Transverse and longitudinal slippage system for short line-method segment box beam side mold

A horizontal and vertical, short-line method, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor cladding, increased costs, and waste of time, so as to avoid excessive adjustment, improve structure, and facilitate use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

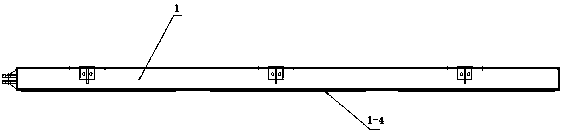

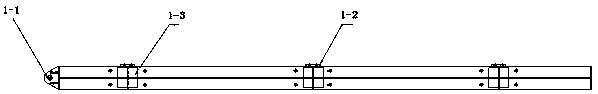

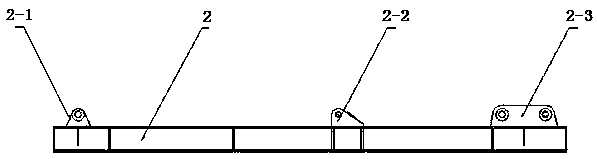

[0033] Such as Figure 1-14 As shown, a horizontal and vertical sliding system for the short-line method segmental box girder side form, including a longitudinal sliding bracket 2, a lateral sliding bracket 1, a connecting bracket 3, a reverse buckle one 4, and a reverse buckle two 5 The main part of the lateral sliding support 1 is assembled and welded by H-shaped steel, and one end is provided with an ear plate 1-1, which is connected to the lateral sliding adjustment lead screw 6 to realize lateral sliding. The lateral sliding support 1 The surface of the surface is provided with a connection hole, and the connection hole is connected with the reverse buckle-4, and the contact part of the main body lower side of the lateral sliding support 1 and the reverse buckle-4 is provided with a contact plate-1-3; The upper side of the main body of the horizontal sliding bracket 1 is connected with the lower side of the main body of the longitudinal sliding bracket 2, and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com