Automatic yarn laying mechanism of glass fiber pultrusion grid continuous production line

A glass fiber and production line technology, applied in the field of automatic yarn laying mechanism of glass fiber pultrusion grid continuous production line, can solve the problems of high manufacturing cost, large space required, many parts and so on, and achieves good yarn laying density, Good yarn laying effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

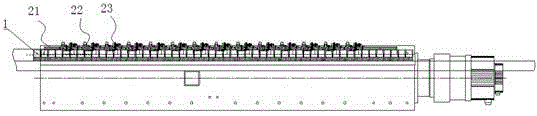

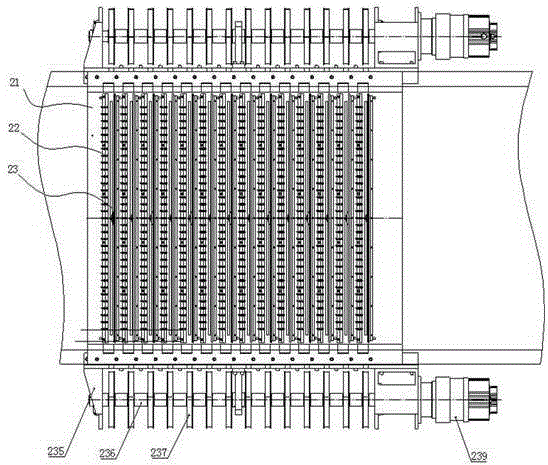

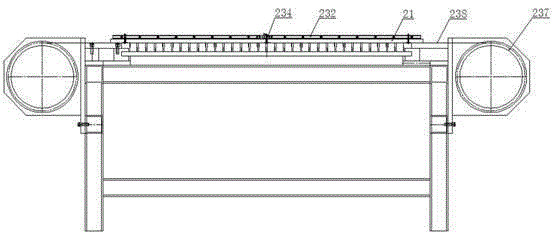

[0028] Such as figure 1 , 2 , 3, mainly includes the longitudinal yarn laying mechanism 22 and the horizontal yarn laying mechanism 23 installed on the fixed mold 21 of the reinforcing fiber insertion section; the specific structure is as follows:

[0029] Reinforced fibers are inserted into the segment stent 21, such as Figure 4 As shown, the fixed mold 21 of the reinforced fiber inserting section is arranged on the moving channel of the moving mandrel of the production line frame, on which are distributed a number of horizontal yarn laying areas 21a and longitudinal yarns distributed along the moving direction of the moving mandrel and arranged at intervals. Laying area 21b, wherein, each weft yarn laying area 21a has a weft yarn laying groove 211 extending perpendicular to the moving direction of the moving mandrel; the longitudinal yarn laying area 21b has a longitudinal yarn Yarn laying slot 212 or several longitudinal yarn laying slots 212 distributed along the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com