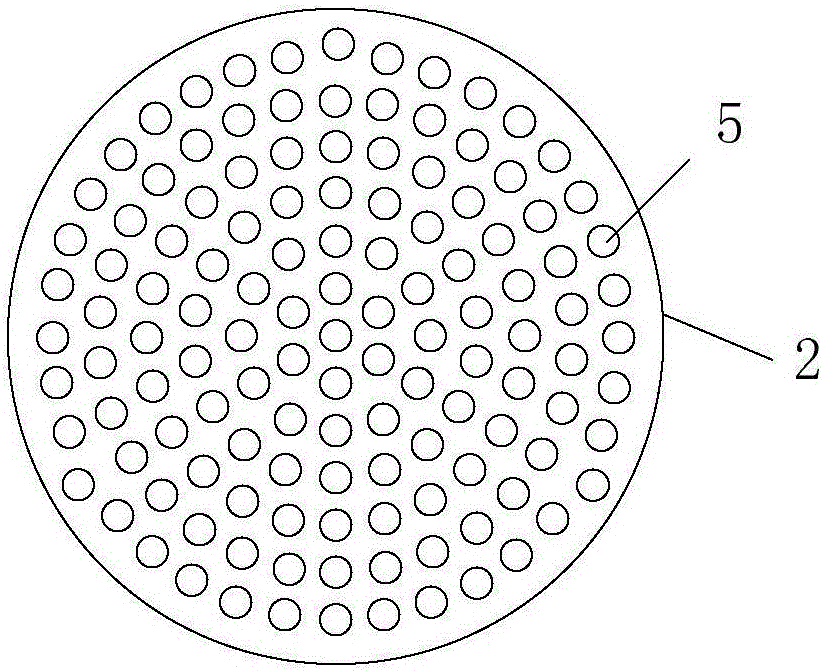

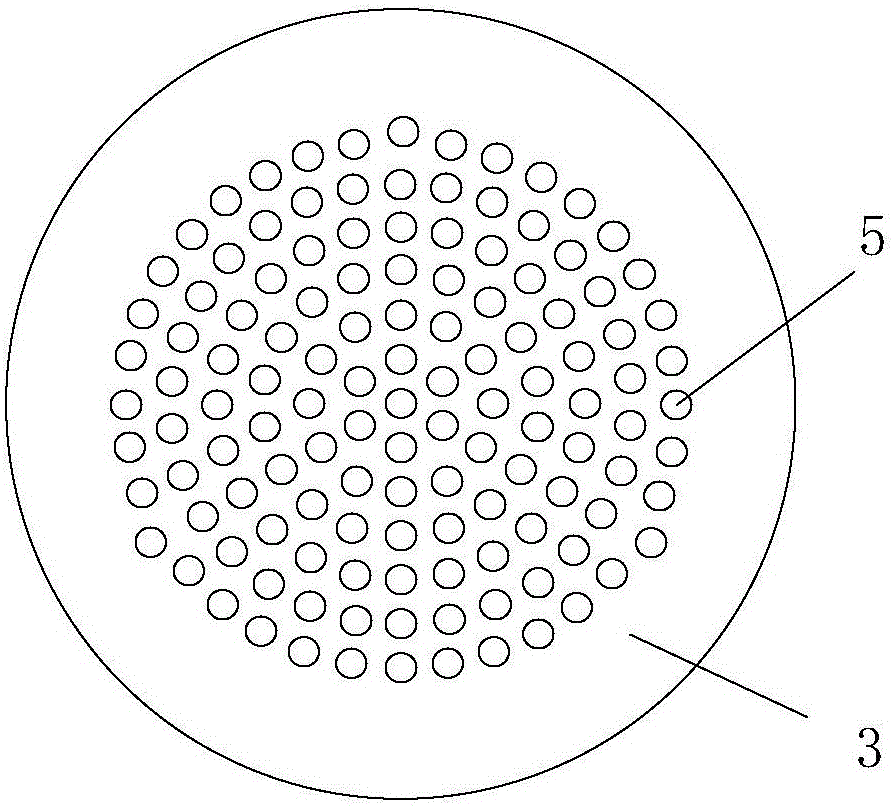

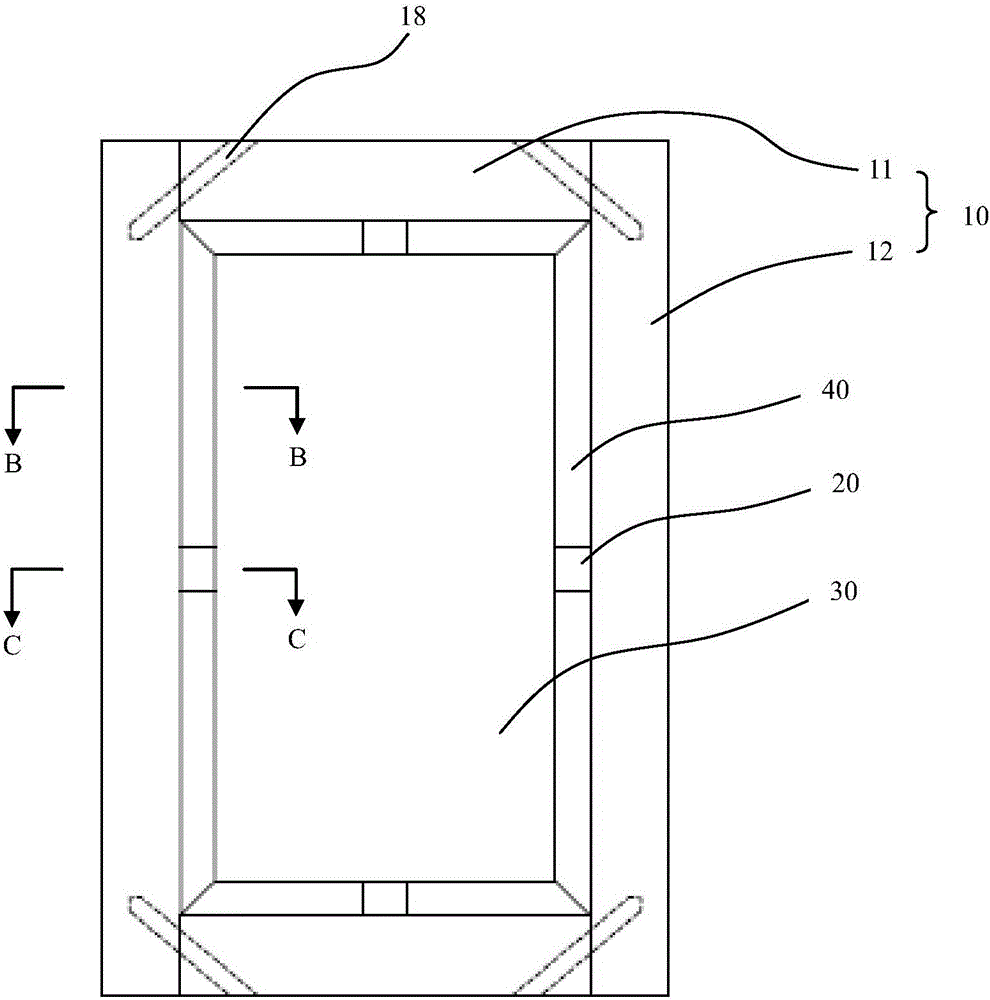

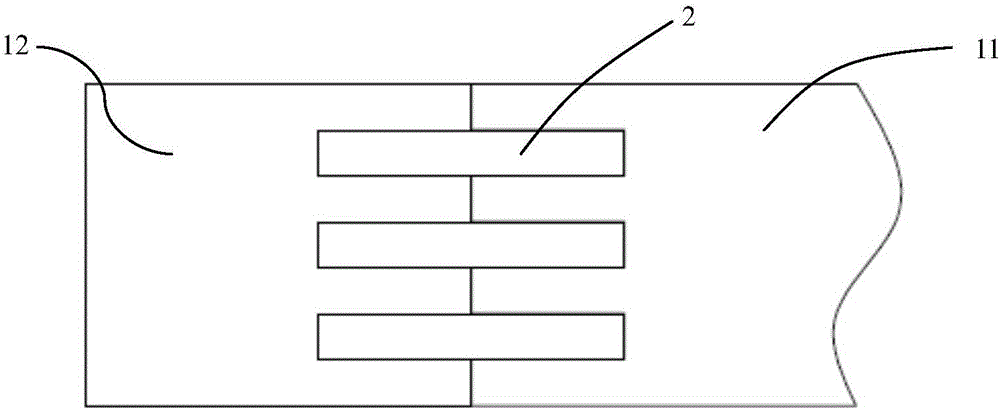

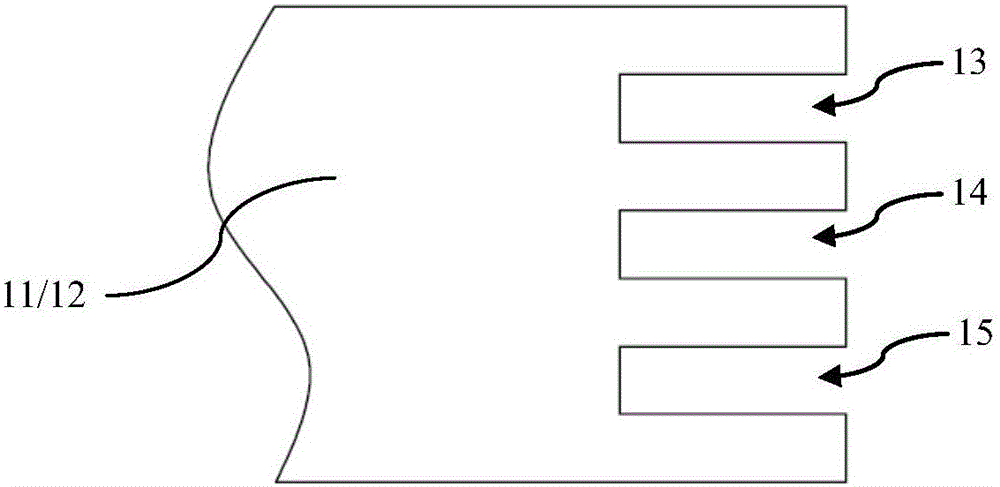

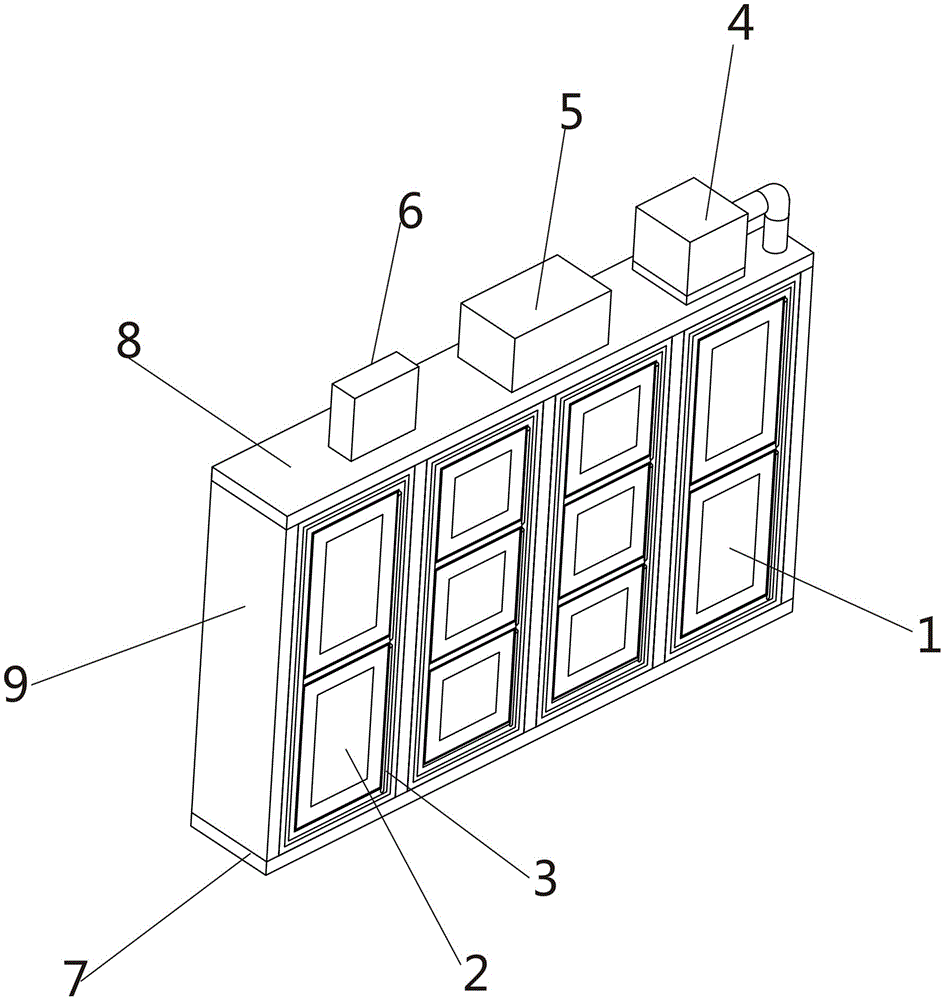

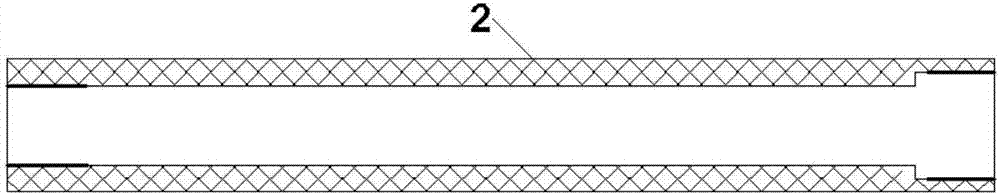

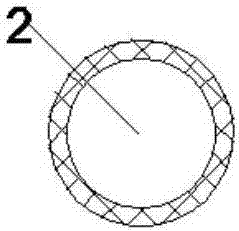

High-packing-density hollow fiber membrane component and membrane unit

InactiveCN104190261AIncrease packing densityUniform and efficient aeration and scrubbingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater collectionHollow fiber membrane

The invention discloses a high-packing-density hollow fiber membrane component which comprises a membrane component body, wherein the membrane component body comprises a water collection plastic part, hollow fiber membrane filaments, a large sealing ring and a small sealing ring; the water collection plastic part comprises a water collection joint, a plastic shell, an intermediate bar, a supporting bolt and a membrane component mounting hole; the water collection joint adopts double-step design; two sealing ring slots are arranged on each step for respectively mounting the large sealing ring and the small sealing ring; and the hollow fiber membrane filaments are uniformly arranged at equal distances. The antifouling resistance of the membrane component is improved, a self-supporting structure of the membrane component is saved, and the sealing property is more reliably ensured. The invention also provides a membrane unit which is a membrane unit formed by assembling the membrane component in batches. Thus modular assembly of the membrane unit is realized. According to the design specification requirement, the number of assembled modules is self-defined, and the membrane unit is flexible and diversified in design.

Owner:浙江洁弗环保科技有限公司

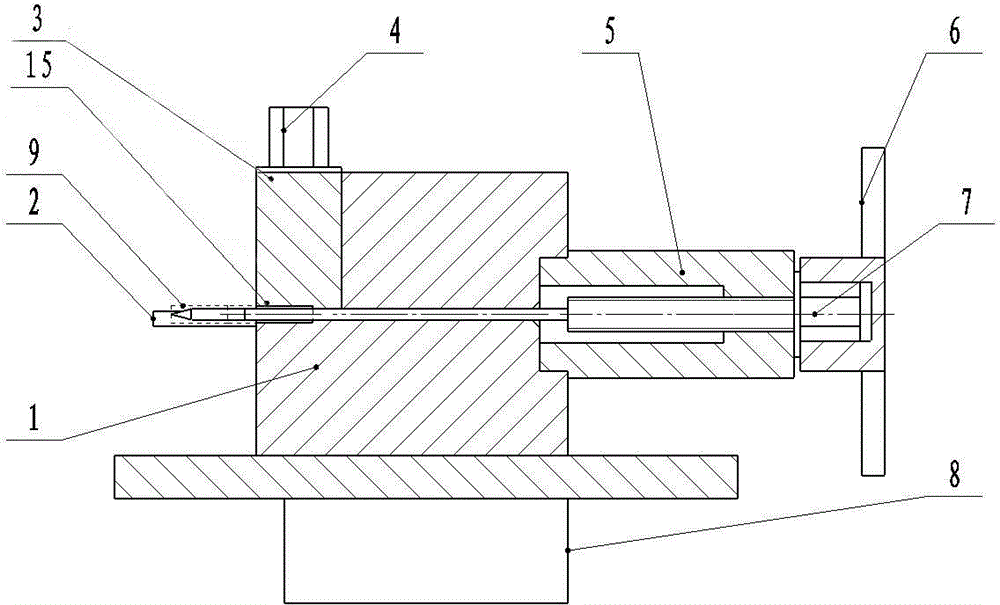

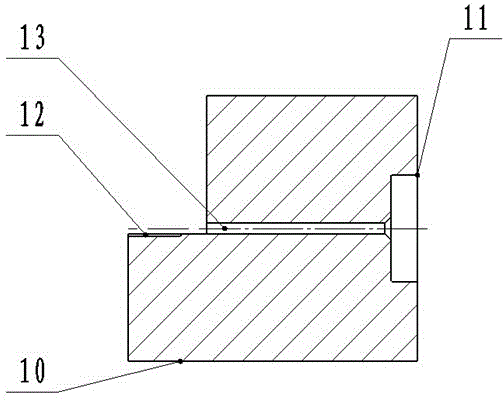

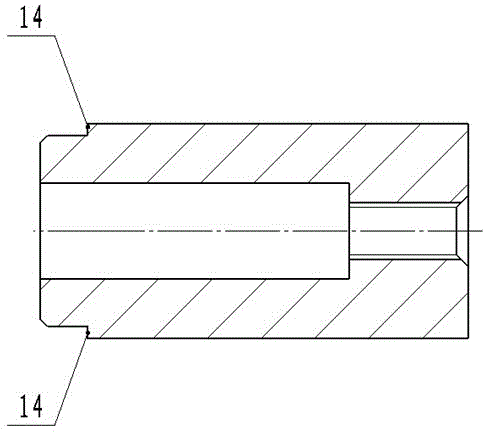

Nuclear fuel element core body removing device

ActiveCN103606387AAvoid secondary damageCollinear Accurate RealizationNuclear energy generationReactor fuel elementsEngineeringTwo step

The invention discloses a nuclear fuel element core body removing device including a fixed clamping block, a movable clamping block, an eject pin and a guide sleeve. The upper end face of the fixed clamping block is formed in a two-step stepped shape; the movable clamping block is arranged on a region at a lower horizontal position of the upper end face of the fixed clamping block and is connected with the fixed clamping block; the end part of one end of the guide sleeve is connected with the side wall of one side at a higher horizontal position of the upper end face of the fixed clamping block. The lower end face of the movable clamping block is provided with an upper semicircular groove, the upper end face of the fixed clamping block is provided with a lower semicircular groove corresponding to the upper semicircular groove position, the fixed clamp block is provided with a circular pore channel for communicating the lower semicircular groove with a guide sleeve internal channel, the center lines of the upper semicircular groove, the lower semicircular groove, the circular pore channel and the guide sleeve internal channel are justified, and one end of the eject pin successively passes through the guide sleeve internal channel and the circular pore channel. By adopting the above structure, the nuclear fuel element core body removing device has compact structure, is easy to transport, can improve the removal efficiency of a core body while being used for removing a core body in a cladded shell, and can avoid the cladded shell from being suffered from secondary damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

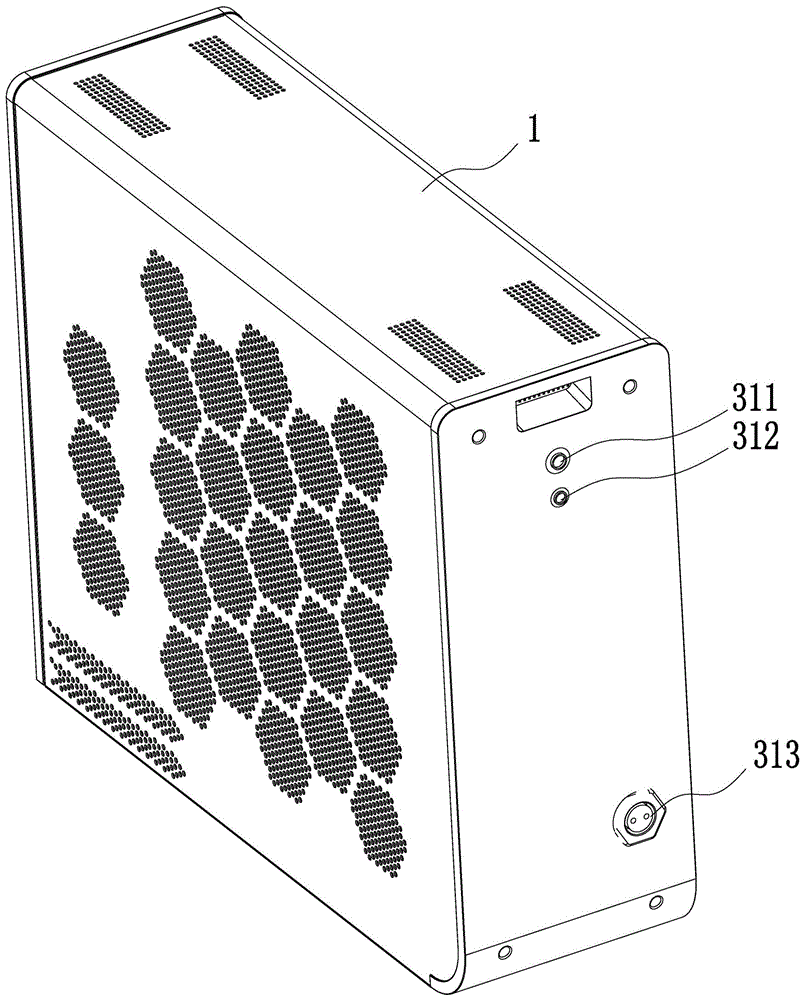

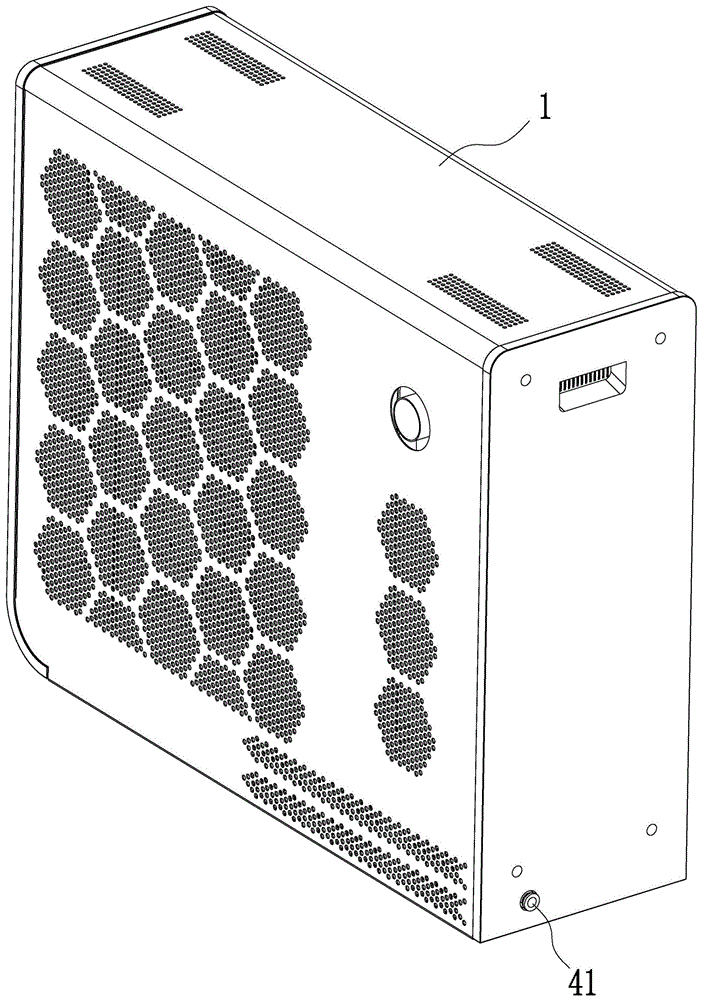

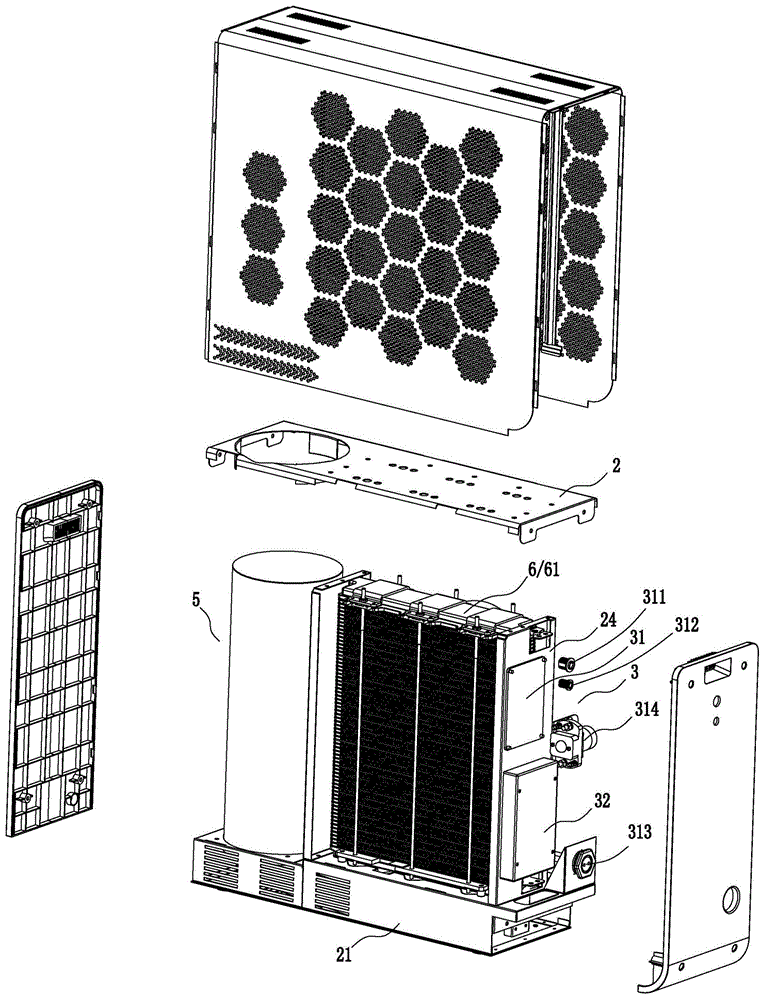

Methanol water reforming hydrogen production generator

ActiveCN106784939ACause damageEasy to installHydrogenFuel cellsElectrochemical responseMethanol water

The invention discloses a methanol water reforming hydrogen production generator. The generator comprises a main case, a rack, an electric control system, a methanol water inlet system, a methanol water reforming hydrogen production system and a generating system, wherein the main case is sleeved at outside of the rack; the rack comprises a base, and a first mounting cavity, a second mounting cavity and a side plate arranged on the base; the methanol water inlet system is arranged in the base; the methanol water reforming hydrogen production system comprises a reformer and a starting device; the reformer is arranged in the first mounting cavity, and the starting device is arranged at the lower end of the reformer; the starting device is used for providing heat for the start process of the reformer by burning the methanol water raw material; the generating system comprises a fuel cell, the fuel cell is arranged in the second mounting cavity, and used for hydrogen and oxygen in the air to generate electrochemical reaction, thereby producing electric energy; the electric control system comprises a control mainboard and a DC-CD convertor, the control mainboard and the DC-CD convertor are arranged on the side plate. The generator is high in modularization degree of each component, easy in assembling and convenient for overhauling and disassembling.

Owner:GUANGDONG NENGTAI SCI & TECH CO LTD

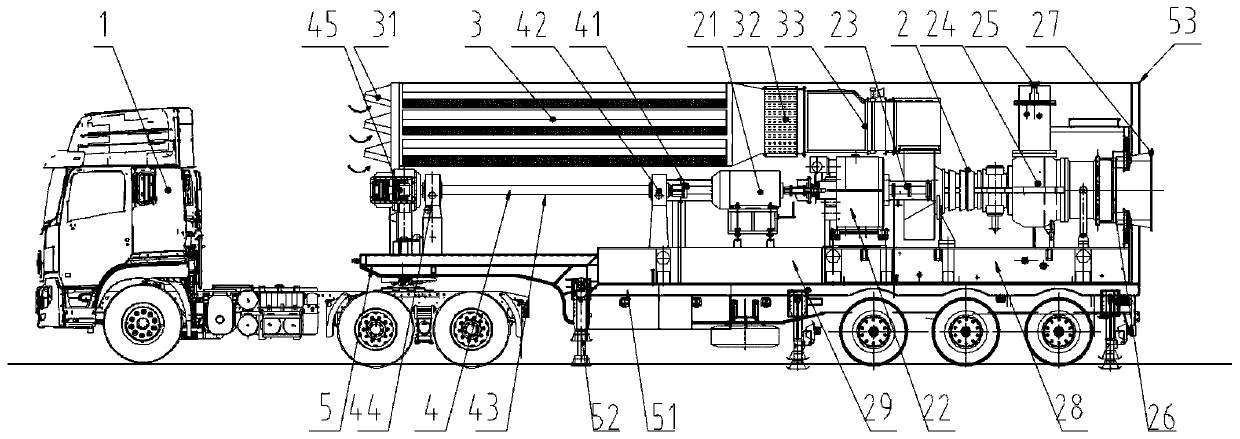

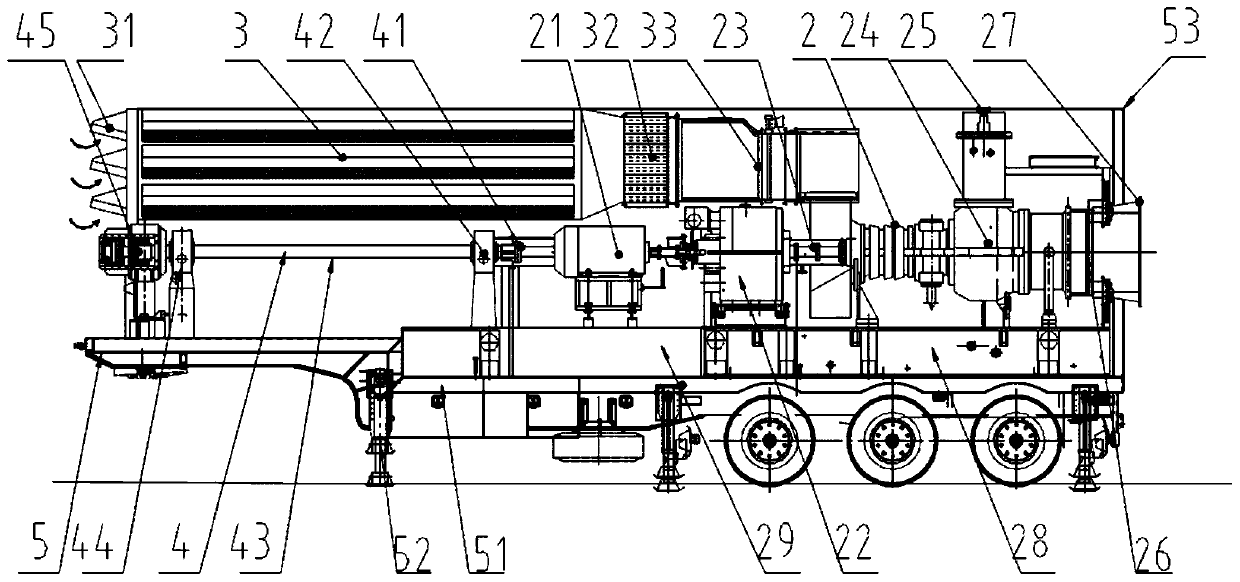

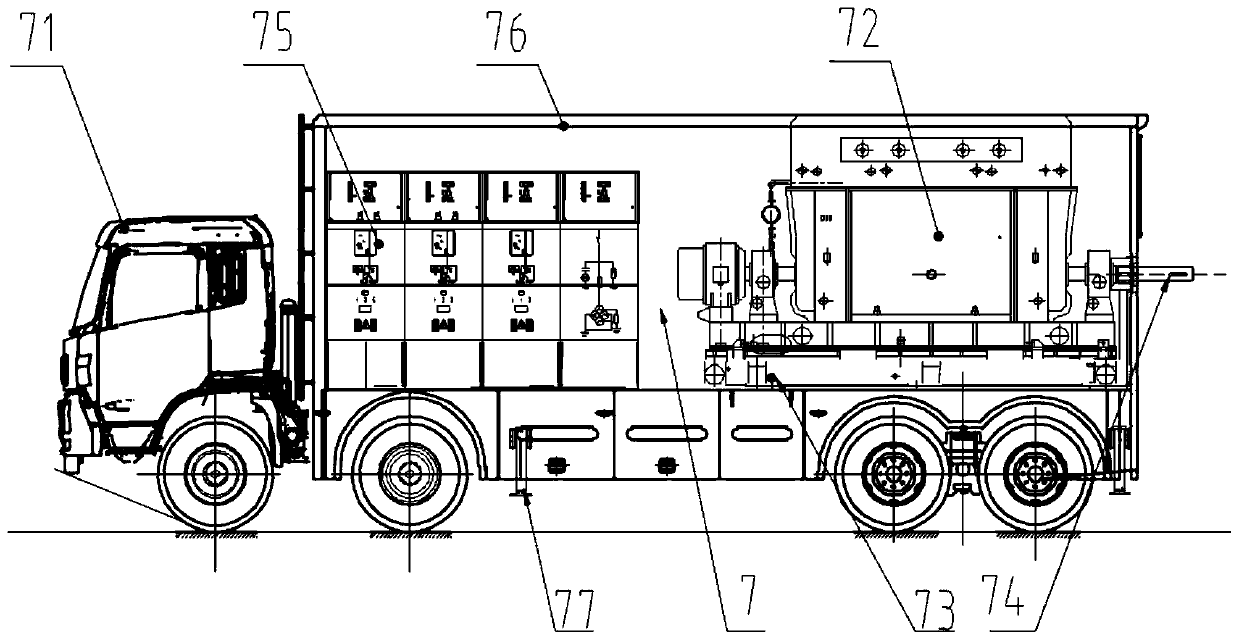

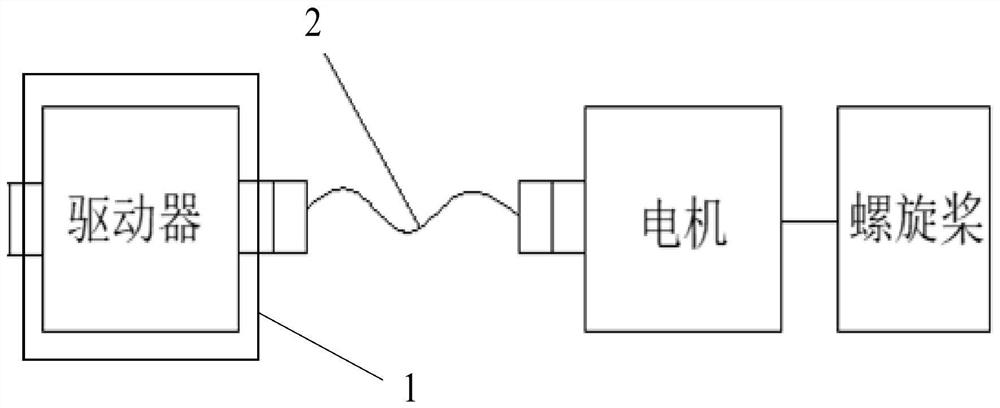

Mobile modular gas turbine power station

PendingCN111594314AMeet high-power emergency power requirementsReduce high frequency noiseTurbine/propulsion engine ignitionTurbine/propulsion engine startersDistribution power systemSemi-trailer

The invention discloses a mobile modular gas turbine power station. The mobile modular gas turbine power station is formed by connecting a first vehicle, a second vehicle and a third vehicle, the first vehicle comprises a gas turbine power system, a transmission system and a semitrailer chassis system, the gas turbine power system comprises a starter, a gearbox, a high-speed coupler and an engine,the transmission system is composed of a low-speed coupler, a first bearing, a transmission shaft, a second bearing and a flexible coupler, and a second vehicle power generation and distribution system comprises a generator, a generator installing base, a generator power shaft and a power distribution cabinet. According to the mobile modular gas turbine power station, a gas turbine is adopted asa prime mover, a power generation system composed of the gas turbine is compactly integrated on a movable chassis, and by adopting a combined mode, the power system, the power generation and distribution system and an exhaust system are correspondingly placed on different mobile carrier platforms, so that modular assembly is realized, and meanwhile, an independent exhaust noise reduction system isadopted for carrying out exhaust heat dissipation and high-frequency noise reduction on the gas turbine.

Owner:LONGYAN HAIDEXIN AUTOMOBILE

Ceramic hollow fibrous membrane filter element component and assembly with same

ActiveCN105879687ABroaden the field of film applicationHigh application strengthSemi-permeable membranesHollow fibreFilter element

The invention relates to a ceramic hollow fibrous membrane filter element component and an assembly with the same. The ceramic hollow fibrous membrane filter element component comprises a plurality of ceramic hollow fibrous membrane tubes, a porous base and a porous cover plate. One end of each ceramic hollow fibrous membrane tube is inserted into a corresponding membrane hole of the base via the porous cover plate, and sealing materials are poured in the ceramic hollow fibrous membrane filter element component. The other end of each ceramic hollow fibrous membrane tube is connected with a corresponding hole in the porous cover plate, so that the ceramic hollow fibrous membrane filter element component can be manufactured. The ceramic hollow fibrous membrane filter element component is hermetically fixed into a shell to form the hollow fibrous membrane assembly. The ceramic hollow fibrous membrane filter element component and the assembly have the advantages that large filling areas of ceramic hollow fibrous membranes can be maintained, ceramic hollow fibers can be sealed, the strength of the hollow fibrous membranes can be improved, and the application field of the hollow fibrous membranes can be expanded.

Owner:NANJING UNIV OF TECH +1

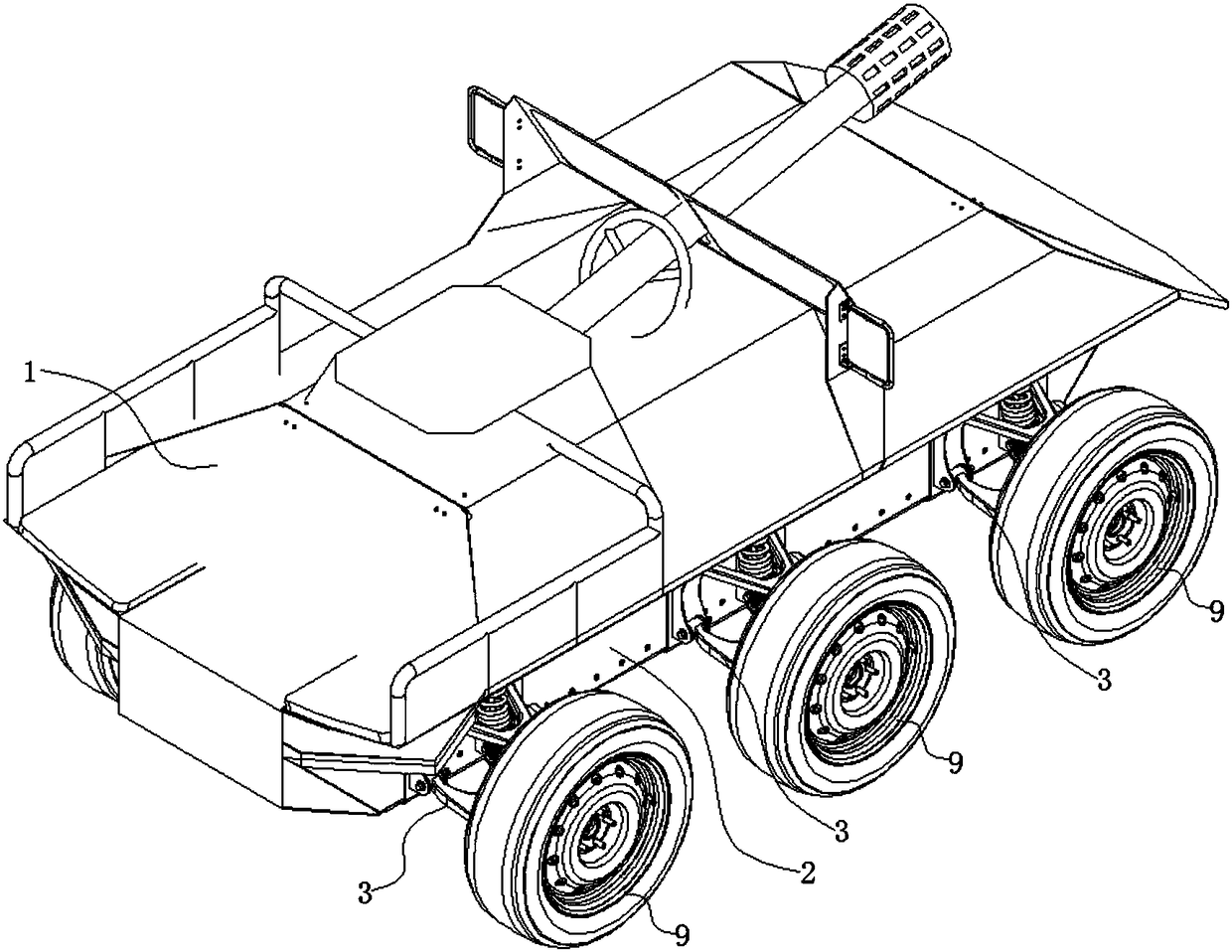

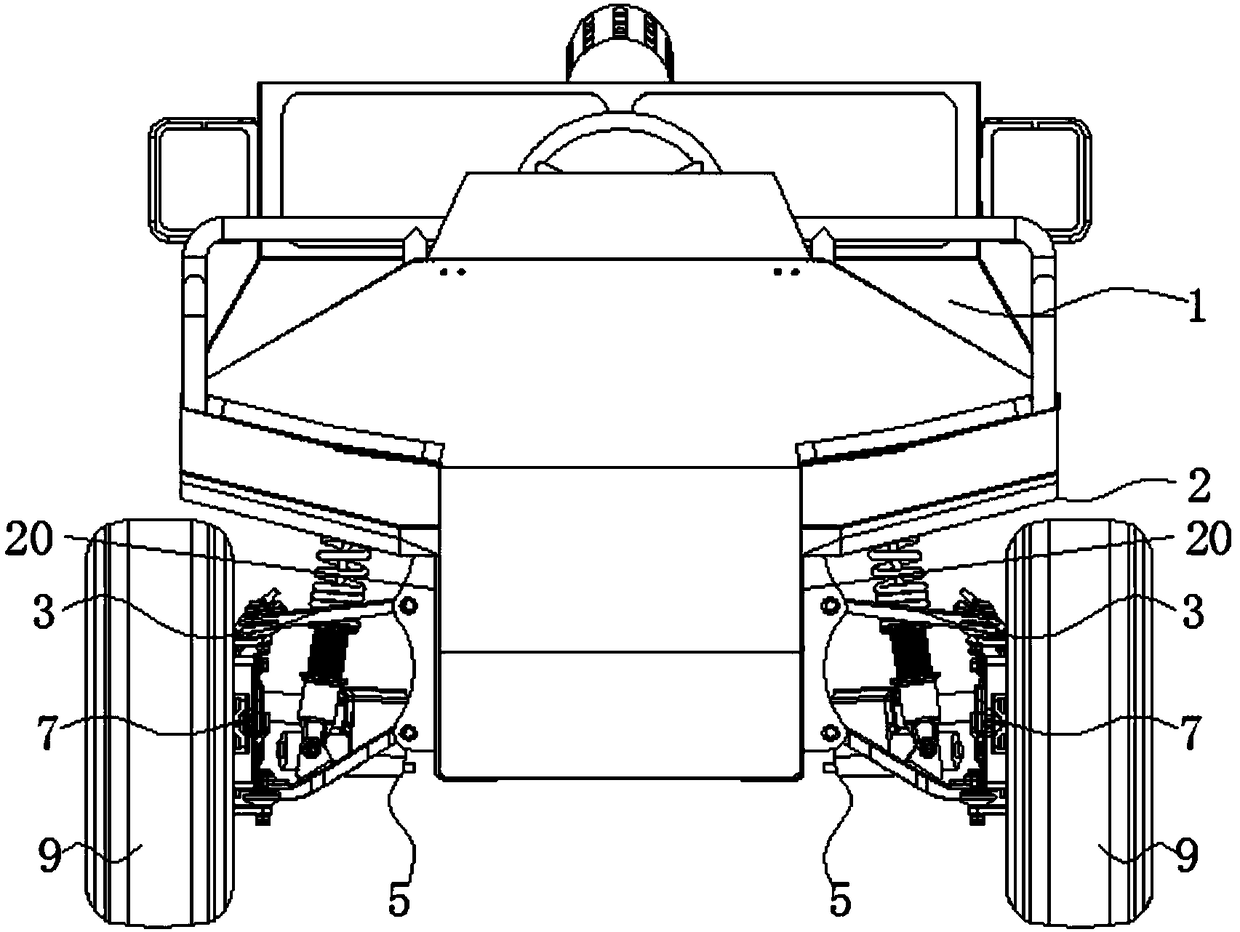

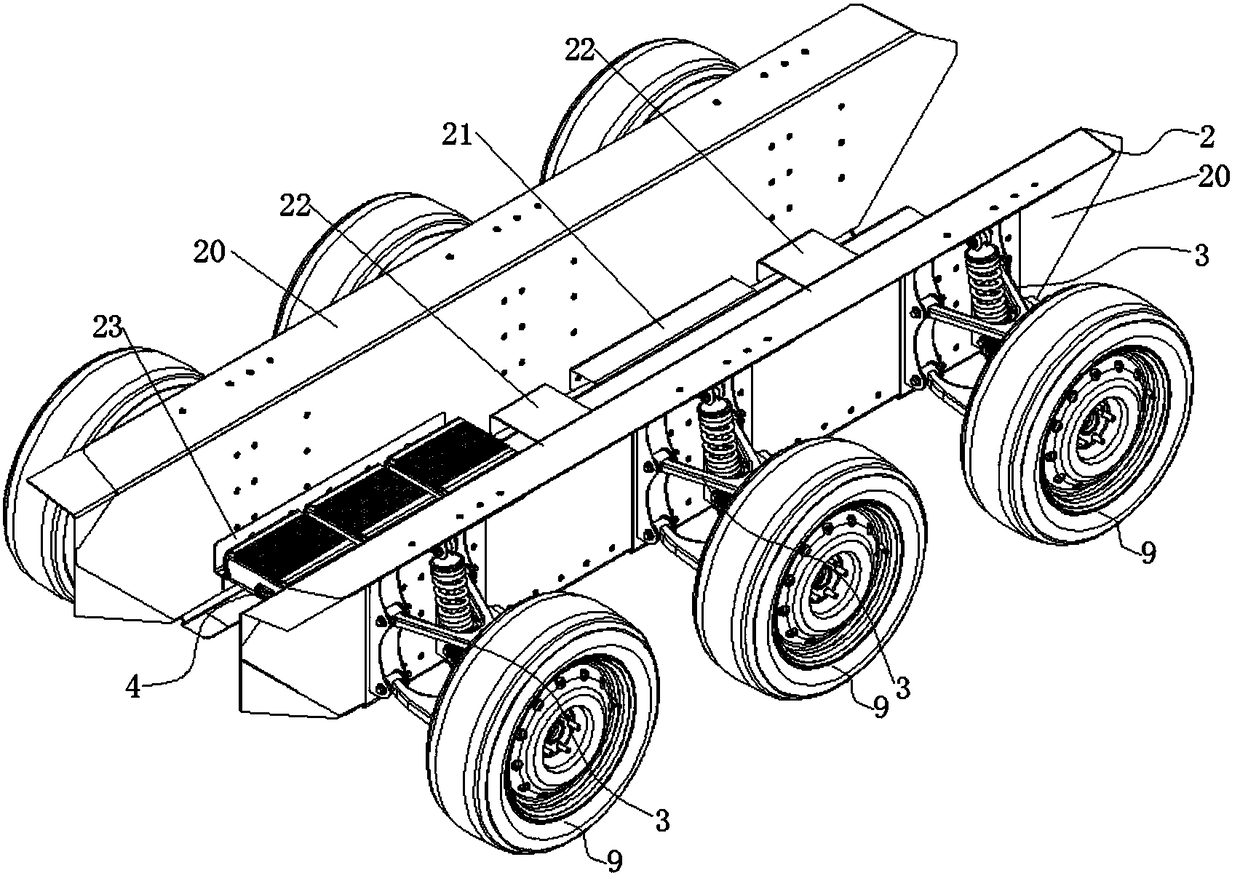

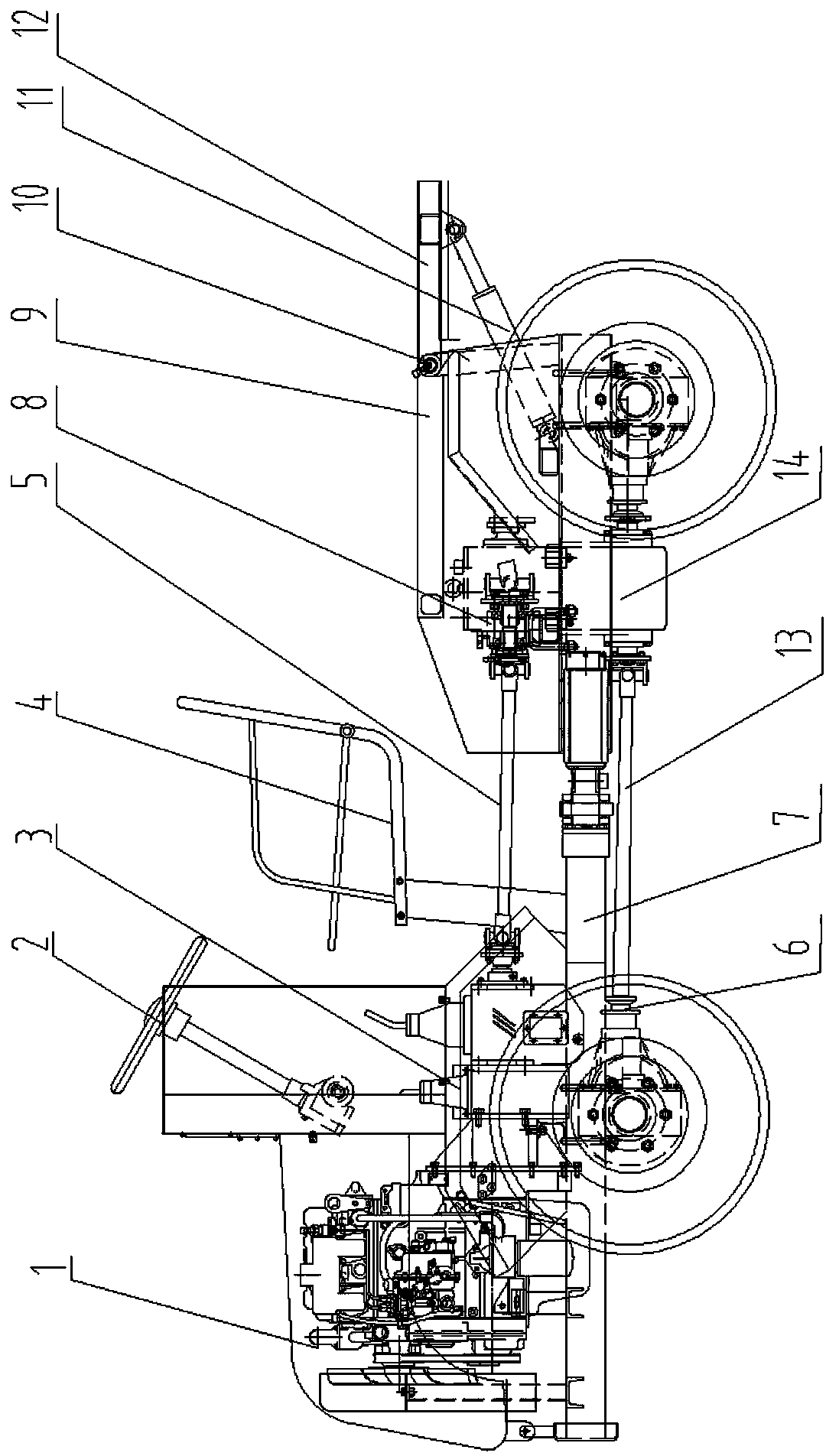

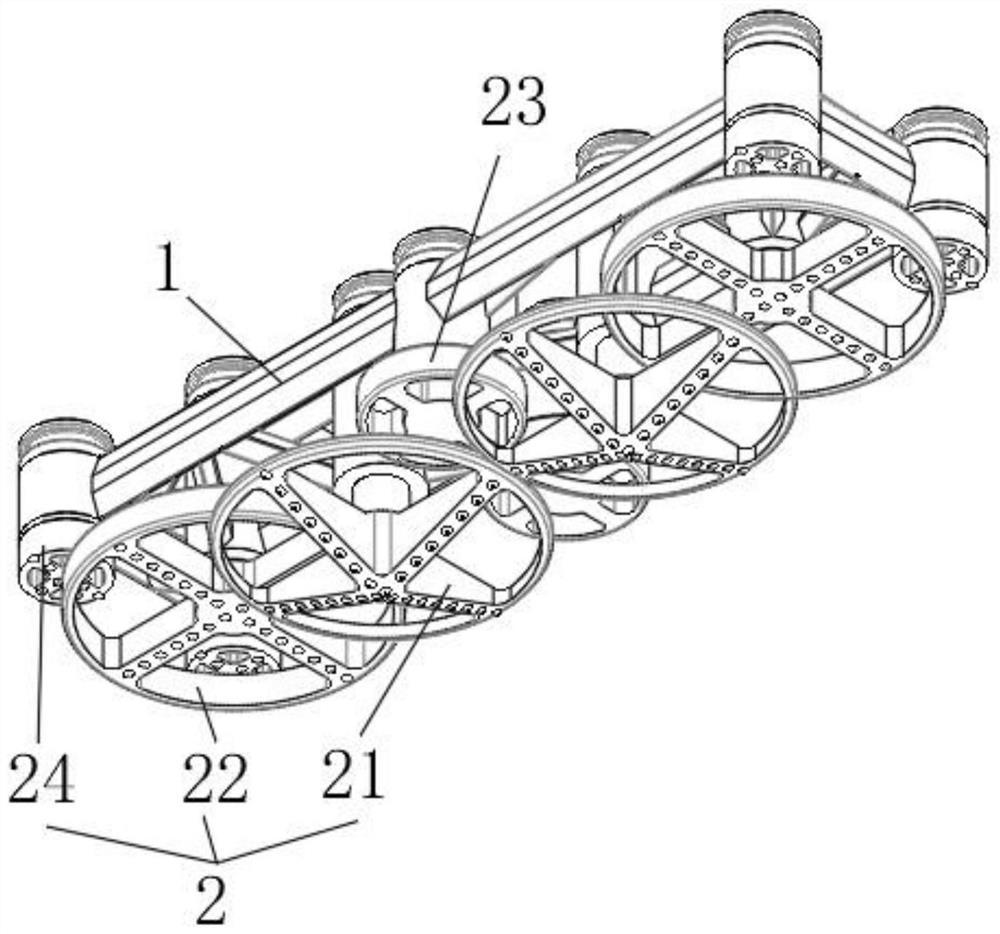

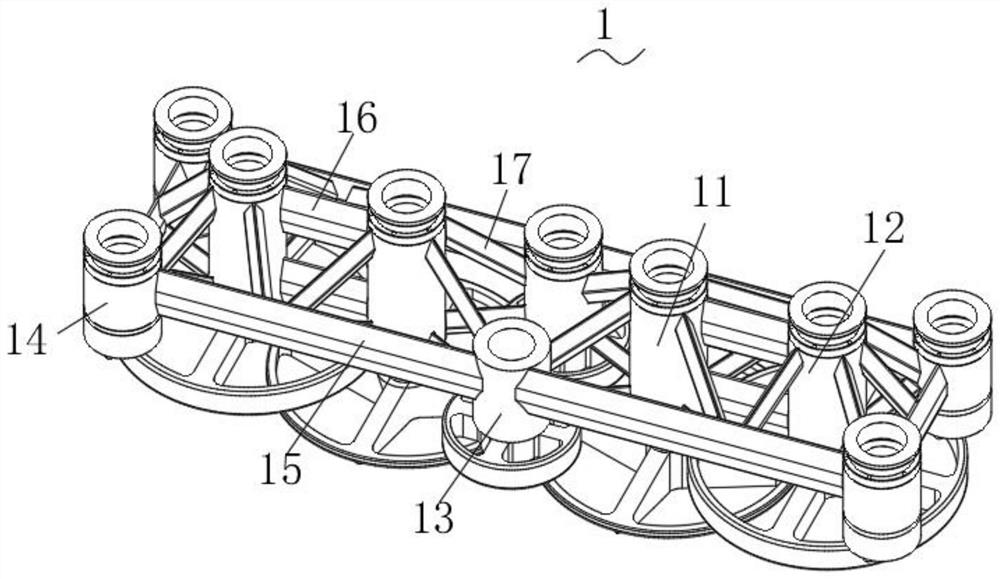

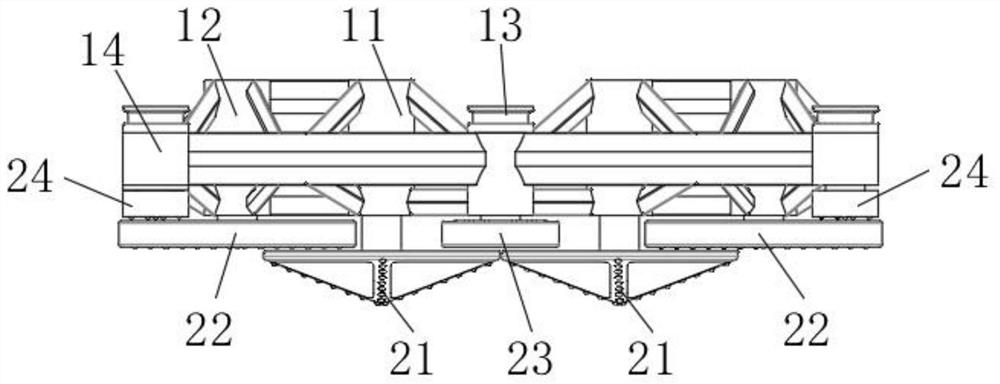

Unmanned platform vehicle and working method thereof

PendingCN108583728ARealize modular loading and unloadingEasy to replace each otherVehiclesControl systemEngineering

The invention discloses an unmanned platform vehicle and a working method thereof. The unmanned platform vehicle comprises a vehicle body, a vehicle frame system, a suspension system, a controlling system, a steering system, a driving system, a braking system, a battery group and wheels. The vehicle body is connected with the upper end of the vehicle frame system; the vehicle frame system comprises side beam plates, a reinforcing piece, a first connecting piece and a second connecting piece; the suspension system is connected with the lateral faces of the side beam plates, and the suspension system comprises suspension frame installation plates, lower fork arms, upper fork arms, dampers, wheel hub frames and wheel hubs; the driving system comprises wheel hub motors, motor cooling pipelinesand guide wire pipelines; one ends of the steering system are hinged to the outer sides of the suspension frame installation plates, and the other sides of the steering system are hinged to the wheelhub frames; the braking system is connected with the wheel hub frames; the wheels are connected with the wheel hubs; and the battery group is connected with the lower ends of the side beam plates. Modular assembly of all parts in the vehicle frame system is achieved; examination and replacement of the parts are convenient; the modular assembly of the suspension system, the driving system and thevehicle frame system is achieved;and replacement is convenient and passing ability is high.

Owner:芜湖正众汽车科技有限公司

Wooden door

ActiveCN105064880AHigh fastnessPrevent shrinkage deformationDoor leavesMechanical engineeringMullion

Owner:周清

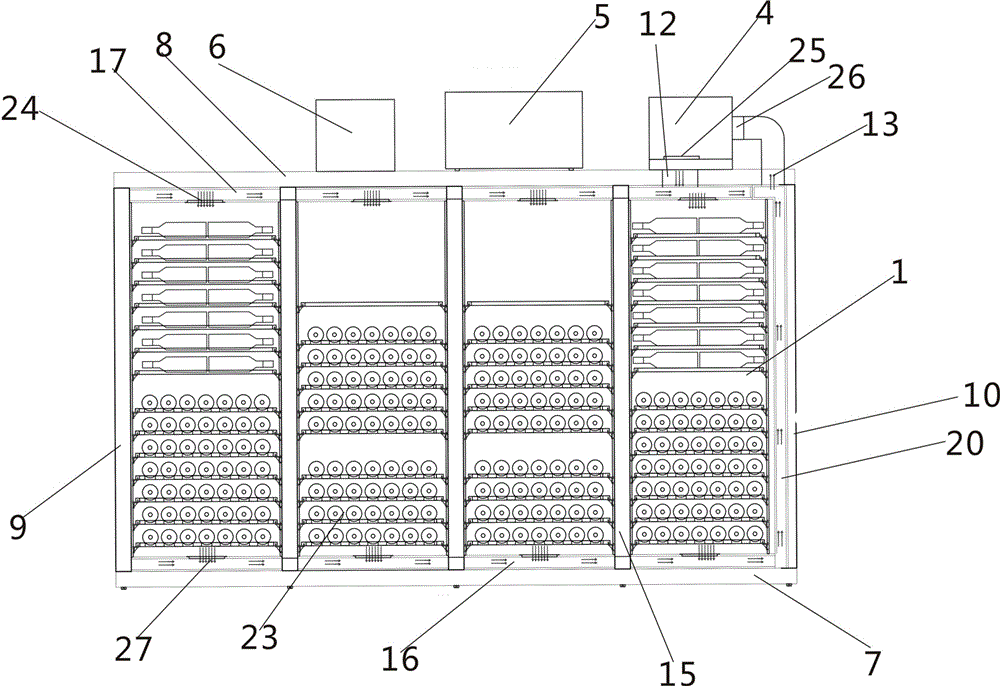

Wall body type wine cabinet

InactiveCN105832004AThe quality remains the sameSolve uneven temperatureCocktail cabinetsEngineeringHumidity

The invention discloses a wall body type wine cabinet, which is characterized by comprising a wine cabinet body consisting of heat insulation fixing elements, a middle side plate, a left side plate, a right side plate, a bottom plate, a back plate and a top plate, wherein the top plate is provided with an air outlet and an air return opening; an air return passage is arranged on the bottom plate; an air outlet passage is arranged under the top plate; the middle side plate is arranged between the air return passage and the air outlet passage; the bottom plate, the air return passage, the air outlet passage and the middle side plate form a plurality of wine storage chambers and are fixedly connected through the heat insulation fixing elements; one wine storage chamber corresponds to one sub air outlet passage and one sub air return passage; a sub air outlet is formed in the bottom of each sub air outlet passage; the top of each air return passage is provided with a sub air return opening; the back plate is arranged at the back side of the wine storage chamber. The wall body type wine cabinet has the beneficial effects that the installation is flexible; the modularized assembly is realized; meanwhile, the wall body type wine cabinet is put in positions of a partition wall or a partition part and a screen; the temperature and the humidity of the wine cabinet are controlled; the wine is stored in a best state, so that the quality of the wine is enabled not to be changed.

Owner:广州方帝斯控温科技有限公司

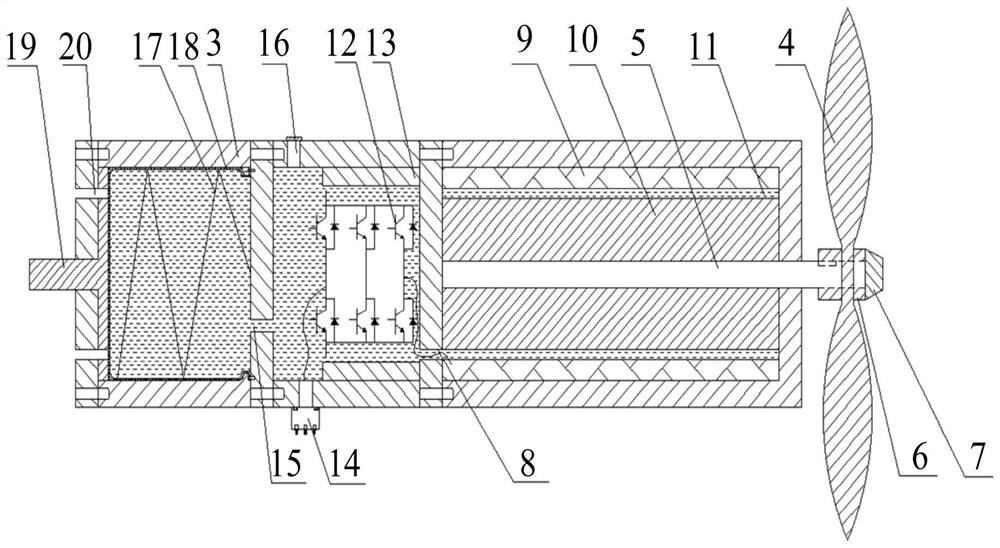

Integrated full-sea-depth propeller

InactiveCN111846172ARealize modular assemblyRealize integrated designUnderwater vesselsUnderwater equipmentUnderwaterElectric machinery

The invention discloses an integrated full-sea-depth propeller, and relates to the technical field of underwater engineering. The propeller comprises a screw propeller arranged outside a shell, a compensation cavity, a driver cavity and a motor cavity, wherein the compensation cavity, the driver cavity and the motor cavity are arranged in the shell and are sequentially connected with one another.A motor is arranged in the motor cavity, an output shaft of the motor penetrates through the shell to be connected with the screw propeller, a first through hole is formed in the side, away from the screw propeller, of the motor cavity, and the motor cavity is connected with the first side of the driver cavity through the first through hole; a driver is arranged in the driver cavity, the driver iselectrically connected with a motor outgoing line, a watertight connector is installed on the side surface of the driver cavity, and the driver is connected with external electrical equipment throughthe watertight connector; and a second through hole is formed in the second side of the driver cavity, the driver cavity is connected with the first side of the compensation cavity through the secondthrough hole, and a compensator is arranged in the compensation cavity and used for compensating external seawater pressure acting on the shell. According to the propeller, the driver and the motor are integrally designed, arrangement weight and a size can be reduced, and a fault occurrence rate is decreased.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

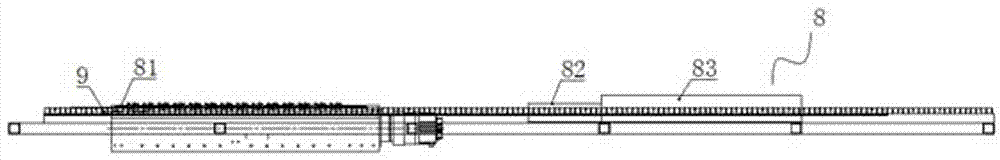

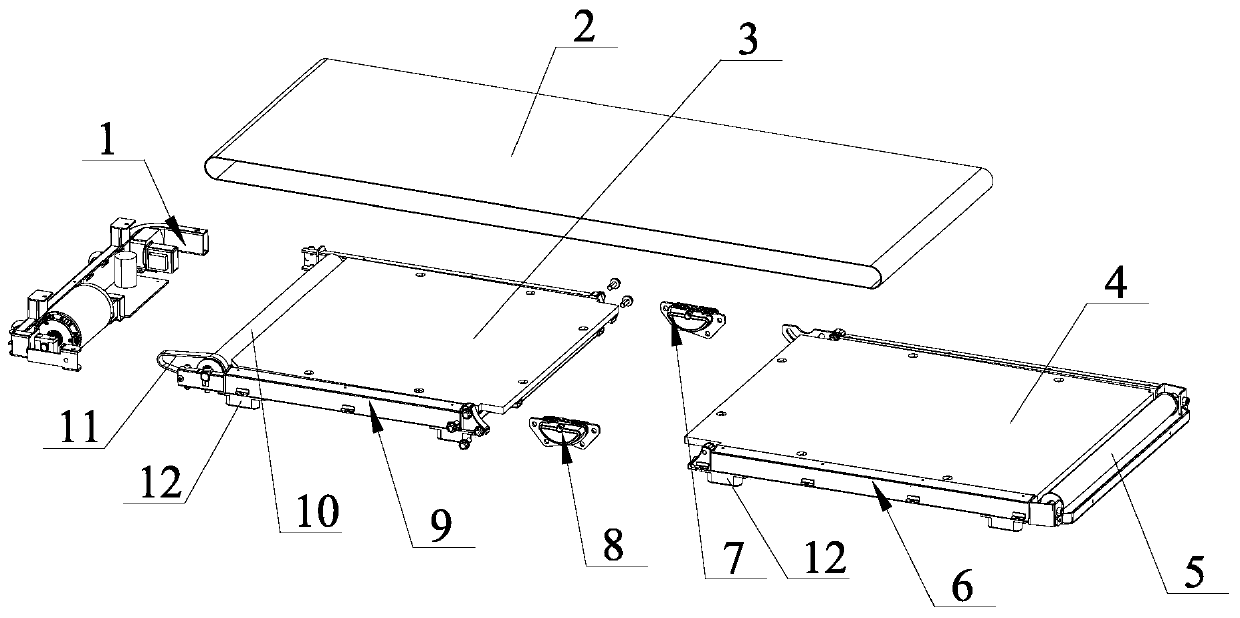

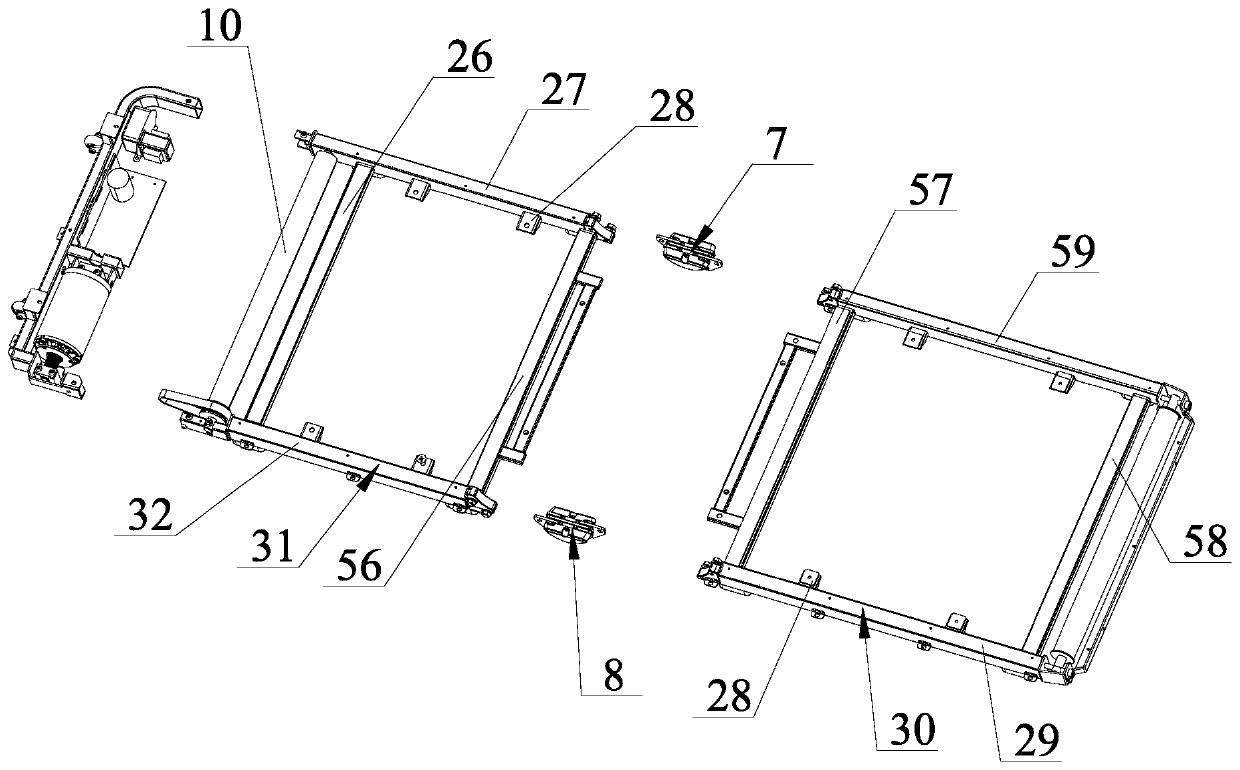

Running machine

PendingCN110559604AReduce volumeImprove yieldMovement coordination devicesCardiovascular exercising devicesMaterials preparationEconomic benefits

The invention discloses a running machine. The running machine comprises a front running table provided with a front roller at the front end, a rear running table provided with a rear roller at the rear end, and a running belt tensioned on the front roller and the rear roller and covering a front running board of the front running table and a rear running board of the rear running table; the running machine further comprises an electric appliance module for assembling a driving transmission mechanism and a control electric appliance on a front frame; the electric appliance module is detachablyconnected with the front end of the front running table; the front running table and the rear running table are detachably connected through a folding mechanism; the front frame of the electric appliance module is provided with an opening facing the front running table; and the rear end parts of two straight rods of the front frame and the front end parts of two side plates of the front running table are of male and female insertion structures and are in threaded connection. The running machine realizes modular assembly, has few parts during assembly, and is simple in structure, convenient inassembly and material preparation, and convenient and rapid to install; the installation procedures and the assembly processes are reduced; the production efficiency is greatly improved; the production cost is greatly reduced; and the economic benefits are is obvious.

Owner:LOCTEK ERGONOMIC TECH CORP

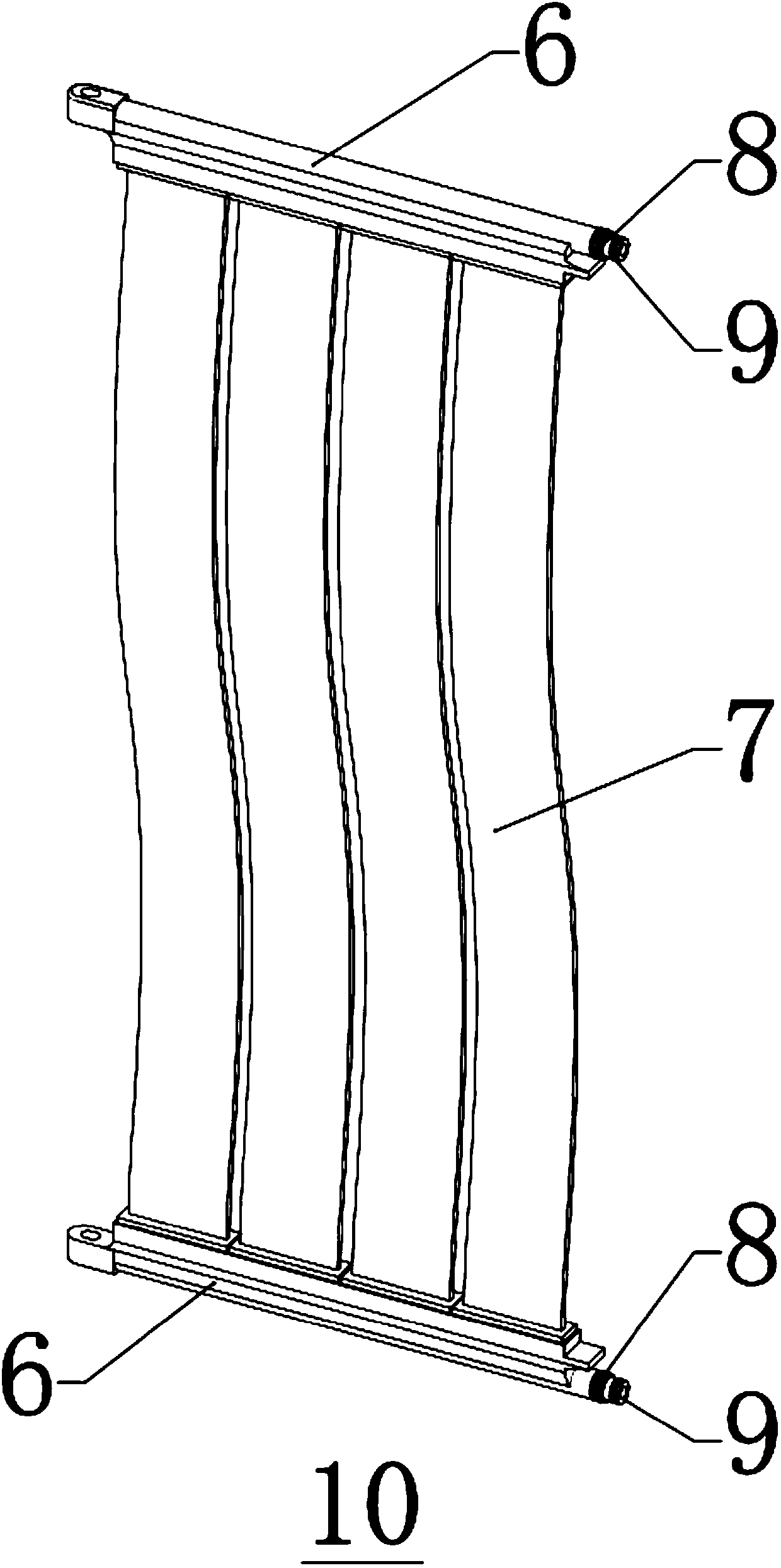

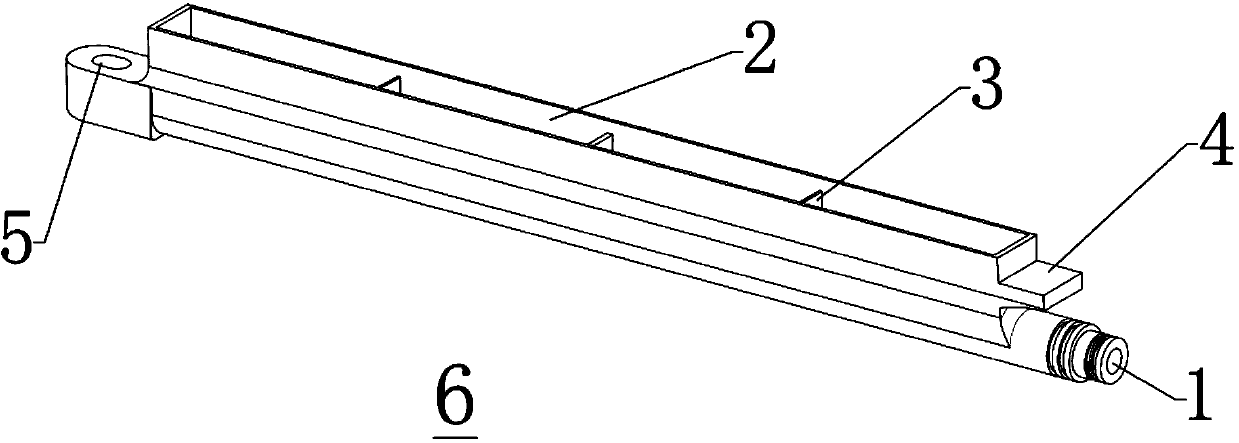

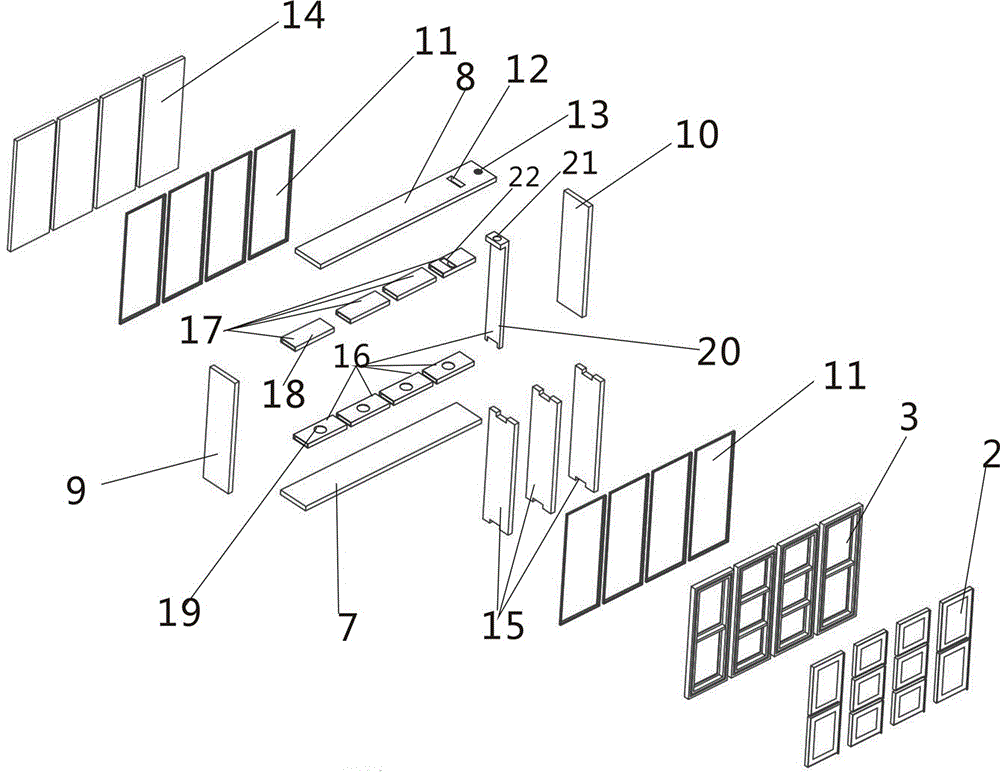

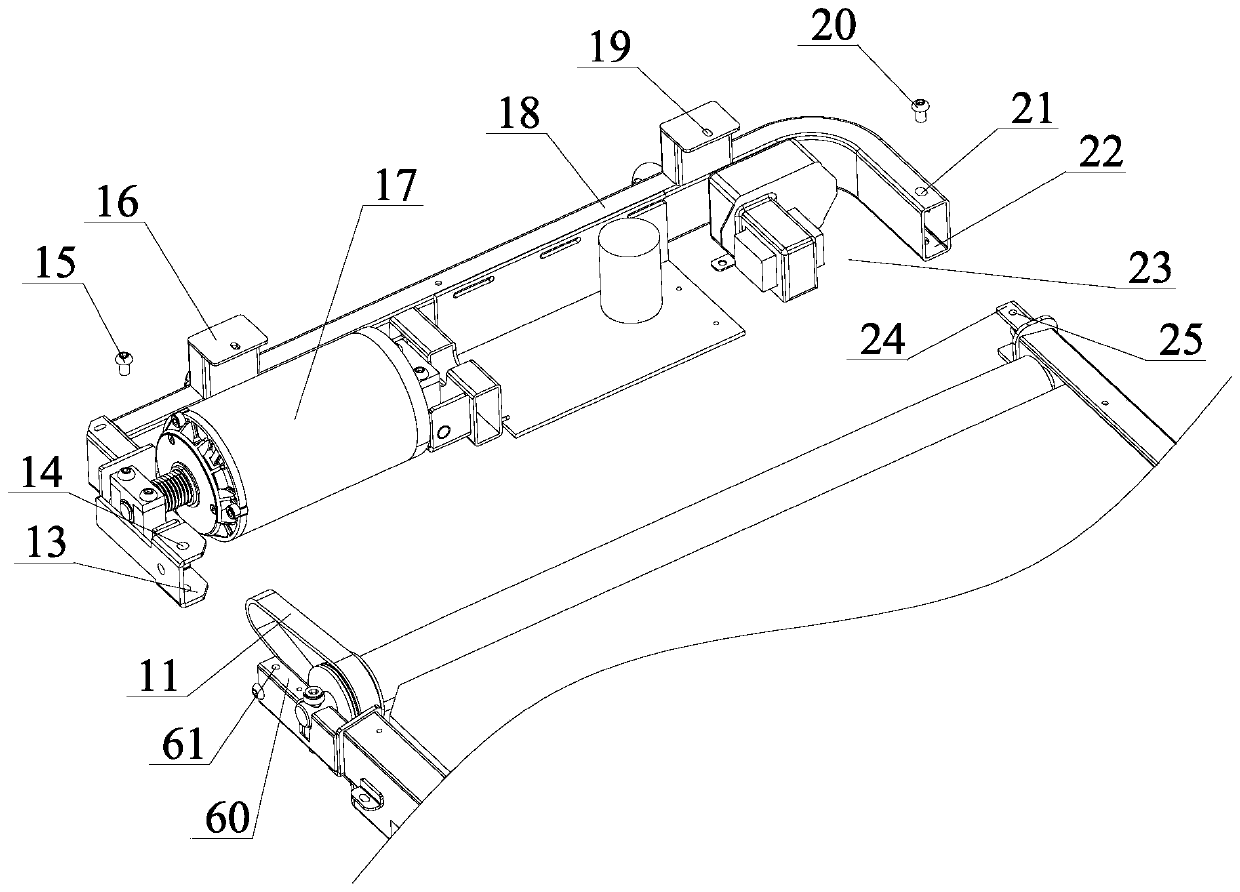

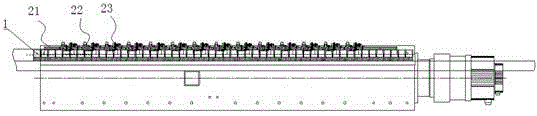

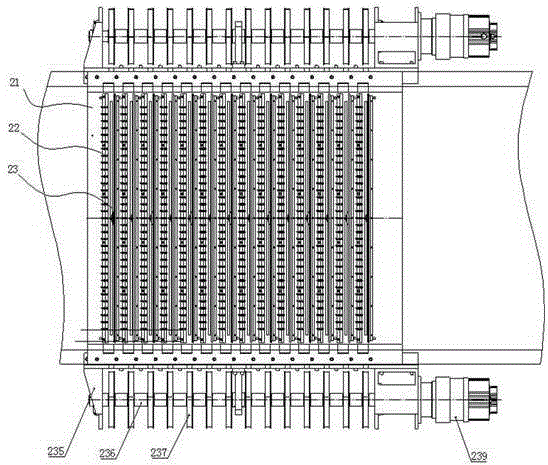

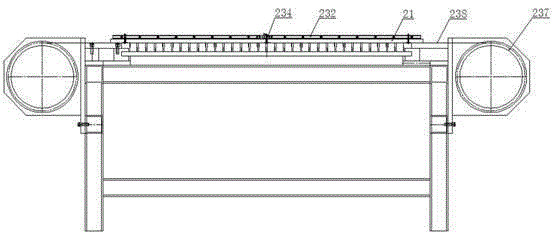

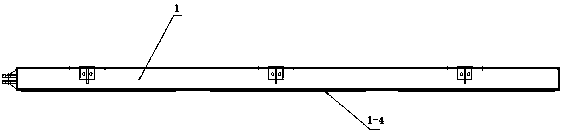

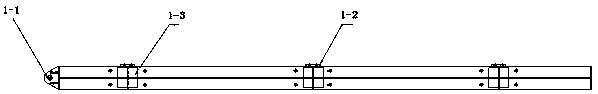

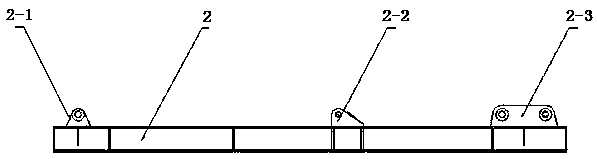

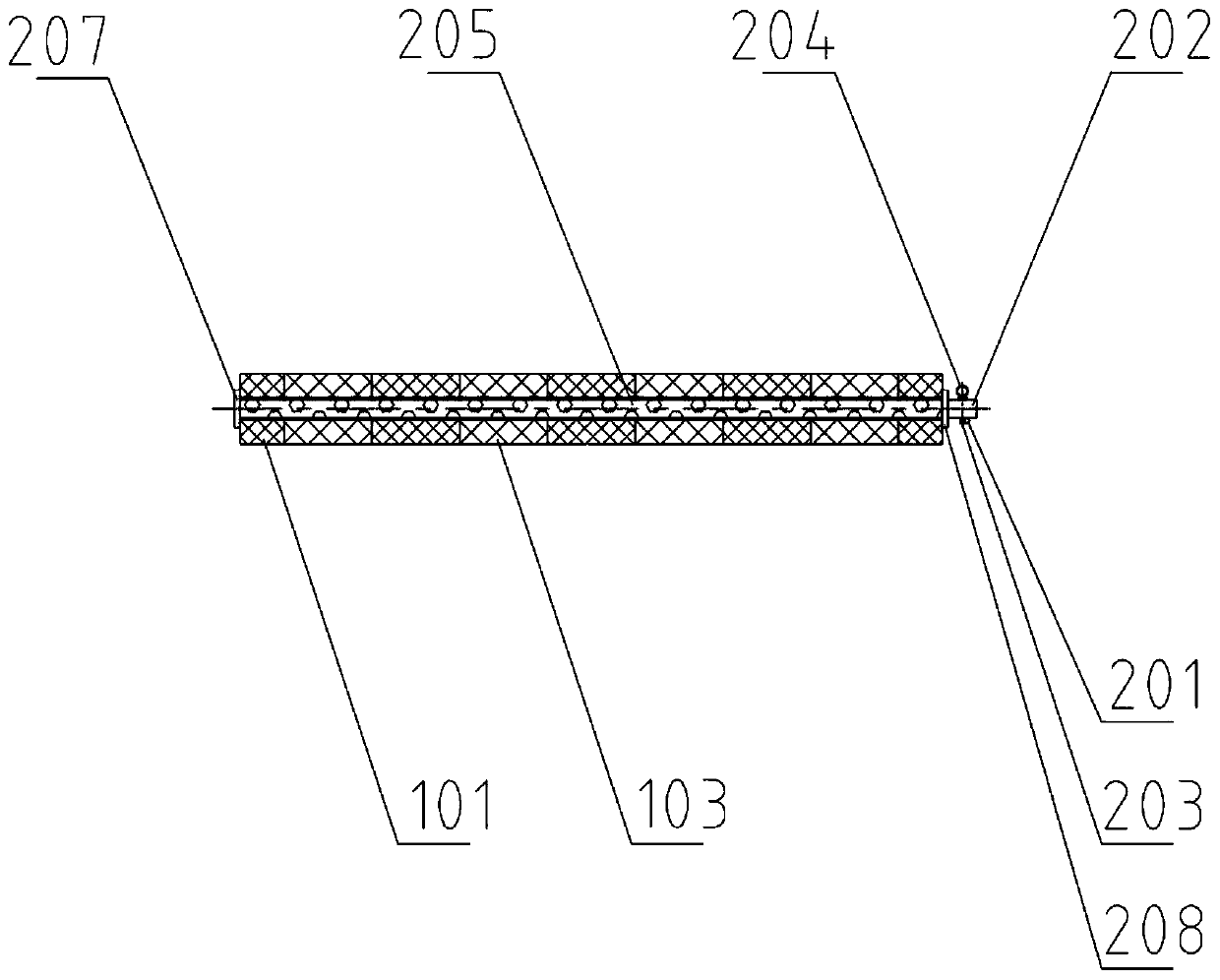

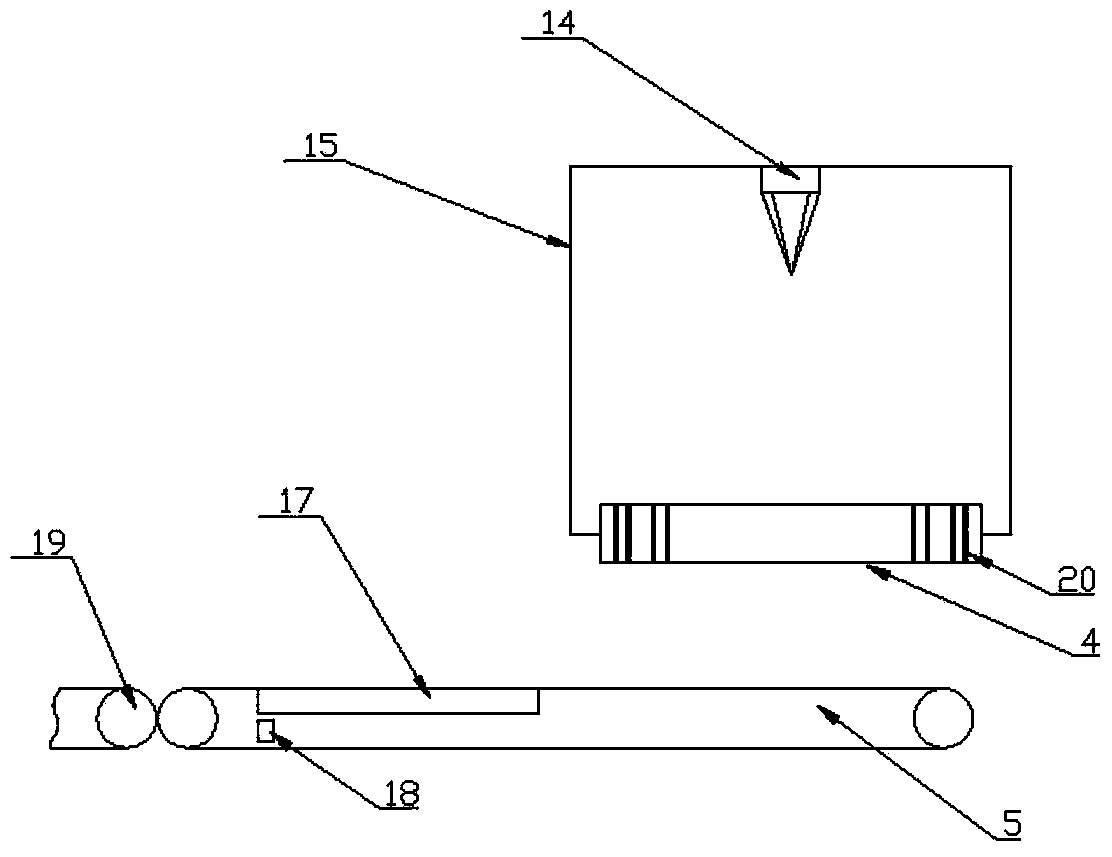

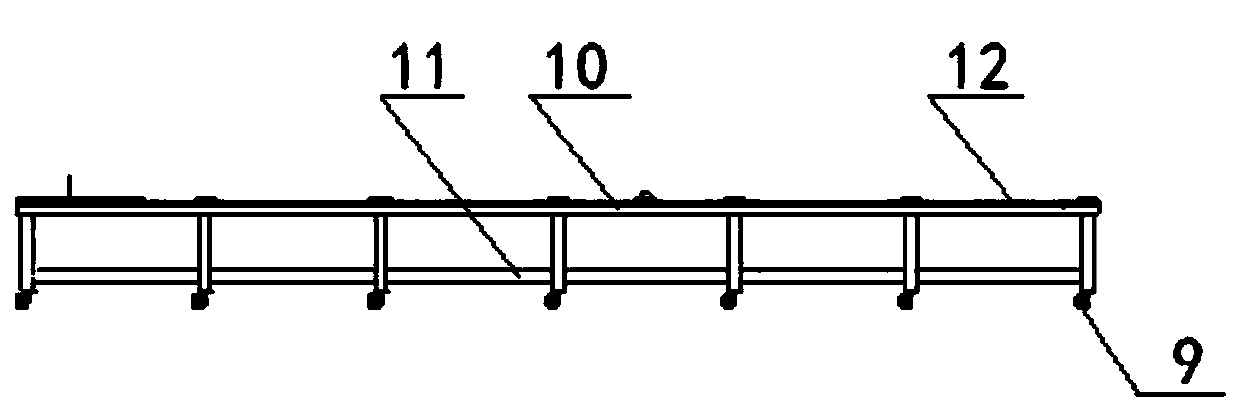

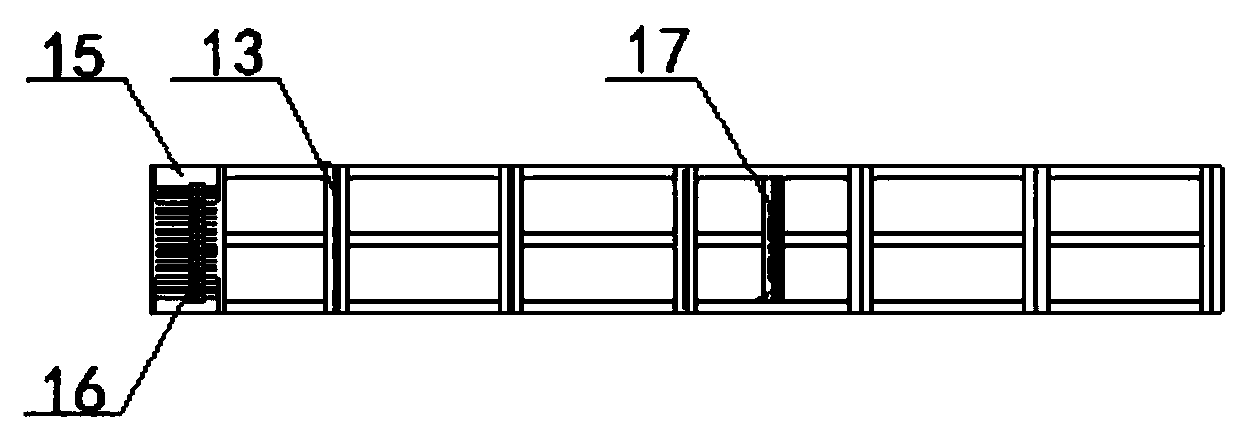

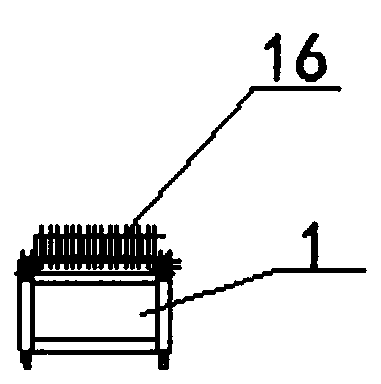

Automatic yarn laying mechanism of glass fiber pultrusion grid continuous production line

The invention relates to an automatic yarn laying mechanism of a glass fiber pultrusion grid continuous production line. The automatic yarn laying mechanism is characterized by comprising a reinforcement fiber placement section fixing template, a longitudinal yarn laying mechanism and a horizontal yarn laying mechanism; a plurality of horizontal yarn laying regions and a plurality of longitudinal yarn laying regions distributed in the movement direction of a movement core template and arranged at intervals are distributed on the reinforcement fiber placement section fixing template; the longitudinal yarn laying mechanism comprises a longitudinal yarn installation base, a pressing sheet and a plurality of pressing sheets distributed in the direction perpendicular to the movement direction of the movement core template; and the horizontal yarn laying mechanism comprises a horizontal yarn installation base, and a horizontal-yarn linear guide rail extending in the direction perpendicular to the movement direction of the movement core template and a horizontal yarn sliding assembly are installed on the horizontal yarn installation base. By means of the automatic yarn laying mechanism, automatic and continuous yarn laying can be achieved, and core conditions are provided for smoothly manufacturing a pultrusion glass fiber grid; and after overall sub-assembling and adjustment are carried out, the automatic yarn laying mechanism is installed on the reinforcement fiber placement section fixing template, modular assembling is achieved, installing accuracy is guaranteed, and independent part replacement can be carried out during maintaining.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

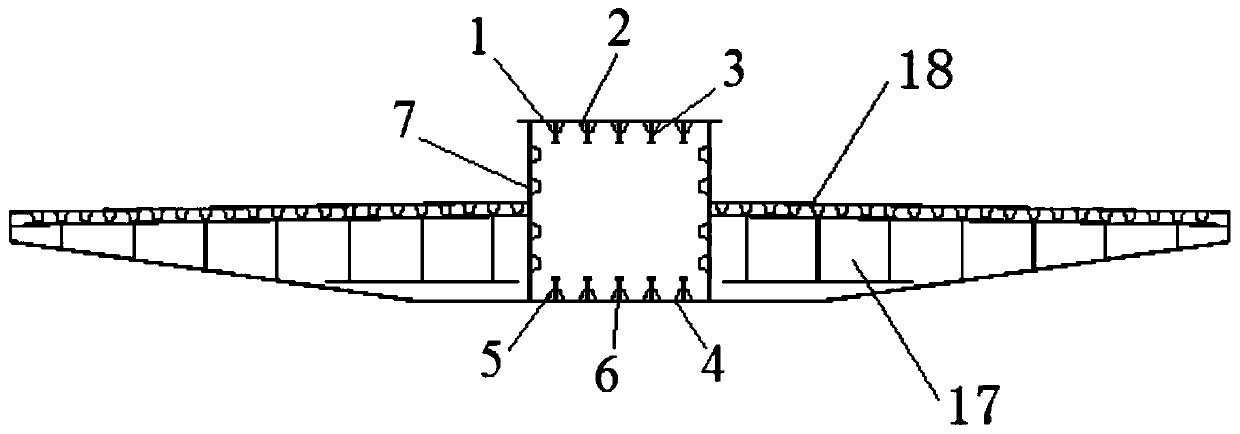

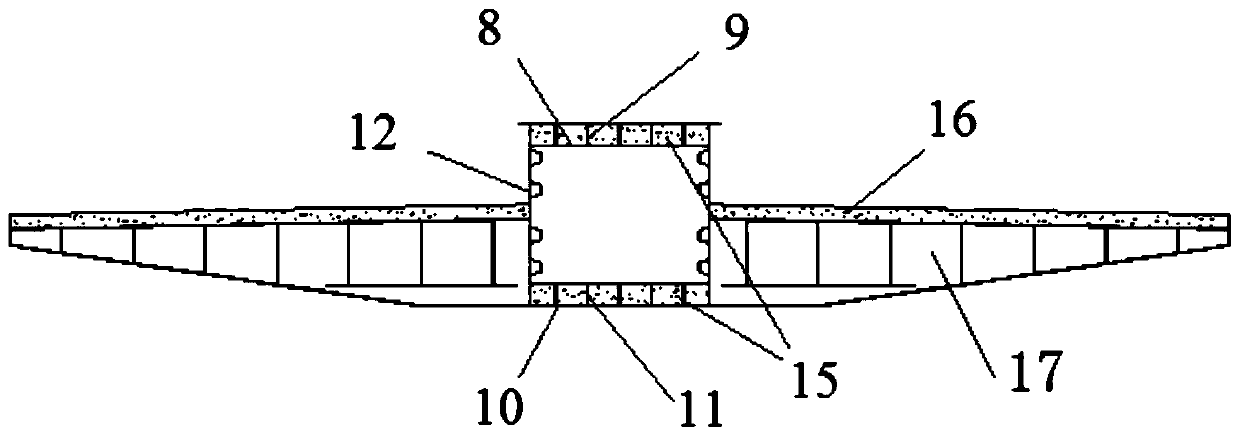

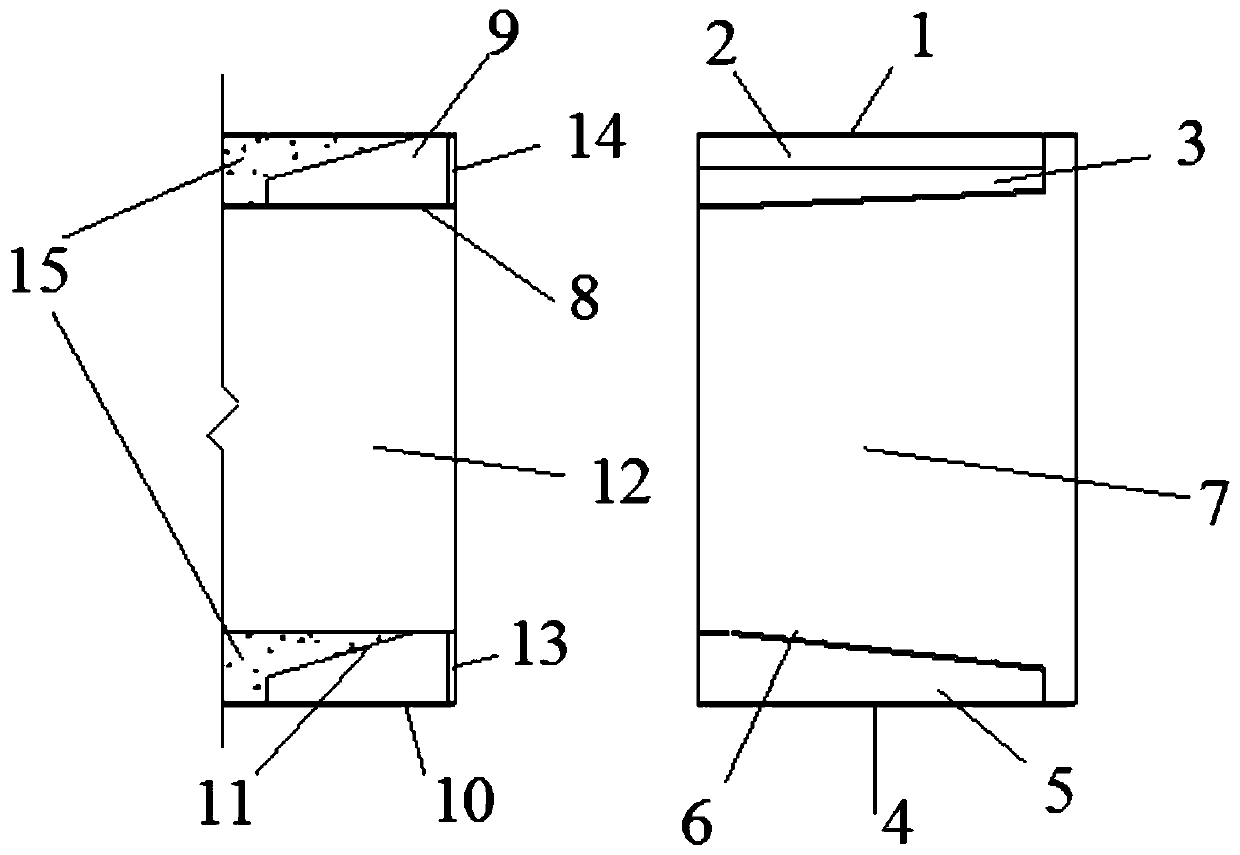

Steel beam and composite beam connecting structure

PendingCN111395148APractice integrated designSimple structureCable-stayed bridgeArchitectural engineeringStringer

The invention relates to a steel beam and composite beam connecting structure. The connecting structure comprises a steel box girder and a composite girder which are connected. The steel box girder comprises a steel box girder main longitudinal beam and steel box girder cantilever slabs connected to the two sides of the steel box girder main longitudinal beam. The steel box girder main longitudinal beam comprises a steel girder top plate, a steel girder bottom plate and a steel girder web. The steel beam top plate and the steel beam bottom plate are connected to upper and lower ends of the steel beam web. The composite girder comprises a composite girder main longitudinal beam and composite girder cantilever slabs connected to the two sides of the composite girder main longitudinal beam. The composite girder main longitudinal beam comprises a composite beam steel top plate, a composite girder steel bottom plate and a composite girder steel web. The composite girder steel top plate andthe composite girder steel bottom plate are respectively connected to the upper end and the lower end of the composite girder steel web, the steel beam web is welded with the composite beam steel web,the composite beam concrete is filled above the composite girder steel top plate, and the composite beam concrete is filled on the composite girder steel bottom plate. The connecting structure has the advantages of being simple in form, smooth in force transmission, convenient to connect and beneficial to standardized manufacturing and modular assembly of the hybrid beam of the cable-stayed bridge.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

Transverse and longitudinal slippage system for short line-method segment box beam side mold

The invention provides a transverse and longitudinal slippage system for a short line-method segment box beam side mold. The transverse and longitudinal slippage system comprises a longitudinal slippage support, a transverse slippage support, a connecting support, reverse buckles I and reverse buckles II, wherein a main body part of the transverse slippage support is formed by group welding of H-shaped steel; a lug plate I is arranged on one end of the transverse slippage support and is connected with a transverse slippage adjusting screw rod, and transverse slippage is realized; a connectinghole is formed in the surface of the transverse slippage support, and the connecting hole is connected with the reverse buckles I; the front end of a main body of the longitudinal slippage support isconnected with a front fulcrum screw of a side mold and is used for supporting a template and a truss of the side mold; the rear end of the main body of the longitudinal slippage support achieves thefunction of supporting the truss of the side mold by connecting a diagonal bracing mechanism and a flange supporting screw; a main body of the connecting support is formed by group welding of I-shapedsteel; two ends of the connecting support are connected with the transverse slippage support; the reverse buckles I are connected with the upper surface of the transverse slippage support; the reverse buckles II are connected with an embedded part of a construction site.

Owner:山东博远重工有限公司

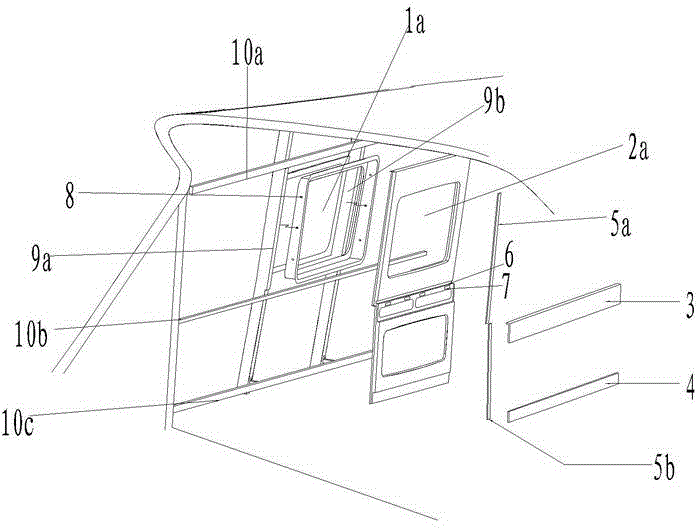

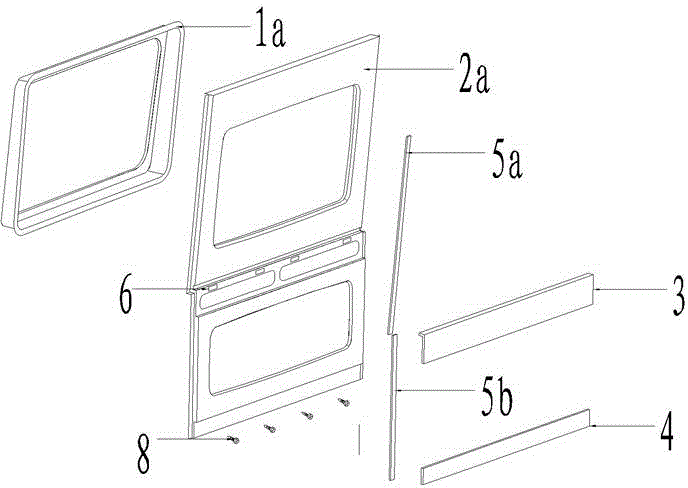

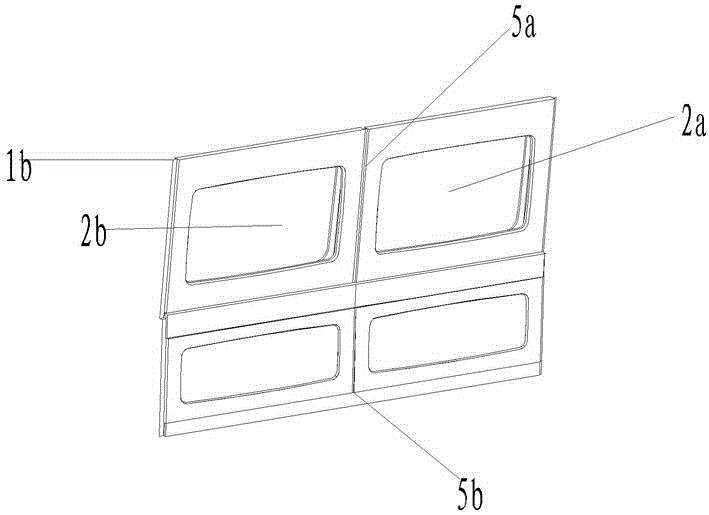

Decorative side wall plate for ship and splicing method thereof

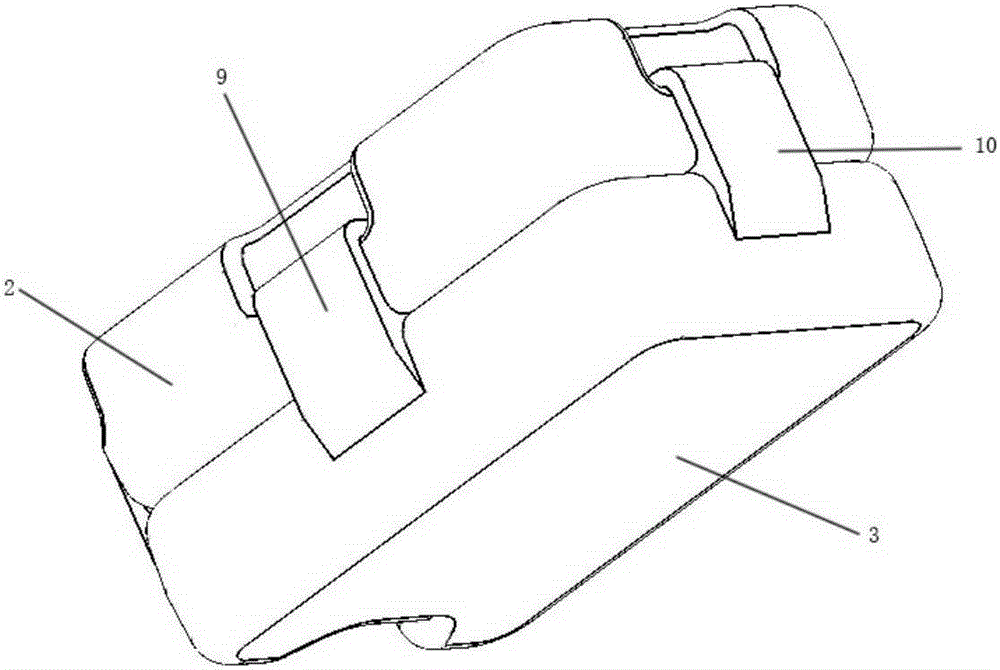

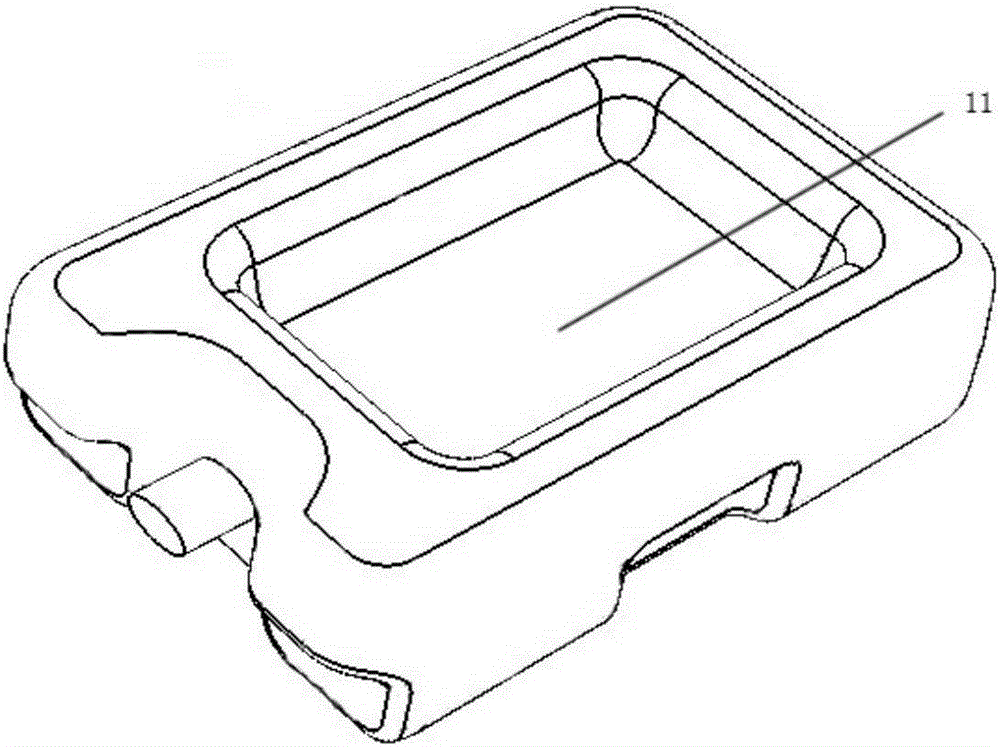

InactiveCN103979075ARealize modular assemblySolve problems such as damp and mildewHull bulkheadsVessel portsHull structureAdhesive

The invention discloses a decorative side wall plate for a ship and a splicing method thereof. The decorative side wall plate comprises a ship body structure component, an inner window sleeve (1) and two side wall plates (2), wherein the two side wall plates are a first side wall plate (2a) and a second side wall plate (2b) respectively; the ship body structure component consists of a left ship body structure component (9a) and a right ship body structure component (9b); the inner window sleeve consists of a first inner window sleeve (1a) and a second inner window sleeve (1b); the first inner window sleeve (1a) and the second inner window sleeve (1b) respectively penetrate through the inner side through two or three self tapping screws (8) on the left and two or three self tapping screws (8) on the right to be fixedly connected with grooves of the left ship body structure component (9a) and the right ship body structure component (9b); the top parts of the first side wall plate (2a) and the second side wall plate (2b) are fixedly connected with an upper aluminum square pipe (10a), a middle aluminum square pipe (10b) and a lower aluminum square pipe (10c) through self tapping screws (8) respectively; the first side wall plate (2a) and the second side wall plate (2b) are fixedly connected with decorative strips through a sealing adhesive (11). The splicing method comprises the steps of connecting the two side wall plates through the sealing adhesive (11) in a splicing way. By the side wall plate, the requirements of high strength, simple construction and convenient operation on the indoor decorative side wall plate for the ship are met.

Owner:YAGUANG TECH GRP CO LTD

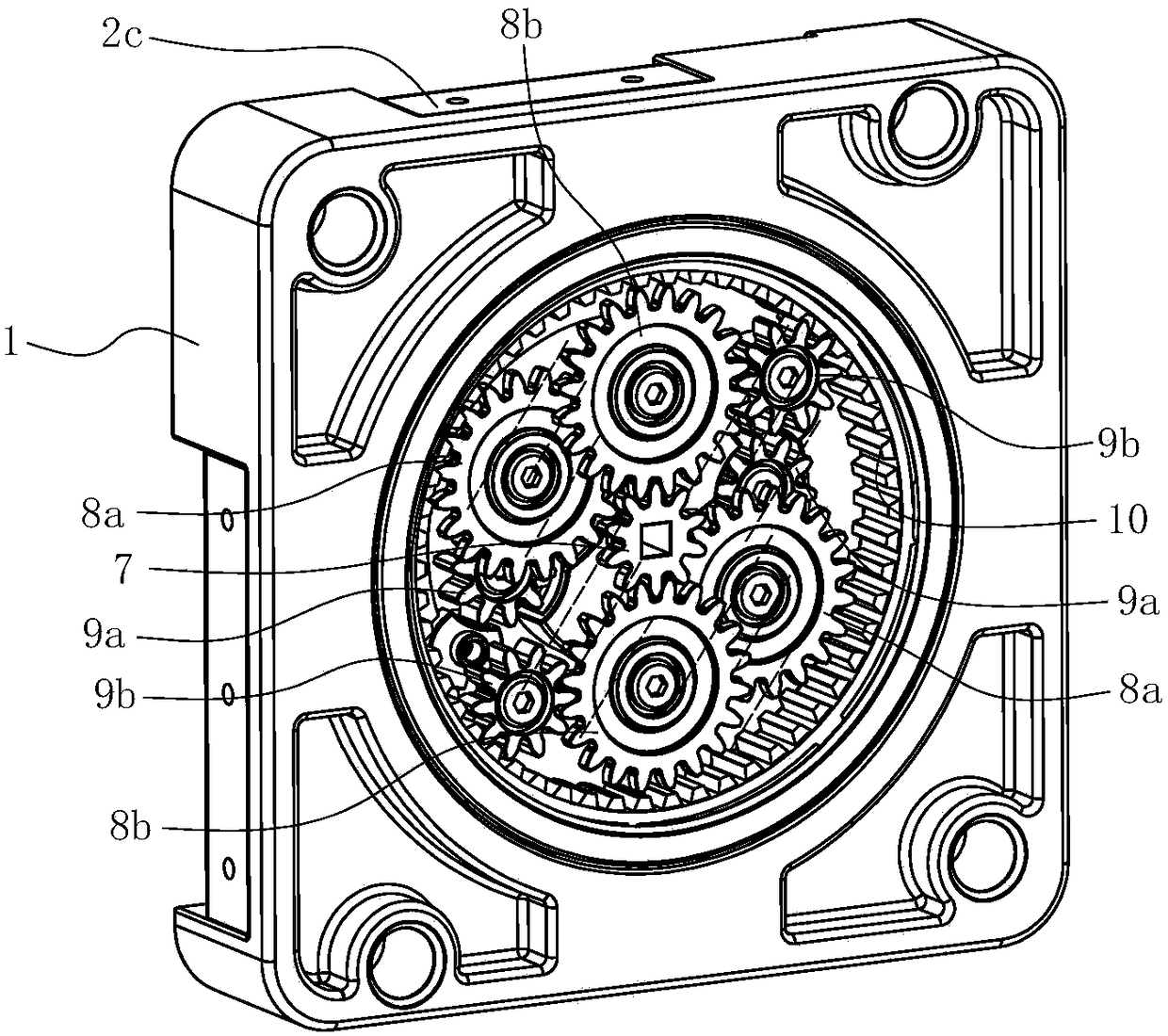

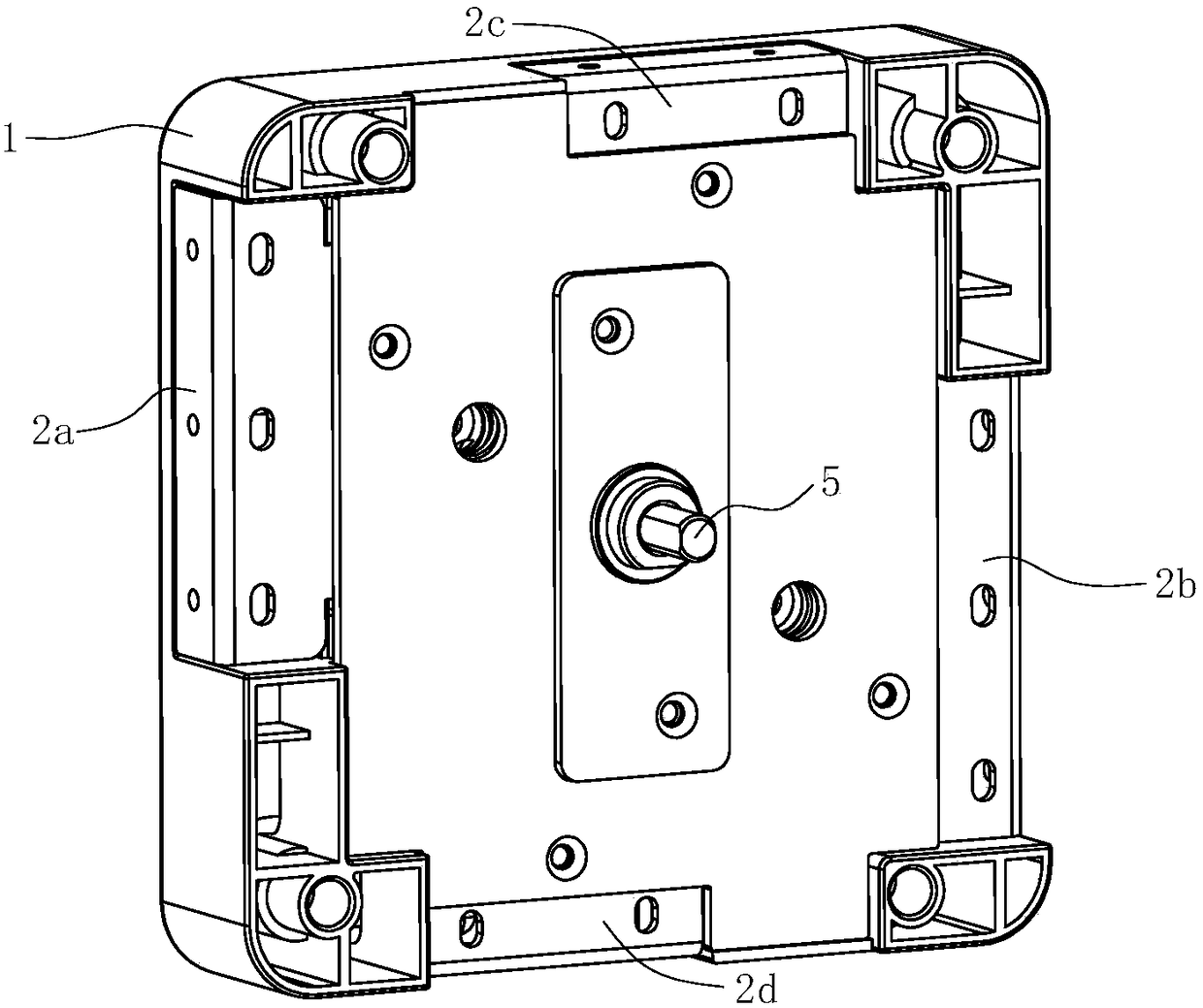

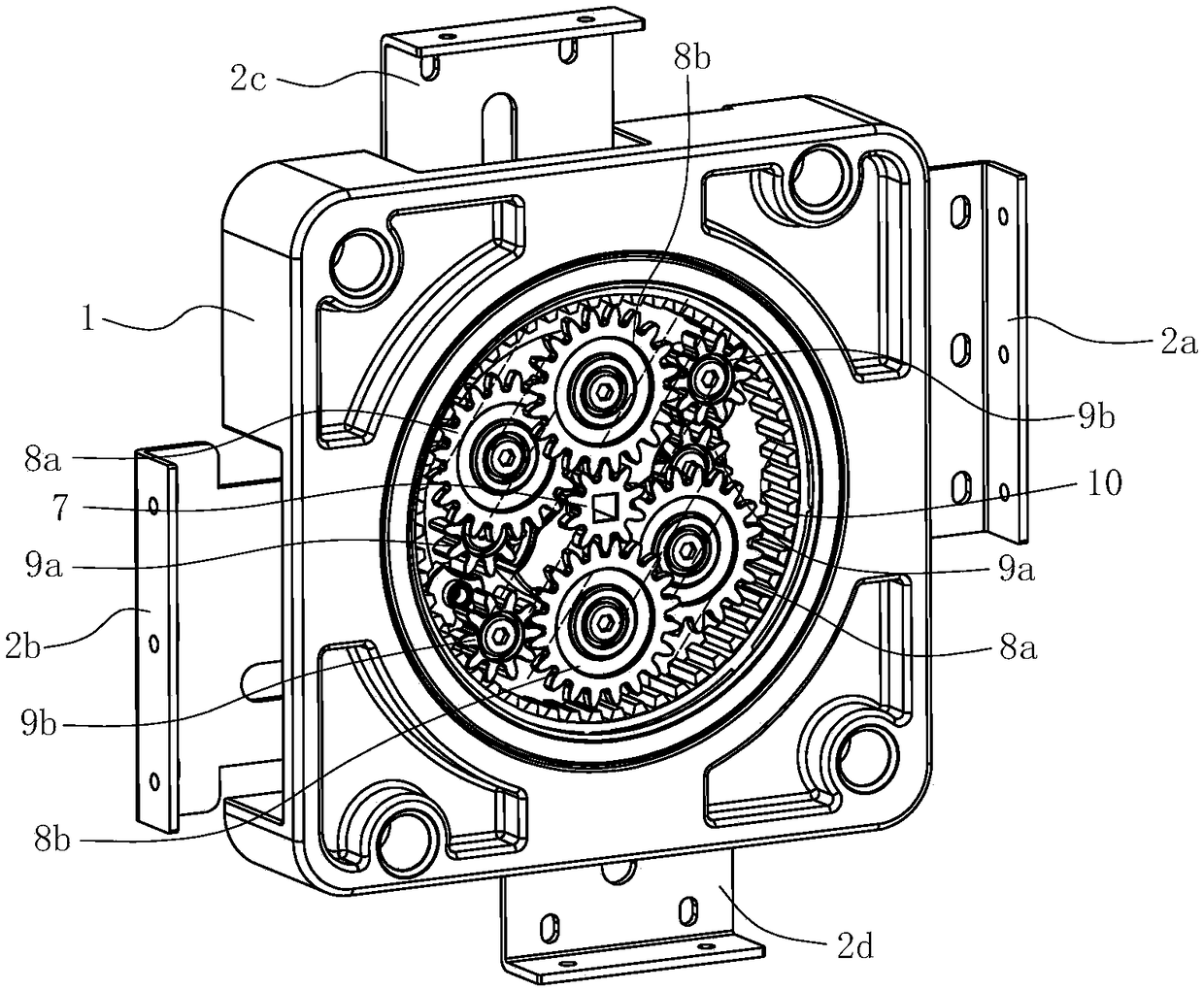

Lock for security door

The invention relates to a lock for a security door. The lock is characterized by comprising a lock shell with a containing cavity, a left sliding plate, a right sliding plate, an output gear, a clutch gear, a handle shaft and a speed reduction gear set. A mounting frame with a mounting shaft is arranged in the containing cavity, the left sliding plate and the right sliding plate are restrained onthe back face of the lock shell, a left rack part is arranged on the left sliding plate, a right rack part is arranged on the right sliding plate, the output gear is arranged on the mounting shaft ina sleeving manner, exposed out of the back face of the lock shell, and engaged with the left rack part and the right rack part in a transmission mode; the clutch gear is arranged on the mounting shaft in a sleeving manner and exposed in the containing cavity, and a clutch structure is arranged between end faces, close to each other, of the clutch gear and the output gear, the handle shaft is movably inserted in a shaft hole of the mounting shaft from the back face of the lock shell, the speed reduction gear set is arranged in the containing cavity, and the handle shaft is in transmission connection with the clutch gear through the speed reduction gear set. The lock for the security door is modular, the lock is suitable for a small-angle rotating handle, and also suitable for a 360-degreerotating handle, in addition, when a lawbreaker forcefully rotates the handle, the handle can idle, and safety is better.

Owner:宁波盛威卓越安全设备有限公司

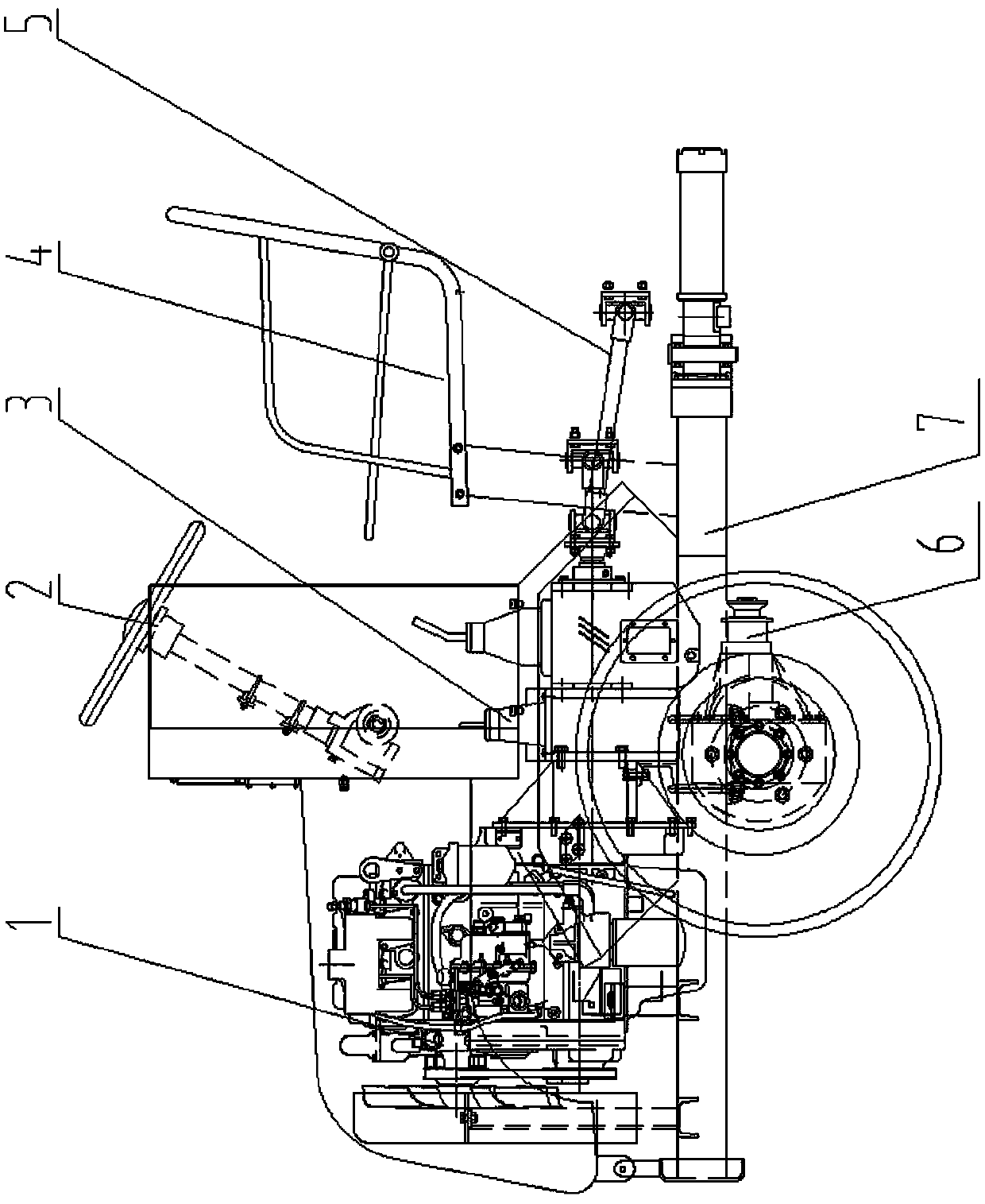

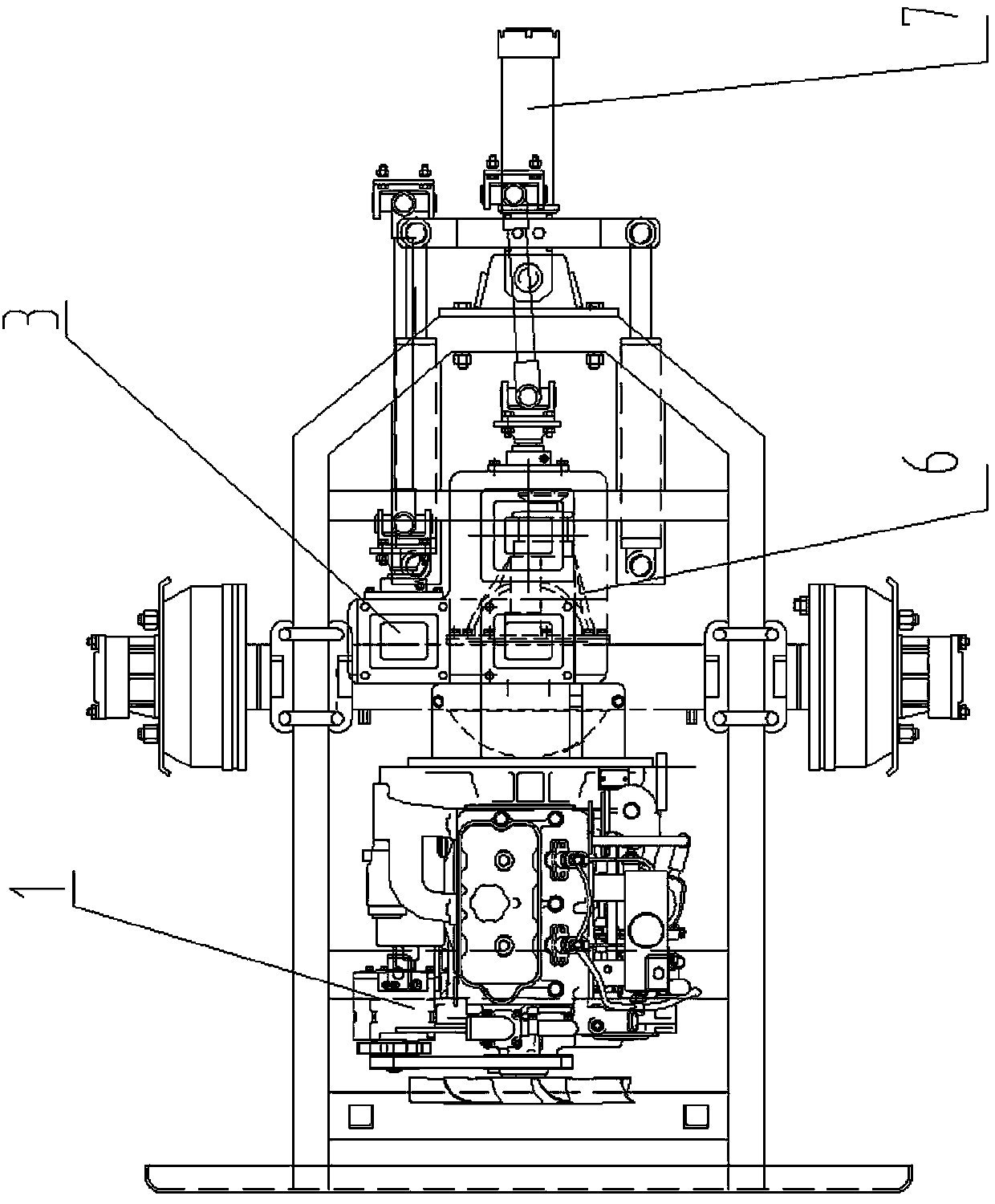

Articulated tractor head and tractor with same

An articulated tractor head comprises an engine, a hydraulic steering gear, a gearbox, a seat, a first transmission shaft, a traction shaft and a front drive bridge. The engine is connected with the input end of the gearbox. The main output end of the gearbox is connected with the first transmission shaft through a telescopic universal coupler. The gearbox is further provided with an auxiliary output end for driving an auxiliary equipment transmission shaft. The front drive bridge is located below the gearbox and functions as front drive. The invention further discloses a articulated tractor. The articulated tractor head is high in bearing capacity. The tractor with the articulated tractor head is simple in structure, provided with multiple power output ends, capable of realizing switching among front drive, rear drive and hydraulic drive, and convenient to operate.

Owner:刘光兵 +2

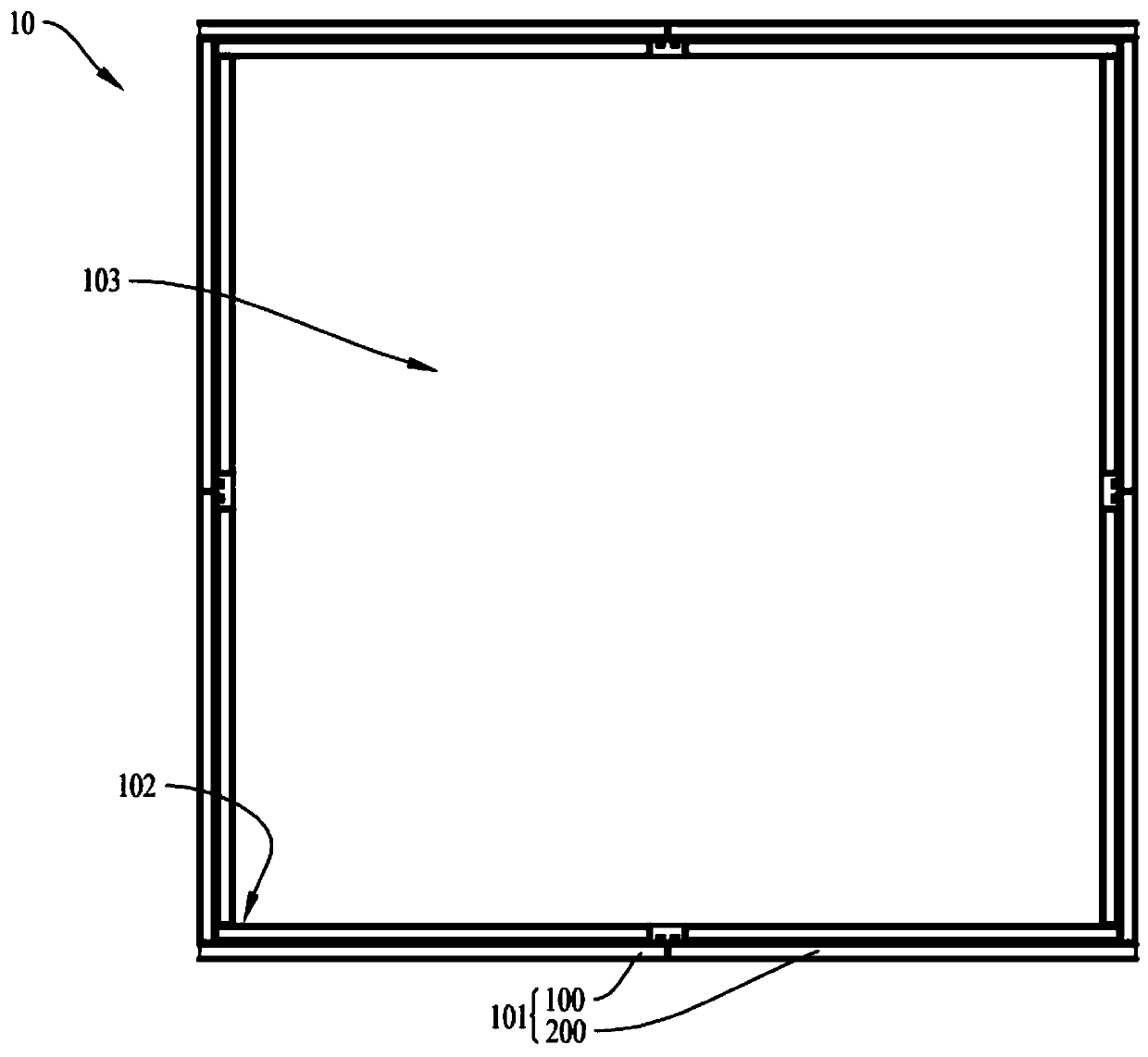

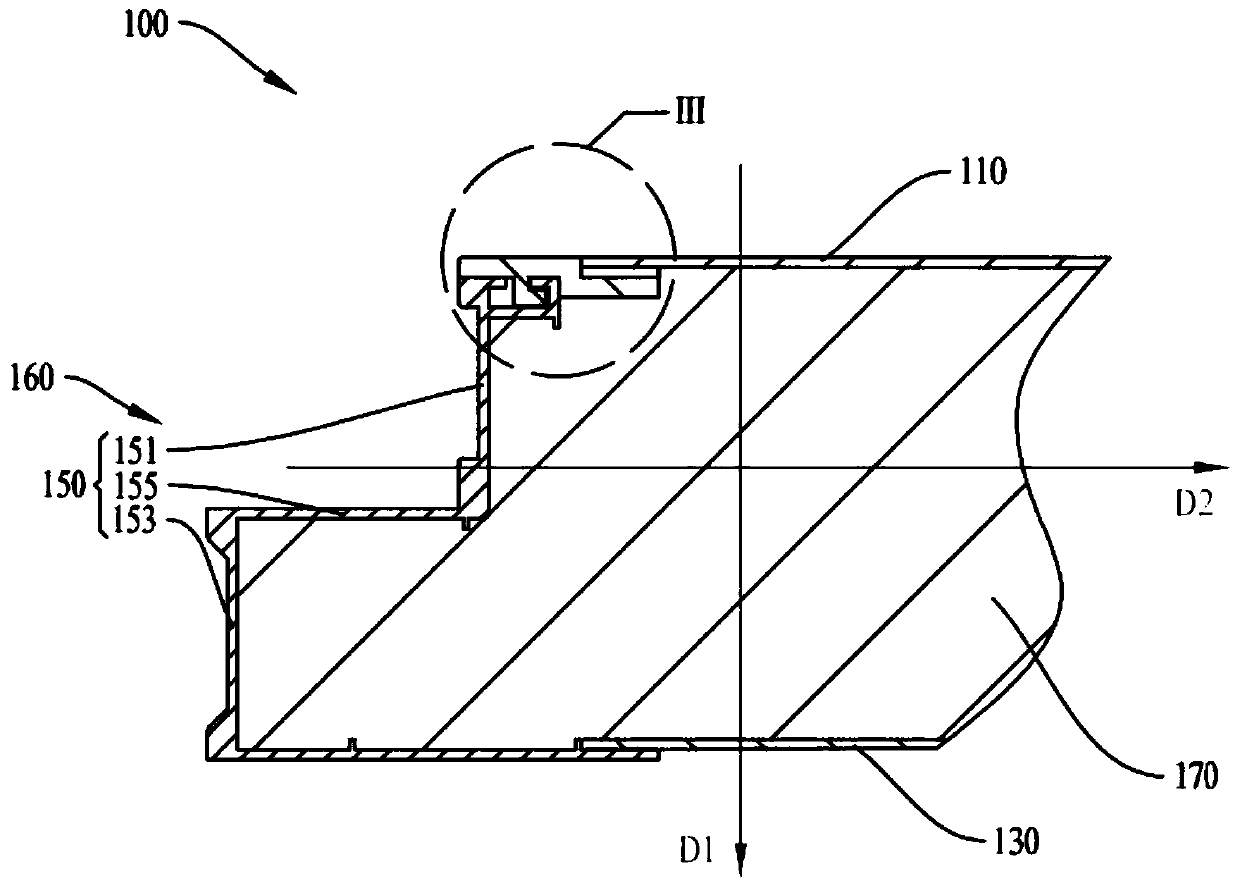

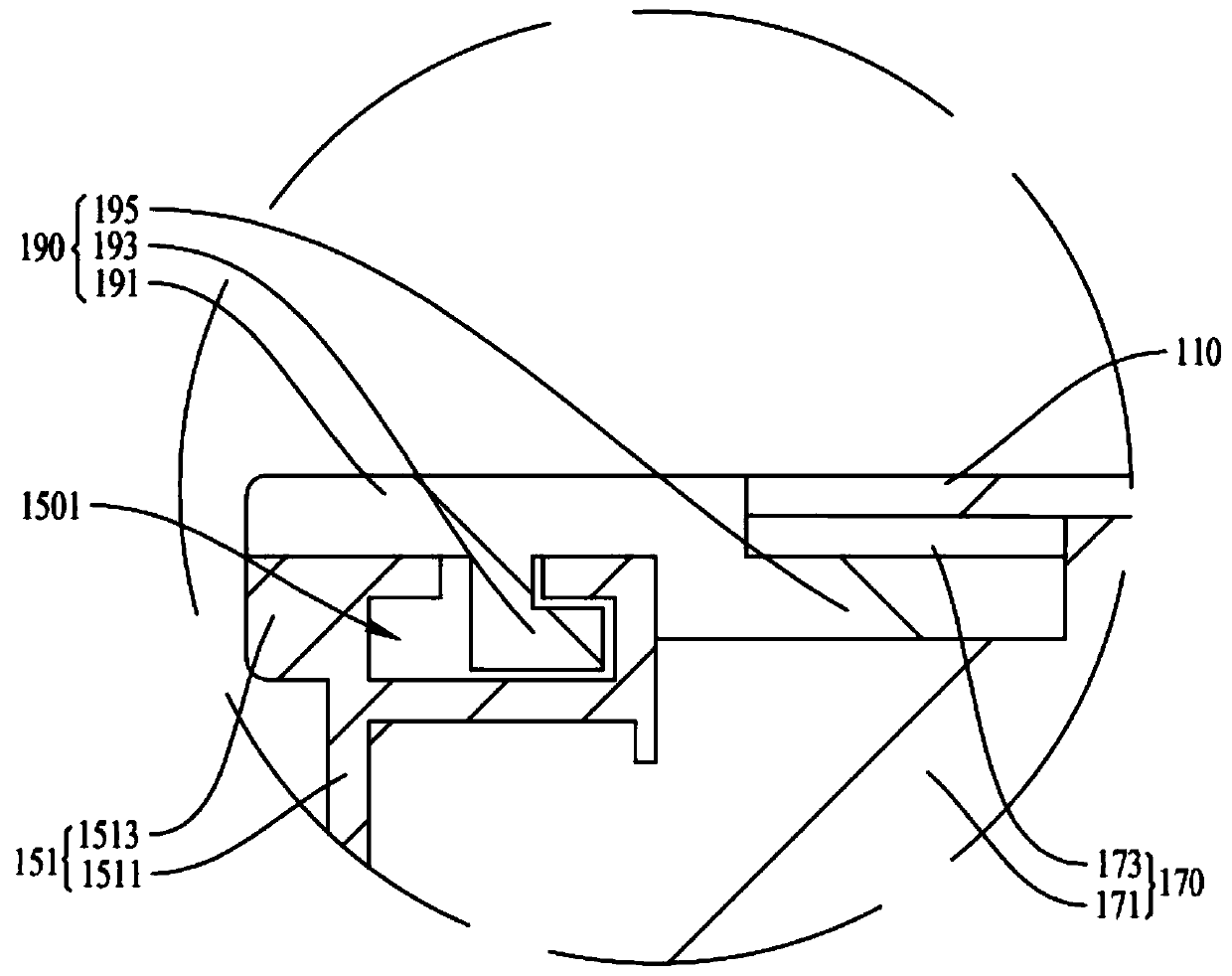

Heat insulating plate assembly and heat insulating box body

PendingCN111256355AEasy and quick assemblyModularHeating and ventilation casings/coversPhysicsEngineering

The embodiment of the invention provides a heat insulating plate assembly. The heat insulating plate assembly comprises a first panel, a second panel, a connecting supporting frame and a heat insulating layer. The first panel and the second panel are oppositely arranged at intervals, the connecting supporting frame is connected between the first panel and the second panel, and a containing grooveis defined by the connecting supporting frame, the first panel and the second panel. The connecting supporting frame comprises a first connecting part, a second connecting part and a third connectingpart, the third connecting part is connected between the first connecting part and the second connecting part, the first connecting part and the second connecting part are staggered, a splicing portion is formed at one end of the heat insulating plate assembly, and the containing groove is filled with the heat insulating layer. The containing groove is filled with the heat insulating layer of theheat insulating plate assembly, so that a heat insulating effect is provided. The splicing portion is formed at the position, at one end of the heat insulating plate assembly, of the connecting supporting frame, so that multiple heat insulating plate assemblies are modularly spliced into a heat insulating box body, and the assembly process of the heat insulating plate assemblies is simple and convenient. The embodiment of the invention further provides the heat insulating box body.

Owner:SHENZHEN ITEAQ NETWORK POWER TECH CO LTD

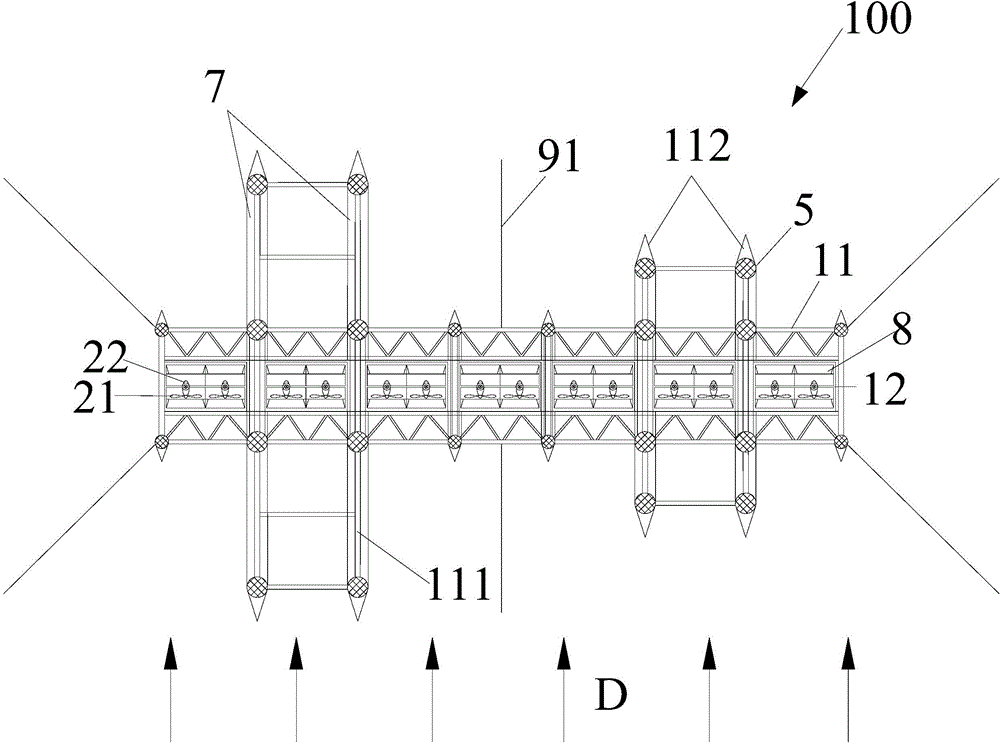

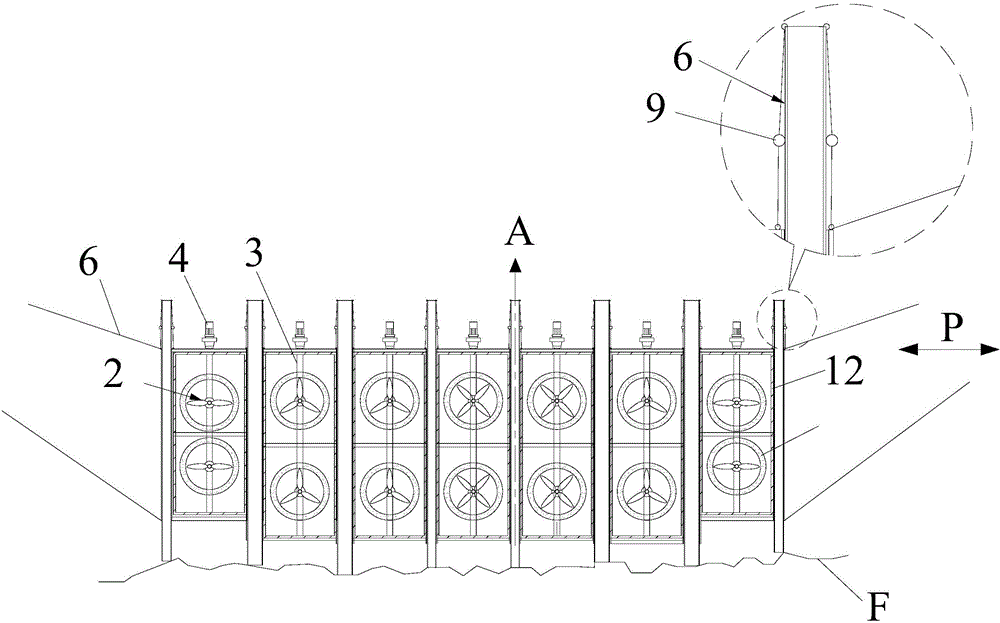

Tidal current energy generating device fixed to water bottom

ActiveCN105443311APut an end to underwater operationsReduce construction difficultyMachines/enginesEngine componentsElectric generatorEngineering

The invention provides a tidal current energy generating device fixed to water bottom. The tidal current energy generating device comprises an outer framework, at least three inner frameworks, at least three horizontal shaft water wheel generators, at least three rotary shafts, multiple outer sleeve pipes and multiple inner sleeve pipes. The at least three inner frameworks are separably arranged in the outer framework. The at least three horizontal shaft water wheel generators are arranged into the at least three inner frameworks.At least one horizontal shaft water wheel generator is correspondingly arranged on each rotary shaft. At least one rotary shaft is correspondingly installed on each inner framework. At least three driving units are connected with the rotary shafts in order to drive the rotary shafts to rotate. The multiple outer sleeve pipes are fixed onto the outer framework. A part of each inner sleeve pipe is connected to the bottom end and the water bottom of a corresponding outer sleeve pipe.

Owner:HANGZHOU LINDONG NEW ENERGY TECH INC +1

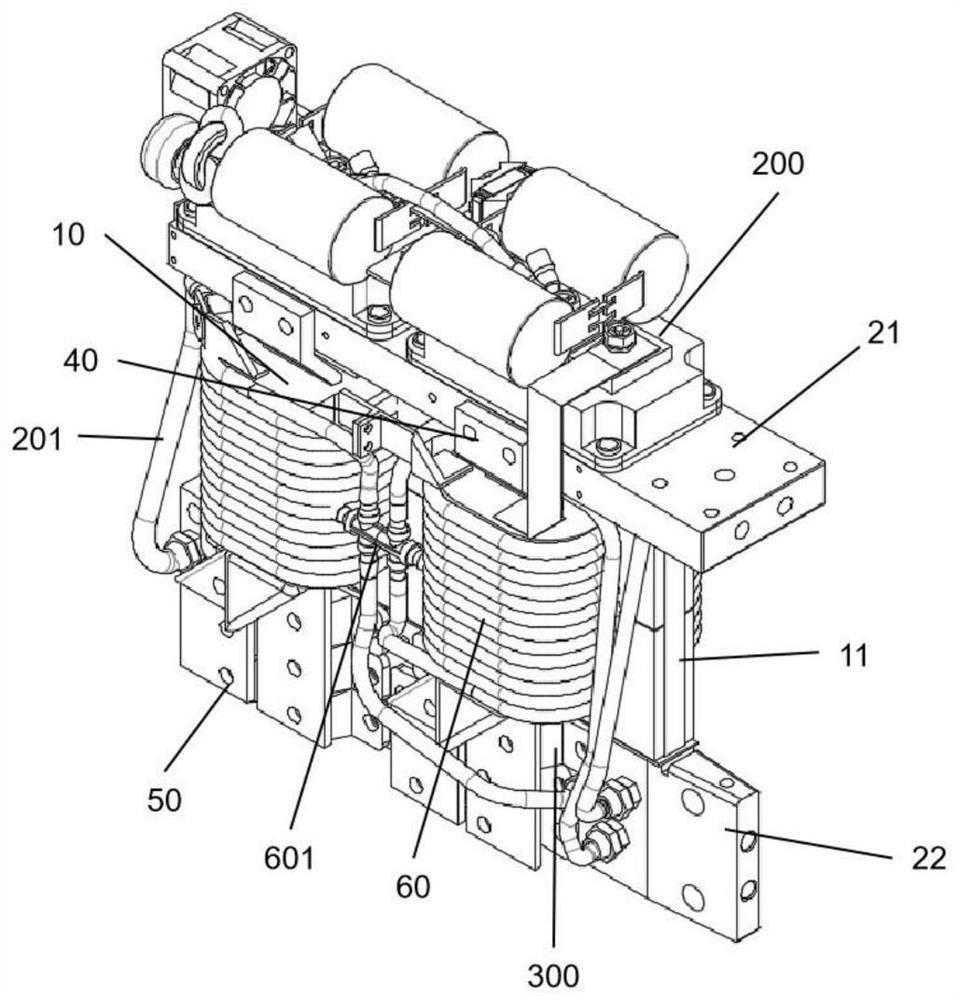

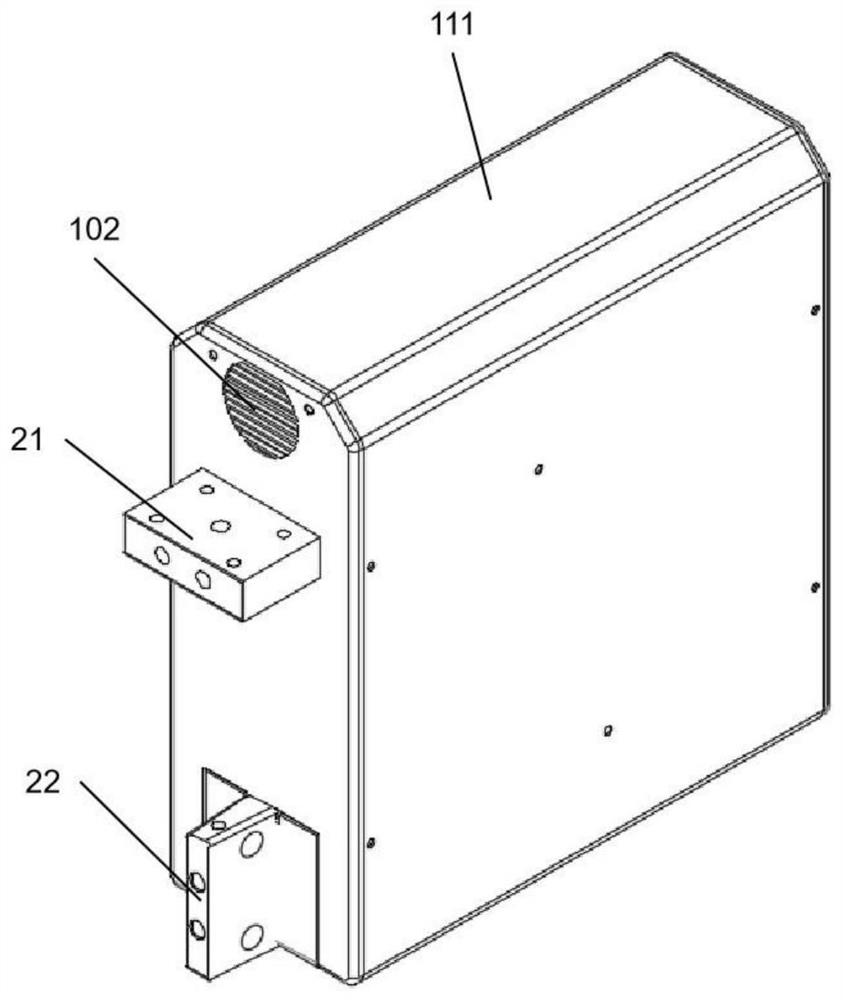

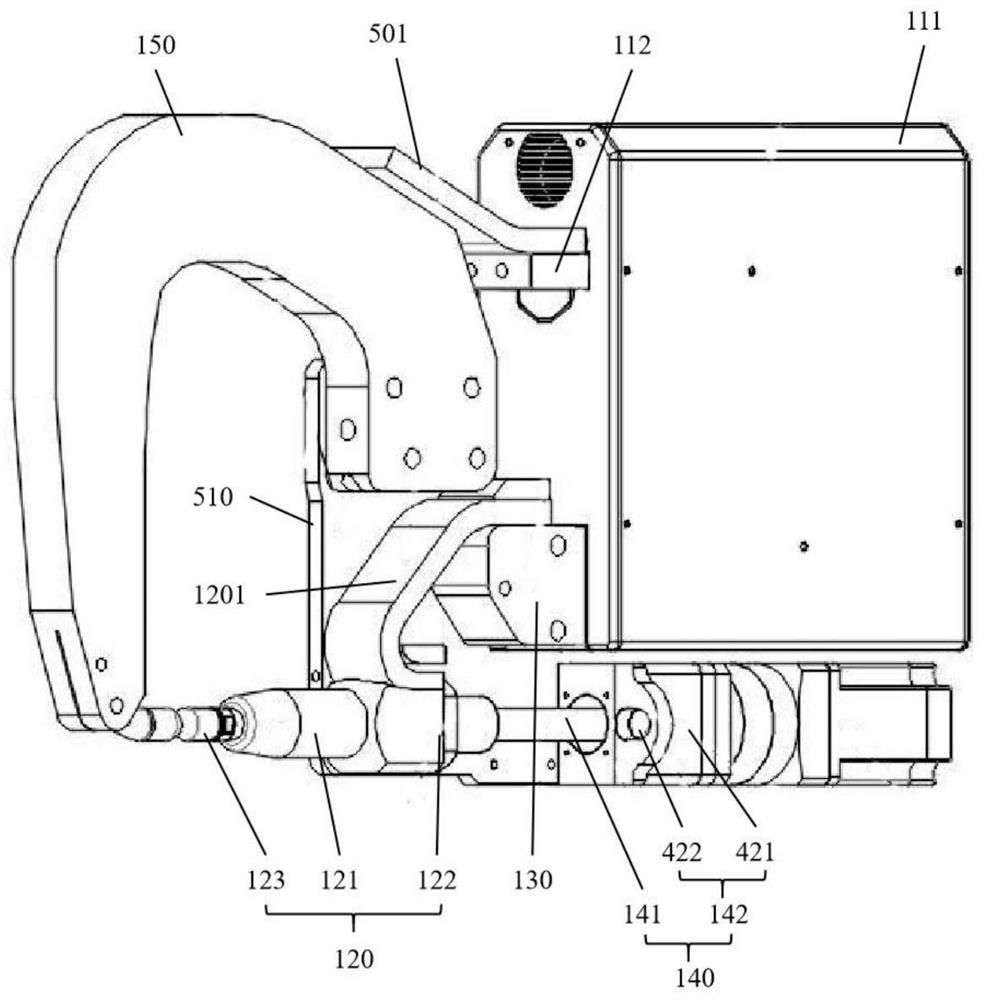

Low-voltage large-current light-weight spot welding machine

PendingCN112756758ARealize modular assemblyMiniaturizationResistance electrode holdersCooled electrodesElectrically conductiveEngineering

The invention provides a low-voltage large-current light-weight spot welding machine. The low-voltage large-current light-weight spot welding machine comprises a welding power source which comprises a box body, a first electrode and a second electrode, wherein the first electrode and the second electrode partially extend out of the box body; a movable arm structure which comprises a movable arm and a nut flange, wherein one end of the movable arm is connected with the nut flange; a connecting block which is arranged between a first conductive bridge and the first electrode; a driving device, wherein a driving rod of the driving device is connected with the nut flange and located at the bottom of the box body; and a stationary arm which is connected with the movable arm through a side connecting plate, wherein the side connecting plate is fixedly connected with the stationary arm and the connecting block through a plurality of fastening bolts, the side connecting plate is rotatably connected to the flange structure, and the movable arm structure, the connecting block, the driving device and the fixed arm are fixedly connected into an electrode holder stress connecting mechanism through the side connecting plate. The electrode holder stress connecting mechanism and the welding power source are mounted integrally. The movable arm structure and the stationary arm structure are compact, so that miniaturized design of an electrode holder is achieved, and the electrode holder and the welding power source are easy to disassemble, so that two electrode holders are switched rapidly.

Owner:HEFEI SANYU ELECTRIC

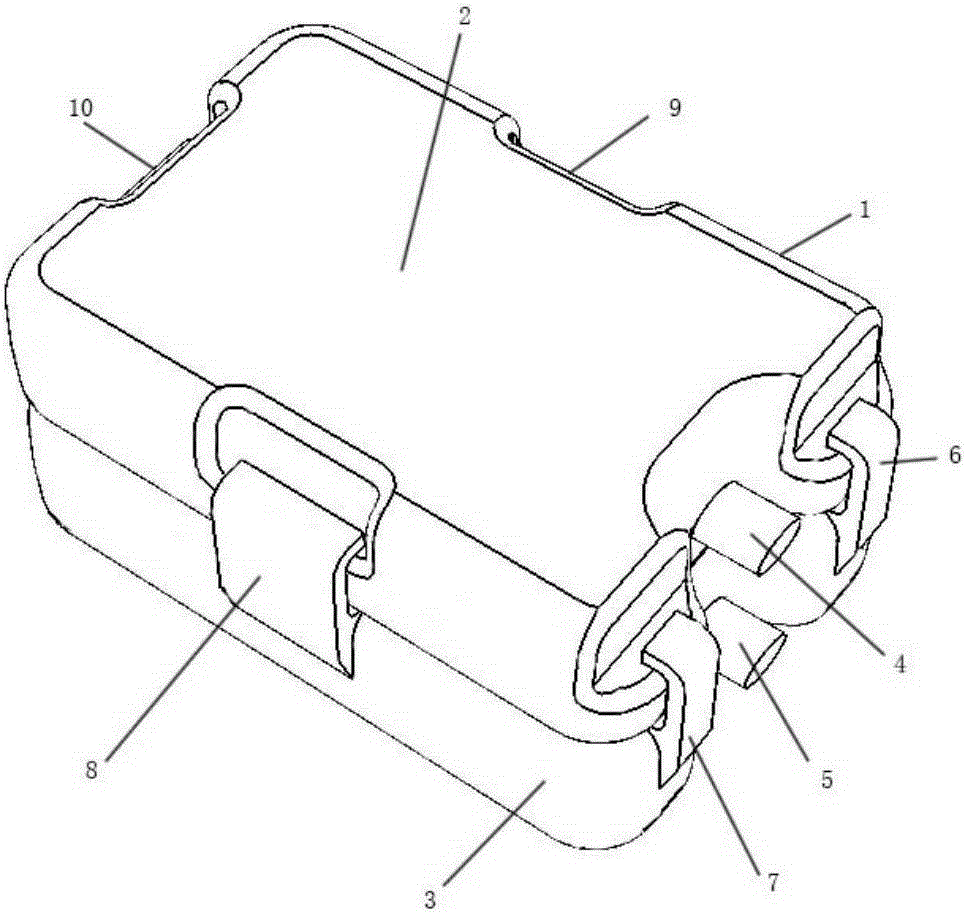

Foam floating bridge rapidly connected through buckling teeth

PendingCN111206490AIncrease buoyancyImprove securityBridge structural detailsFloating bridgesArchitectural engineeringPontoon bridge

The invention relates to a foam floating bridge rapidly connected through buckling teeth, which is characterized in that a plurality of positioning holes are vertically and uniformly distributed in bridge plates, a group of parallel edges of the bridge plates are respectively provided with I-shaped buckling teeth and II-shaped buckling teeth, and the plurality of bridge plates are mutually buckledand connected in series to form a floating bridge structure; the bridge also comprises a lock catch assembly which comprises a fixed rod and a key, a mounting through hole is formed along the centerof the buckling part, the fixed rod is arranged in the mounting through hole in a penetrating manner, and a locking hole is formed in the fixed rod. The displacement of the bridge plate in three directions is limited at the same time through the lock catch assembly; the connection strength and reliability can be improved, the buckling teeth and the quick plug pins are used for carrying out buckling operation; convenient and time-saving installation can be achieved, the safety performance and splicing manufacturability of the installed floating bridge are improved, the fixed rod injected with the foam structure has the self-floating performance, the floating capacity of the bridge plate is improved, reinforcing is conducted in the mode that the long rods are inserted into the positioning holes, local materials can be used, the materials such as bamboo poles can be used, the connecting structure is economical and environmentally friendly, the connecting structure can be repeatedly used,and the maintenance cost is reduced.

Owner:江苏东方生态清淤工程有限公司

Multi-layer composite drill bit assembly for ditching work

ActiveCN111827391AIncrease the ditch areaRealize multiple cutsSoil-shifting machines/dredgersTool bitEngineering

The invention provides a multi-layer composite drill bit assembly for ditching work. The multi-layer composite drill bit assembly for ditching work comprises an assembly frame. The top of the assemblyframe is detachably connected with a drive assembly, a bottom face bearing of the assembly frame is connected with a tool bit assembly, the drive assembly is in transmission connection with the toolbit assembly, and the drive assembly is used for driving all cutterheads in the tool bit assembly to rotate. The tool bit assembly comprises the multiple cutterheads, the cutterheads are arranged intoan inverted pyramid layer by layer from top to bottom, the cutterheads on each layer are transversely distributed horizontally, all the cutterheads between the adjacent layers are mutually staggered,and all the cutterheads located on the same layer are mutually spaced. The drill bit assembly can be overall replaced according to the area of a working face, it is not needed to adjust a whole drilling machine, the equipment can be modularly assembled, and the application range is wider; and by means of the cutterheads distributed on multiple layers, on one hand, the ditching area can be increased, on the other hand, multi-cutting can be achieved, and the ditching effect is better.

Owner:安徽腾兴工程设备制造有限公司

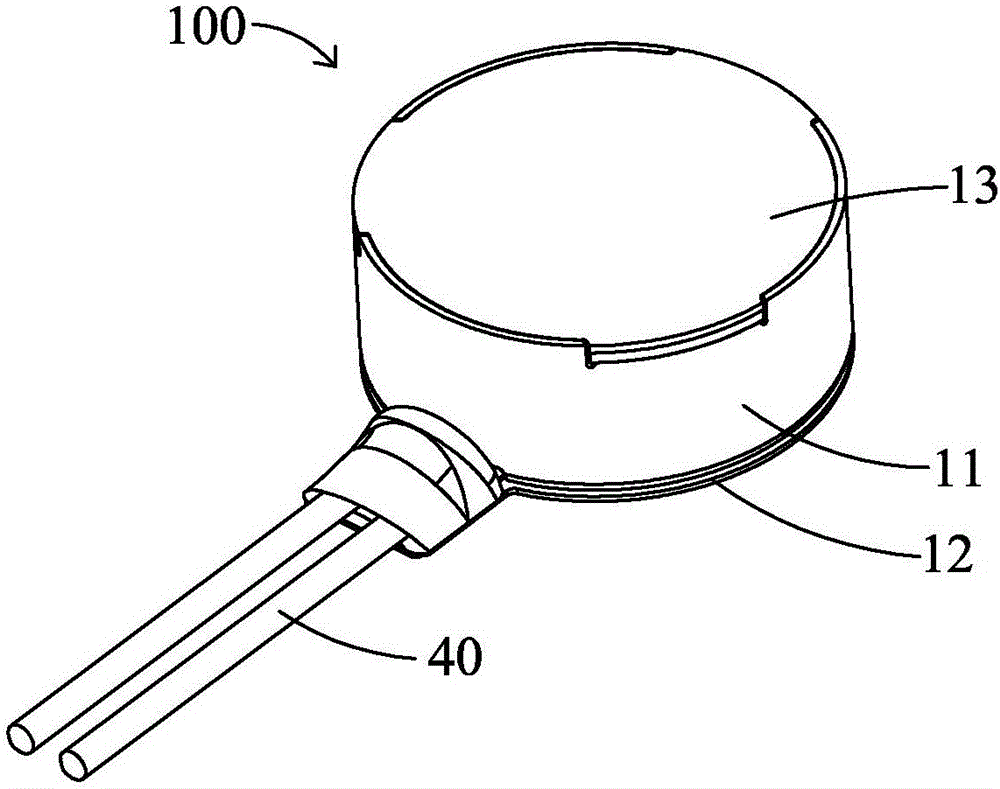

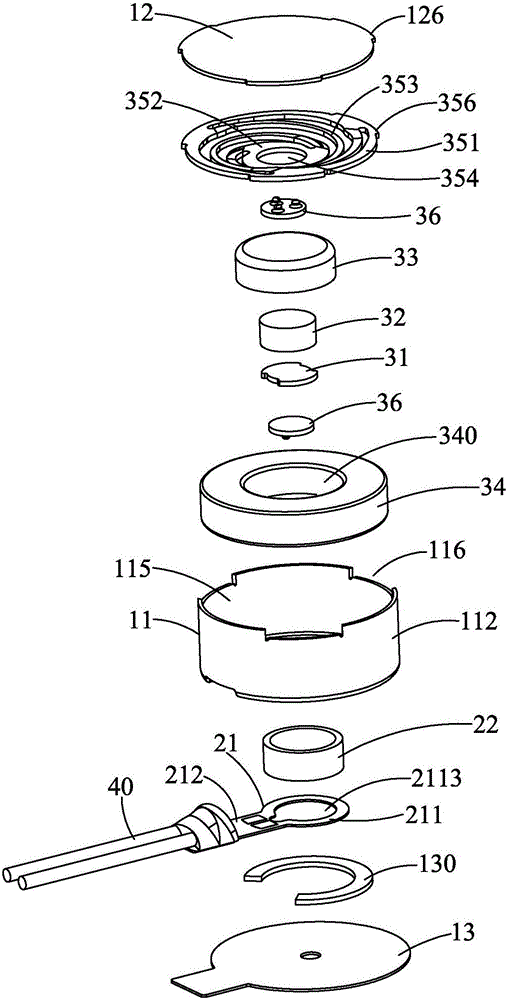

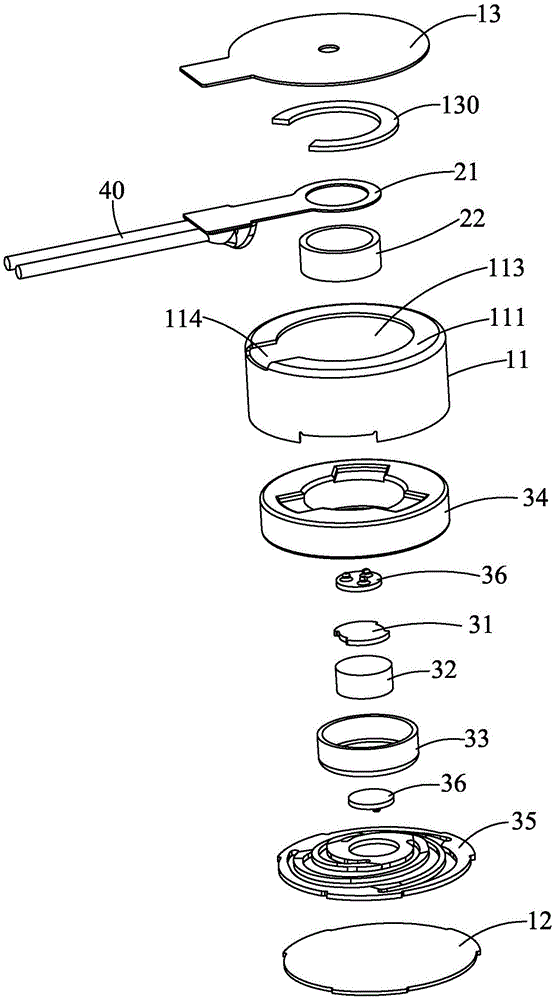

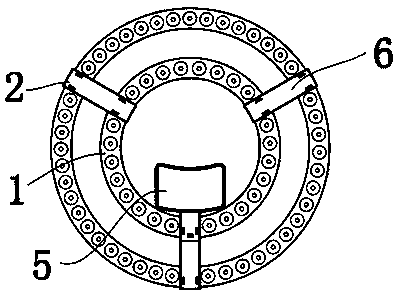

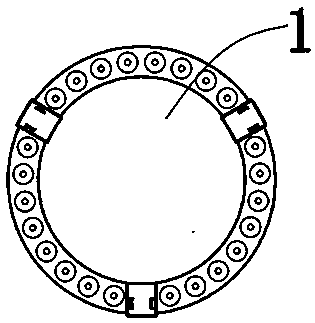

Flat vibration motor

InactiveCN105680661AReduce mistakesRealize modular assemblyMechanical energy handlingEngineeringElectrical and Electronics engineering

The invention relates to a flat vibration motor, which comprises a housing, an upper cover plate, a lower cover plate, a circuit board, a coil, a pole core, a magnetic steel, a magnetic bowl, a mass block and a spring board, wherein the magnetic steel is fixed in the magnetic bowl; the mass block is provided with a fixing hole for fixing the magnetic bowl; the spring board comprises an outer ring, an inner ring and a plurality of elastic connection parts connecting the inner ring and the outer ring; the outer ring is fixed on the housing; the top surface of the magnetic bowl or the mass block is fixed in the inner ring; the housing is provided with a bottom wall, an annular side wall extending upwardly and convexly from the periphery of the bottom wall and accommodating space formed between the bottom wall and the side wall; a vertical-through accommodating hole is arranged in the bottom wall; the circuit board, the coil and the lower cover plate form a stator module and are together upwardly assembled in the housing. Thus, the assembly precision is improved.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

Refrigerating box and refrigerating system

InactiveCN105292778ARefrigerated temperature remains constantSimple structureShock-sensitive articlesRigid containersEngineeringFluid supply

The invention provides a refrigerating box. The refrigerating box comprises a box body (1) with a sealable containing cavity (13). The box body (1) comprises an upper box body (2) and a lower box body (3) which are detachably connected in a sealed manner. The walls / wall of the upper box body (2) and / or the lower box body (3) are / is of hollow structures / a hollow structure and provided with a cooling cavity / cooling cavities for containing cold insulation fluid and openings where the fluid of the cooling cavity can flow through. The invention further provides a refrigerating system. The refrigerating system comprises the refrigerating box and a cold insulation fluid supply device. The cold insulation fluid supply device and the cooling cavity are connected through detachable cold insulation fluid. By means of the technical scheme, the refrigerating temperature in the refrigerating box can keeps constant for a long time, and thus the refrigerating effect is improved remarkably.

Owner:ZHEJIANG SHENGCHUANG PRECISION MEDICAL TECH CO LTD

All-automatic pancake folding production line and application thereof

InactiveCN103999921ARealize fully automatic foldingEasy to operateBakery product preservationProduction lineConveyor belt

The invention discloses an all-automatic pancake folding production line and an application thereof, and belongs to the technical field of traditional food processing. The production line is composed of two conveying folding lines, one transverse and one longitudinal, wherein the transverse conveying folding line is composed of four stages of conveyor belts, sensors and folding devices; the longitudinal conveying folding line is composed of one or more than one conveyor belt, a sensor and a folding device. The production line is characterized in that the prepared pancakes are conveyed or put on the first-stage conveyor belt, and all-automatic folding of the pancakes is realized by virtue of the conveying of various stages of conveyor belts and the folding operations of the folding devices and folding pieces. The contribution of the all-automatic pancake folding production line to the prior art is that all-automatic folding and pipeline operations of pancakes are realized, and therefore, the pancake folding efficiency is greatly improved and the labor can be saved; the all-automatic pancake folding production line has excellent market prospect and is applicable to large-scale production of pancakes.

Owner:JIXI HANLEER FOOD

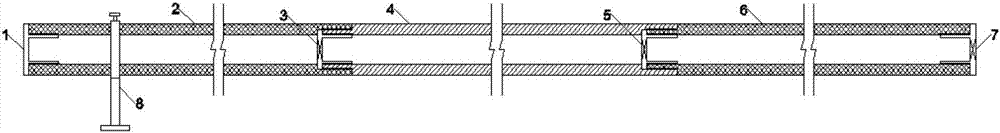

Portable water drain pipe device and method applicable to underground construction water disaster treatment

ActiveCN107218441ARealize standardized productionRealize modular assemblyPipe supportsPipe elementsWater pipeEngineering

The invention discloses a portable water drain pipe device and method applicable to underground construction water disaster treatment. The portable water drain pipe device comprises an end sleeve, a middle sleeve, a bottom sleeve and a support; the end sleeve, the middle sleeve and the bottom sleeve are connected through threads; a first filter net is arranged at the connecting position of the end sleeve and the middle sleeve, a second filter net is arranged at the connecting position of the middle sleeve and the bottom sleeve, and a third filter net is arranged at an outlet of the bottom sleeve; the support is installed nearby a water outlet of the end sleeve and comprises a trapezoidal frame with a trapezoidal cross section, a rotary shaft is connected to the top of the trapezoidal frame, and a stainless steel circular ring is driven by the rotary shaft to rotate to achieve angle adjusting of the stainless steel circular ring; and a rotary button is arranged on the stainless steel circular ring and can achieve fixing of the rotary button and the sleeves.

Owner:SHANDONG UNIV

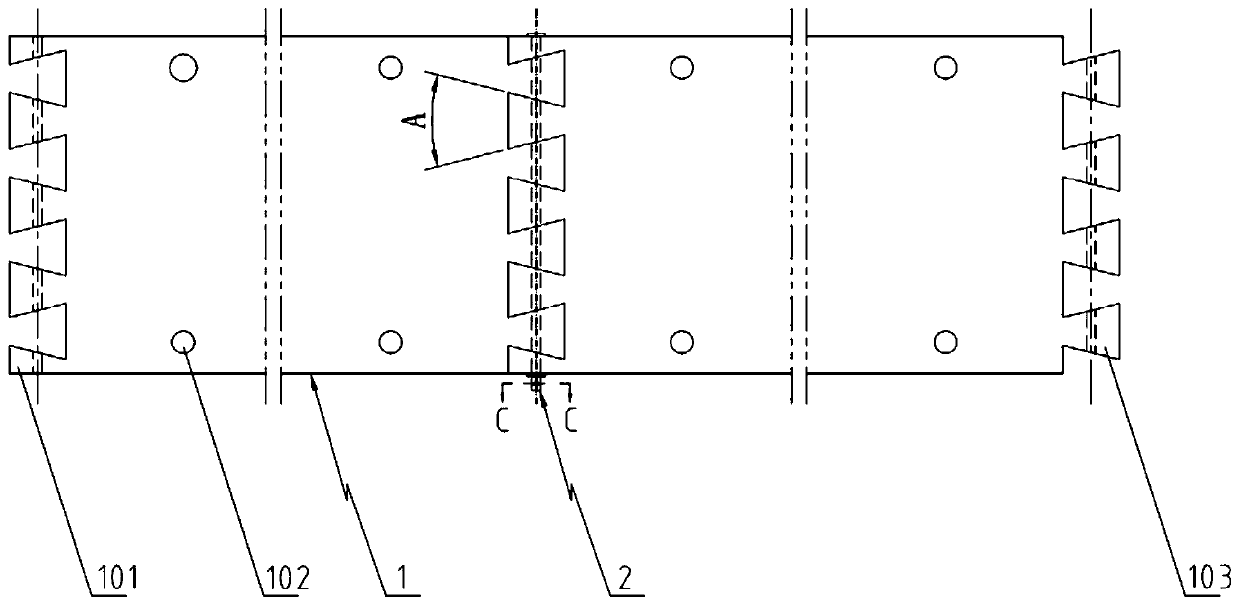

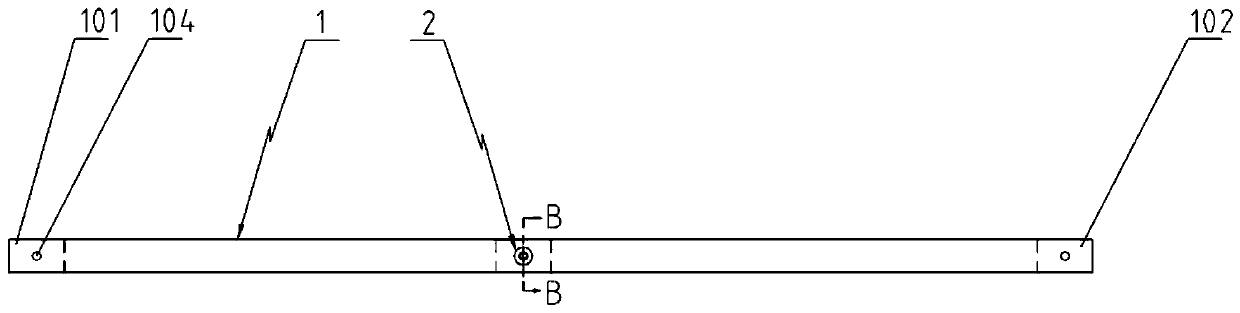

Modular assembling tool for brake tube banks

ActiveCN110948431AAchieve precise positioningRealize modular assemblyAssembly machinesWork holdersStructural engineeringVehicle brake

The invention discloses a modular assembling tool for brake tube banks. The modular assembling tool comprises a supporting longitudinal beam and a plurality of supporting frames which are connected below the supporting longitudinal beam side by side, one end of the upper surface of the supporting longitudinal beam is provided with an end supporting plate, the end supporting plate is slidably connected with an end positioning plate, the other end of the upper surface of the supporting longitudinal beam is provided with a pipeline spacing positioning module and a plurality of supporting mountingplates, and the pipeline spacing positioning module and each supporting mounting plate are slidably connected with the supporting longitudinal beam. According to the modular assembling tool, a flexible positioning tool plate is arranged so that the requirements of assembly work of different railway vehicle tube banks can be met through a single set of tool die plates, and modular assembly of thedifferent types of railway vehicle brake tube banks is achieved; the manufacturing cost of the die plates e is greatly reduced, and the efficiency for operators to assemble the tube banks is effectively improved; and meanwhile, a corresponding reading meter ruler and steel ruler are arranged so that accurate positioning of the tube bank assembly can be achieved, and the practicability is high.

Owner:河北京车轨道交通车辆装备有限公司

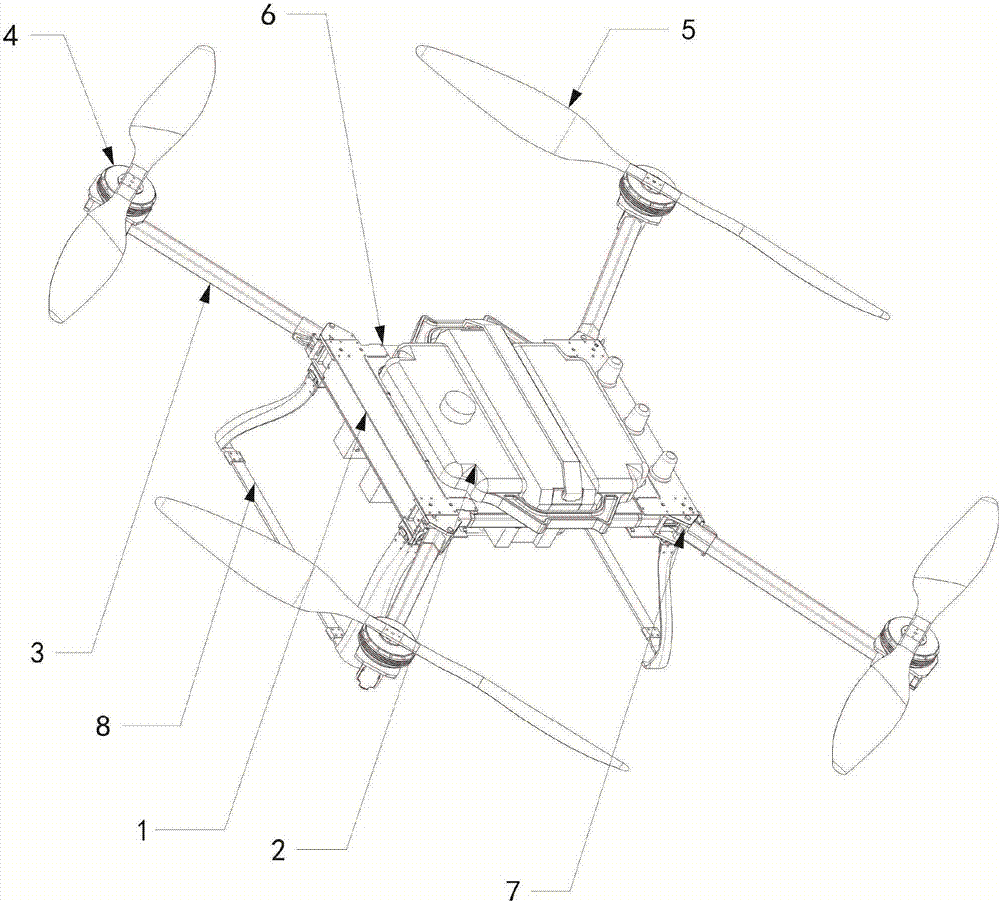

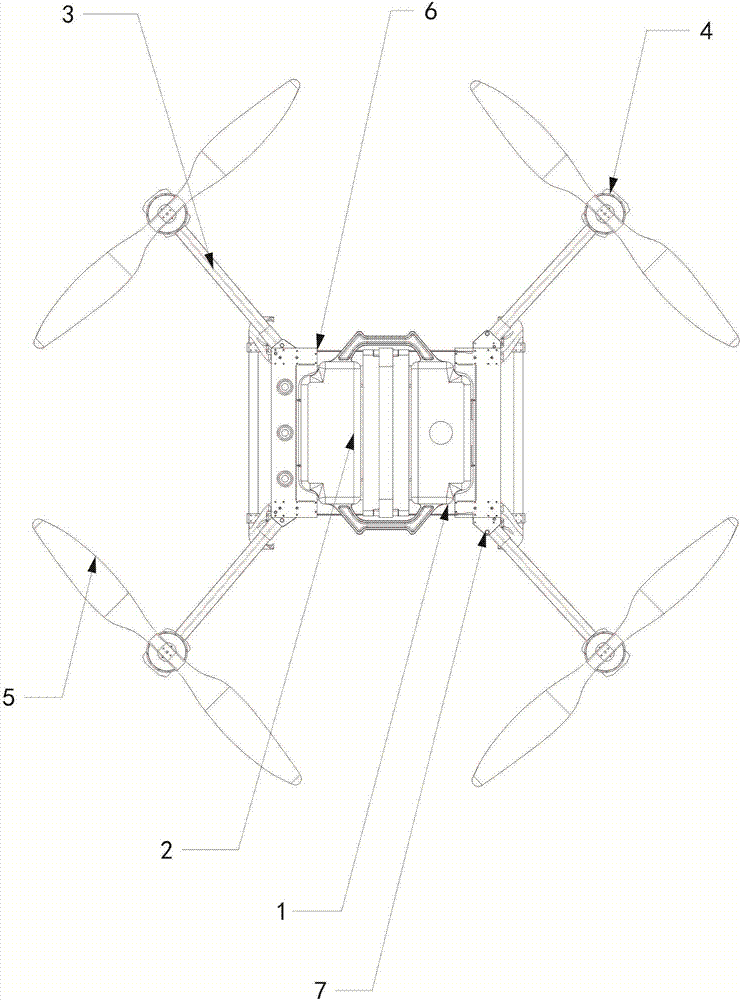

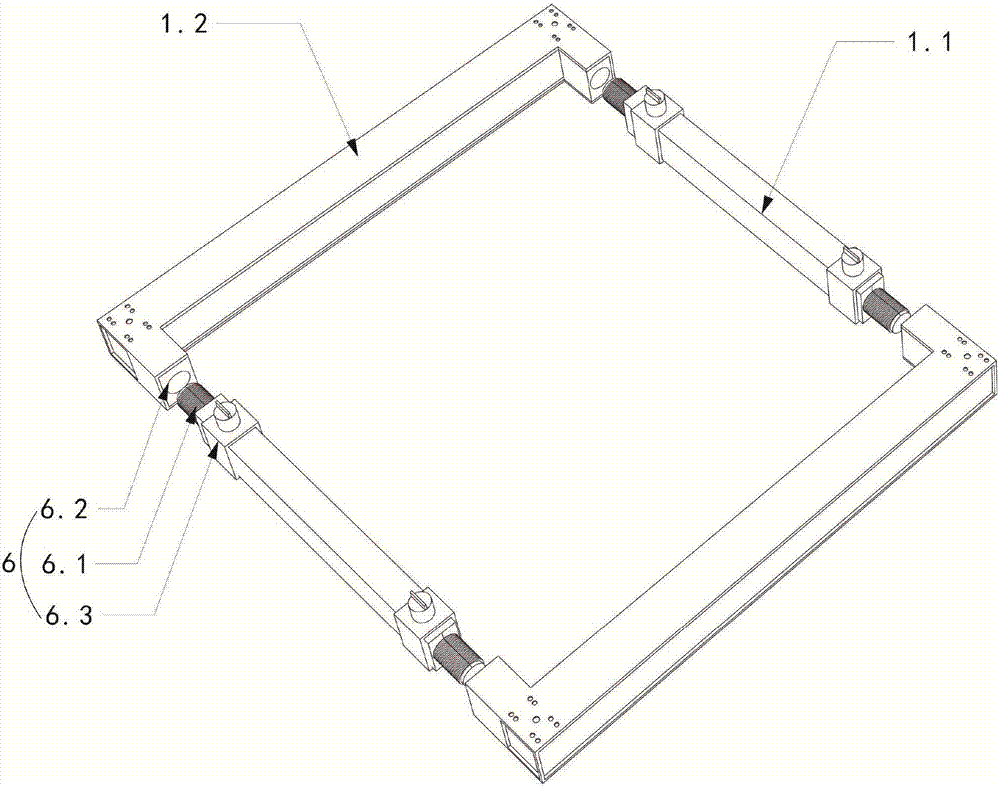

Modular assembled four-axis plant protection unmanned aerial vehicle (UAV)

PendingCN107380418AIncrease production speedEasy maintenanceFuselage framesRotocraftControl engineeringUncrewed vehicle

The invention relates to the technical field of unmanned aerial vehicles (UAVs), and in particular discloses a modular assembled four-axis plant protection UAV, comprising a chassis and a power control center, wherein the power control center is fixed in the center of the chassis by means of an installation clamping groove; four corners of the chassis are respectively connected with a cantilever, ends of the cantilevers are respectively connected with a motor, and output shafts of the motors are respectively connected with a propeller; the chassis comprises an X-axis direction module and a Y-axis direction module; the X-axis direction module and the Y-axis direction module respectively have a cavity structure which is provided with two openings in two ends and has hollow interior; the X-axis direction module is connected with the Y-axis direction module by means of an inserting mechanism; four rotary connecting pieces are respectively installed at the four corners of the Y-axis direction module; the cantilevers are connected with the rotary connecting pieces by means of the inserting mechanism. The modular assembled four-axis plant protection UAV can enable the chassis, the cantilevers and the like of the UAV to be integrated and modularized while guaranteeing the structural safety, the later assembly and maintenance of the UAV can be facilitated, and the service life of the UAV is prolonged.

Owner:河南谷翼自动化科技有限公司

Novel LED module

PendingCN110319358ARealize modular assemblyReduce usageElectric circuit arrangementsSemiconductor devices for light sourcesEngineeringInjection molding machine

The invention discloses a novel LED module. The novel LED module comprises an LED inner light source board and an LED outer light source board, the LED inner light source board and the LED outer lightsource board both are formed by fixation of PCB boards and plastic parts with the same size through a hot-melt adhesive, the LED inner light source board and the LED outer light source board are assembled as a whole by a plurality of connecting rods, a driving power supply is installed at the inner end of any connecting rod, and the driving power supply is located at the inner side of the LED inner light source board. According to the novel LED module, a set of molds is used for simultaneously producing the plastic parts with various specifications and sizes on an injection molding machine, PCB boards with various specifications and sizes corresponding to the sizes of the plastic parts with various specifications and sizes in a manufacturing machine of PCB board hardware molds are manufactured, the PCB boards with various specifications and sizes are printed, the plastic parts and the PCB boards with the same size are taken for hot-melting and mixing, thus the plastic parts are combined with the PCB boards, and thus the LED inner light source boards and the LED outer light source boards with various specificationsand sizes are manufactured.

Owner:陈建平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com