Integrated full-sea-depth propeller

A technology of thrusters and shells, which is applied in the field of integrated and integrated full-sea deep thrusters, can solve the problems of higher requirements on materials and processing technology, increased weight and volume of submersibles, increased cost and failure rate, etc. The effect of reduced volume and weight, reduced installation difficulty, and overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

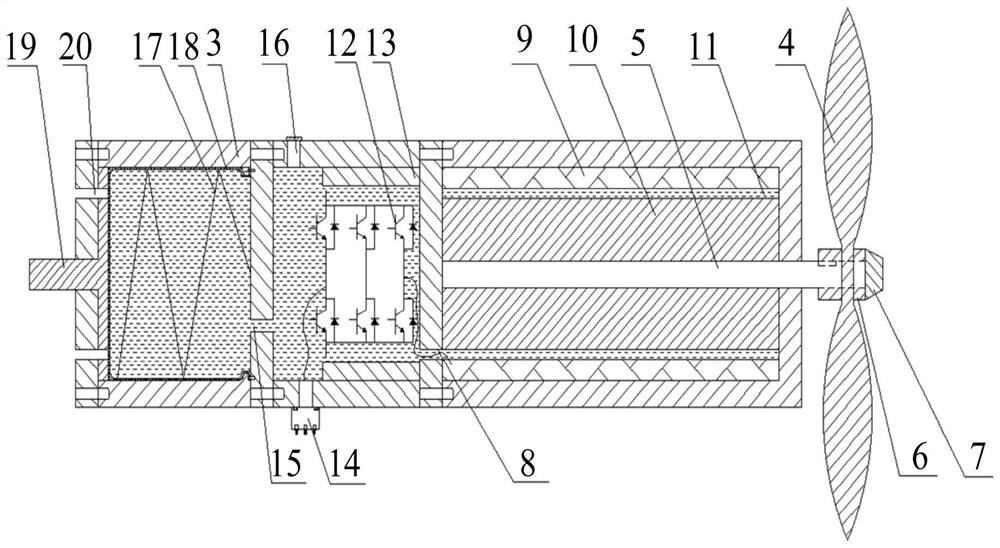

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] like figure 2 As shown, the present application discloses an integrated full-sea deep thruster, which includes a propeller 4 arranged outside the casing 3 and a compensation chamber, a driver chamber and a motor chamber arranged in the casing 3 and communicated in sequence. The propeller 4 of the present application is made of carbon fiber composite material through hot-press forming technology, which ensures the compactness of the structure and further reduces the overall weight. A motor is arranged in the motor cavity, and the output shaft 5 of the motor passes through the housing 3 and is connected to the propeller 4 through the lock nut 6. The diversion cap 7 is arranged outside the lock nut 6 to produce a streamlined shape and reduce resistance. A first through hole 8 is opened on the side of the motor cavity away from the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com