Novel LED module

A LED module, a new technology, applied in the direction of lighting devices, light sources, parts of lighting devices, etc., can solve the problems of backward production methods, high production costs, single shape, etc., to reduce production costs, improve efficiency, and reduce molds The effect of manufacturing and use of injection molding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

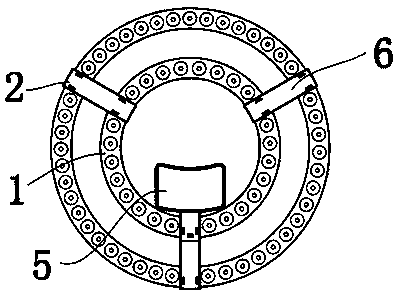

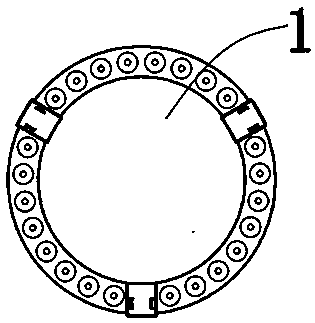

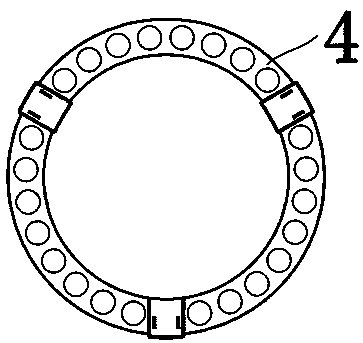

[0021] see Figure 1-4 , the present invention provides a technical solution: a new type of LED module, including an LED inner light source board 1 and an LED outer light source board 2, the LED inner light source board 1 is assembled at the inner side of the LED outer light source board 2, Both the LED inner light source board 1 and the LED outer light source board 2 are formed by fixing PCB boards 3 and plastic parts 4 of the same size through hot melt adhesive, and the LED inner light source board 1 and the LED outer light source board 2 are connected by several The rods 6 are assembled as a whole, and the inner end of any one of the connecting rods 6 is installed with a driving power supply 5 , and the driving power supply 5 is located at the inner side of the LED inner light source board 1 .

[0022] Specifically, the size of the LED inner light source board 1 is smaller than the size of the LED outer light source board 2 .

[0023] Specifically, the LED inner light sour...

Embodiment 2

[0025] see Figure 5 , the present invention provides a technical solution: a new type of LED module, including two LED inner light source boards 1 and one LED outer light source board 2, and the two LED inner light source boards 1 are sequentially assembled on the sides of the LED outer light source board 2 At the inner side, the two LED inner light source boards 1 and one LED outer light source board 2 are formed by fixing PCB boards 3 and plastic parts 4 of the same size through hot melt adhesive, and the two LED inner light source boards 1 and one LED outer light source board 2 An LED external light source board 2 is assembled into a whole through several connecting rods 6, and the inner end of any one of the connecting rods 6 is installed with a driving power supply 5, and the driving power supply 5 is located at the inner side of the LED inner light source board 1 with the smallest size. place.

[0026] Specifically, the size of the LED inner light source board 1 is sma...

Embodiment 3

[0029] see Figure 6 , the present invention provides a technical solution: a new type of LED module, including four LED inner light source boards 1 and one LED outer light source board 2, the four LED inner light source boards 1 are sequentially assembled on the LED outer light source board 2 At the inner side, the four LED inner light source boards 1 and one LED outer light source board 2 are all made of PCB boards 3 and plastic parts 4 of the same size fixed by hot melt adhesive, and the four LED inner light source boards 1 and 1 An LED external light source board 2 is assembled into a whole through several connecting rods 6, and the inner end of any connecting rod 6 is installed with a driving power supply 5, and the driving power supply 5 is located at the inner side of the LED inner light source board 1 with the smallest size. .

[0030] Specifically, the size of the LED inner light source board 1 is smaller than the size of the LED outer light source board 2 .

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com