Wooden door

A wooden door and frame technology applied to wooden doors. In this field, it can solve the problems of mutual interference of paints of different colors, easy cracking of paint, and inability to spray different colors on wooden doors, so as to prevent shrinkage and deformation and improve the overall fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

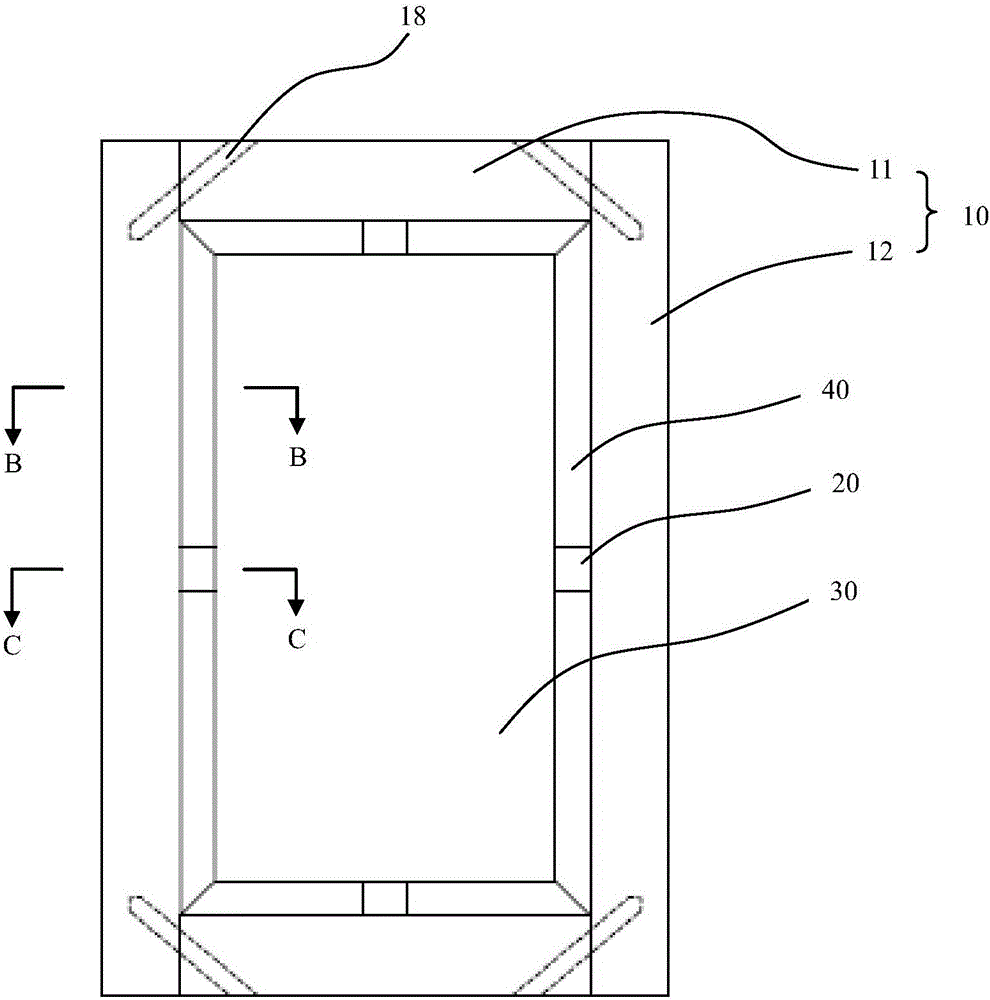

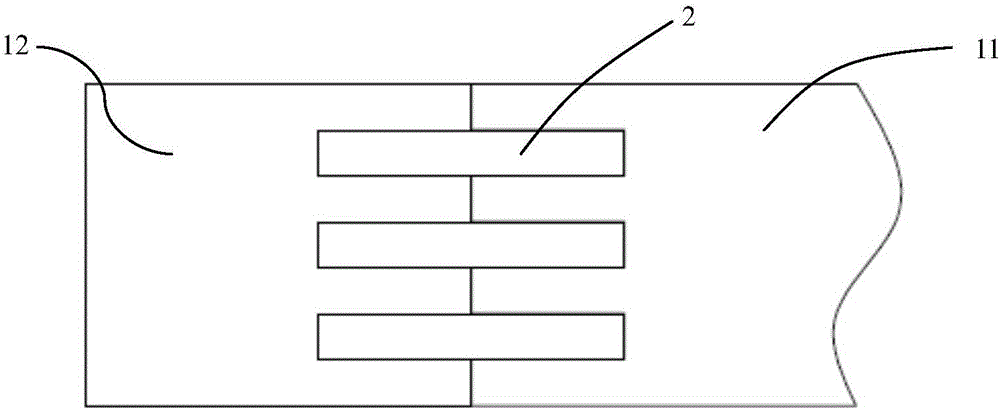

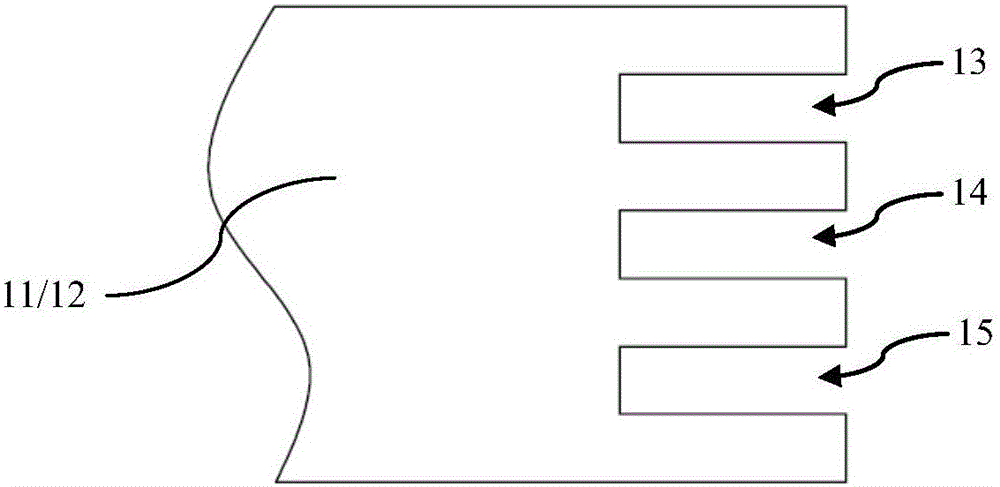

[0036] Please refer Figure 1 to Figure 7 A specific embodiment of a wooden door of the present invention is shown.

[0037] In this embodiment, a wooden door includes: a movably assembled frame 10 composed of a horizontal frame 11 and a vertical frame 12; a plurality of clamping members 20, The core board 30 partially clamped by the clamping member 20 and the wire assembly 40 inserted into the frame 10 and clamped at least the side edge 301 of the core board 30.

[0038] It should be noted that, in this embodiment, the frame 10 can be provided with two clamping members 20 on the opposite inner side of the vertical direction, or two clamping members 20 can be provided on the opposite inner side of the left and right direction, or at the same time. Four clamping members 20 are provided on the inner sides of the four sides in the four directions of up, down, left, and right, or a larger number of clamping members 20, as long as the core board 30 is pre-fixed by the clamping members 2...

Embodiment 2

[0052] Combined reference Figure 4 versus Figure 8 As shown, the main difference between this embodiment and the first embodiment is that the clamping member 20 further includes a screw 213 that continuously and vertically penetrates the two clamping portions 212.

[0053] In order to further improve the clamping effect of the clamping portion 212 on the side edge 301 of the core plate 30, a through hole 210 can be provided on the clamping portion 212, and bolts or other fixing devices can be used to clamp the two clamping portions 212. Therefore, the clamping effect of the clamping member 20 on the side edge 301 of the core board 30 is improved. At the same time, the bottom of the groove 14 is not provided with the elastic element 141 in the first embodiment, but a certain distance is still maintained between the two first insertion portions 211 and the groove 14, and a gap 1410' is formed, and has It has the same function as the gap 1410 in the first embodiment.

[0054] For o...

Embodiment 3

[0056] Please refer Picture 9 The third embodiment of a wooden door of the present invention is shown.

[0057] The main difference between this embodiment and the first and second embodiments is that, in this embodiment, the two first insertion portions 211 of the clamping member 20 are an integral structure. For other technical solutions of this embodiment, please refer to the second embodiment, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com