Tidal current energy generating device fixed to water bottom

A technology of power generation device and tidal current energy, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as high difficulty, reduced impeller speed, and inability to commercialize horizontal axis hydro-generators, reducing maintenance and installation costs, enabling assembly and replacement, overcoming non-commercialization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

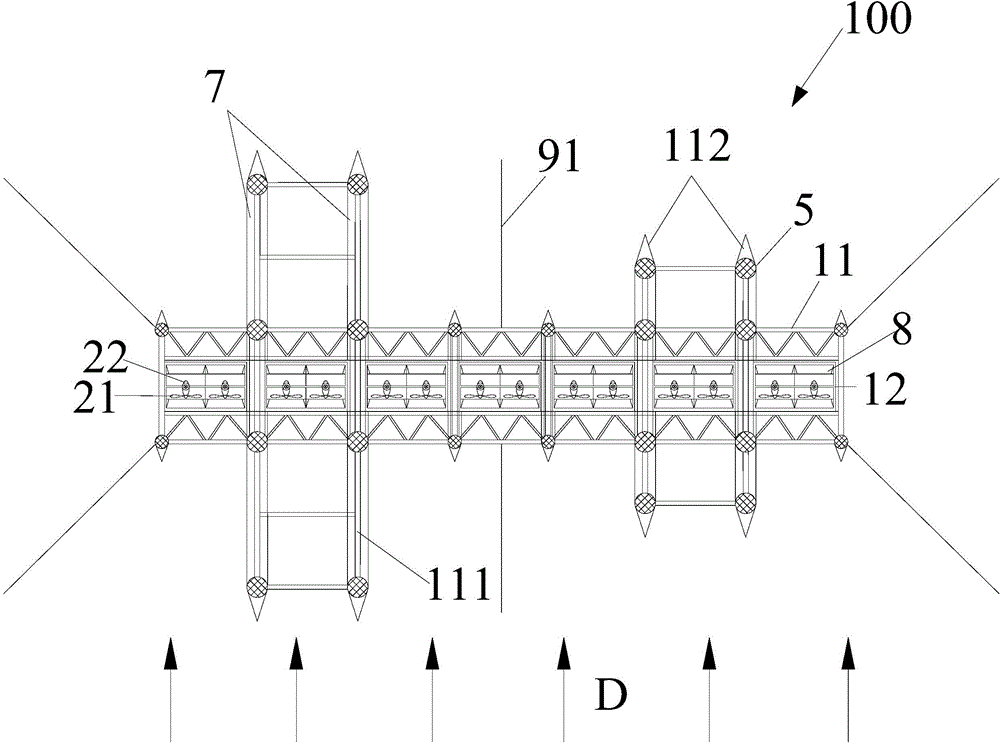

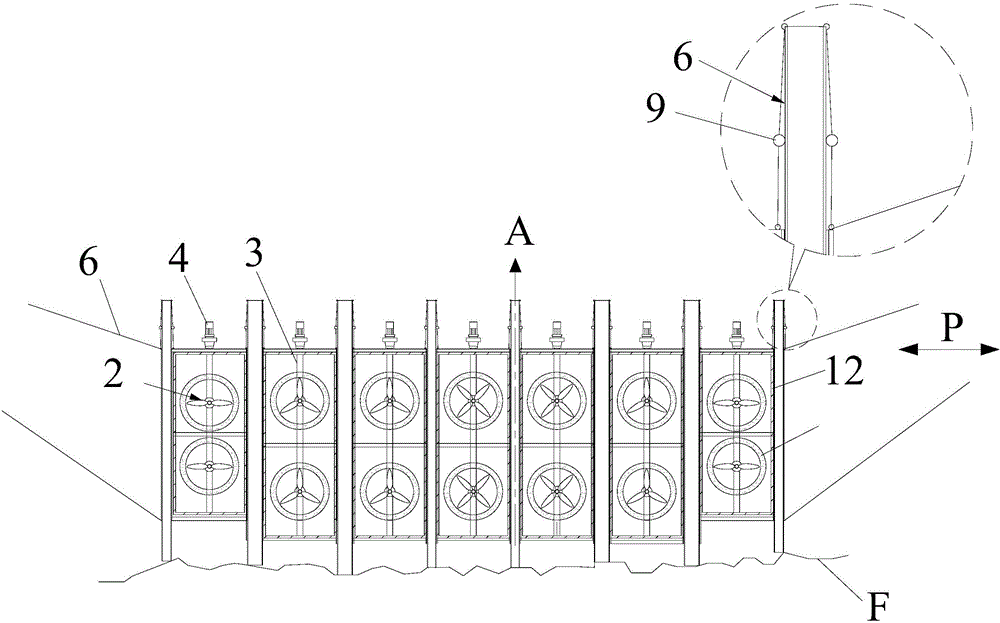

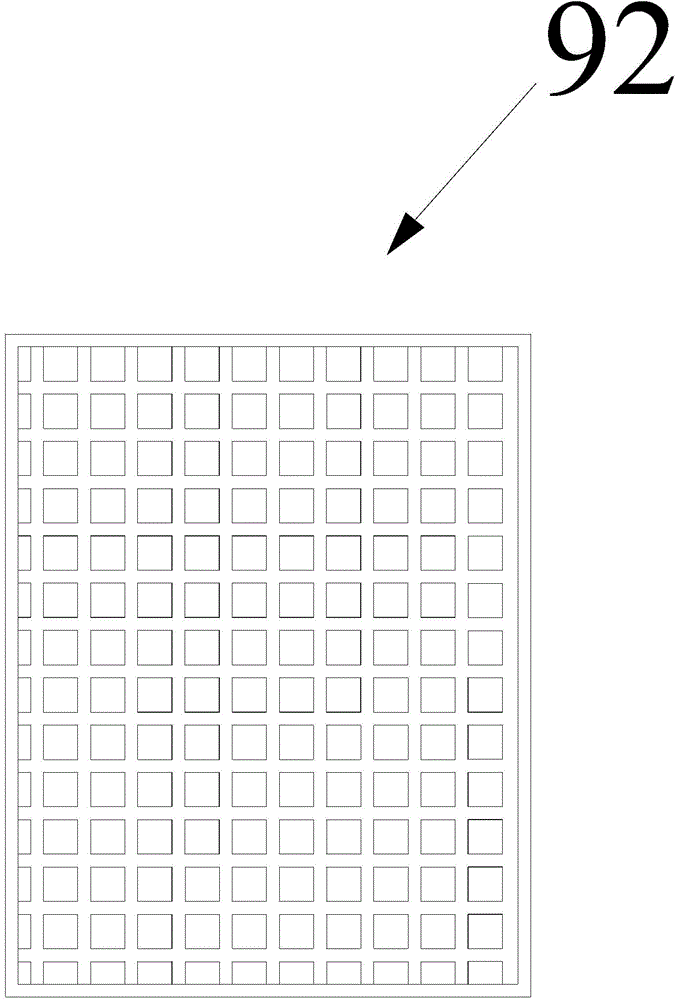

[0031] figure 1 Shown is a top view of the tidal current energy generating device fixed on the bottom of the water according to the first embodiment of the present invention. figure 2 Shown is a front view of the tidal current energy generating device fixed on the bottom of the water according to the first embodiment of the present invention when no pile is driven. image 3 Shown is a schematic diagram of the fence in the tidal current energy generation device fixed on the bottom of the water according to the first embodiment of the present invention. Figure 4 Shown is a schematic diagram of a part of the outer frame and the outer sleeve provided according to the first embodiment of the present invention. Figure 5 Shown is a schematic diagram of the piling process for fixing the tidal current energy generating device to the bottom of the water according to the first embodiment of the present invention. Please also refer to Figure 1 to Figure 5 .

[0032] In the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com