Glass fiber cloth infiltrating testing method

A technology of glass fiber cloth and testing method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as poor repeatability, poor repeatability of test results, and large human interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

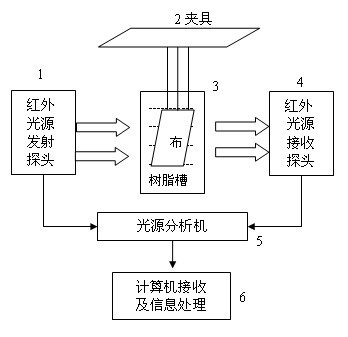

Method used

Image

Examples

specific Embodiment 1

[0037] Specific example 1: 7628 cloth 1# glass fiber cloth (cloth thickness 0.18mm, glass fiber yarn used is ECG75 1 / 0 0.7Z, warp and weft density is 44*33) infiltration test data are as follows:

[0038]

[0039] Calculation method of transmittance percentage data of emitted light source

[0040] The percent transmittance in the 10th second is [(673.7-508.7) / (683.8-508.7)]*100%=5.5%

[0041] The percent transmittance at the 16th second is [(665.6-508.7) / (683.8-508.7)]*100%=10.1%

[0042] The percentage of transmittance corresponding to other times can be deduced by analogy.

specific Embodiment 2

[0043] Specific embodiment two: 7628 cloth 2# glass fiber cloth infiltration test data

[0044]

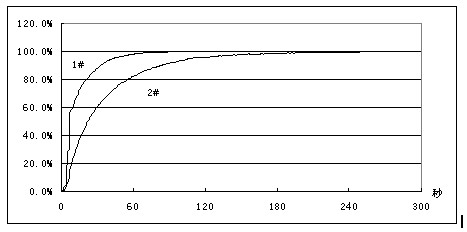

[0045] According to the time data collected during the soaking process, and the percentage of light receiving data after the emitted light source passes through the soaked fiber product

[0046] ratio, draw a curve figure 2 .

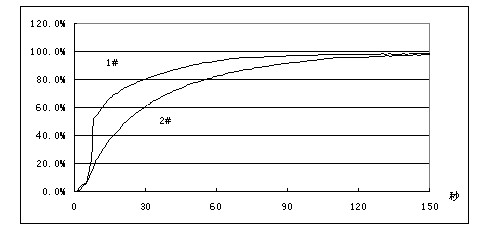

[0047] Should figure 2 The graphic curve reflects the continuous test process of the wettability of the 7628 glass fiber fabric. The closer the curve is to the vertical axis, the faster and better the wettability of the glass fiber fabric. figure 1 The wettability of the 1# sample is better than that of the 2# sample, so the wettability of various fiber fabrics can be distinguished. In this method, the computer automatically performs the test and records the data, which is more humanized than the previous resin infiltration method, so the test is more accurate. In this experiment, the data is obtained through two tests for drawing, and the 7628 clo...

Embodiment 1

[0050] The result comparison of embodiment one, embodiment two and comparative example one different experimental methods

[0051] From the above examples and comparative examples, the experimental cloth sample is a thicker 7628 glass fiber cloth, and different wettability test methods reflect that the wettability of the 7628 cloth 1# sample is faster than that of 2#, but the test data in the comparative example is scattered , the difference is large, although it can be used to distinguish the wettability of different products, but the accuracy is not enough for repeated experimental tests, and the test time is long, the testers need to wait for a long time, and the solvent will continue to volatilize It will cause the viscosity of the resin to increase and affect the test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com