Articulated tractor head and tractor with same

A technology of tractor and machine head, applied in the field of tractors, which can solve the problems of inability to realize mutual conversion of front-drive, limited range of use, single function, etc., and achieve the effect of simple structure, wide application and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

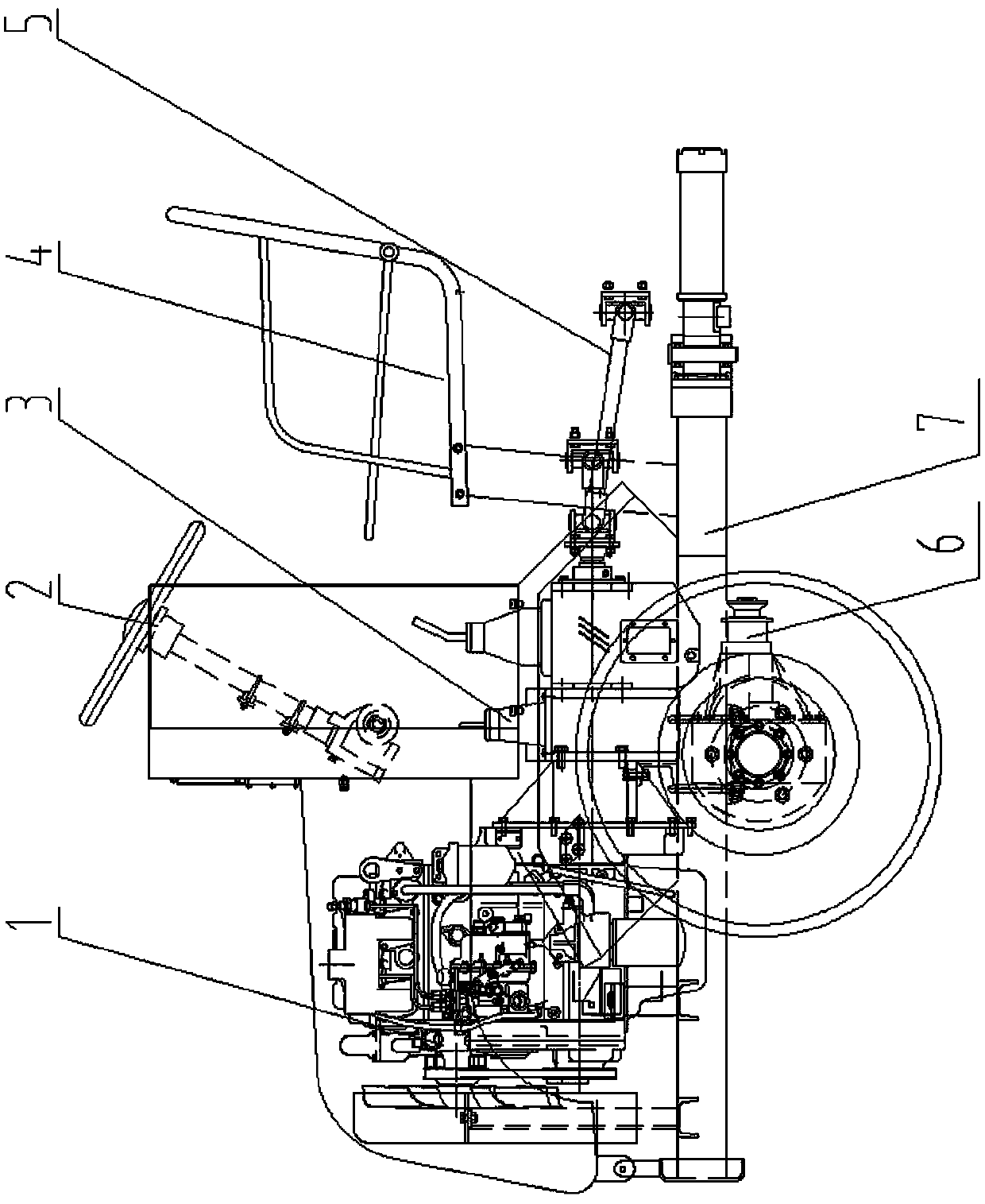

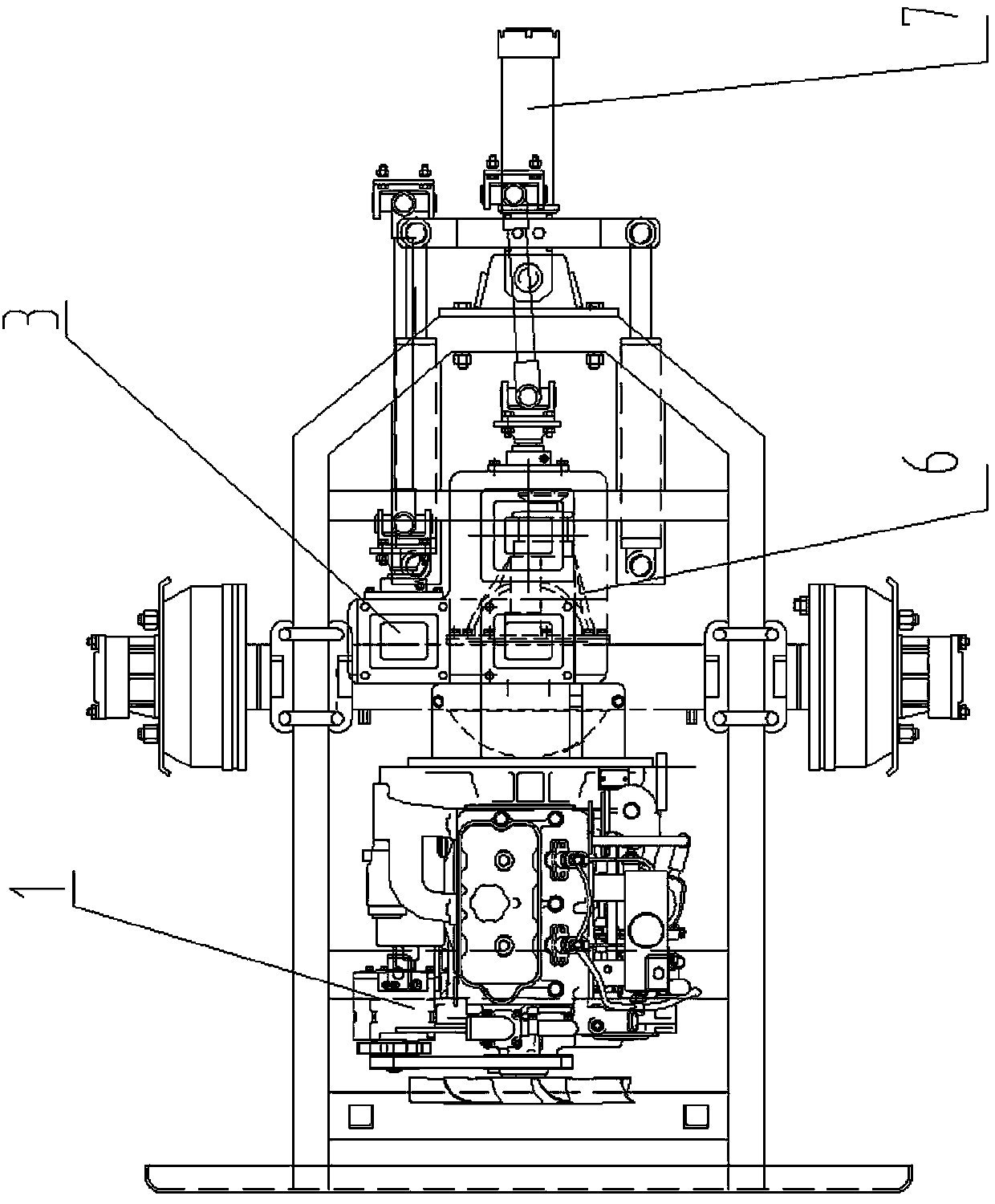

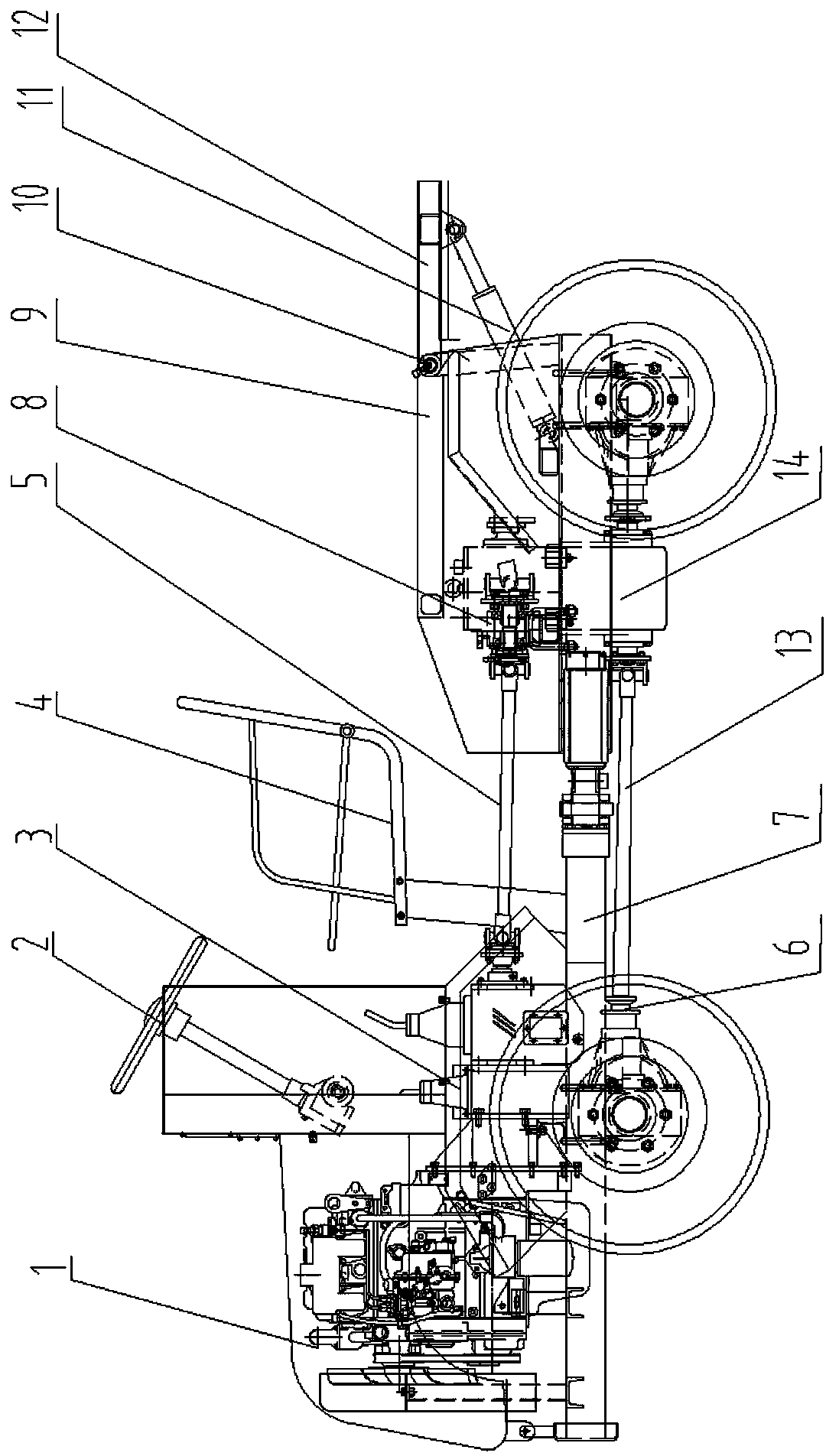

[0026] refer to image 3 , a kind of waist steering tractor, is made up of machine head, transfer case 14, hydraulic cylinder 11, steering arm 9, frame (not marked in the figure), bearing box 8 and front axle transmission shaft 13; said machine head includes Engine 1, hydraulic steering gear 2, gearbox 3, seat 4, first transmission shaft 5, traction shaft 7 and front drive axle 6; the input end of the engine 1 is connected with the gearbox 3; the gearbox 3 The main output end is connected with the first drive shaft 5 through a telescopic universal joint 8; the gearbox 3 is also provided with an auxiliary output end for driving an additional equipment drive shaft; the front drive axle 6 is located at the Below, it acts as a front drive.

[0027] The input end of the transfer case 14 is connected with the first transmission shaft 5; the output end of the transfer case 14 includes an oil pump drive, a front axle drive output end and a rear axle drive output end; the oil pump of ...

Embodiment 2

[0033] refer to Figure 4 , a bent-over steering tractor (with a rotary tiller), consisting of a machine head, a transfer case 14, a hydraulic cylinder 11, a steering arm 9, a frame (not shown in the figure), a bearing box 8, a front axle drive shaft 13 and a rotary The cultivator drive shaft 15 is composed; the input end of the transfer case 14 is connected with the first drive shaft 5; the machine head includes the engine 1, the hydraulic steering gear 2, the gearbox 3, the seat 4, and the first drive shaft 5. The traction shaft 7 and the front drive axle 6; the engine 1 is connected to the input end of the gearbox 3; the main output end of the gearbox 3 is connected to the first transmission shaft 5 through a telescopic universal joint 8; The gearbox 3 is also provided with an auxiliary output end for driving the transmission shaft of additional equipment; the front drive axle 6 is located below the gearbox 3 and plays the role of front drive.

[0034] The output end of th...

Embodiment 3

[0040] refer to Figure 5 , a waist-steering tractor (with a plow), consisting of a machine head, a transfer case 14, a hydraulic cylinder 11, a steering arm 9, a frame (not shown in the figure), a bearing box 8 and a front axle drive shaft 13; The nose includes an engine 1, a hydraulic steering gear 2, a gearbox 3, a seat 4, a first transmission shaft 5, a traction shaft 7 and a front drive axle 6; the engine 1 is connected to the input end of the gearbox 3; The main output end of the gearbox 3 is connected to the first transmission shaft 5 through a telescopic universal joint 8; the gearbox 3 is also provided with an auxiliary output end for driving an additional equipment transmission shaft; the front drive axle 6 is located under the gearbox 3 and plays the role of front drive.

[0041] The input end of the transfer case 14 is connected with the first transmission shaft 5; the output end of the transfer case 14 includes an oil pump drive, a front axle drive output end and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com