Light-weight partition wall structure and installing method thereof

A light-weight, mounting surface technology, applied to walls, building components, building structures, etc., can solve the problem of affecting the construction progress of lightweight slatted partition walls, affecting the construction quality of lightweight slatted partition walls, and requiring high levels of worker operation problem, to achieve the effect of solving the cracking phenomenon, reducing the cracking phenomenon and reducing the operation of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

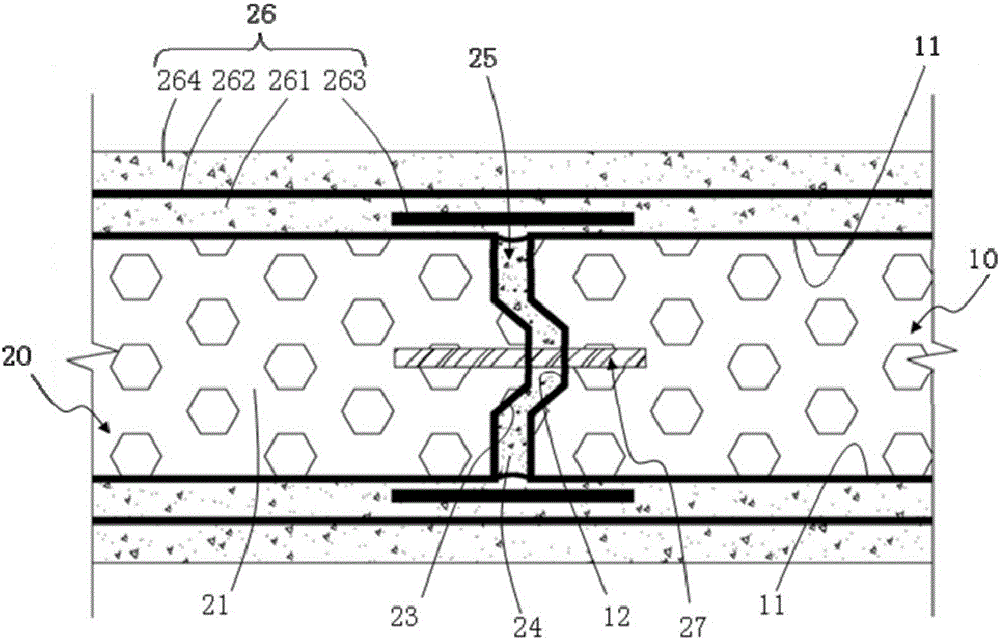

[0055] see Figure 1 to Figure 3 , the present invention provides a prefabricated corner structure of a lightweight partition wall, which includes a corner member 20 , a wall panel 10 , an adhesive 25 for bonding the corner member 20 and the wall panel 10 , a surface layer 26 and steel bars 27 . in:

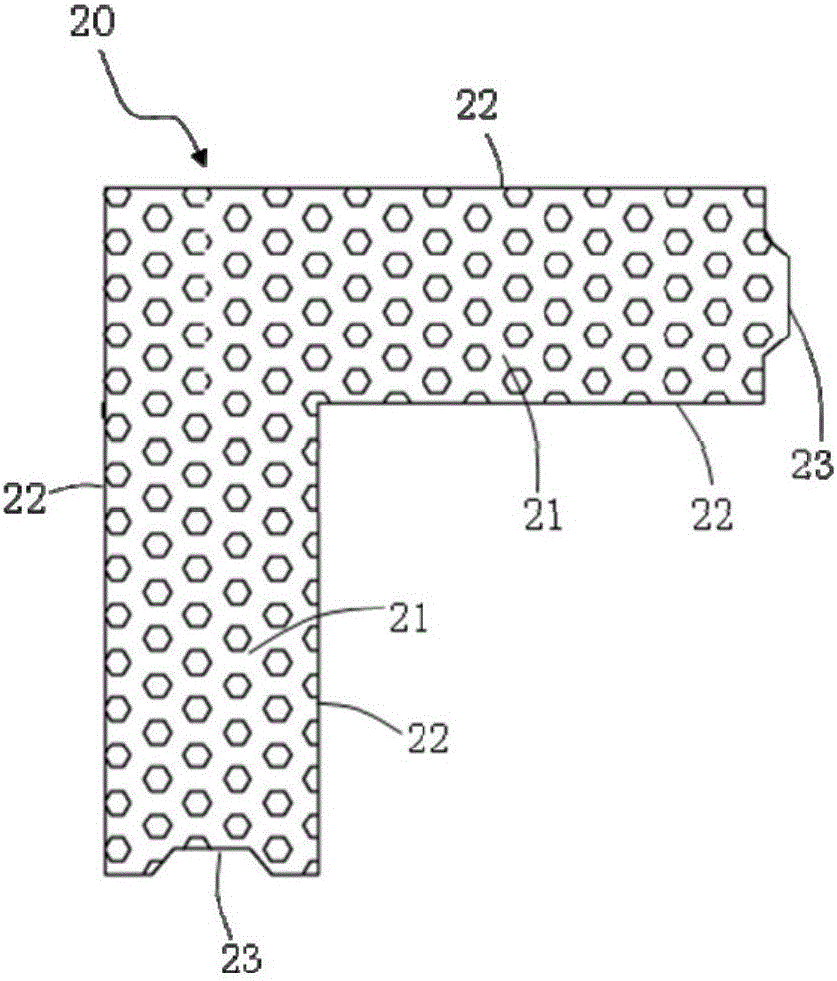

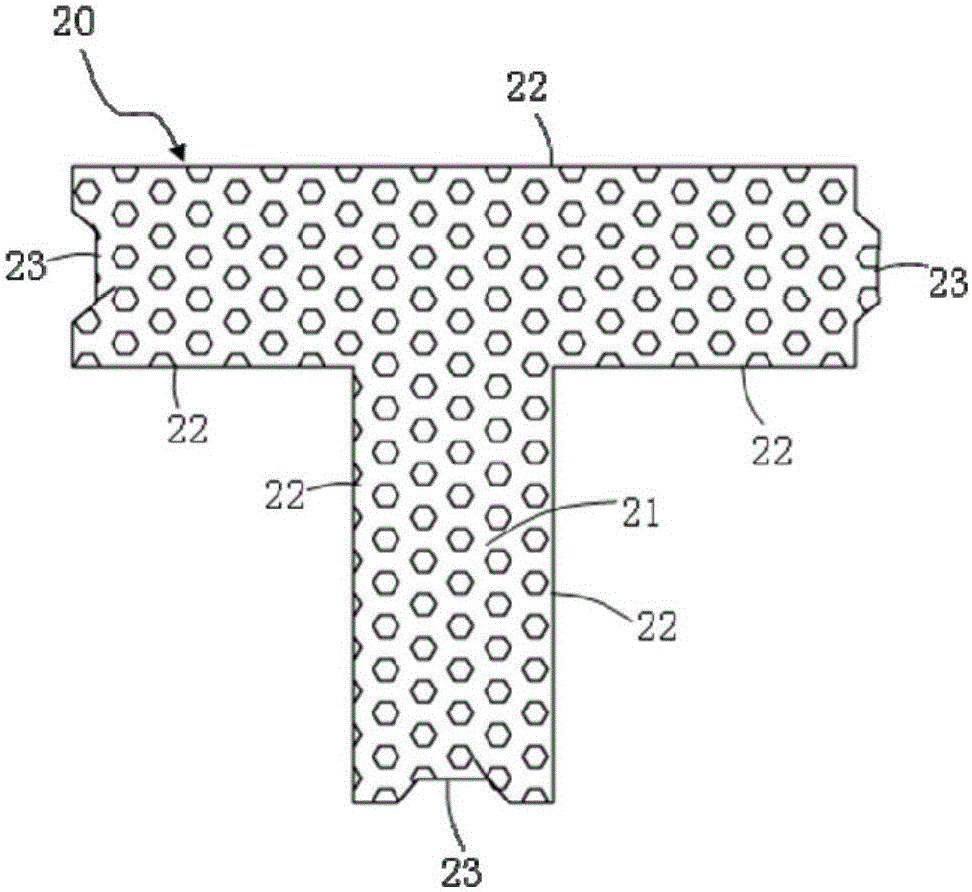

[0056] The corner member 20 is a lightweight wallboard member with polystyrene particles, which has two boards 21, the two boards 21 are vertically connected and integrally formed into the corner member 20, so that the corner member 20 is shaped as figure 2 L-shaped or image 3 T-shaped integrated partition wall corner components; such as figure 2 The L-shaped corner member 20, its plate portion 21 is formed with two splicing end faces 23; as image 3 The T-shaped corner member 20 is formed with three spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com