Wall maintaining method based on automatic temperature measurement and temperature stress reduction

A temperature stress and wall technology, applied in the processing of building materials, ceramic molding machines, manufacturing tools, etc., can solve the problem of not effectively reducing the peak temperature of the wall, controlling the early temperature cracks of the wall, and not playing a positive role. Effectively delay the cooling speed of the wall and other problems, and achieve the effect of simple structure, improved construction quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

[0020] The present invention proposes a reasonable and effective wall maintenance method, which can effectively reduce the hydration heat temperature stress of the wall and reduce the cracking of the wall. The specific steps of the method are as follows:

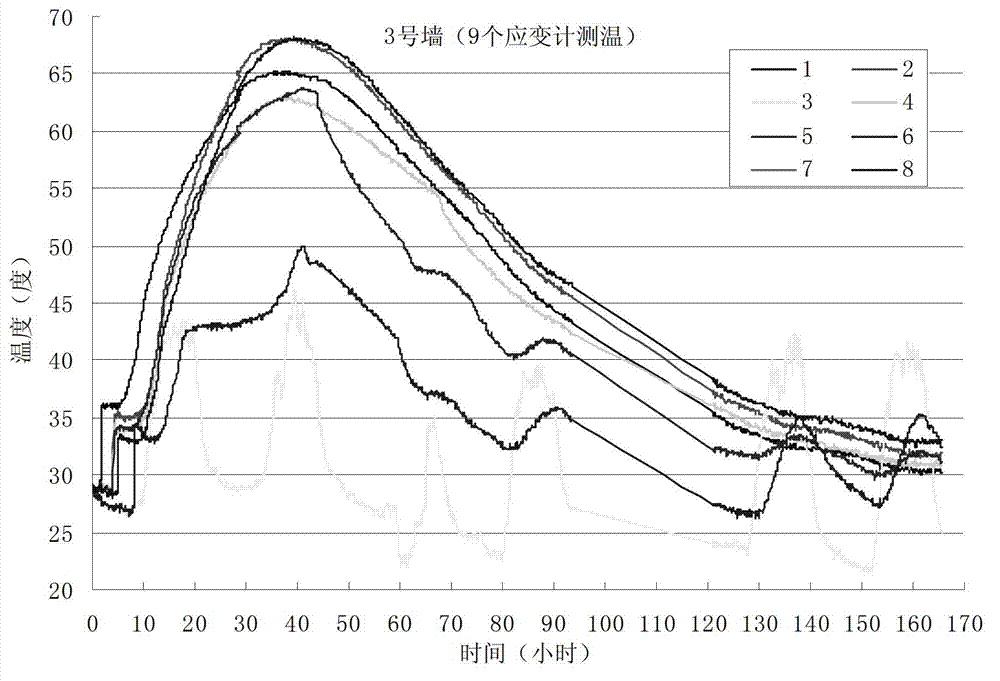

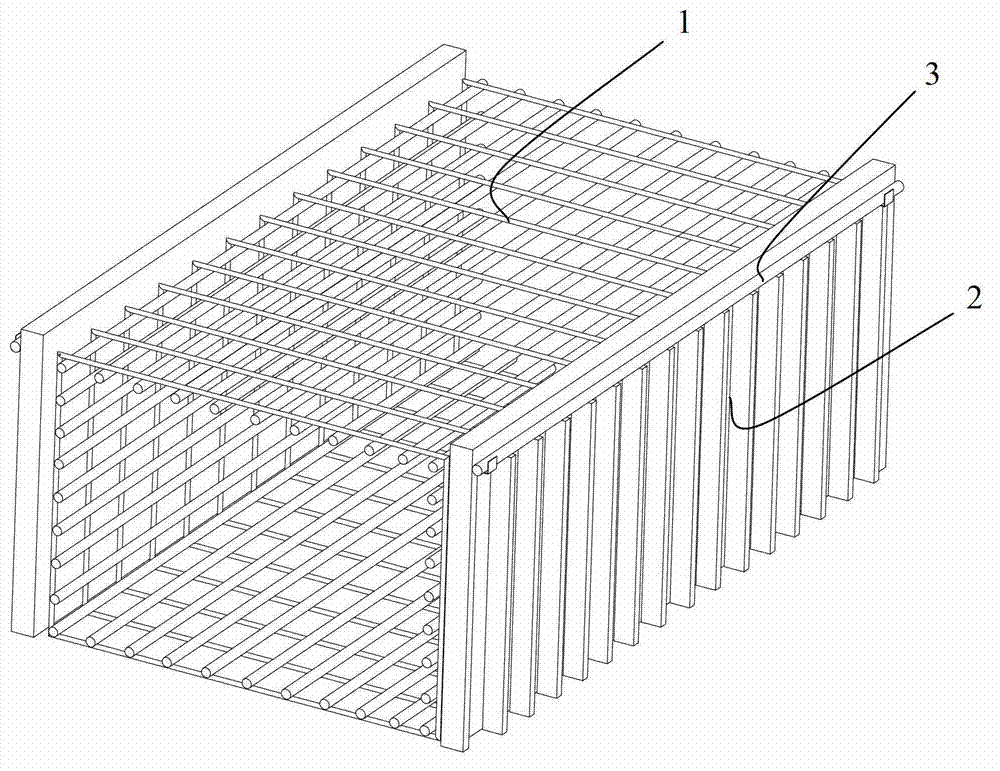

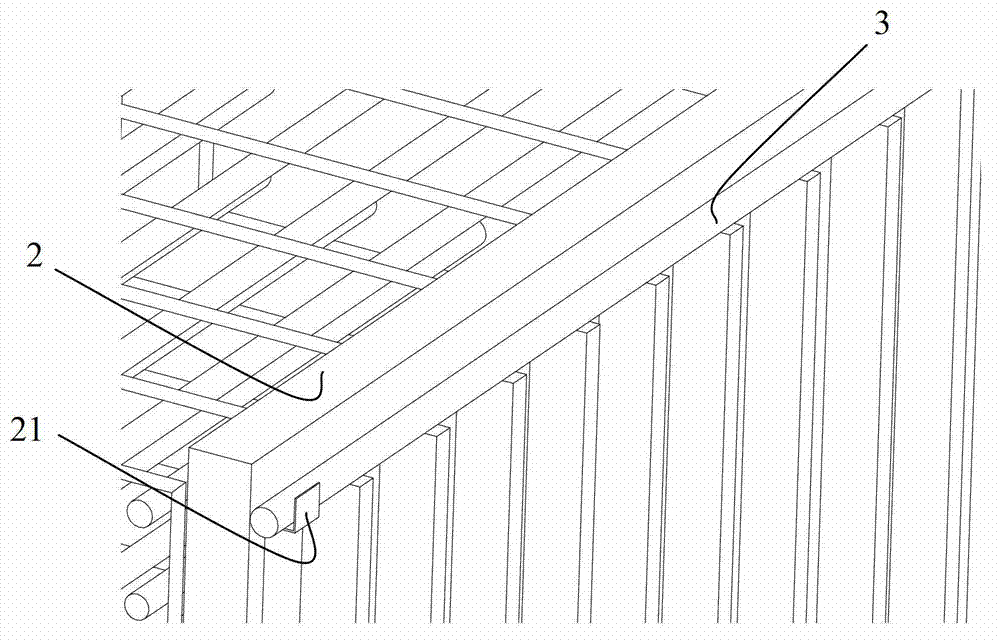

[0021] combine figure 2 , image 3 As shown, first debug the wireless thermometer, connect the wireless thermometer to the computer to keep the distance between the two within 500 meters, and then install the temperature sensor of the debugged wireless thermometer before the concrete wall 1 is poured. Installed at different heights and thicknesses inside the wall (reinforcement cage to be poured) 1, the temperature inside the concrete is measured by a temperature sensor, the formwork 2 is installed outside the reinforcement cage to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com