Decorative side wall plate for ship and splicing method thereof

A technology of side wall panels and decorative panels, applied in the direction of hull bulkheads, hulls, ship parts, etc., can solve the problems of discoloration of the soft package of portholes, damp and moldy substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

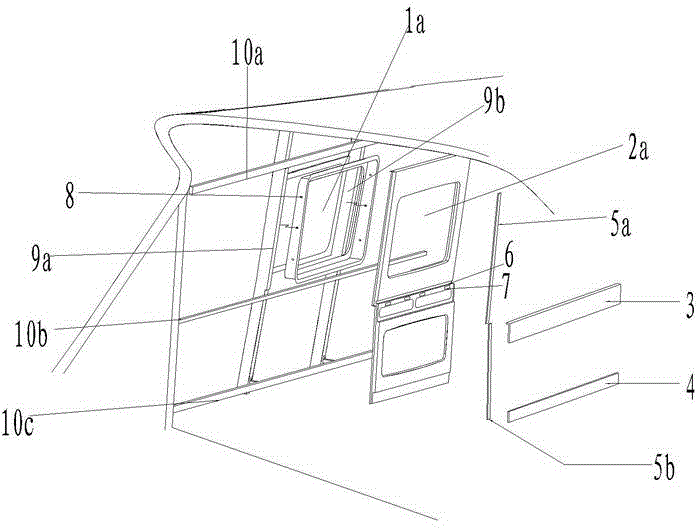

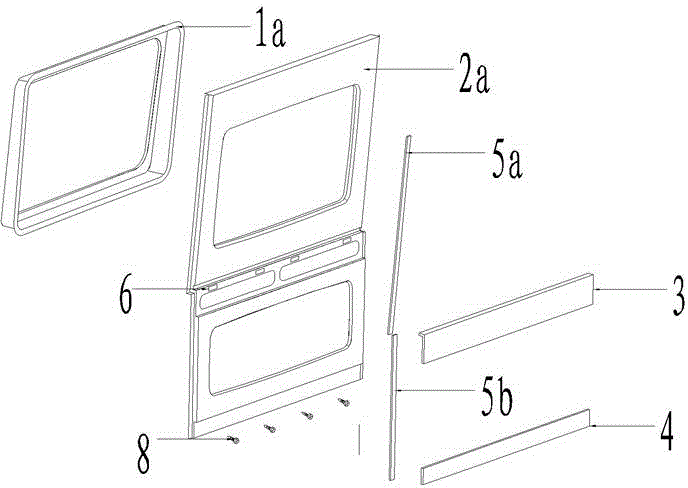

[0027] attached by the manual figure 1 It can be seen that the marine interior decoration side wall panel of the present invention includes a ship hull structure, an inner window cover 1, and a side wall panel 2. The side wall panel is divided into two pieces, and the two sidewall panels The plates are the first side wall plate 2a and the second side wall plate 2b, the hull structural parts are the left hull structural part 9a and the right hull structural part 9b, and the inner window cover is the first inner window cover 1a and the second inner window cover 1a. The window cover 1b, the first inner window cover 1a and the second inner window cover 1b are fixedly connected to the grooves of the left hull structure 9a and the right hull structure 9b through the inner side through 2 or 3 self-tapping screws 8 on the left and right respectively; The top of the first side wall plate 2a is fixedly connected with the upper aluminum square tube 10a by self-tapping screws 8, and the ...

Embodiment 2

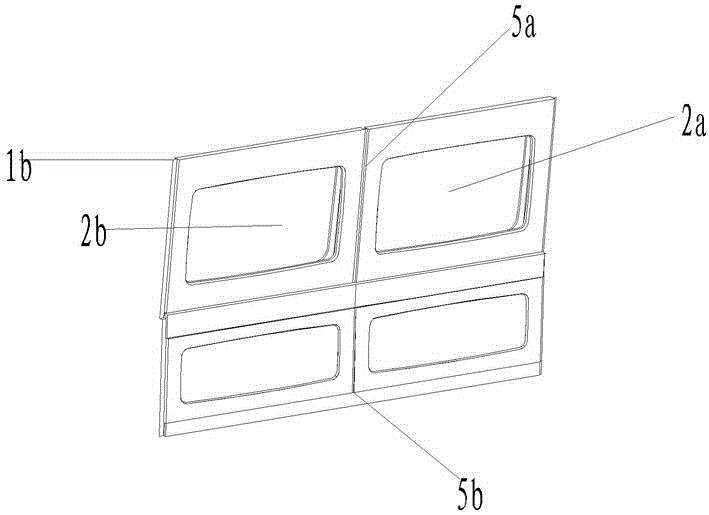

[0038] Such as image 3 As shown, the assembling method of the marine interior decoration side wall panels of the present invention requires at least two side wall panels and inner window covers. During installation, the top of the second side wall panel 2b is fixed to the upper aluminum square tube 10a by self-tapping screws 8 Connection, the opening of the second side wall plate 2b is fixedly connected to the middle aluminum square tube 10b by self-tapping screws 8, and the bottom of the second side wall plate 2b is fixed on the lower aluminum square tube 10c by self-tapping screws 8. The decorative panel is fixed in the groove 6 of the second side wall panel 2b by snap-fit fasteners 7 , and the skirting board 4 is fixed on the bottom of the second side wall panel 2b by sealant 11 .

[0039] The top of the first side wall plate 2a is fixedly connected to the upper aluminum square tube 10a by self-tapping screws 8, and the opening of the first side wall plate 2a is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com