Method for soldering spiral welded pipe

A spiral welded pipe and welding technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high internal and external quality of the weld, frequent adjustment of the position of the welding torch head, and welding offset welding seam forming quality. Achieve stable and reliable welding process, avoid excessive welding seam height, and ensure the effect of welding seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

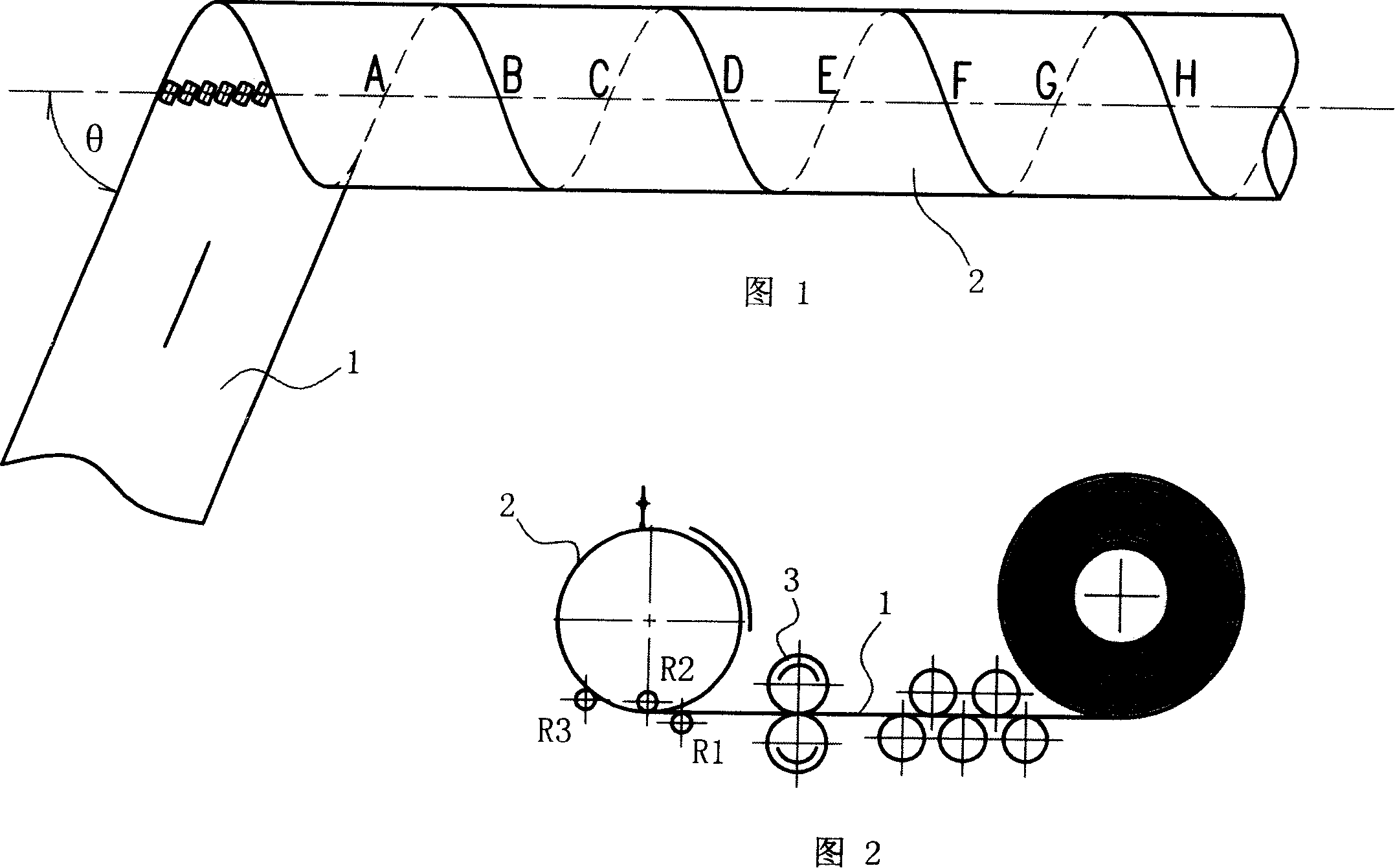

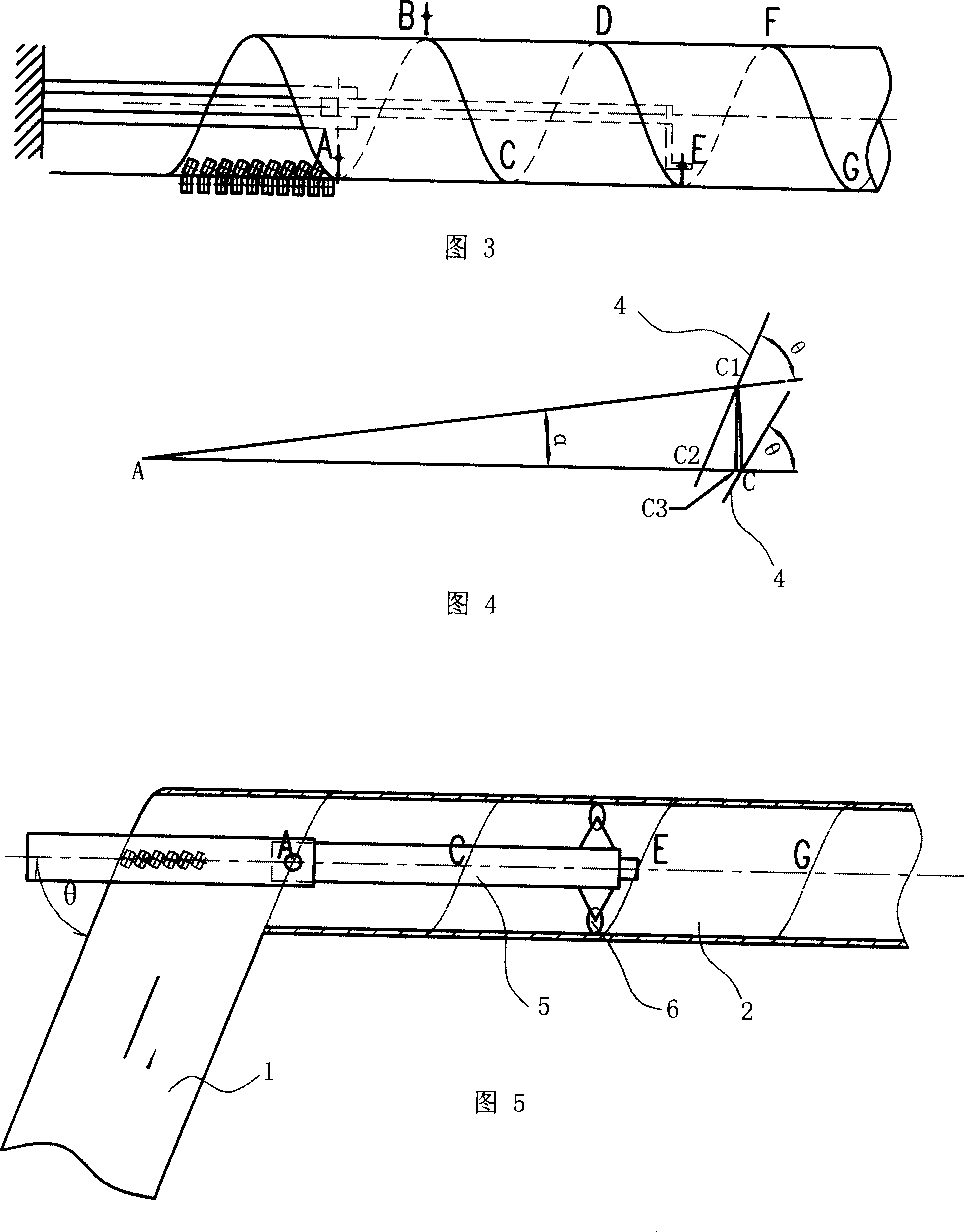

[0021] A spiral welded pipe welding method, comprising continuously sending the steel strip to the spiral welded pipe former according to the helix angle θ, and setting the first internal welding torch at the initial position A of the spirally formed pipe of the steel strip to form the steel strip The spiral seam is pre-welded, and an external welding torch is installed at part II B, which is half a pitch away from the I place A in the extension direction of the spiral welded pipe, to perform external welding on the spiral seam of the steel strip; in the extension direction of the spiral welded pipe, it is A The second internal welding torch is set at the position III of the two pitches to carry out fine internal welding on the steel strip spiral seam. The front end of the bracket 5 is provided with four rollers 6 that can rotate according to the tangential direction of the inner wall of the spirally rotated spiral welded pipe, and the four rollers are distributed along the cir...

Embodiment 2

[0023] The difference between this example and the previous example is that the beveling equipment is set at C, which is one pitch away from the I place A in the extension direction of the spiral welded pipe, and the bevel is reprocessed for the pre-internal welding seam to make it U-shaped or V-shaped. Shaped groove, as in the above example, fine internal welding is welded in the groove.

Embodiment 3

[0025] What this example is different from Example 1 is that the outer welding torch is set at the D place where the spiral welded pipe extension direction is one and a half pitch away from the said I place A to carry out external welding to the spiral seam of the steel strip; Three pitch places G at I place A carry out precision internal welding, and correspondingly, the pendulum support 5 stretches a distance relative to Example 1 so that the second internal welding torch is positioned at G place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com