Flat vibration motor

A flat vibration motor and cover plate technology, applied in electric components, control mechanical energy, electrical components, etc., can solve the problems of uneven product quality, high assembly difficulty, and difficulty in ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

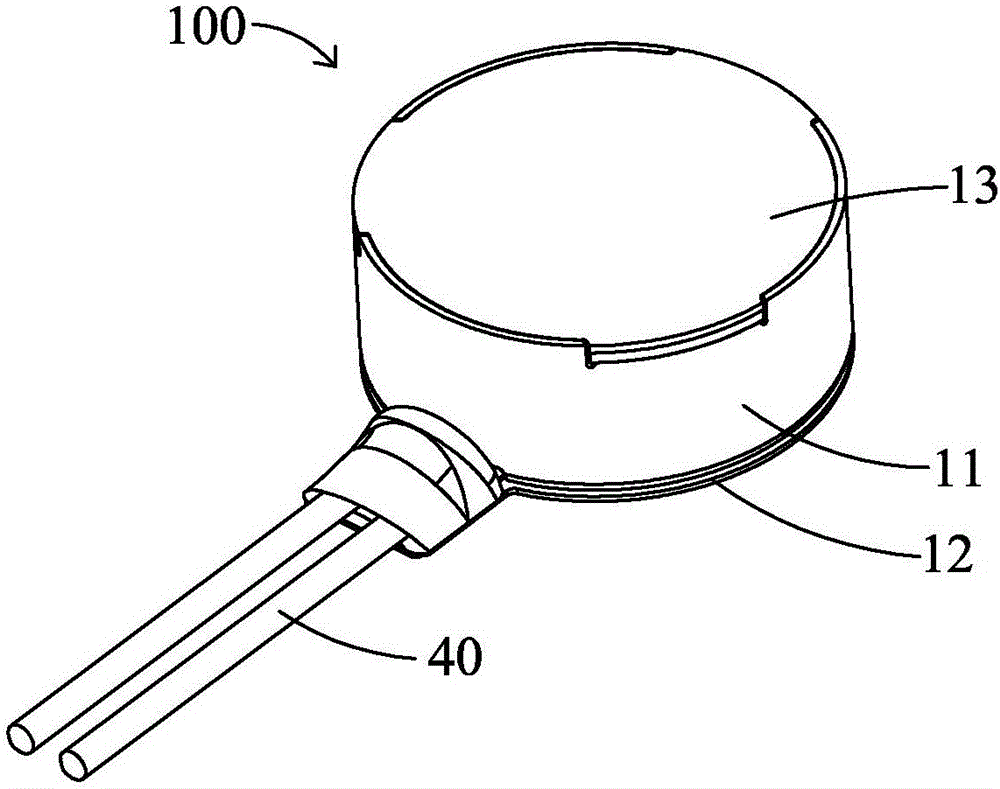

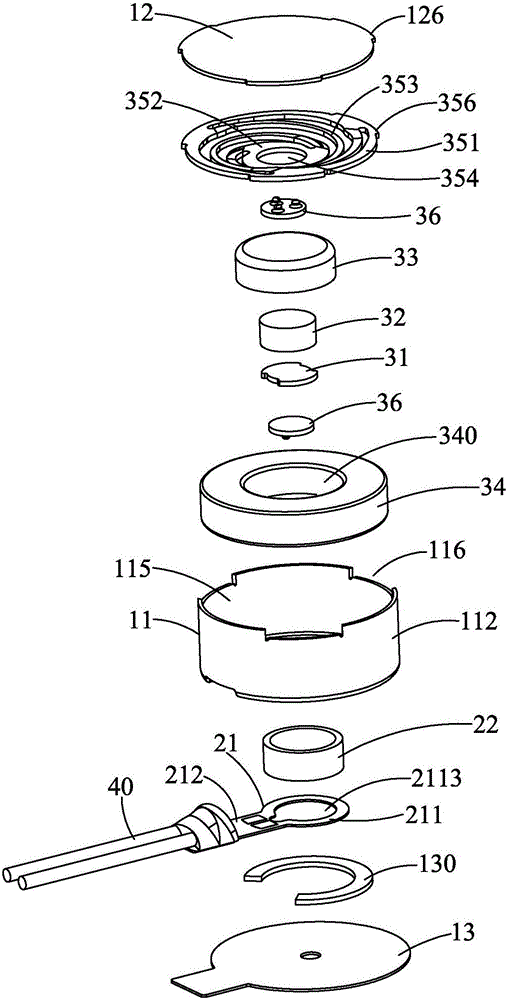

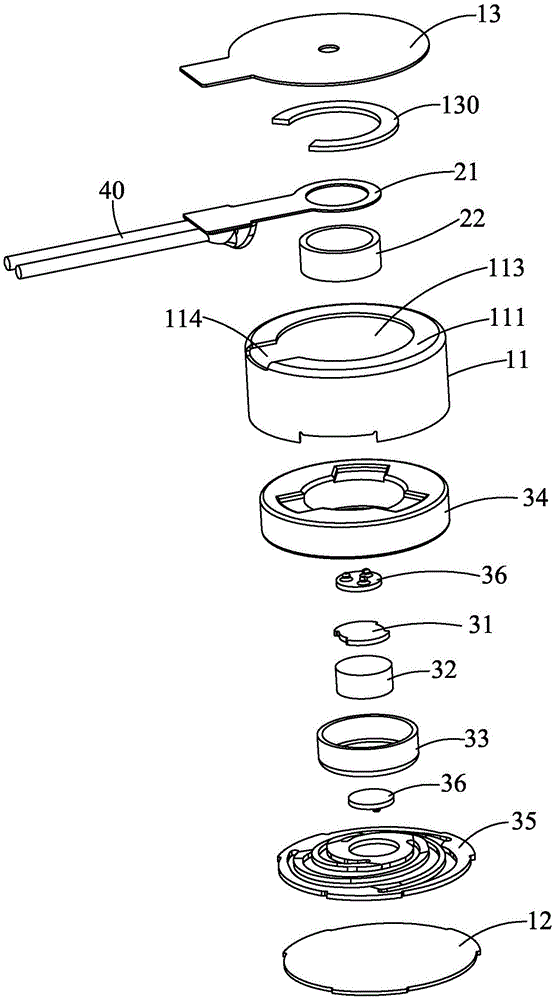

[0010] see Figure 1 to Figure 4 As shown, the flat vibration motor 100 of the present invention includes a casing 11, an upper cover plate 12, a lower cover plate 13, a circuit board 21, a coil 22, a pole core 31, a magnetic steel 32, a magnetic bowl 33, a mass block 34, and a spring plate 35 , two buffer spacers 36.

[0011] The casing 11 includes a bottom wall 111, an annular side wall 112 protruding upward from the periphery of the top wall 111, and a receiving space 115 formed between the bottom wall 111 and the side wall 112. The bottom wall 111 is provided with a vertically penetrating A circular receiving hole 113 and an outlet 114 , the receiving hole 113 is disposed at the center of the bottom wall 111 , and the outlet 114 penetrates the bottom wall 111 from the receiving hole 113 to the outside. The top of the sidewall 112 defines a plurality of notches 116 at intervals.

[0012] The upper cover 12 is downwardly fixed on the side wall 112 to cover the receiving sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com