High-packing-density hollow fiber membrane component and membrane unit

A fiber membrane and membrane module technology, applied in the field of water treatment, can solve the problems of reducing the reliability of the circumferential sealing structure, and achieve the effects of uniform and efficient aeration and scrubbing, increasing packing density and high structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

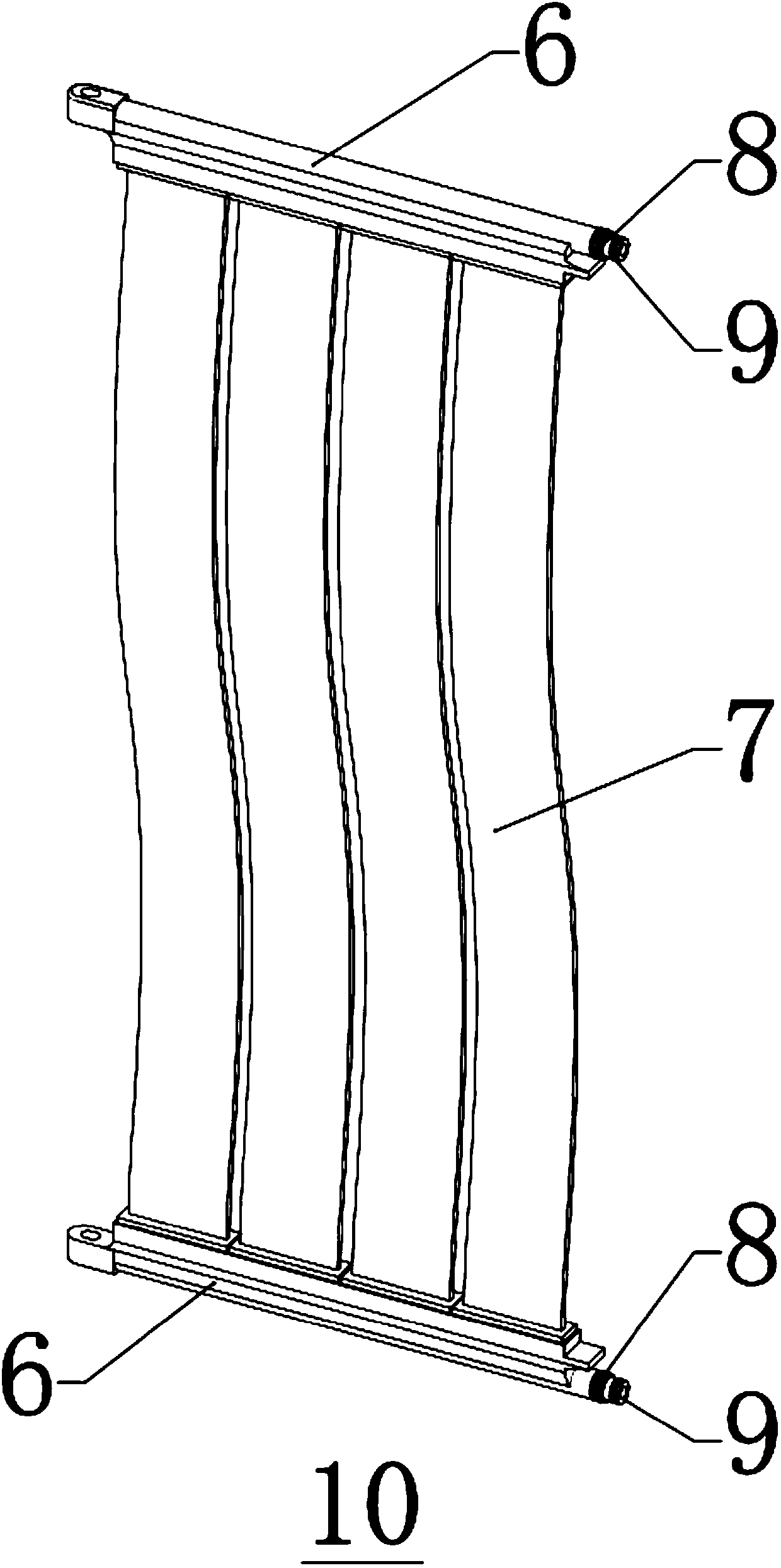

[0027] The present invention is a high packing density hollow fiber membrane module, such as figure 1 As shown, the membrane module 10 is composed of a water-collecting plastic part 6 , a hollow fiber membrane 7 , a large sealing ring 8 and a small sealing ring 9 .

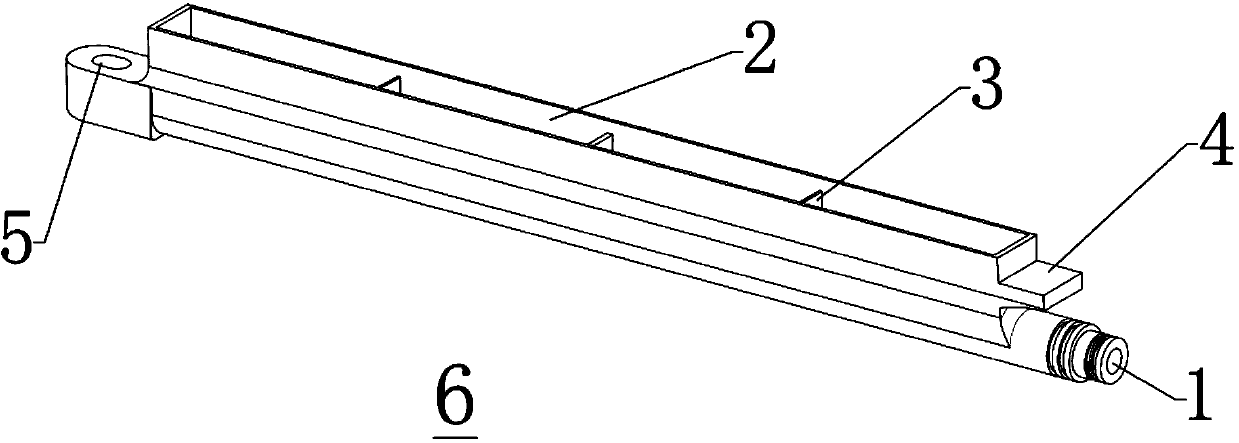

[0028] Such as figure 2 As shown, the water-collecting plastic part 6 is an integral plastic structural part, including structures such as a water-collecting interface 1, a plastic part housing 2, ribs 3, a supporting tongue 4, and a membrane module installation hole 5. The water collection interface 1 adopts a double-step design, and two sealing ring grooves are arranged on each step, and the large sealing ring 8 and the small sealing ring 9 are assembled respectively. The supporting tongue 4 is a unique structure of the patent of the present invention, and the supporting tongue 4 can carry the entire we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com