Carbon dioxide gas shielded welding machine and method of controlling arc strike by adopting digital pulse

A technology of gas shielded welding and carbon dioxide, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of slow wire feeding arc ignition, difficult to use, etc., achieve high arc ignition success rate, improve service life, and reliability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

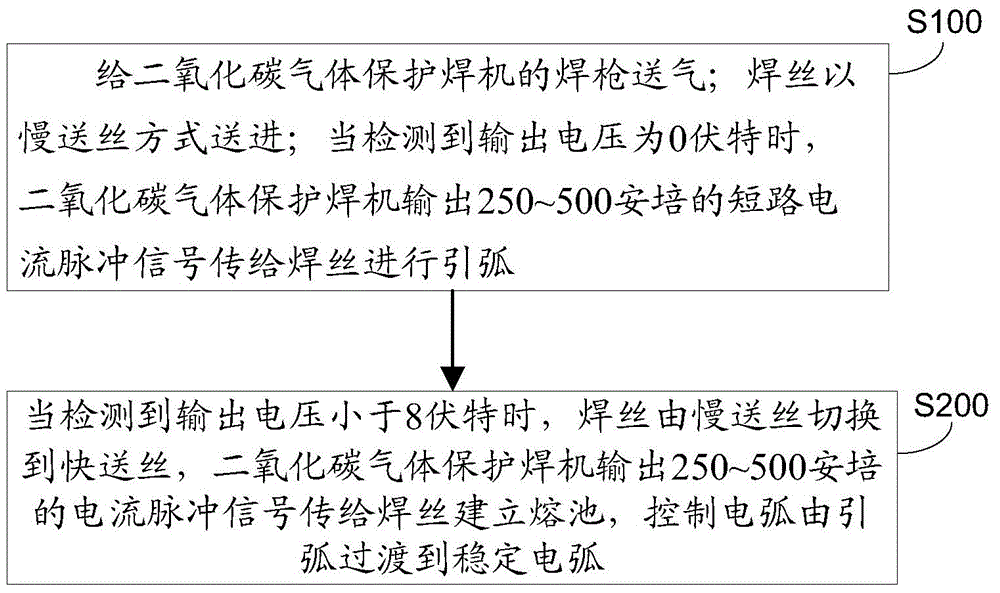

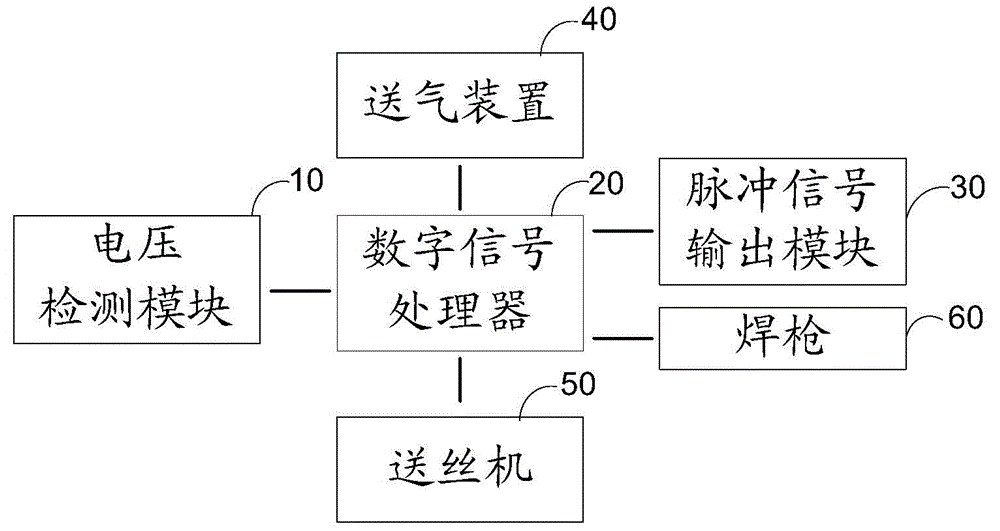

[0034] The invention provides a method for controlling the arc ignition of a carbon dioxide gas shielded welding machine by using digital pulses, referring to figure 1 , In one embodiment, the method for controlling the arc ignition of a carbon dioxide gas shielded welding machine using digital pulses includes an arc ignition stage and an arc transition stage, wherein,

[0035] The arc ignition phase includes the following steps:

[0036] Step S100, supply air to the welding gun of the carbon dioxide gas shielded welding machine; the welding wire is fed in a slow wire feeding mode; when the output voltage is detected to be 0 volts, the carbon dioxide gas shielded welder outputs a short-circuit current pulse signal of 250-500 amperes to the welding wire strike the arc;

[0037] In this embodiment, when the arc is str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com