Metal half hole molding method and manufacture method of printed circuit board

A printed circuit board and hole forming technology, which is applied in the direction of printed circuit manufacturing, printed circuit, and electrical connection formation of printed components, can solve problems such as failure to reach, achieve the effect of improving forming quality and overcoming residual copper wire burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

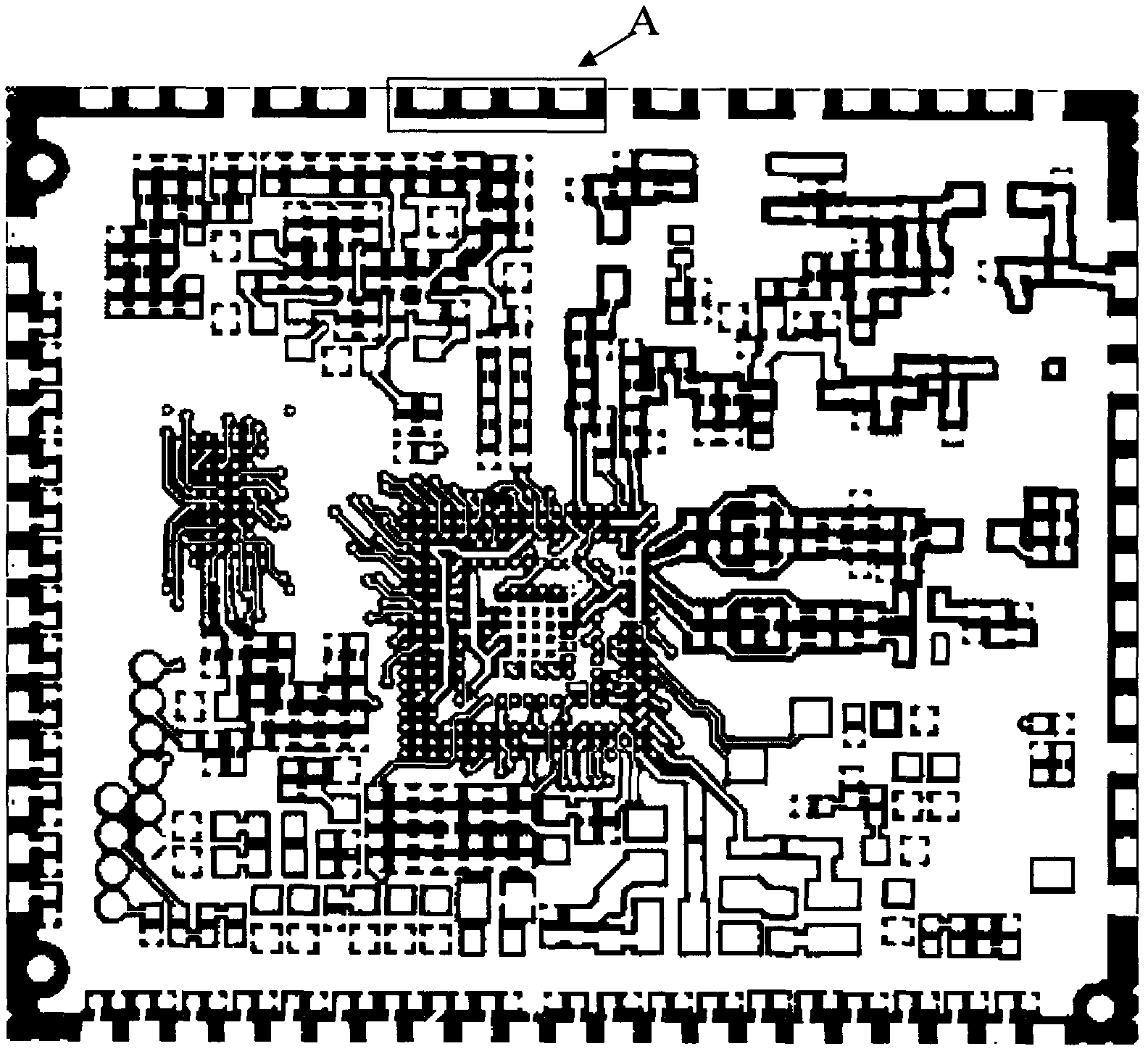

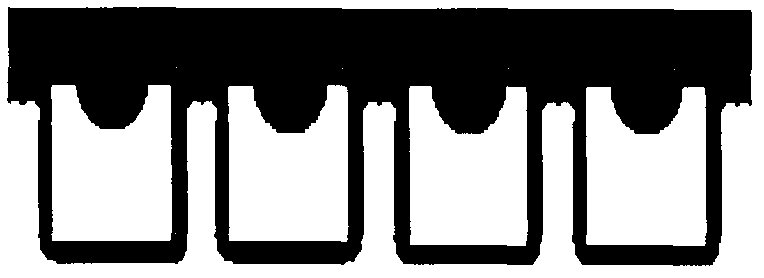

[0027] Image 6 It shows a schematic diagram of forming a metal half hole in the milling process according to an embodiment of the present invention. In the process of manufacturing a PCB, before the film removal / alkaline etching / soldering process, the printed circuit board is formed through the process of milling metal half hole.

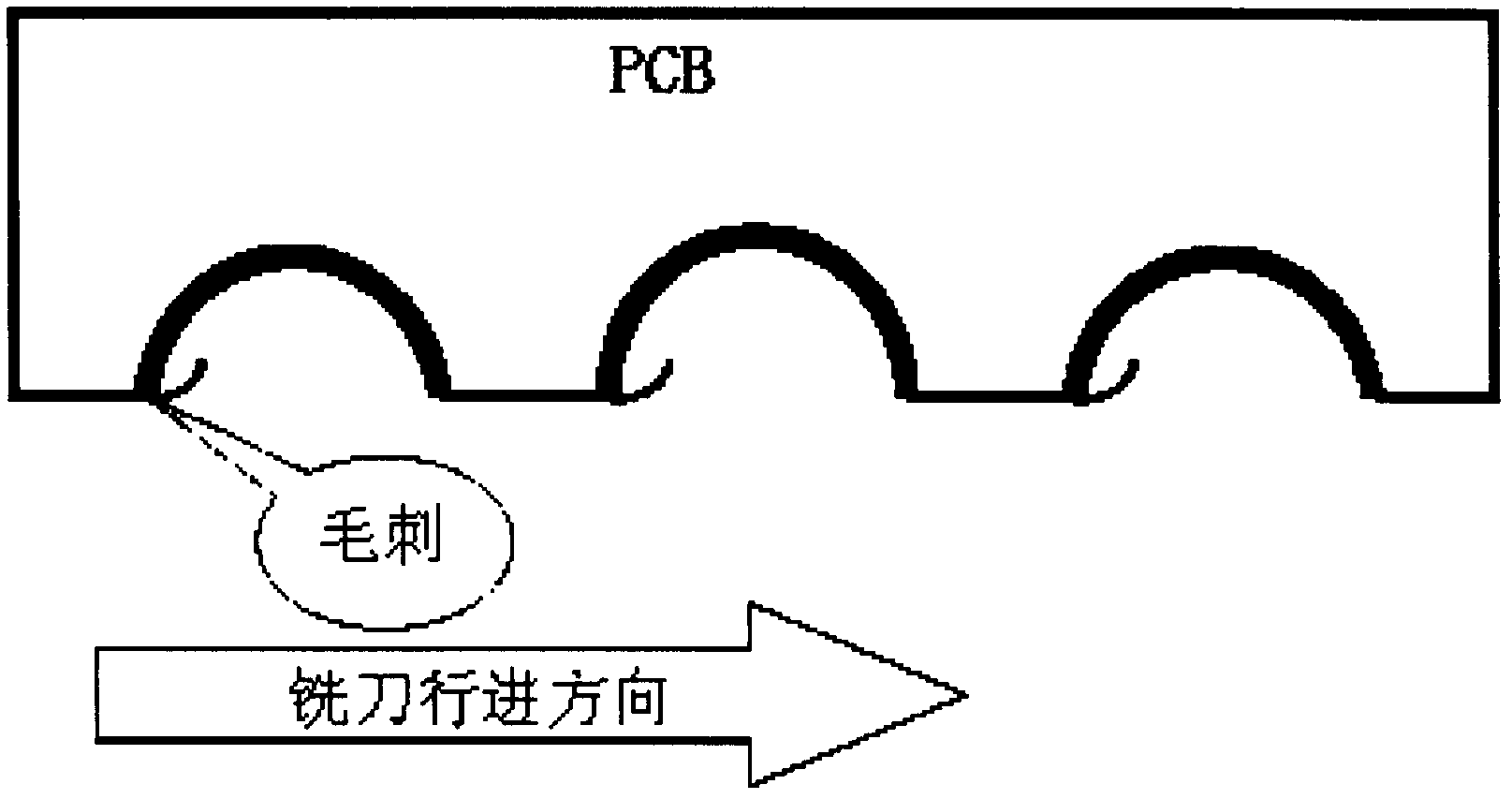

[0028] The related technology is to form the metal half hole at the same time when the milling board is forming the shape of the PCB, so the purpose of adding the second drilling process is to avoid the copper wire burr when the milling board is forming the metal half hole. In this embodiment, the process of milling the metal half hole is advanced before the film removal / alkaline etching / sn stripping process, so that the milling process can be removed by the film removal / alkaline etching / sn stripping pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com