Apparatus for preparing S type metallic honeycomb

A technology of metal honeycomb and locking device, applied in muffler device, exhaust device, metal processing equipment, etc., can solve the problems of high rolling requirements and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

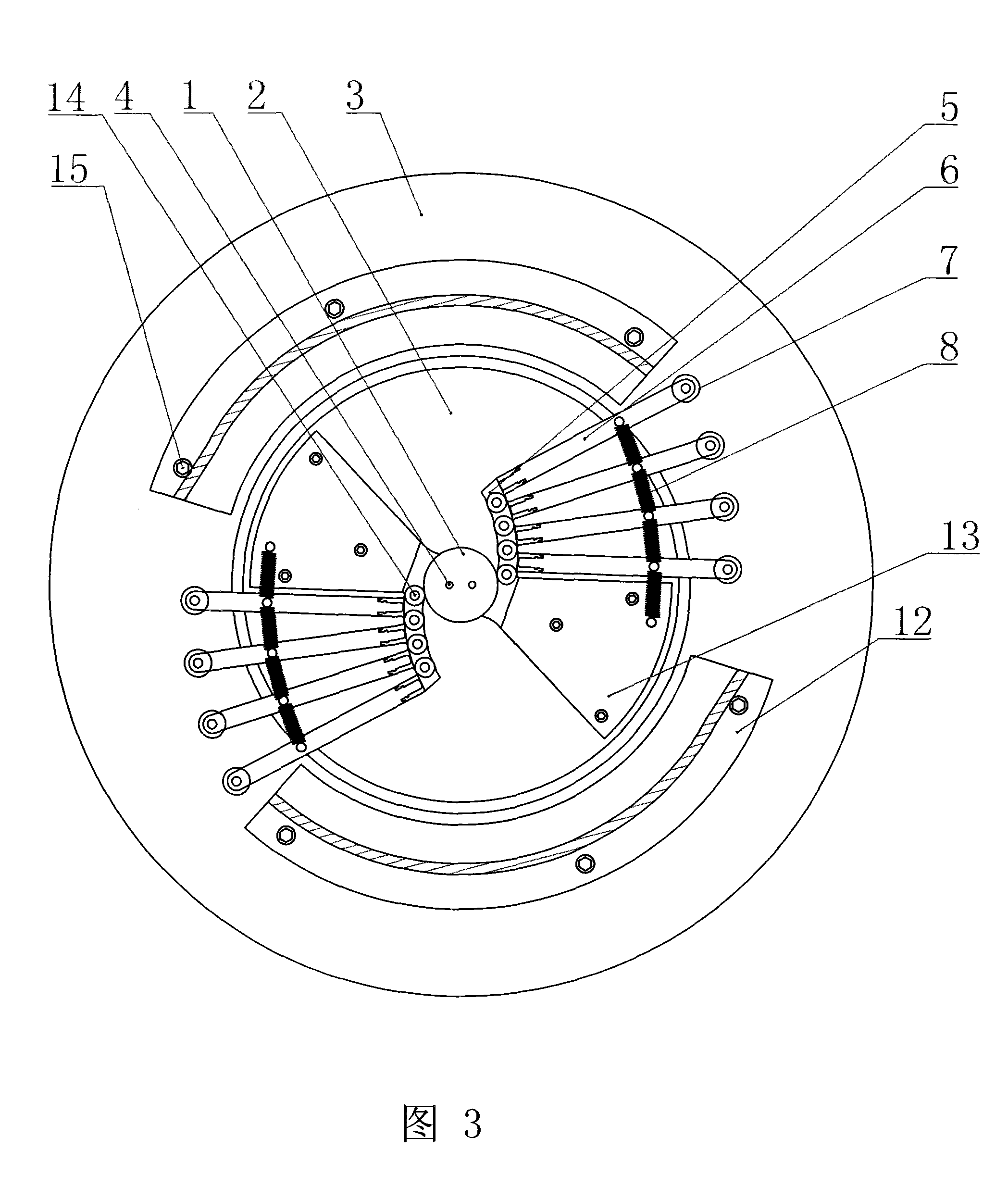

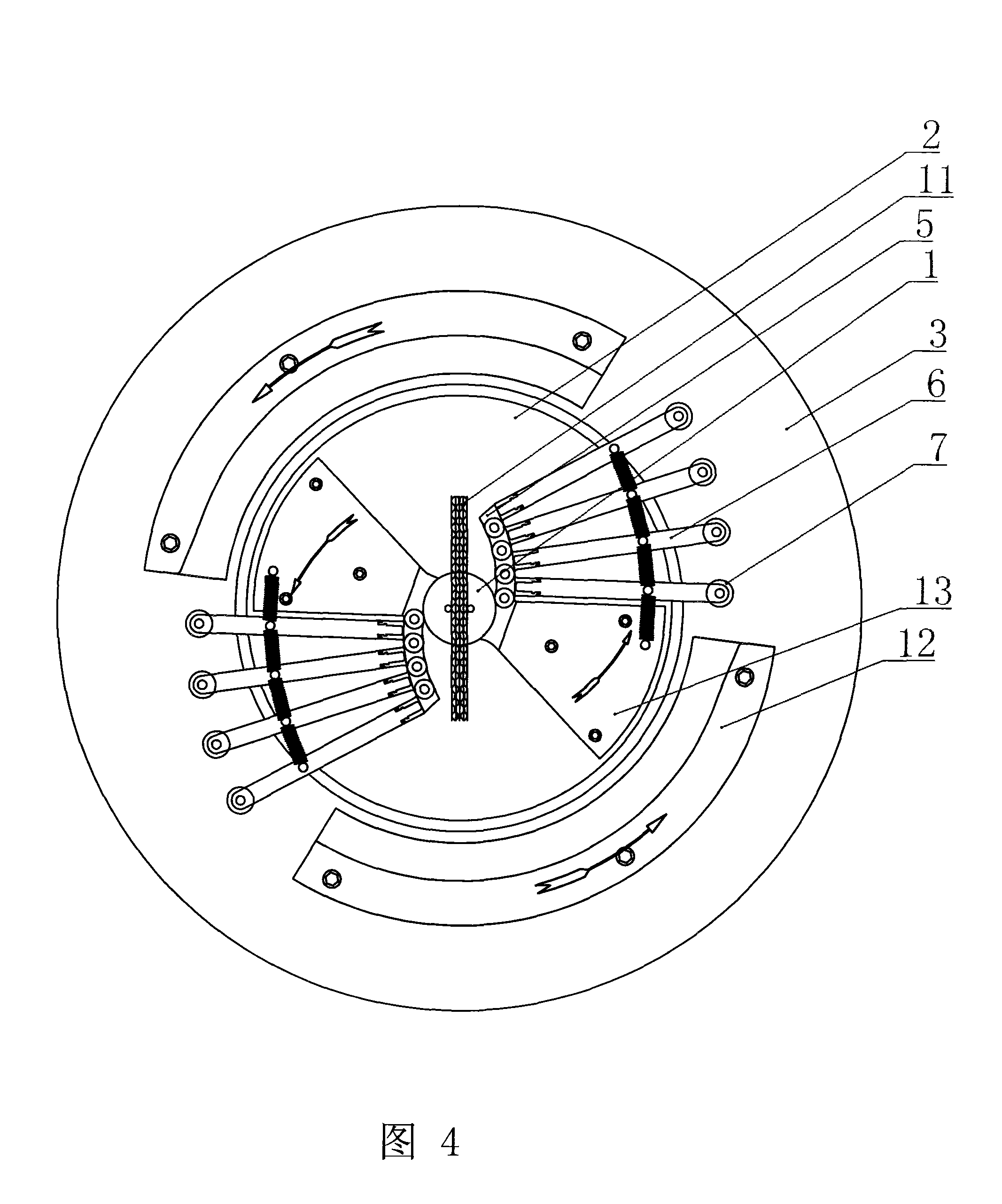

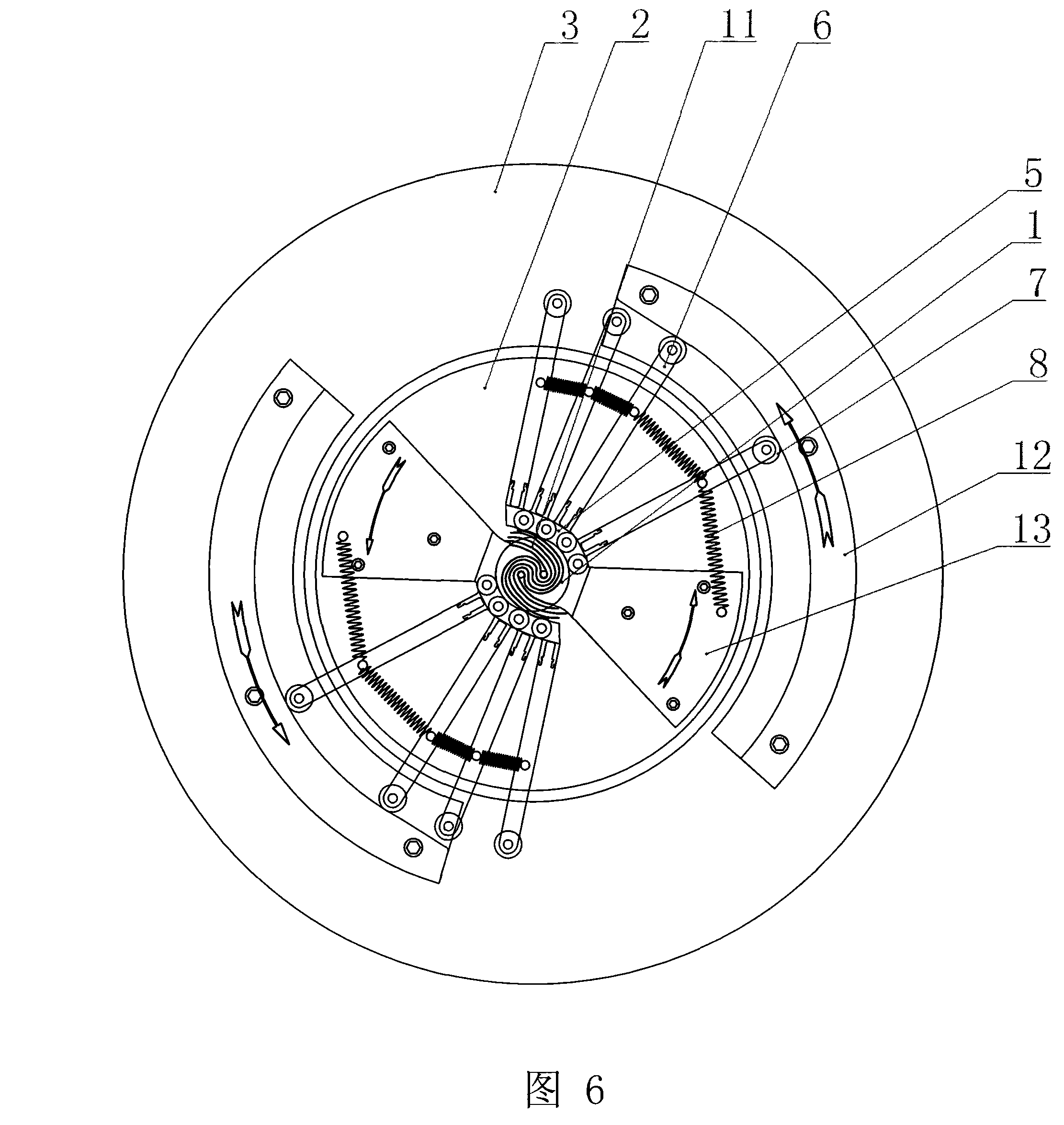

[0019] As shown in Figures 3 to 7, this embodiment of the present invention includes a cylindrical fixed column 1 and two groups of forming sections 5 that can be gradually closed to each other to form a mold, and two coaxial fixed rods are arranged at the top of the fixed column 1 4. The described forming section 5 of every group is made up of five sections, is hinged with pin 14 to become chain structure between every section.

[0020] A mold locking device is connected to the outside of the forming section 5, and the structure of one embodiment of the mold locking device is: the inner end of a radial driving rod 6 is connected to the outside of each section of the forming section 5, and the driving rod The outer end of 6 is equipped with bearing 7, is connected with spring 8 between each adjacent driving rod 6. The fixed column 1 is installed in the axial hole of an inner disc 2 , and an outer disc 3 is arranged on the outer edge of the inner disc 2 . One section at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com